- DL manuals

- WarmFlow

- Boiler

- Kabin Pak Combi KC70HE

- User manual

WarmFlow Kabin Pak Combi KC70HE User manual

Boiler Manual

Incorporating:

Guarantee Registration

User Instructions

Installation Instructions

Service Instructions

Service Record

High Efficiency

Condensing Boilers

For use with kerosene only

Models covered by this manual:

U-Series

Utility

U70HE

U90HE

U120HE

U150HE

Utility Pumped

UP70HE

UP90HE

UP120HE

UP150HE

Utility System

US70HE

US90HE

US120HE

Utility Combi

UC70HE

UC90HE

K-Series

Kabin Pak

K70HE

K90HE

K120HE

K150HE

Kabin Pak Pumped

KP70HE

KP90HE

KP120HE

KP150HE

Kabin Pak System

KS70HE

KS90HE

KS120HE

Kabin Pak Combi

KC70HE

KC90HE

Leave this manuaL with the end user

Summary of Kabin Pak Combi KC70HE

Page 1

Boiler manual incorporating: guarantee registration user instructions installation instructions service instructions service record high efficiency condensing boilers for use with kerosene only models covered by this manual: u-series utility u70he u90he u120he u150he utility pumped up70he up90he up1...

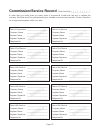

Page 2: Commissioning

This manual is accurate at the date of printing (e&oe) but will be superseded and should be disregarded if specifications and/or appearances are changed in the interests of continued product improvement. Code 3307 issue 3 aug 08 lisburn lissue industrial estate, moira road, lisburn, co antrim, n ire...

Page 3

Page contents page userinstructions .....................................................................................................................................................................2 condensingboilerinstallationrequirements ...........................................................

Page 4: Userinstructions

Page 2 userinstructions dualthermostat the radiator temperature is regulated via the boiler control thermostat. The thermostat is user adjustable from 55°c at its minimum setting (dial ‘0’) to 85°c at its maximum setting (dial ‘5’). In order to provide an additional level of safety there is a high l...

Page 5

Page 3 fillingloop if the system pressure falls below the minimum (eg, removal of radiator for decorating purposes) then the system should be topped up using the filling loop valve. After the system has been topped up the pressure gauge should read bar when the system is cold. The valve must be full...

Page 6: Condensingboilerinstallation

Page 4 condensingboilerinstallation requirements the warmflow condensing boiler can be fitted to most installations using standard practices and techniques. There are however a number of considerations that must be taken into account. . All existing systems must be properly flushed to remove any sed...

Page 7: Beforefittingacombiboiler

Page 5 beforefittingacombiboiler theinstallermustcheck: . What the maximum hot water demand placed on the boiler is likely to be. Not every installation is suitable for a combi boiler. Systems requiring very high hot water flow rates may be better suited with an unvented cylinder. 2. That the mains ...

Page 8

Page 6 1.0 generalinformation 1.1 introduction note: all our domestic appliances have been independently tested and accreditedasexceedingtheminimumsedbukefficiencylevelsrequiredfor theirtype,incompliancewiththebuildingregulationsapproveddocument l1a, l1b for england and wales, the building standards...

Page 9

Page 7 1.3 combigeneralrequirements the boiler will have a dhw priority when both domestic hot water (dhw) and central heating (ch) are selected. So if the flow switch is closed or the heat store has not been satisfied the entire output of the boiler is directed to dhw before the boiler will switch ...

Page 10

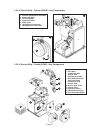

Page 8 1.4 baffle positioning the primary heat exchanger baffles consist of one heavy baffle stack (4mm thick) at the bottom, 3 lighter baffle stacks (3mm thick) in the middle and baffle plate (3mm thick) at the top. Upon installation or after servicing, ensur e the baffles ar e in the corr ect or d...

Page 11

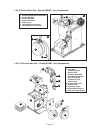

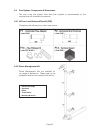

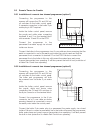

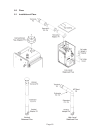

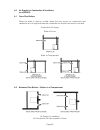

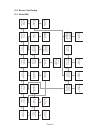

Page 9 1.5 components 1.5.1 u-series utility – casing components 1. Boiler assembly 2. Top casing (r emovable) 3. Rear casing 4. Side casing 5. Fr ont casing (r emovable) 1 2 3 4 5 models up to 120 he 150 he models 1. Boiler assembly 2. Top fr ont casing (r emovable) 3. Top rear casing (r emovable) ...

Page 12

Page 0 1.5.2 u-series utility – pr e-wir ed (uhe) – key components 1. Heat exchanger 2. Condensing unit 3. Auto air v ent 4. Service door 5. ‘dual-safe’ thermostat 6. Heat exchanger baffles 7. Service door 8. Service door cover 9. Condensate t rap 10. Riello rdb 2.2 bur ner 11. Heating flow connecti...

Page 13

Page 1.5.3 u-series utility – pumped (uphe) – key components 1. Heat exchanger 2. Condensing unit 3. Pipework assembly 4. Pr essur e relief v alve 5. Auto air v ent 6. Cir culating pump 7. Auto air v ent 8. Service door 9. ‘dual-safe’ thermostat 10. Heat exchanger baffles 11. Service door 12. Servic...

Page 14

Page 2 1.5.4 u-seriesutility–system(ushe)–keycomponents 1. Pumped(uphe)boilerassembly 2. Systemkit(sk1) 3. Pressuregauge 4. Expansionvessel 5. Fillingloop 6. Heatingflowconnection 7. Heatingreturnconnection 1 6 7 3 4 2 5 1.5.5 u-seriesutility–combi(uche)–keycomponents 1. Heatexchanger 2. Heatstore 3...

Page 15

Page 3 1.5.6 k-series kabin pak – casing components 1. Boiler assembly 2. Top casing (r emovable) 3. Flue assembly (r emovable) 4. Rear flue casing 5. Blanking plug (r emovable) 6. Rear casing (r emovable) 7. Side casing 8. Fr ont casing (r emovable) 1 2 3 4 5 6 7 8 models up to 120 he 150 he models...

Page 16

Page 4 1.5.7 k-series kabin pak – pr e-wir ed (khe) – key components 1. Heat exchanger 2. Condensing unit 3. Auto air v ent 4. Service door 5. ‘dual-safe’ thermostat 6. Heat exchanger baffles 7. Service door 8. Service door cover 9. Condensate t rap 10. Riello rdb 2.2 bur ner 11. Heating flow connec...

Page 17

Page 5 1.5.8 k-series kabin pak – pumped (kphe) – key components 1. Heat exchanger 2. Condensing unit 3. Pipework assembly 4. Pr essur e relief v alve 5. Auto air v ent 6. Cir culating pump 7. Auto air v ent 8. Service door 9. ‘dual-safe’ thermostat 10. Heat exchanger baffles 11. Service door 12. Se...

Page 18

Page 6 1.5.9 k-serieskabinpak–system(kshe)–keycomponents 1. Pumped(kphe)boilerassembly 2. Systemkit(sk1) 3. Pressuregauge 4. Expansionvessel 5. Fillingloop 6. Heatingflowconnection 7. Heatingreturnconnection 1.5.10 k-serieskabinpak–combi(kche)–keycomponents 1. Heatexchanger 2. Heatstore 3. Condensin...

Page 19

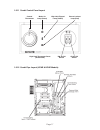

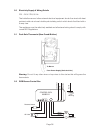

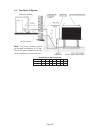

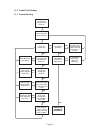

Page 7 1.5.11 combicontrolpanellayout control thermostat mainson lamp(green) highlimittripped lamp(yellow) burnerlockout lamp(red) hwon/off switch chon/off switch highlimitthermostatreset (underneath) 1.5.12 combipipelayout(uche&kchemodels).

Page 20

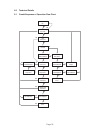

Page 8 2.0 technicaldetails 2.1 combisequenceofoperationflowchart power on timer calling for heat hw selected flow switch closed dhw tank stat satisfied ch selected ch pump only runs room stat satisfied boiler stat satisfied boiler limit stat tripped burner fires dhw pump only runs hw limit stat sat...

Page 21

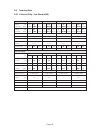

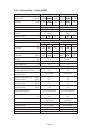

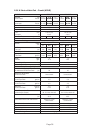

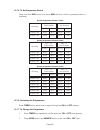

Page 9 2.2 dimensions 2.2.1 u-seriesutility(uhe,uphe&ushemodelsupto120he) u120he dims a b c d e f g h j k l m n p r s t u v w x y z 600 413 865 766 134 666 86 75 50 687 21 104 226 47 41 390 104 54 51 71 91 718 812 2.2.2 u-seriesutility(150hemodels) u150he dims a b c d e f g h j k l m n p r s t u v w...

Page 22

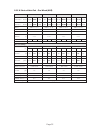

Page 20 2.2.3 u-seriesutility(uchemodels) uche dims a b c d e f g h j k l m n p r s t u v w x y 600 595 865 766 134 388 207 666 47 226 42 94 718 91 71 51 54 104 390 71 104 197 model a b c d e f g h j k l m n p r s t u v w x y uc~ 600 595 865 766 134 388 207 666 47 226 42 94 718 91 71 51 54 104 390 7...

Page 23

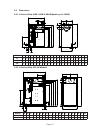

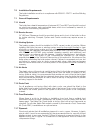

Page 2 2.2.4 k-serieskabinpak(khe,kphe&kshemodelsupto120he) k120he dims a b c d e f g h j k l m n p r s t u v 700 413 900 40 67 40 210 705 50 50 161 93 773 67 90 117 52 415 65 2.2.5 k-serieskabinpakbasetray(khe,kphe&kshemodelsupto120he) front k120he basetray dims model a b c d e f g h j k l m n p r ...

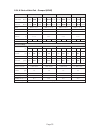

Page 24

Page 22 2.2.6 k-serieskabinpak(150hemodels) k150he dims a b c d e f g h j k l m n p r s t u v 595 997 876 1155 93 161 75 70 120 55 85 155 850 100 100 320 122 630 120 2.2.7 k-serieskabinpakbasetray(150hemodels) front k150he basetray dims model a b c d e f g h j k l m n p r s t u v k150he 595 997 876 ...

Page 25

Page 23 2.2.8 k-serieskabinpak(kchemodels) 2.2.9 k-serieskabinpakbasetray(kchemodels) kche dims a b c d e f g h j k l m n p r s t u v w x 700 600 900 770 210 396 209 92 161 52 50 50 705 117 67 40 90 40 67 415 65 front kche basetray dims model a b c d e f g h j k l m n p r s t u v w x kc~ 700 600 900...

Page 26

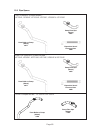

Page 24 2.3 flueoptions,components&dimensions the use of any flue system other than that supplied or recommended by the manufacturer will invalidate the warranty. 2.3.1 helowlevelbalancedfluekit(fbf) comprising the following four main components. 1. Diverterassembly 2. Extension 3. Elbow 4. Terminal...

Page 27

Page 25 2.3.3 warmflowheboilerfluecomponents:80/125Ø note: 1. Fluefittingkitrequired. 2. Ifterminalislessthan2metresabovegroundlevelterminalguardmustbefitted. 3. Extensionpipesandflueadaptorlengthsquotedareeffectivelengthsandnottheactuallength ofthepiece. 4. Alldimensionsinmmunlessotherwisestated..

Page 28

Page 26 2.3.4 vertical&highlevelterminaloptions note: 1. Allfluescanutiliseanycombinationofbends,straights,adaptorsandterminals. 2. Ensureflueisarrangedsuchthatitfallscontinuouslytowardstheboiler. 3. Thelowlevel,highlevelandverticalbalancedfluesystemscanuseanycombinationof flueextensionpiecesuptothe...

Page 29

Page 27 2.4 condensatedisposal the warmflow high efficiency condensing boiler is supplied with a factory fitted, self sealing condensate trap. The trap has been fitted inside the boiler casing to the right hand side. The condensate drainage pipe within the boiler is a flexible plastic hose which can...

Page 30

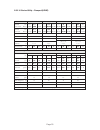

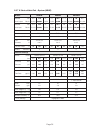

Page 28 2.5 technicaldata 2.5.1 u-seriesutility–pre-wired(uhe) u90he u70he model nominal kw heat output btu/hr nominal kw heat input btu/hr burner head secondary air damper flue mm diameter in flue gas temp °c smoke bacarach 4.7 50,000 17.6 60,000 2 7,650 2 7,650 23.5 80,000 27. 92,380 5.3 52,50 18....

Page 31

Page 29 2.5.2 u-seriesutility–pumped(uphe) up90he up70he model nominal kw heat output btu/hr nominal kw heat input btu/hr burner head secondary air damper flue mm diameter in flue gas temp °c smoke bacarach 4.7 50,000 17.6 60,000 2 7,650 2 7,650 23.5 80,000 27. 92,380 5.3 52,50 18.4 62,600 22 75,000...

Page 32

Page 30 2.5.3 u-seriesutility–system(ushe) us90he us70he model nominal kw heat output btu/hr nominal kw heat input btu/hr burner head secondary air damper flue mm diameter in flue gas temp °c smoke bacarach 4.7 50,000 17.6 60,000 2 7,650 2 7,650 23.5 80,000 27. 92,380 5.3 52,50 18.4 62,600 22 75,000...

Page 33

Page 3 2.5.4 u-seriesutility–combi(uche) uc90he uc70he model nominal kw heat output btu/hr nominal kw heat input btu/hr burner head secondary air damper flue mm diameter in flue gas temp °c smoke bacarach 4.7 50,000 17.6 60,000 2 7,650 2 7,650 23.5 80,000 27. 92,380 5.3 52,50 18.4 62,600 22 75,000 2...

Page 34

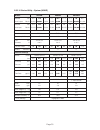

Page 32 2.5.5 k-serieskabinpak–pre-wired(khe) k120he k90he k70he model nominal kw heat output btu/hr nominal kw heat input btu/hr burner head secondary air damper flue mm diameter in flue gas temp °c smoke bacarach 4.7 50,000 17.6 60,000 2 7,650 2 7,650 23.5 80,000 27. 92,380 27. 92,380 30 102,400 3...

Page 35

Page 33 2.5.6 k-serieskabinpak–pumped(kphe) kp90he kp70he model nominal kw heat output btu/hr nominal kw heat input btu/hr burner head secondary air damper flue mm diameter in flue gas temp °c smoke bacarach 4.7 50,000 17.6 60,000 2 7,650 2 7,650 23.5 80,000 27. 92,380 5.3 52,50 18.4 62,600 22 75,00...

Page 36

Page 34 2.5.7 k-serieskabinpak–system(kshe) ks90he ks70he model nominal kw heat output btu/hr nominal kw heat input btu/hr burner head secondary air damper flue mm diameter in flue gas temp °c smoke bacarach 4.7 50,000 17.6 60,000 2 7,650 2 7,650 23.5 80,000 27. 92,380 5.3 52,50 18.4 62,600 22 75,00...

Page 37

Page 35 2.5.8 k-serieskabinpak–combi(kche) kc90he kc70he model nominal kw heat output btu/hr nominal kw heat input btu/hr burner head secondary air damper flue mm diameter in flue gas temp °c smoke bacarach 4.7 50,000 17.6 60,000 2 7,650 2 7,650 23.5 80,000 27. 92,380 5.3 52,50 18.4 62,600 22 75,000...

Page 38

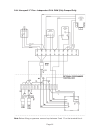

Page 36 3.0 electricitysupply&wiringdetails 220 – 240v. Ph, 50 hz the boiler/burner and other external electrical equipment should be wired with heat resistant cable via a fused double pole isolating switch which should be fitted with a 5 amp fuse. The appliance must be effectively earthed and all e...

Page 39

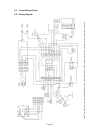

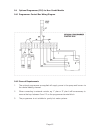

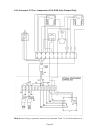

Page 37 3.3 combiwiringdetails 3.3.1 wiringdiagram the 3 pin mains plug must be supplied with a permanent live to allow the pump overrun stat and r elay to operate corr ectly ..

Page 40

Page 38 3.3.2 wiringschematic b u r n e r d .H .W .P u m p c .H .P u m p tr ip le po le re la y n .C . B o il e r s t a t n .O . N .C . N .O . N .O . N .C . C c c co il 7 20 21 24 25 22 14 n n n n n 10 8 1 26 29 n 26 28 30 3 19 23 17 18 16 5 l1 n e l1 n m a in s p lu g h .W . C .H . T a n k s t a t ...

Page 41

Page 39 3.3.3 fittingaroomthermostattoacombi in order to provide frost protection for the fabric of the building a frost thermostat should be fitted in the coldest room in the house. To prevent over heating of the property a pipe thermostat should be fitted on the return pipe close to the boiler. Th...

Page 42

Page 40 3.4 installationofawarmflowcombioptionalprogrammer(pc1) . Disconnect the electrical supply. 2. Drop down control box front (2 screws). 3. Disconnect the 6 pin plug from the ch/hw on/off switched. 4. With a sharp knife cut out the outline of the panel knockout through the facia label from the...

Page 43

Page 4 3.5 remotetimersforcombis 3.5.1 installationofaremotetwochannelprogrammer(option1) connecting the programmer in this manner will bypass the ch and hw on/ off switches on the boiler control panel. A separate connection to the boiler 3 pin mains plug is not required. Inside the boiler control p...

Page 44

Page 42 3.6 optionalprogrammer(pu1)fornon-combimodels 3.6.1 programmercontrolboxwiringdiagram 3.6.2 generalrequirements . The optional programmer as supplied will supply power to the pump and burner via the central heating channel. 2. When connecting to external controls, eg ‘y’ plan or ‘s’ plan it ...

Page 45

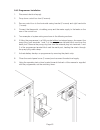

Page 43 3.6.3 programmerinstallation . Disconnect electrical supply. 2. Drop down control box front (2 screws). 3. Secure control box to the horizontal casing bracket (2 screws) and right hand side ( screw). 4. Connect the thermostat, circulating pump and the mains supply to the leads on the rear of...

Page 46

Page 44 3.6.4 honeywell‘y’plan–independentch&dhw(fullypumpedonly) note: before fitting programmer remove loop between 3 and 2 on the terminal block..

Page 47

Page 45 3.6.5 honeywell‘s’plan–independentch&dhw(fullypumpedonly) note: before fitting programmer remove loop between 3 and 2 on the terminal block..

Page 48

Page 46 4.0 oilsupply . Oil tank steel tanks constructed to bs799 : part 5 should be painted on the outside only and mounted on piers to prevent corrosion. Plastic oil tanks are also available and can be suitable for installation at ground level. However, oil should never be stored in translucent pl...

Page 49

Page 47 headh(m) id8mm id10mm 0.5 1 2 3 35 25 5 8 00 00 70 30 0.5 30 00 3.5 6 20 1.5 20 90 totalmaximumpipelength(m) 4.2 twopipesystem formaximumpipelengthandliftcontactde-aeratormanufacturer. 4.3 de-aeratorsystem.

Page 50

Page 48 headh(m) id8mm id10mm 0.5 1 2 3 35 25 5 8 00 00 70 30 0.5 30 00 3.5 6 20 1.5 20 90 totalmaximumpipelength(m) 4.4 onepipeliftsystem note: the pump vacuum should not exceed a maximum of 0.4 bar. Above this gas is released from the oil thus leading to burner lock out..

Page 51

Page 49 5.0 flues 5.1 installationofflues.

Page 52

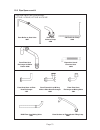

Page 50 5.1.1 installationofabalancedflue(fbf) . Make a suitable sized hole in the wall or ceiling for the flue. For the dimensions of the boiler, see the dimensions section of this manual. For the dimensions of the flue system, see the flue kits & dimensions section of this manual. Note: the caviti...

Page 53

Page 5 5.2 conventionalflues the flue system should be designed in accordance with local bye-laws and the building regulations. Draught stabilisers are not recommended for oil fired boilers. Sharp bends or horizontal runs should be avoided and the flue should terminate 2 feet (600mm) above the ridge...

Page 54

Page 52 theseareminimumdimensionsandareonlyquotedasaguidelines. Terminatingpositionsmustbeatleast1.8metresfromanoilstoragetankunless awallwithatleast30minfireresistanceandextending300mmhigherand widerthanthetankisprovidedbetweenthetankandtheterminatingposition. From an internal or external corner or...

Page 55

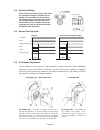

Page 53 6.0 airsupplyforcombustion&ventilation (seebs5410) 6.1 openflueboilers when the boiler is sited in a cellar where the only access for combustion and ventilation air is at high level then the combustion air should be ducted to low level. Combustion air supply boiler in room boiler in compartm...

Page 56

Page 54 7.0 installationrequirements the boiler installation must be in compliance with bs540 : part and the building regulations. 7.1 generalrequirements 7.1.1 hearth the boiler has a hearth temperature of between 50°c and 85°c and should be stood on a rigid, non-porous, non-combustible base, which...

Page 57

Page 55 7.2 sealedsystems 7.2.1 expansionvessel refer to bs7074: part and bs5449 for details of expansion vessel sizing. The values given in the table below are for total system volumes which include the primary water capacity of the boiler which can be found in the technical data section of this ma...

Page 58

Page 56 7.3 combidomestichotwater 7.3.1 mainswaterpressure to protect the appliance and to prevent excessive flow rates, a pressure reducing valve must be fitted to limit the maximum supply pressure to 3 bar. We strongly advise that all installation pipework is run in copper. However, if plastic pip...

Page 59

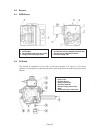

Page 57 8.0 burners 8.1 rdbburner 8.2 oilpump the burner is supplied for use with a one pipe system. For use on a two pipe system, it is necessary to remove the return port plug and fit a small by-pass plug as shown. 1. Pump 2. Controlbox 3. Resetbuttonwithlock-outlamp 4. Flangewithinsulatinggasket ...

Page 60

Page 58 8.3 electrodesetting 8.4 burnerstart-upcycle 8.5 airdamperadjustment the air damper is set in factory. This regulation is purely indicative. Each installation however, has its own working conditions: actual nozzle output; positive or negative pressure in the combustion chamber, the need of e...

Page 61

Page 59 9.0 commissioning&servicing 9.1 commissioning note:it is the responsibility of the installer to ensure that the boiler is properly commissionedbyanoftectrainedandregisteredtechnician.Failuretodo sowillinvalidateallwarranties. Before firing ensure that all the baffles are in place, as they ma...

Page 62

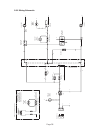

Page 60 10.0 burnerfaultfinding 10.1 riellordb ok yes yes yes no no no yes no no no no no no no no no yes yes yes bur ner motor runs lock out within 1 second lock out after 12 second pur ge ignition spark pr oved pump pr oduces pr essur e nozzle a to m is in g fu el combustion air set corr ect combu...

Page 63

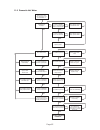

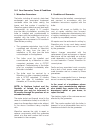

Page 6 11.0 combifaultfinding 11.1 centralheating yes yes yes no yes yes no yes no no no switch on power, set selectors for ch on and dhw off. Set all controls to call for heat. Does the burner fire? Is lockout lamp on burner or panel lit? Is high limit thermostat lamp lit? Is there continuity acros...

Page 64

Page 62 11.2 domestichotwater switch on power, set selectors to ch off and dhw on. Is dhw pump working? Is there continuity across connection 20 and 21 on the pcb? Check wiring, replace tank thermostat. Is there continuity across 25 and 27? Check wiring, replace relay, replace pcb. Check wiring, rep...

Page 65

Page 63 12.0 optionalboilermounteddigitaltimer 12.1 operatinginstructions 12.1.1 afterinstallation when you first install the cr2032 battery (by removing the clear plastic strip from the rear of the timer) you must press the ‘reset’ button, the lcd display will display fully for 3 seconds. Then lcd ...

Page 66

Page 64 12.1.2 builtinprogramme for convenience, the timer module has a built in programme, however, it can be easily adjusted (see section 2.5 to change the programmes). The timer offers 3 options for both ch and hw programme period. Off: off all the time. Auto: to run your time schedule for period...

Page 67

Page 65 setdayprogrammeperiod1on/off 22:30 07:30 22:30 06:30 hw/ch2 ch/ch1 22:30 06:30 22:30 07:30 hw/ch2 ch/ch1 mon–fri timeschedule mon–fri timeschedule period on period off switching setdayprogrammeperiod3on/off 22:30 22:30 6:30 4:00 2:00 0:30 07:30 22:30 22:30 6:30 4:00 2:00 08:30 06:30 hw/ch2 c...

Page 68

Page 66 12.1.8 manualselect . Press select to toggle through on/auto/off modes as indicated by the timer status. 2. On mode turns on the timer. 3. Off mode turns off the timer. 4. Auto mode runs the set programme. 12.1.9 manualselect this function is only applicable when your timer is set on auto mo...

Page 69

Page 67 13.0 spares 13.1 rdb2.2spares no code 3514157 3514257 3514557 description 3005787 • • • gasket 2 3006384 • • • flange 3 3020494 • cup-shaped head 3 3020258 • cup-shaped head 3 3020055 • cup-shaped head 4 3008860 • • • electrode assembly 5 3008875 • • • screw 6 300886 • • • nozzle holder 7 30...

Page 70

Page 68 13.2 rdb3.2spares no code 3748941 description 3005795 • gasket 2 3008637 • flange 3 300574 • end ring 4 300573 • diffuser disc 5 300774 • blast tube assembly 6 3006552 • electrode bracket 7 300753 • electrode assembly 8 3008794 • high voltage lead 9 3008957 • collar 0 3008876 • pressure gaug...

Page 71

Page 69 13.3 pipespares utility pumped & system models - up70he, up90he, up20he, us70he, us90he & us20he kabin pak pumped & system models - kp70he, kp90he, kp20he, ks70he, ks90he & ks20he 50he pumped models - up50he & kp50he pumpflowpipe (22mm) 3015 pumpflowpipe (22mm) 3015 expansionvessel pressureh...

Page 72

Page 70 13.3 pipesparescont’d utility and kabin pak combi models - uc70he, uc90he, kc70he & kc90he fromboilertogatevalve 3097 chflowfrompump 3100 fromgate valvetopump 3098 fromplateheat exchangertoboiler return3096 fromheatstoretoplate heatexchanger 1997 fromflowswitchtomixing valve&plateheatexchang...

Page 73

Page 7 13.4 shortpartslist–boiler partdescription code flow switch 476 tank & boiler control thermostat 23 boiler limit thermostat (combi models) 28 tank limit thermostat 226 pump overrun thermostat 308 plate heat exchanger 599 twin head pump 230 5/60 pump (for replacement head) 602 3 pole relay 827...

Page 74

Page 72 14.0 yourguarantee,terms&conditions 1. Warmflowguarantees the boiler, including all controls, plate heat exchangers and associated equipment contained within the boiler casing, the burner and flue system if supplied by warmflow against defective parts and faulty workmanship, for period of 2 ...

Page 76

Page 74 notes.

Page 77

Page 75 notes.

Page 78

Page 76 notes.

Page 80: Armflow Engineering Ltd

Tear along perfora tion business repl y ser vice licence no bel 1609 customers from roi please affix st amp w armflow engineering ltd appliance registration dept lissue industrial estate moira road lisbur n co antrim bt28 2rf 2.