- DL manuals

- Wasp

- Printer

- WPL606

- User Manual

Wasp WPL606 User Manual

WPL606 Thermal Label Printer

User’s Guide

For Wasp Technologies

DT/TT Printer

Copyright Wasp Bar Code Technologies 2004.

All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any

means without the written permission of Wasp Bar Code Technologies. The

information contained in this document is subject to change without notice.

Wasp is a trademark of Wasp Bar Code Technologies. All other trademarks are the

property of their respective owners.

Document Revised August 13th, 2001

Summary of WPL606

Page 1

Wpl606 thermal label printer user’s guide for wasp technologies dt/tt printer copyright wasp bar code technologies 2004. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means without the written permission of wasp bar code technologies. The i...

Page 2: Contents

Contents 1. Product introduction ..............................................................1 1.1 specification .................................................................................................. 1 1.1.1 printer .........................................................................

Page 3

Appendix 1: lcd control panel operation map.......................19 3.

Page 5: 1. Product Introduction

1. Product introduction thank you for purchasing the w606 bar code printer. This guide will describe all of the common operations needed to operate and maintain your w606. 1.1 specification 1.1.1 printer item specification printing mode thermal transfer and direct thermal resolution 203dpi max. Prin...

Page 6

1.1.4 bar code code 39, code 93, code128 subsets a b and c, code 11, codabar, interleaved 2 of 5, ean-8, ean-13, ean-128, upc-a, upc-e, ean, upc, ean 2 or 5 digit add-on, upc 2 or 5 digit add-on, cpost, msi plessy, postnet, ean-14, itf-14, pdf-417, maxicode, datamatrix, qr code 1.2 optional items cu...

Page 7: 2. Getting Started

2. Getting started 2.1 unpacking and inspection after receiving the bar code printer, carefully inspect the device and its packaging. The printer is specially packaged to withstand damage in shipping. In case of evident damage, contact the carrier directly to specify the nature and extent of damage....

Page 8

External label feed opening centronics port figure 2: printer rear view rs-232c port power switch power supply connector print head lift lever ribbon rewind spindle ribbon supply spindle label spindle media guide bar label guide ribbon tension adjustment knob usb port print head pressure adjustment ...

Page 9

2.4 buttons, indicators and adjustment knobs power indicator when the printer is in the power-on state, the power indicator is lit. On-line indicator this green on-line indicatoris lit when the printer is ready. The on-line indicator blinks when in pause mode. Error indicator the red error indicator...

Page 10

Lcd display shows “carriage open” and the red error light will come on. After closing the print head lift lever, the on-line light will blink. Press the feed button to re-register the label. Ribbon tension adjustment knob the ribbon tension adjustment knob offers 6 levels of tension to adjust for di...

Page 11: 3. Set Up

3. Set up 3.1 setting up the printer 1. Place the printer on a flat, secure surface 2. Make sure the power switch is off 3. Connect the printer to the computer with the provided rs-232c, centronics/parallel, or usb cable 4. Plug the power cord into the power supply connector at the rear of the print...

Page 12

Figure 6: ribbon under pint had 6. Pull the paper core up to the rewind spindle and slide it on. Slide both the ribbon and rewind spindle all the way to be flush with the case side of the spindle. The wasp logo will face up again figure 7: ribbon placed onto rewind spindle 7. Roll the rewind spindle...

Page 13

3.3 label roll installation 1. Open the printer panels and the print head lift lever 2. Rotate the label guide clockwise away from the media guide bar 3. Insert a new label roll into the label spindle 4. Pull labels leading edge forward under the black media guide bar, through the gap/black mark sen...

Page 14

3.4 peel-off sensor installation (sold separately) 1. Turn the printer off 2. Open the lower front panel 3. Snap the peel-off sensor onto the bar that is under the print head pressure adjustment knobs horizontally bar peel-off sensor figure 12: peel sensor attached to bar socket for peel-off sensor ...

Page 15

3.5 loading label for peel-off mode 1. Open the front and top printer doors 2. Open the print head left lever 3. Pull several inches of labels out through the front of the printer and remove the label(s) from the backing 4. Feed the label backing between the platen roller and the silver peeler rolle...

Page 16

3.6 self-test to initiate the self-test mode, press the menu button to advance the selection to printer test. Press the exe button to enter the submenu and press the menu button to advance the selection to printer config. Press exe button to print the printer’s internal settings. During self-test, a...

Page 17

Hex decimal data related to left column of ascii data ascii data figure 18: printout of dump mode 13.

Page 18: 4. Calibration

4. Calibration there are two power-on button combinations to initialize the printer settings and to calibrate sensors on the w606. 4.1 printer initialization printer initialization will restore printer settings to defaults. Do this if labels are printing incorrectly and all other solutions have fail...

Page 19

To initialize the printer: 1. Turn off the printer power 2. Hold down the pause and feed buttons and turn on the printer power 3. Release the buttons once the power, on-line, and error lights are lit note: the printing method, thermal transfer or direct thermal printing, will be set automatically at...

Page 20

4.3 troubleshooting guide the following guide lists the most common problems that may be encountered when operating this bar code printer. If the printer still does not function after all suggested solutions have been invoked, please contact the customer service. Condition reasons solutions no ribbo...

Page 21: 5. Printer Maintenance

5. Printer maintenance the printer should be cleaned regularly to maintain high quality printing. 5.1 cleaning the print head 1. Switch off and unplug the printer 2. Open the printer cover 3. Open the print head lift lever 4. Remove the ribbon. (if loaded) 5. Rub the wasp thermal printer cleaning pe...

Page 22: 6. Support and Warranty

6. Support and warranty 6.1 product support if you experience any problems with your wasp printer that you are unable to resolve, use our online support site to register and report the problem then call for technical assistance at (214) 547-4100, monday through friday, 8:00 am – 5:00 pm central stan...

Page 23

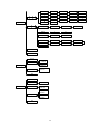

Appendix 1: lcd control panel operation map 1. Print setup 0~999 (*0) auto. Ribbon manual bline auto bline 2. Sensor calib. Speed auto. Gap cutter batch * tear mode peel on manual ribbon cutter on manual gap exit reference y reference x offset density direction lang. 3. System setup simplified chine...

Page 24

Country * 8 7 * none parity data bit odd even baud 2 * 1 stop bit(s) 57600 56000 38400 19200 *9600 4800 2400 restore defaults exit avail. Memory file list 4. File mngment dram: 512kb free pause: del. All feed: exit delete file(s) exit * 001 002 003 031 032 033 034 036 038 039 041 042 046 045 044 061...