- DL manuals

- Walker

- Lawn Mower

- MS

- Operator's Manual

Walker MS Operator's Manual

Summary of MS

Page 1

Operator’s manual safety, assembly, operating, and maintenance instructions model ms ™ please read and save these instructions beginning s/n: 117172 for safety, read all safety and operation effective date: 05-07-12 instructions prior to operating machine p/n 5000-23.

Page 2: Foreword

Foreword thank you. . .For purchasing a walker mower. Every effort has been made to provide you with the most reliable mower on the market, and we are sure you will be among our many satisfied custom- ers. If for any reason this product does not perform to your expectations, please contact your loca...

Page 3: Table of Contents

Table of contents general information ________________ 1 highlighted information _____________ 1 glossary ____________________________ 1 identifying number locations ________ 1 engine serial number location _______ 2 servicing of engine and drivetrain components ______________ 2 specifications _____...

Page 4: Table of Contents

Table of contents maintenance instructions __________ 42 maintenance schedule chart _______ 42 important tips for care of the subaru engine ________________ 43 fuel system _________________________ 43 starting _____________________________ 43 cooling system ______________________ 43 air cleaner syst...

Page 5: General Information

General information 1 highlighted information walker manufacturing recommends that any service requiring special training or tools be performed by an authorized walker mower dealer. There are sev- eral general practices to be aware of in the area of safety. Most accidents associated with the opera- ...

Page 6: General Information

General information 2 serial number tractor serial number location serial number mower deck serial number location engine serial number location refer to the engine manual that accompanies this manual or the photo below for the location of the engine serial number. Serial number engine serial number...

Page 7: Specifications

Specifications 3 model ms engine manufacturer/model subaru robin, ex40, 1 cyl. (air-cooled) displacement cu. In. (cc) 24.65 (404) max. Power hp (kw) 14.0 (10.4) @ 3600 rpm governed rpm 3600 max. Torque lb·ft (n·m) 19.9 (27.0) @ 2400 rpm idle rpm 1300 spark plug type ngk bpr5es spark plug gap in. (mm...

Page 8: Specifications

Specifications 4 model ms transmission (continued) transmission fluid factory service mobil 1 synthetic motor oil (15w-50) transmission oil capacity oz. (l) 19 (.56) transmission cooling cooling fan mounted on drive pulley ground travel speed forward mph (km/h) reverse mph (km/h) 0-5 (0-8) infinitel...

Page 9: Specifications

Specifications 5 model ms dimensions (continued) width in. (cm) tractor only (outside standard tire) 35 (89) (outside optional wide tire) 37.75 (96) with 36 in. (91 cm) 37 (94) with 42 in. (107 cm) 43 (109) height in. (cm) tractor 44.5 (113) weight lb (kg) tractor only 639 (290) with dghs36 715 (324...

Page 10: Specifications

Specifications 6 model ms ghs system blower 10 in. Diameter, three-blade paddle wheel blower brake belt scrubber brake [works in combination with pto clutch, stops blower within five (5) seconds of pto disengagement] max. Blower rpm 4000 grass catcher capacity gal / bu / l 63 / 6.7 / 238 full signal...

Page 11: Component Identification

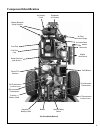

Component identification 7 front view and right side view note: control identification shown in operating instructions section. Anti-scuff roller grass handling system 6.7 bushel catcher catcher door safety latch catcher lift / dump handle counterweight spring and protective cover deck support arm d...

Page 12: Component Identification

Component identification 8 rear view and left side view catcher door removable grass catcher screen (not visible) catcher exhaust deflector catcher door gas spring catcher door gas spring protective cover catcher lift / dump handle anti-scuff roller catcher door handle left hand drive wheel rotating...

Page 13: Component Identification

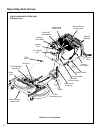

Component identification 9 top view (body raised) muffler air cleaner cover donaldson air cleaner carburetor air intake hose air filter restriction gauge rubber bumpers (body support) fuel tank cap fuel tank rh transmission lockout lever tractor pto gearbox starter solenoid (not shown) rh hydrostati...

Page 14

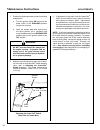

Safety instructions - before operating 10 pay particular attention to any information labeled danger, warning, caution, important, and note in this manual. When you see the safety alert symbol ( ), read, understand, and follow the instructions. Fail ure to comply with safety instructions may result ...

Page 15

Safety instructions - before operating 11 6. Do not wear loose fitting clothing that could get caught in moving parts. Do not operate this ma- chine while wearing shorts; always wear ade- quate protective clothing, including long pants. Wearing safety glasses, safety shoes, and a helmet is advisable...

Page 16

Safety instructions - operating 12 1. Operate the mower only in daylight or in good artificial light with good visibility of the area being mowed. 2. Sit on the seat when starting the engine and operating the machine. Keep feet on the deck footrests at all times when the tractor is moving and/or mow...

Page 17

Safety instructions - operating 13 14. The maximum recommended slope operat- ing angle is 15 degrees or 26% grade. When operating the machine on a slope, reduce speed and use caution to start, stop, and maneuver. To prevent tipping or loss of control of the ma- chine, avoid sharp turns or sudden cha...

Page 18

Safety instructions - maintenance 14 1. To prevent accidental starting of the engine when servicing or adjusting the machine, re- move the key from the ignition switch and dis- connect the spark plug wire. 2. To reduce fire hazards, keep the engine free of grass, leaves, excessive grease, and dirt. ...

Page 19: Safety Instructions

Safety instructions 15 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 20: Safety Instructions

Safety instructions 16 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 21: Assembly Instructions

Assembly instructions 17 setup instructions walker mowers are shipped partially assembled. After uncrating the tractor and mower deck, initial setup is required. Note: during the process of unpacking, any dam- aged or missing parts should be noted and reported to the delivering carrier immediately (...

Page 22: Assembly Instructions

Assembly instructions 18 battery charging danger batteries produce explosive gases • charge the battery in a well-ventilated area, so that gases produced while charg- ing can dissipate. • keep sparks, flames, and smoking mate- rials away from the battery at all times. • make sure the battery cap ven...

Page 23: Assembly Instructions

Assembly instructions 19 4. Tighten the bolt and nut until the axle spacer tube bottoms against the inside of the wheel fork (will not turn) while the wheel and spacer washers (if used) spin freely without binding. Spacer washer axle bolt axle spacer tube deck caster wheel installation note: if semi...

Page 24: Assembly Instructions

Assembly instructions 20 attach spring roller wheels tilt-up spring and roller wheel installation on rear discharge deck mower deck installation on tractor deck installation 1. Lightly grease each deck support arm (2) on the tractor. Refer to mower deck installation pho- to for location of deck supp...

Page 25: Assembly Instructions

Assembly instructions 21 spring tension adjustment nut located under lower spring hook (not visible) hitch pins lock deck on support arms counterweight springs clip onto body with body tilted up deck counterweight spring installation 6. Raise mower body (instead of lifting the front of deck) and cli...

Page 26: Assembly Instructions

Assembly instructions 22 deck leveling 1. Position mower on a smooth, level surface. Set the cutting height to the highest position - 4 in. (102 mm) - for easy access under the deck to measure blade height. Refer to adjusting cutting height in operating instructions. Note: a block of wood cut 4 in. ...

Page 27: Assembly Instructions

Assembly instructions 23 preoperating checklist before operating the mower for the first time, and as a routine before daily operations, it is important to make sure the mower is properly prepared and ready for operation. The following is a list of items to be checked. (for a mower with frequent ope...

Page 28: Assembly Instructions

Assembly instructions 24 inspect three (3) drive belts engine, pto, and hydrostatic ground drive. Check hydrostatic transmission oil level refer to lubrication for checking hydrostatic transmission fluid level in maintenance instruc tions. Check tire pressure deck caster wheel = 20 psi (137 kpa) dr...

Page 29: Operating Instructions

Operating instructions 25 control identification, location, and function caution before operating the mower, become famil- iar with the location and function of all op- erator controls. Knowing the location, function, and operation of these controls is important for safe and efficient operation of t...

Page 30: Operating Instructions

Operating instructions 26 engine throttle the throttle control lever (red knob) is located on the left side of the seat and is used to control engine speed. Moving the lever forward toward the fast position increases engine speed; moving it back- ward toward the idle position decreases engine speed....

Page 31: Operating Instructions

Operating instructions 27 transmission lockout levers the transmission lockout levers disengage the hy- drostatic transmissions. By lifting the lever on top of the transmission and locking it into place with the lockout cam, the hydrostatic transmissions are re- leased to permit freewheeling. By rel...

Page 32: Operating Instructions

Operating instructions 28 operating controls (top view from drivers point of view) blade clutch (pto) neutral-park position right wheel steering lever choke parking brake throttle off position on position the forward speed control also establishes the neutral-park position of the steering levers ful...

Page 33: Operating Instructions

Operating instructions 29 starting the engine caution before operating the mower, read and un- derstand all safety instructions and operat ing instructions. Warning never run the engine in an enclosed or poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless and deadly gas. 1....

Page 34: Operating Instructions

Operating instructions 30 1. Move the fsc out of neutral-park position to the desired forward speed. Do not hold for ward on steering levers. It is not necessary to hold the fsc lever in position since a friction lock maintains the selected lever position (and forward travel speed). Warning in case ...

Page 35: Operating Instructions

Operating instructions 31 note: smooth action on the steering levers will produce smooth mower operation. Remem- ber to keep the engine and ground speed slow until learning the control response. Warning when moving forward, do not suddenly put the tractor in reverse by rapidly pulling on the steerin...

Page 36: Operating Instructions

Operating instructions 32 caution if the cutting blades strike a stationary ob- ject while mowing, stop the mower imme- diately, disconnect the spark plug wire, lift the deck, and inspect the deck and blades thoroughly for damage. Make sure that the blade timing has not been dis turbed (the blades s...

Page 37: Operating Instructions

Operating instructions 33 lift handle deck support pin hitch pin cutting height adjustment transmission lockout important: do not tow this mower with the transmission lockout engaged. Towing can produce excessive internal pressure and damage the trans- mission. To move the mower with the engine not ...

Page 38: Operating Instructions

Operating instructions 34 avoid low hanging branches important: operate the engine at full throttle when mowing, to allow the engine to produce full horsepower and to increase efficiency of the engine cooling system. • keep the mower deck and discharge chute clean. • mow with sharp blades. A dull bl...

Page 39: Operating Instructions

Operating instructions 35 maximum recommended slope - do not operate on steep slopes 22 in. 15° 60 in. Maximum recommended slope danger do not mow or dump grass within 5 feet (1.5 meters) of an embankment or retaining wall with drop off. Recommendations for tilt-up deck operation/transport to avoid ...

Page 40: Operating Instructions

Operating instructions 36 catcher door pto clutch rear discharge mower deck shear bolt pto and blade gear drive exhaust deflector catcher door safety latch exhaust screen (removable) catcher door spring grass catcher dump handle powerfil ® delivery spout body chute assembly blower deck discharge chu...

Page 41: Operating Instructions

Operating instructions 37 general information the grass handling system (ghs) consists of a rear discharge mower deck connected to a 10 in. (25 cm) blower and a rear mounted grass catcher with 6.7 bushel (238 liters) capacity. The ghs blow- er operates any time the mower blade clutch is en- gaged an...

Page 42: Operating Instructions

Operating instructions 38 clogging checklist in case of clogging, there will be a distinct change in the sound of the blower, i.E., the blower sound will stop. Also, the mower deck will begin to leave a trail of grass clippings. When this occurs, stop the engine, disconnect the spark plug wire, and ...

Page 43: Operating Instructions

Operating instructions 39 • check that the openings in the removable air exhaust screen in the grass catcher are not plugged. If the screen is clogged, refer to cleaning the ghs exhaust screen in this section. Note: an optional exhaust screen with larger holes (3/4”) is available for use when mowing...

Page 44: Operating Instructions

Operating instructions 40 dumping the catcher danger do not mow or dump grass within 5 feet (1.5 meters) of an embankment or retaining wall with drop off. For dumping, the catcher either tailgate dumps into a disposal area or dumps into the optional dump bag. The dump bag is a reusable nylon fabric ...

Page 45: Operating Instructions

Operating instructions 41 4. Tilt the catcher back to dump into the bag by lifting on the catcher lift handle on the lower front corner of the catcher with the one hand while continuing to hold up on the bag strap(s) with the other hand. Refer to photos for posi- tioning the bag and dumping. 5. Lowe...

Page 46: Maintenance Instructions

Maintenance instructions 42 maintenance schedule chart - recommended service intervals - model ms service item daily 25 hours 50 hours 100 hours yearly every 2 years ref. Page check engine crankcase oil level x 44 check/clean engine air cooling system* x 53 clean grass buildup under deck x 54 clean ...

Page 47: Maintenance Instructions

Maintenance instructions subaru tips 43 important tips for care of the subaru engine fuel system • fuel must be clean - free from water, dirt, and or- ganic material. • clean the fuel filter on a regular basis and when contamination is suspected or found in the fuel. Starting • start engine with the...

Page 48: Maintenance Instructions

Maintenance instructions lubrication 44 lubrication warning do not attempt to lubricate the machine with the engine running. Disengage the pto clutch, shut off the machine, and re- move the ignition key. Proper lubrication is an important maintenance pro- cedure. It reduces wear and makes the machin...

Page 49: Maintenance Instructions

Maintenance instructions lubrication 45 changing engine crankcase oil change the engine crankcase oil after every 50 hours of operation as follows: 1. Park the mower on a level surface with the en gine stopped. The engine oil should be warm before draining. If not warm from opera- tion, start the en...

Page 50: Maintenance Instructions

Maintenance instructions lubrication 46 ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 blade drive gearbox oil* 2 3 tee gearbox, deck oil* 1 4 deck caster wheel bearing grease 2 5 universal joint shaft assembly ...

Page 51: Maintenance Instructions

Maintenance instructions lubrication 47 chassis and deck lubrication points 10 8 30 13 31 26 & 32 27 & 33 15 30 9 26 27 28 29 25 25 20 9 14 15 11 12 18 16 8 10 11 12 13 2121 2323 2222 21 22 24 18 19 17 19 2 3 1 4 6 7 6 6 7 6 4 2 1 5.

Page 52: Maintenance Instructions

Maintenance instructions lubrication 48 mower deck gearbox lubrication the mower deck gearboxes (tee gearbox and blade drive gearboxes) are connected as a unitized as- sembly, and oil flows freely between them. The gear- boxes are permanently lubricated (oil filled) and sealed requiring no scheduled...

Page 53: Maintenance Instructions

Maintenance instructions lubrication 49 gear axle lubrication • the gear axle oil lubrication is sae e.P. 80w-90 (api gl-5) gear lube. • check the axle oil level after every 100 hours of operation by removing the oil level plug. If additional oil is needed, remove the breather vent on top of ax le a...

Page 54: Maintenance Instructions

Maintenance instructions cleaning 50 cleaning caution if a pressure washer is used on the ex- posed working parts, avoid water on the electrical parts and the engine cooling sys- tem. Engine air cleaner system donaldson radialseal™ air cleaner a remote mounted donaldson radialseal™ air cleaner provi...

Page 55: Maintenance Instructions

Maintenance instructions cleaning 51 air indicator restriction gauge push button to reset indicator after service air filter restriction gauge location inspect the paper element after every 100 hours of service and replace the element and safety filter yearly (or when dirty or damaged). More frequen...

Page 56: Maintenance Instructions

Maintenance instructions cleaning 52 radial sealing surface primary filter element safety filter canister air filter element replacement 10. Install the cover with the word “top” properly oriented to the top of the canister. Give the cover a slight twist as it reaches the canister to make sure the t...

Page 57: Maintenance Instructions

Maintenance instructions cleaning 53 engine cooling system cooling air intake system to prevent engine overheating and possible engine damage, clean grass clippings, chaff, and dirt from the rotating engine cooling air intake screen after every 8 hours of operation. In certain mowing con- ditions (d...

Page 58: Maintenance Instructions

Maintenance instructions cleaning 54 grass buildup in mower deck housing danger before raising or removing the mower deck for cleaning, stop the engine, re move the ignition key, and disconnect the spark plug wire. 1. Raise the deck lock lever handle on each side of the carrier frame and pull out to...

Page 59: Maintenance Instructions

Maintenance instructions cleaning 55 ghs blower normally, the ghs blower operates with no mainte- nance or cleaning. However, when mowing grass that is dirty and damp (especially springtime mow- ing), a deposit of dirt may accumulate inside the blower housing, causing wear and binding of the blower ...

Page 60: Maintenance Instructions

56 maintenance instructions cleaning/ checking/servicing hydrostatic transmission cooling fins keeping the cooling fins on the hydrostatic transmis- sions clean and free of obstruction is essential to avoid overheating the transmission fluid and short- ening transmission life. The cooling fins shoul...

Page 61: Maintenance Instructions

57 maintenance instructions checking/servicing 3. Replace filler caps. Important: do not overfill the battery. Electro- lyte will overflow through the vent tube onto parts of the machine and will result in severe corrosion. Cleaning the terminals if battery terminals are corroded, remove battery fro...

Page 62: Maintenance Instructions

58 maintenance instructions checking/servicing warning do not try to straighten a blade that is bent. Never weld a broken or cracked blade. Always replace with a new blade to assure safety. 4. If the blade cutting edge is dull or nicked, it should be sharpened. Remove blades for sharpening by graspi...

Page 63: Maintenance Instructions

59 maintenance instructions checking/servicing drive belts raise the body and inspect the condition of the three (3) drive belts after every 25 hours of operation -- engine, pto drive, and ground drive. If the belts show signs of cracking or deteriorating, the belts should be replaced. Refer to repl...

Page 64: Maintenance Instructions

60 maintenance instructions checking/servicing safety switch system warning it is important to check and maintain the safety switch system for safe operation of the machine. There are three (3) safety interlock switches on the tractor; seat switch, fsc neutral - park switch, and pto switch. If any o...

Page 65: Maintenance Instructions

61 maintenance instructions replacing/repairing replacing/repairing danger to prevent accidental starting of the en- gine when replacing parts or repairing the machine, remove the key from the ignition switch and disconnect the spark plug wire. Important: always use genuine factory re- placement par...

Page 66: Maintenance Instructions

62 maintenance instructions replacing/repairing engine belt 1. To remove the engine belt: a. Relax the belt by depressing the spring- loaded idler arm. B. Roll the belt off the compound pulley and remove the belt. Engine belt (disengaged) 2. Reverse the removal procedure to replace the engine belt. ...

Page 67: Maintenance Instructions

63 maintenance instructions replacing/repairing pto drive belt 1. To remove the pto drive belt: a. Remove the engine belt, as described in previous section. B. Remove 1/4-20 x 3/4 bolt locating belt guide on gearbox pulley and rotate guide to clear belt. C. Move blade clutch (in direction of engage-...

Page 68: Maintenance Instructions

64 maintenance instructions replacing/repairing ground drive belt 1. To remove the ground drive belt: a. Raise the spring-loaded idler to relax belt. B. Slide belt off pulleys, then release the idler. Ground drive belt assembly (disengaged) 2. Reverse the procedure to install the ground drive belt. ...

Page 69: Maintenance Instructions

65 maintenance instructions replacing/repairing blade overload shear bolts the cutting blade is keyed to the blade hub by two (2) shear bolts (10-24 x 5/8 in. Stainless steel ma- chine screws). These bolts are designed to shear and protect the blade drive gearbox from damage if the blade encounters ...

Page 70: Maintenance Instructions

66 maintenance instructions replacing/repairing mower blades mower blades are removed and remounted as de- scribed in sharpen mower blades instructions (re- fer to checking/servicing in this section). Dur- ing the course of sharpening and inspecting mower blades, if there are any of the following co...

Page 71: Maintenance Instructions

67 maintenance instructions adjustments adjustments steering levers an adjustment range of approximately 3 in. (76.2 mm) is available on the steering levers - the levers can be adjusted forward or aft depending on the arm length of the operator. The levers can be adjusted by loos- ening the locknut ...

Page 72: Maintenance Instructions

68 maintenance instructions adjustments 1. Position the discharge chute so that it is pointing straight back. A. Turn the ignition switch on and move the blade clutch to the engaged position (engine not running). B. Open the catcher back door and monitor the spout position (as it oscillates) and mov...

Page 73: Operator’S Notes

69 operator’s notes.

Page 74: Operator’S Notes

70 operator’s notes.

Page 75

71 limited warranty for walker commercial rider mower 1. What this warranty covers, and for how long: walker manufacturing company will, at its option, repair or replace, without charge, any part covered by this warranty which is found to be defective in material and/or workmanship within one (1) ye...

Page 76

Walker mfg. Co. • 5925 e. Harmony road, fort collins, co 80528 • (970) 221-5614 form no. 050712 printed in usa www.Walkermowers.Com © 2014 walker mfg. Co.