- DL manuals

- Wacker Neuson

- Portable Generator

- G50

- Operator's Manual

Wacker Neuson G50 Operator's Manual

Summary of G50

Page 1

5000189846 05 0911 5 0 0 0 1 8 9 8 4 6 operator’s manual mobile generator g 50 en.

Page 2

Copyright notice © copyright 2011 by wacker neuson production americas llc all rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permissio...

Page 3: G 50

G 50 foreword wc_tx001048gb.Fm 3 foreword save these instructions—this manual contains important instructions for the machine models below. These instructions have been written expressly by wacker neuson production americas llc and must be followed during installation, operation, and maintenance of ...

Page 4: Foreword

Foreword g 50 4 wc_tx001048gb.Fm manufacturer’s approval this manual contains references to approved parts, attachments, and modifications. The following definitions apply: approved parts or attachments are those either manufactured or provided by wacker neuson. Approved modifications are those perf...

Page 5: Table of Contents

Wc_bo5000189846_05toc.Fm 5 table of contents g 50 foreword 3 1 safety information 9 1.1 signal words used in this manual ....................................................... 9 1.2 machine description and intended use ............................................. 10 1.3 operating safety .............

Page 6: Table of Contents

6 wc_bo5000189846_05toc.Fm table of contents g 50 4.13 engine start switch .............................................................................43 4.14 voltage adjustment rheostat ..............................................................43 4.15 warning light ...............................

Page 7: Table of Contents

Wc_bo5000189846_05toc.Fm 7 table of contents g 50 6.10 camlocks ............................................................................................ 71 6.11 containment system .......................................................................... 72 6.12 wiring diagram (factory-installed...

Page 8: Table Of Contents

8 wc_bo5000189846_05toc.Fm table of contents g 50

Page 9: G 50

G 50 safety information wc_si000533gb.Fm 9 1 safety information 1.1 signal words used in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Notice:...

Page 10: Safety Information

Safety information g 50 10 wc_si000533gb.Fm 1.2 machine description and intended use this machine is a mobile electric power source. The wacker neuson mobile generator consists of a trailer-mounted cabinet containing an electric alternator, a fuel tank, and a diesel engine. A control panel, receptac...

Page 11: G 50

G 50 safety information wc_si000533gb.Fm 11 • electric shock and arc flash • personal injury from improper lifting the trailer tongue • typical hazards related to towing a trailer on roads and highways to protect yourself and others, make sure you thoroughly read and understand the safety informatio...

Page 12: Safety Information

Safety information g 50 12 wc_si000533gb.Fm 1.3 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and the engine m...

Page 13: G 50

G 50 safety information wc_si000533gb.Fm 13 1.3.10 do not start a machine in need of repair. 1.3.11 use the emergency stop button only in an actual emergency. Do not restart the engine until the cause of the trouble has been determined and fixed. 1.3.12 wear hearing protection when operating equipme...

Page 14: Safety Information

Safety information g 50 14 wc_si000533gb.Fm 1.4 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. Personal protective equipment (ppe) we...

Page 15: G 50

G 50 safety information wc_si000533gb.Fm 15 1.4.6 do not allow untrained personnel to service this equipment. Only trained electrical technicians should be allowed to service the electrical components of this equipment. 1.4.7 do not modify the machine without the express written approval of the manu...

Page 16: Safety Information

Safety information g 50 16 wc_si000533gb.Fm 1.5 operator safety while using internal combustion engines operating safety when running the engine: • keep the area around exhaust pipe free of flammable materials. • check the fuel lines and the fuel tank for leaks and cracks before starting the engine....

Page 17: G 50

G 50 safety information wc_si000533gb.Fm 17 1.6 towing safety towing a large trailer requires special care. Both the trailer and vehicle must be in good condition and securely fastened to each other to reduce the possibility of an accident. 1.6.1 verify that the hitch and coupling on the vehicle are...

Page 18: Labels

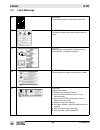

Labels g 50 18 wc_si000520gb.Fm 2 labels 2.1 label locations wc_gr007670 avertissement avertissement advertencia advertencia warning warning warnung warnung 114885 114885 avertissement avertissement warning warning warnung warnung advertencia advertencia p a gg kk hh l cc u b g t aa jj x j k dd m1 m...

Page 19: G 50

G 50 labels wc_si000520gb.Fm 19 u jj wc_gr007671 v v w w o y v p r c f s g v d b pp e uu rr ss tt.

Page 20: Labels

Labels g 50 20 wc_si000520gb.Fm 2.2 label meanings a warning! Pressurized contents. Do not open when hot! B warning! Lock doors. Access can cause electric shock or injury. C notice never change switch position with engine run- ning. Results in damage to machine. D warning! Electric shock can cause s...

Page 21: G 50

G 50 labels wc_si000520gb.Fm 21 f warning! To prevent hearing loss, wear hearing protection. Hand injury if entangled in moving belt. Rotating machinery! Do not reach inside with engine running. Warning! Hot surface caution! Avoid spraying water into generator. G warning! Hot surface h warning elect...

Page 22: Labels

Labels g 50 22 wc_si000520gb.Fm l warning! Read and understand the supplied operator’s manual before operating the machine. Failure to do so increases the risk of injury to yourself and others. M1 m2 warning! To reduce the risk of electrical shock and arc flash, read the operator’s manual. Improper ...

Page 23: G 50

G 50 labels wc_si000520gb.Fm 23 p warning! To prevent hearing loss, wear hearing protection when operating the machine. Warning! Pressurized contents. Do not open when hot! Warning! Hand injury if entangled in moving belt. Warning! Rotating machinery! Do not reach inside machine with engine running....

Page 24: Labels

Labels g 50 24 wc_si000520gb.Fm v tie-down point w electrical ground x.

Page 25: G 50

G 50 labels wc_si000520gb.Fm 25 y operator’s manual must be stored on machine. Replacement operator’s manual can be ordered through your local wacker neuson distributor. Z remote start operation. Read operator’s manual for instructions. Aa cc drain containment system. Dd operating the main circuit b...

Page 26: Labels

Labels g 50 26 wc_si000520gb.Fm gg generator and receptacle wiring hh engine wiring jj protecting our environment fluid containment system kk diagnostic menu navigation.

Page 27: G 50

G 50 labels wc_si000520gb.Fm 27 ll a nameplate listing the model number, item num- ber, revision number, and serial number is attached to each unit. Please record the informa- tion found on this nameplate so it will be available should the nameplate become lost or damaged. When ordering parts or req...

Page 28: Labels

Labels g 50 28 wc_si000520gb.Fm tt (camlock models only) warning! Electric shock and arc flash can cause serious injury or death..

Page 29: G 50

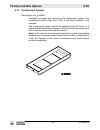

G 50 lifting and transporting wc_tx001580gb.Fm 29 3 lifting and transporting 3.1 lifting the machine a central lifting eye is located at the top of the generator and is attached to a lifting frame inside the housing. Crushing / machine damage hazard. Make sure the lifting devices have sufficient cap...

Page 30: Lifting and Transporting

Lifting and transporting g 50 30 wc_tx001580gb.Fm notice: when towing, maintain extra space between vehicles and avoid soft shoulders, curbs and sudden lane changes. If you have not pulled a trailer before, practice turning, stopping, and backing up in an area away from heavy traffic. Do not exceed ...

Page 31: G 50

G 50 lifting and transporting wc_tx001580gb.Fm 31 notes:.

Page 32: Operation

Operation g 50 32 wc_tx001049gb.Fm 4 operation preparing for first use to prepare your machine for first use: 4.0.1 make sure all loose packaging materials have been removed from the machine. 4.0.2 check the machine and its components for damage. If there is visible damage, do not operate the machin...

Page 33: G 50

G 50 operation wc_tx001049gb.Fm 33 4.3 refueling the machine requirements • machine shut down • engine cool • machine/fuel tank level with the ground • fresh, clean fuel supply procedure perform the procedure below to refuel the machine. 4.3.1 remove the fuel cap. 4.3.2 fill the fuel tank until the ...

Page 34: Operation

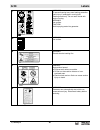

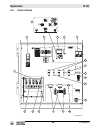

Operation g 50 34 wc_tx001049gb.Fm 4.4 control panel em ergency stop a Ø hz v r b a s le r diagnostics diagnosen diagnosticos diagnostics aus aus apagado apagado arret arret off off remote start remote start fernstart fernstart arranque remoto arranque remoto demarrage a demarrage a distance distanc...

Page 35: G 50

G 50 operation wc_tx001049gb.Fm 35 ref. Description ref. Description a main circuit breaker o remote run terminal block b voltage adjustment rheostat p emergency stop switch d pre-alarm/shutdown led q interlock switch e lcd panel r customer connection terminal lugs f engine start switch s ground con...

Page 36: Operation

Operation g 50 36 wc_tx001049gb.Fm 4.5 voltage selector switch see graphic: wc_gr001682 the voltage selector switch is located in a separate enclosure on the generator on the opposite side of the machine. The selector switch is a three-position switch which mechanically changes the connections betwe...

Page 37: G 50

G 50 operation wc_tx001049gb.Fm 37 4.6 emergency stop switch see graphic: wc_gr006062 the emergency stop switch (p) is the red button located below the receptacle panel and can be accessed with the panel doors closed. Activate the emergency stop switch by pushing the red button in. Pushing the emerg...

Page 38: Operation

Operation g 50 38 wc_tx001049gb.Fm 4.7 generator monitoring generator information is displayed on the top line of the lcd panel and is scrolled continuously while the generator is operating, to show the voltage, amperage and frequency of each phase. Volts “v”- displays the ac output voltage being pr...

Page 39: G 50

G 50 operation wc_tx001049gb.Fm 39 4.8 engine monitoring with the engine start switch set to “run/start” or “remote start”, engine information will be continuously displayed on the bottom line of the lcd panel. Oil —displays engine oil pressure. The gauge registers oil pressure between 0–100 psi. No...

Page 40: Operation

Operation g 50 40 wc_tx001049gb.Fm 4.9 engine shutdown faults the engine control module (ecm) continuously monitors vital engine functions for seven fault conditions. When a fault condition occurs, the engine will shut down and the lcd panel will display the fault causing the shutdown. To reset the ...

Page 41: G 50

G 50 operation wc_tx001049gb.Fm 41 4.10 current overload fault along with engine functions, the ecm continuously monitors the current load in each phase. The values for current overload are programmed into the ecm at the factory and are different for each generator size. 4.10.1 when an overcurrent c...

Page 42: Operation

Operation g 50 42 wc_tx001049gb.Fm 4.12 main line circuit breaker see graphic: wc_gr005866 the main line circuit breaker (a) is located on the control panel. In the off “o” position, this breaker interrupts power from the selector switch to the terminal lugs at the bottom of the generator panel. Not...

Page 43: G 50

G 50 operation wc_tx001049gb.Fm 43 4.13 engine start switch see graphic: wc_gr005866 the engine start switch (f) is a three-position switch: “remote start”, off “o”, and “start/run”. The “remote start” position is the normal setting used when using the generator as a back-up power supply connected t...

Page 44: Operation

Operation g 50 44 wc_tx001049gb.Fm 4.16 connection lugs see graphic: wc_gr005864 the customer connection lugs (r) are located on left at the bottom of the panel behind a hinged door. The lugs provide connection points for attachment of outside loads. A large label like the one shown in section termi...

Page 45: G 50

G 50 operation wc_tx001049gb.Fm 45 4.17 grounding the generator location a ground connection is located at the customer connection terminal lugs. Function this ground connection is used for electrically grounding the generator when necessary to comply with the national electrical code and other fede...

Page 46: Operation

Operation g 50 46 wc_tx001049gb.Fm 4.18 convenience receptacles see graphic: wc_gr005864 the generator is equipped with two 120v/240v twist lock receptacles (l) rated at 50a, and one 120v/240v twist lock receptacle (m) rated at 30a. The two 120v duplex receptacles (n) are equipped with ground fault ...

Page 47: G 50

G 50 operation wc_tx001049gb.Fm 47 4.21 terminal connections all connections to the terminals must be made by a trained electrician. Backfeed from the generator into the utility’s distribution system can cause a serious injury or death to utility workers! Improper connection of generator to a buildi...

Page 48: Operation

Operation g 50 48 wc_tx001049gb.Fm 4.22 before starting before putting the generator into service, review each item on the following checklist. Because generators are often run for long periods of time unattended, it is important to make sure that the unit is set up properly to reduce possible probl...

Page 49: G 50

G 50 operation wc_tx001049gb.Fm 49 when using the generator as a stand-by or substitute power supply, make sure the voltage and phase rotation of the line connections match those of the utility lines or of any other power source normally used. Failure to match phase rotation and voltage may cause eq...

Page 50: Operation

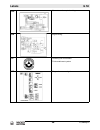

Operation g 50 50 wc_tx001049gb.Fm wc_gr001677 e m ergenc y s to p a Ø hz v r b a s le r diagnostics diagnosen diagnosticos diagnostics aus aus apagado apagado arret arret off off remote start remote start fernstart fernstart arranque remoto arranque remoto demarrage a demarrage a distance distance ...

Page 51: G 50

G 50 operation wc_tx001049gb.Fm 51 4.24 running the generator see graphic: wc_gr005866 leave the engine start switch (f) in the “start/run” position while the generator is operating. If the generator was started using a remote switch, leave engine start switch in the “remote start” position. Let the...

Page 52: Operation

Operation g 50 52 wc_tx001049gb.Fm 4.25 engine power correction factors performance data conditions performance data on john deere engines are measured at the following standard conditions: • 744 mm (29.31 in.) of mercury dry air pressure • 0% relative humidity • 25°c (77°f) air intake temperature •...

Page 53: G 50

G 50 operation wc_tx001049gb.Fm 53 4.28 automatic/remote start-up see graphic: wc_gr005938 in the “remote start” position the generator can be started remotely, either through a transfer switch or some other type of remote start switch. “remote start” is the normal setting when using the generator a...

Page 54: Operation

Operation g 50 54 wc_tx001049gb.Fm 4.29 remote/transfer switch when the generator is used as a stand-by power supply, it must be equipped with a device which isolates it from the utility’s distribution system. Failure to isolate the generator from the utility’s electrical distribution system could c...

Page 55: Mobile Generator

Using the lcd panel and keypad mobile generator 54 wc_tx001182gb.Fm 5 using the lcd panel and keypad see graphic: wc_gr005938, wc_gr006064 during normal operation, the lcd panel (e) displays current information on machine performance and operating status. The keypad (g) provides access to additional...

Page 56: Mobile Generator

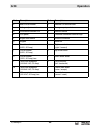

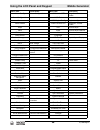

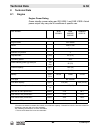

Mobile generator using the lcd panel and keypad wc_tx001182gb.Fm 55 5.1 navigating the menus the label pictured below is a navigational aid to access the various diagnostic menus programmed into the lcd. See the accompanying table for information about the menu items. . Metering settings metering en...

Page 57: Mobile Generator

Using the lcd panel and keypad mobile generator 56 wc_tx001182gb.Fm menu item description menu item description alarm config alarm configuration j1939 active dtc diagnostic trouble codes alarm configuration j1939 data alarms j1939 engine config engine configuration alarm–status j1939 previous dtc di...

Page 58: Mobile Generator

Mobile generator using the lcd panel and keypad wc_tx001182gb.Fm 57 5.2 entering passwords see graphic: wc_gr006068 some configuration procedures require a password to be entered before changes can be made. Once a password has been entered, it remains in the memory until the machine is shut off. Not...

Page 59: Mobile Generator

Using the lcd panel and keypad mobile generator 58 wc_tx001182gb.Fm 5.3 adjusting screen contrast the display contrast of the lcd panel can be adjusted to suit the operator’s preference, or for increased visibility in jobsites with low or bright ambient light. 5.3.1 to access the main menu, press th...

Page 60: Mobile Generator

Mobile generator using the lcd panel and keypad wc_tx001182gb.Fm 59 5.4 setting the time or date see graphic: wc_gr005938 the control module features a clock powered by a separate battery. Follow the steps below to change the time or date. 5.4.1 to access the main menu, press the right arrow button ...

Page 61: Mobile Generator

Using the lcd panel and keypad mobile generator 60 wc_tx001182gb.Fm 5.5 changing user preferences changing display units the lcd panel can be configured by the operator to display system information in either metric units or english units. 5.5.1 to access the main menu, press the right arrow button ...

Page 62: Mobile Generator

Mobile generator using the lcd panel and keypad wc_tx001182gb.Fm 61 5.6 changing / disabling low fuel fault see graphic: wc_gr005938 the low fuel fault value can be changed or disabled through the diagnostics menu. (for example, you may wish to reduce the value so that the machine operates for a lon...

Page 63: Mobile Generator

Using the lcd panel and keypad mobile generator 62 wc_tx001182gb.Fm 5.7 changing cooldown time see graphic: wc_gr005938 a cooldown timer activates when the machine is no longer receiving a remote run signal. This timer is factory set to zero (0) minutes. The cooldown time can be changed if desired. ...

Page 64: Factory-Installed Options

Factory-installed options g 50 64 wc_tx001016gb.Fm 6 factory-installed options this machine may be equipped with one or more of the following factory-installed options. To verify if any of these options are installed on your machine, contact wacker neuson corporation at 1-800-770- 0957. A nameplate ...

Page 65: G 50

G 50 factory-installed options wc_tx001016gb.Fm 65 6.2 electronic governor see graphic: wc_gr001714, wc_gr001716 the electronic governor option consists of an electronic module (b) and an electronic actuator (d). The module senses rotation of the flywheel, then sends a signal to the electronic actua...

Page 66: Factory-Installed Options

Factory-installed options g 50 66 wc_tx001016gb.Fm 6.3 automatic lcd heat to improve the performance of the lcd panel in cold weather, the lcd panel control module is equipped with an lcd heater. The heater draws power from the panel control module and is active only when the panel control module is...

Page 67: G 50

G 50 factory-installed options wc_tx001016gb.Fm 67 6.4 low coolant shutdown see graphic: wc_gr001708 the low-coolant shutdown system consists of an electronic sensor that monitors coolant level. The sensor (a) is mounted to the radiator and wired into the ecm. The sensor probe (b) is submerged in ra...

Page 68: Factory-Installed Options

Factory-installed options g 50 68 wc_tx001016gb.Fm 6.5 lube level maintainer see graphic: wc_gr005771, wc_gr005772, wc_gr005778 the lube level maintainer system protects the engine from low oil levels by providing an additional 6-quart oil reservoir. Oil from the reservoir is gravity-fed from the oi...

Page 69: G 50

G 50 factory-installed options wc_tx001016gb.Fm 69 6.6 temperature-activated shutters see graphic: wc_gr005770, wc_gr001707 the shutters (a) are mounted to the top of the generator enclosure. The shutters are designed to keep the engine compartment warm, thus increasing engine temperature during col...

Page 70: Factory-Installed Options

Factory-installed options g 50 70 wc_tx001016gb.Fm 6.8 extended run tank an extended run, 331-gallon fuel tank provides a 63-hour run time under a continuous full load. The long run time eliminates the need for daily refueling, saving money on fuel deliveries. The tank is fully fluid- contained and ...

Page 71: G 50

G 50 factory-installed options wc_tx001016gb.Fm 71 6.10 camlocks a second optional outlet panel features camlock connectors for easy tool changes. Each connector is protected by a spring-loaded cover. Notice: separate overcurrent protection must be provided. Do not exceed 400 amps per receptacle. Wa...

Page 72: Factory-Installed Options

Factory-installed options g 50 72 wc_tx001016gb.Fm 6.11 containment system see graphic: wc_gr002647 overspills and leaks are captured in the containment system. The containment system holds over 110% of the fluid contained in the machine. The containment system should be checked every 50 hours or 2 ...

Page 73: G 50

G 50 factory-installed options wc_tx001016gb.Fm 73 6.12 wiring diagram (factory-installed options) wire colors b black r red y yellow or orange g green t tan br brown pr purple l blue v violet cl clear sh shield p pink w white gr gray ll light blue.

Page 74: Factory-Installed Options

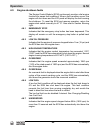

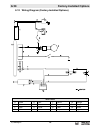

Factory-installed options g 50 74 wc_tx001016gb.Fm 6.13 wiring diagram components (factory-installed options) see graphic: wc_gr001868 ref description ref description 1 thermostat module 7 positive air shutoff solenoid actua- tor 2 terminal block 8 auxiliary relay terminals 3 1 amp fuse 9 plug 1, en...

Page 75: G 50

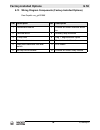

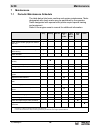

G 50 maintenance wc_tx001050gb.Fm 75 7 maintenance 7.1 periodic maintenance schedule the table below lists basic machine and engine maintenance. Tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equipment. Refe...

Page 76: Maintenance

Maintenance g 50 76 wc_tx001050gb.Fm 7.2 new machines 7.2.1 run generator at least 60–100% of continuous load for the first 100 hours. 7.2.2 change engine oil and replace oil filter after the first 50 hours. 7.3 resetting the periodic maintenance timer after maintenance has been performed on the gen...

Page 77: G 50

G 50 maintenance wc_tx001050gb.Fm 77 7.3.1 to access the main menu, press the right arrow button (1) on the keypad (g). Note: if there are active alarms or pre-alarms, press the left arrow button (4) three times to access the main menu. 7.3.2 using the up/down arrow buttons (2,3), select settings an...

Page 78: Maintenance

Maintenance g 50 78 wc_tx001050gb.Fm 7.5 servicing the air cleaner see graphic: wc_gr000511 replace the air filter cartridge (c) when yellow indicator of the engine air filter gauge reaches the red line. To replace the air filter cartridge: • remove the end cover (d), then discard the entire air fil...

Page 79: G 50

G 50 maintenance wc_tx001050gb.Fm 79 7.6 engine oil checking oil check engine oil daily before starting engine. • do not operate engine if oil level is below add mark on dipstick. Always keep oil level within the crosshatch pattern or “full” mark on dipstick. • change oil after first 100 hours of op...

Page 80: Maintenance

Maintenance g 50 80 wc_tx001050gb.Fm 7.7 checking engine coolant check the coolant level of the radiator with the engine cold. After initial filling of radiator to 3/4" below bottom of filler neck, maintain proper level in overflow bottle daily. Never remove radiator cap or drain plug while engine i...

Page 81: G 50

G 50 maintenance wc_tx001050gb.Fm 81 7.8 troubleshooting automatic shutdown there are six automatic shutdown conditions: • low oil pressure • high coolant temperature • engine overspeed • engine underspeed • engine overcrank • low fuel level when these occur, the operator can perform certain diagnos...

Page 82: Maintenance

Maintenance g 50 82 wc_tx001050gb.Fm 7.8.9 check the high temperature shutdown sender and connecting wiring on engine block. Check for continuity between sender on engine block and engine control module. See wiring diagrams. 7.8.10 if sender and wiring are good, consult engine manufacturer’s operato...

Page 83: G 50

G 50 maintenance wc_tx001050gb.Fm 83 7.9 maintaining the trailer tires - keep tires inflated to the proper pressure as shown on the tire sidewall, and check tread periodically for wear. Replace tires as required. Wheels - check that lug nuts holding wheels are tight. Replace any missing nuts immedia...

Page 84: Technical Data

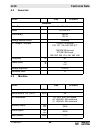

Technical data g 50 84 wc_td000414gb.Fm 8 technical data 8.1 engine engine power rating gross standby power rating per iso 8528-1 and sae j1995. Actual power output may vary due to conditions of specific use. * run times are based on useable fuel volume, not on fuel tank capacity. “useable fuel volu...

Page 85: G 50

G 50 technical data wc_td000414gb.Fm 85 8.2 generator 8.3 machine model: g 50 g 50 ert generator make/type mecc alte / brushless / 4 pole model eco32-3l/4 prime rating kva 3Ø: 60 1Ø: 34 voltage selector switch 3 position ac voltages available 120/240 1Ø zig-zag 120, 127, 139, 240, 254, 277 120/208 3...

Page 86: Technical Data

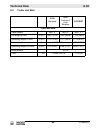

Technical data g 50 86 wc_td000414gb.Fm 8.4 trailer and skid g 50 standard g 50 custom & cold weather g 50 ert trailer and skid trailer model mgt 2 mgt 2 mgt 3.1 dry weight of skid kg (lbs.) 1442 (3178) 1482 (3268) 1746 (3849) operating weight of skid kg (lbs.) 1716 (3783) 1757 (3873) 2776 (6121) tr...

Page 87: G 50

G 50 technical data wc_td000414gb.Fm 87 8.5 dimensions mm (in.) machine a b c d e f g g 50 skid 965 (38) — — — 2445 (96.25) 1346 (53) 1476 (58.1) g 50 trailer — 2032 (80) 1715 (67.5) 4064 (160) — — — g 50 ert skid 1156 (45.5) — — — 2794 (110) 1816 (71.5) 1946 (76.6) g 50 ert trailer — 2464 (97) 2032...

Page 88: Technical Data

Technical data g 50 88 wc_td000414gb.Fm notes:.

Page 89

G 50 schematics wc_tx001582gb.Fm 89 9 schematics this page is intentionally left blank..

Page 90

Schematics g 50 90 9.1 generator and receptacle wiring 1 16 9 10 15 14 t11 1 9 7 3 1 5 10 8 12 2 6 4 t1 g y x g y x g x y grn r1 r2 t3 t6 t2 36 36a re re yel vi 5c 5b wht 6 5a 5 4 3a 3 4a 7 am s t a v o l hz blu/w 60hz blu bl gr blk l3 t11 t3 2 t4 n l2 t8 l1 t9 26 6 25 1 1 1 1 3 1 9 1 1 1 1 1 1 g n ...

Page 91

G 50 schematics wc_tx001582gb.Fm 91 9.2 generator and receptacle wiring components ref. Description ref. Description 1 lug safety limit switch 16 generator 2 mechanical lugs 17 voltage regulator with 4a fuse 3 plug 3 - current transformer 18 voltage adjustment rheostat 4 plug 4 - line voltage inputs...

Page 92

Schematics g 50 92 9.3 engine wiring wc_gr007884 12 blk 13 59 red 10awg 12 65 11 gry blk 14 63 51 47 46 wht bond to front panel door ground to enclosure box stud red 10awg 11 50 l0 grd l l2 ground to engine block red 4awg l1 org org 45 yel 47 wht yel blk ground to engine block 56 57 87 62 20 17 95 4...

Page 93

G 50 schematics wc_tx001582gb.Fm 93 9.4 engine wiring components ref. Description ref. Description 1 electronic control unit 15 starter motor 2 plug 1 - engine sender inputs 16 alternator 3 plug 2 - contact inputs 17 mechanical lugs 4 remote start-off-start/run switch 18 main circuit breaker 5 relay...

Page 94

Schematics g 50 94 9.5 trailer wiring standard and hydraulic brakes electric brakes w c _ g r 0 0 0 5 2 2 b r b r w w b r w g b r w y b r w b r w y g b r w 1 9 8 6 2 1 0 3 b r b r 7 7 3 g y br w r r r br w r r + – w w w w br br br br br br w wc_gr000523 y w g r w r r 1 4 5 5 2 9 6 8 7 7 10 br w.

Page 95

G 50 schematics wc_tx001582gb.Fm 95 9.6 trailer wiring components ref. Description 1 front right side amber light 2 front left side amber light 3 trailer plug 4 battery 5 brake solenoid 6 right tail light 7 license plate holder lights 8 left tail light 9 rear right side red light 10 rear left side r...

Page 98

Wacker neuson produktion gmbh & co. Kg, preußenstraße 41, d-80809 münchen, tel.: +49-(0)89-3 54 02-0 fax: +49 - (0)89-3 54 02-390 wacker neuson production americas llc, n92w15000 anthony ave., menomonee falls, wi 53051 tel. : (262) 255-0500 fax: (262) 255-0550 tel.: (800) 770-0957 wacker neuson limi...