- DL manuals

- Wacker Neuson

- Water Pump

- PTS 4V

- Operator's Manual

Wacker Neuson PTS 4V Operator's Manual

Summary of PTS 4V

Page 1

5000193035 05 0315 5 0 0 0 1 9 3 0 3 5 operator’s manual pump pts 4v en.

Page 2

Copyright notice © copyright 2015 by wacker neuson production americas llc all rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permissio...

Page 3: Pts 4V

Wc_tx003328gb.Fm 3 pts 4v foreword foreword save these instructions—this manual contains important instructions for the machine models below. These instructions have been written expressly by wacker neuson production americas llc and must be followed during installation, operation, and maintenance o...

Page 4: Foreword

Wc_tx003328gb.Fm 4 foreword pts 4v expectations for information in this manual this manual provides information and procedures to safely operate and maintain the above wacker neuson model(s). For your own safety and to reduce the risk of injury, carefully read, understand, and observe all instructio...

Page 5: Ec Declaration of Conformity

20 1 5-c e- pt s 4 v_ en _ f m10 .F m manufacturer wacker neuson production americas llc, n92w15000 anthony avenue, menomonee falls, wisconsin 53051 usa product product product category product function item number net installed power measured sound power level guaranteed sound power level pts 4v ce...

Page 7: Table of Contents

Wc_bo5000193035_05toc.Fm 7 table of contents pts 4v foreword 3 ec declaration of conformity 5 1 safety information 9 1.1 signal words used in this manual ....................................................... 9 1.2 machine description and intended use ............................................. 1...

Page 8: Table of Contents

8 wc_bo5000193035_05toc.Fm table of contents pts 4v 5.9 adjusting the carburetor .....................................................................35 5.10 changing mechanical seal coolant ....................................................35 5.11 adjusting the impeller clearance ...................

Page 9: Pts 4V

Wc_si000770gb.Fm 9 pts 4v safety information 1 safety information 1.1 signal words used in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Notic...

Page 10: Safety Information

Wc_si000770gb.Fm 10 safety information pts 4v 1.2 machine description and intended use this machine is a centrifugal trash pump. The wacker neuson trash pump consists of a trailer with integral fuel tank onto which are mounted a diesel engine, and an impeller pump with ports for water suction and di...

Page 11: Pts 4V

Wc_si000770gb.Fm 11 pts 4v safety information 1.3 safety guidelines for operating the machine operator training before operating the machine: read and understand the operating instructions contained in all manuals delivered with the machine. Familiarize yourself with the location and proper use of a...

Page 12: Safety Information

Wc_si000770gb.Fm 12 safety information pts 4v safe operating practices when operating this machine: remain aware of the machine’s moving parts. Keep hands, feet, and loose clothing away from the machine’s moving parts. When operating this machine: do not operate a machine in need of repair. Personal...

Page 13: Pts 4V

Wc_si000770gb.Fm 13 pts 4v safety information 1.4 service safety service training before servicing or maintaining the machine: read and understand the instructions contained in all manuals delivered with the machine. Familiarize yourself with the location and proper use of all controls and safety de...

Page 14: Safety Information

Wc_si000770gb.Fm 14 safety information pts 4v personal protective equipment (ppe) wear the following personal protective equipment (ppe) while servicing or maintaining this machine: close-fitting work clothes that do not hinder movement safety glasses with side shields hearing protection safety-toed...

Page 15: Pts 4V

Wc_si000770gb.Fm 15 pts 4v safety information 1.5 operator safety while using internal combustion engines operating safety when running the engine: keep the area around exhaust pipe free of flammable materials. Check the fuel lines and the fuel tank for leaks and cracks before starting the engine. D...

Page 16: Labels

Wc_si000771gb.Fm 16 labels pts 4v 2 labels 2.1 label locations wc_gr010881 d e f g h j k m n o a b c d c.

Page 17: Pts 4V

Wc_si000771gb.Fm 17 pts 4v labels 2.2 label meanings a danger asphyxiation hazard. Engines emit carbon monoxide. Do not run the machine indoors or in an enclosed area. Never use inside a home or garage, even if doors and windows are open. Only use outside and far away from windows, doors, and vents....

Page 18: Labels

Wc_si000771gb.Fm 18 labels pts 4v d warning do not open if pump is hot. Hot water and/or steam inside could be pressurized. E warning never pump volatile, flammable, or low-flash-point fluids. These fluids could ignite or explode. F notice lifting point g guaranteed sound power level in db(a) h key ...

Page 19: Pts 4V

Wc_si000771gb.Fm 19 pts 4v labels j throttle control lever: turtle = idle or slow rabbit = full or fast k this machine may be covered by one or more patents. M warning operation of this equipment may create sparks that can start fires around dry vegetation. A spark arrester may be required. The oper...

Page 20: Lifting and Transporting

Wc_tx003329gb.Fm 20 lifting and transporting pts 4v 3 lifting and transporting lifting the machine do not attempt to lift the pump unassisted. Use appropriate lifting equipment such as slings, chains, hooks, ramps, or jacks. Make sure lifting equipment is attached securely and has enough weight- bea...

Page 21: Pts 4V

Wc_tx003330gb.Fm 21 pts 4v operation 4 operation 4.1 preparing the machine for first use 1. Make sure all loose packaging materials have been removed from the machine. 2. Check the machine and its components for damage. If there is visible damage, do not operate the machine! Contact your wacker neus...

Page 22: Operation

Wc_tx003330gb.Fm 22 operation pts 4v 4.3 before starting 1. Read safety instructions at the beginning of this operator’s manual. 2. Place pump as near to water as possible, on a firm, flat, level surface. 3. To prime pump, remove prime plug (a) and fill pump housing with water. If the pump housing i...

Page 23: Pts 4V

Wc_tx003330gb.Fm 23 pts 4v operation wc_gr008086 a d c b f c e c.

Page 24: Operation

Wc_tx003330gb.Fm 24 operation pts 4v 4.4 starting follow the instructions below and read starting and stopping instuctions found in the engine owner’s manual. 1. Open the fuel valve (b1). 2. If the engine is cold, pull out the choke control (a1). If the engine is hot, push in the choke control (a2)....

Page 25: Pts 4V

Wc_tx003330gb.Fm 25 pts 4v operation a1 a2 c1 c2 b2 b1 d2 d1 d3 wc_gr010883 e.

Page 26: Operation

Wc_tx003330gb.Fm 26 operation pts 4v 4.6 operation pump should begin pumping water within a minute depending on length of suction hose and height of pump above water. Longer hoses will require more time. If pump does not prime, check for loose fittings or air leak in suction hose. Make sure strainer...

Page 27: Pts 4V

Wc_tx003330gb.Fm 27 pts 4v operation 4.9 hoses and clamps suction hoses (a) must be rigid enough not to collapse when pump is operating. Discharge hoses (b) are usually thin-walled collapsible hoses. Rigid hoses similar to those used as suction hoses may also be used as discharge hoses. Note: suctio...

Page 28: Maintenance

Wc_tx003331gb.Fm 28 maintenance pts 4v 5 maintenance 5.1 maintaining the emission control system for machines sold in north america: normal maintenance, replacement, or repair of emission control devices and systems may be performed by any repair establishment or individual; however, warranty repair...

Page 29: Pts 4V

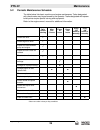

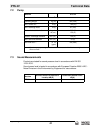

Wc_tx003331gb.Fm 29 pts 4v maintenance 5.2 periodic maintenance schedule the table below lists basic machine and engine maintenance. Tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equipment. Refer to the eng...

Page 30: Maintenance

Wc_tx003331gb.Fm 30 maintenance pts 4v 5.3 engine oil check engine oil level daily before starting engine. Add oil as required. 1. To check oil level, place machine on a level surface. 2. Clean area around oil fill (d) and remove dipstick (b). 3. Pour oil (a) slowly, checking oil level occasionally ...

Page 31: Pts 4V

Wc_tx003331gb.Fm 31 pts 4v maintenance 5.4 changing the engine oil drain oil while engine is still warm. 1. Remove oil fill cap (a) and drain plug (b) to drain oil. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine to collect any liquid which...

Page 32: Maintenance

Wc_tx003331gb.Fm 32 maintenance pts 4v 5.5 servicing the air cleaner service air cleaner frequently to prevent carburetor malfunction. Notice: do not run the engine without the air cleaner. Severe engine damage will occur. Do not use gasoline or other types of low flash point solvents for cleaning t...

Page 33: Pts 4V

Wc_tx003331gb.Fm 33 pts 4v maintenance 5.6 cleaning and checking the spark plug when clean or replace the spark plug as needed to ensure proper operation. Refer to your engine owner’s manual. Note: refer to section “technical data” for the recommended spark plug type and the electrode gap setting. P...

Page 34: Maintenance

Wc_tx003331gb.Fm 34 maintenance pts 4v 5.7 cleaning the muffler and deflector overview the muffler and deflector must be cleaned regularly to prevent combustible debris such as leaves, grass, or twigs from igniting. Requirements engine is stopped. Engine is cool to the touch. Cleaning the muffler fo...

Page 35: Pts 4V

Wc_tx003331gb.Fm 35 pts 4v maintenance 5.9 adjusting the carburetor notice: the carburetor has been factory-set to operate efficiently under most conditions. To avoid permanently damaging the engine, do not make any adjustments to the carburetor. Contact your wacker neuson dealer for assistance if t...

Page 36: Maintenance

Wc_tx003331gb.Fm 36 maintenance pts 4v 5.11 adjusting the impeller clearance if it is necessary to replace impeller or volute insert, be sure clearance between impeller and insert is adjusted correctly. The impeller (e) should be as close to the insert (a) as possible without rubbing against it. Cle...

Page 37: Pts 4V

Wc_tx003331gb.Fm 37 pts 4v maintenance 5.12 cleaning the pump after pumping water containing a large amount of dirt or debris, clean out inside of pump housing. 1. Remove drain plug (a) from pump housing and drain any water left in pump. 2. Loosen the four knobs (b) holding the pump cover and remove...

Page 38: Maintenance

Wc_tx003331gb.Fm 38 maintenance pts 4v 5.13 long-term storage if pump is being stored for more than 30 days: do not open priming plug, discharge plug, or cover when pump is hot. 1. After pump has cooled, remove discharge plug from pump housing and drain out any water left in the housing. 2. Remove p...

Page 39: Pts 4V

Wc_tx003332gb.Fm 39 pts 4v troubleshooting 6 troubleshooting problem / symptom reason / remedy pump does not take in water. Not enough priming water in housing. Engine speed too low. Adjust speed. Strainer plugged. Clean strainer. Suction hose damaged. Replace or repair suction hose. Air leak at suc...

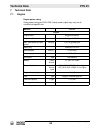

Page 40: Technical Data

Wc_td000560gb.Fm 40 technical data pts 4v 7 technical data 7.1 engine engine power rating gross power rating per sae j1995. Actual power output may vary due to conditions of specific use. Machine pts 4v engine engine make briggs and stratton engine model vanguard 305447 max. Rated power @ rated spee...

Page 41: Pts 4V

Wc_td000560gb.Fm 41 pts 4v technical data 7.2 pump 7.3 sound measurements products are tested for sound pressure level in accordance with en iso 11201:2010. Sound power level is tested in accordance with european directive 2000/14/ec - noise emission in the environment by equipment for use outdoors....

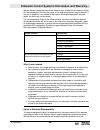

Page 42: Technical Data

Wc_td000560gb.Fm 42 technical data pts 4v 7.4 dimensions mm (in.) 111891111891 11755411 7 5 5 4 890 (35) 915 (36) 890 (35) wc_gr008090

Page 43

Emission control systems information and warranty— wc_tx001754gb.Fm 43 8 emission control systems information and warranty — gasoline the emission control warranty and associated information is valid only for the u.S.A., its territories, and canada. 8.1 emission control system background information...

Page 44

Emission control systems information and warranty—gasoline 44 wc_tx001754gb.Fm tampering and altering tampering with or altering the emission control system may increase emissions beyond the legal limit. If evidence of tampering is found, wacker neuson may deny a warranty claim. Among those acts tha...

Page 45

Emission control systems information and warranty— wc_tx001754gb.Fm 45 wacker neuson dealer/service center determines it is defective or causes a failure of a warranted part, the claim for repair of the engine/equipment may be denied. If the part in question is not related to the reason the engine/e...

Page 46

Emission control systems information and warranty—gasoline 46 wc_tx001754gb.Fm engine/equipment be retained, but wacker neuson cannot deny warranty coverage solely for the lack of receipts or for the failure to ensure the performance of all scheduled maintenance. Normal maintenance, replacement, or ...

Page 60

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · n92w15000 anthony ave. · menomonee falls, wi 53051 · tel. : (262) 255-0500 · fax: (262) 255-0550 ·tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & ...