- DL manuals

- Water Right

- Water Filtration Systems

- Clear Flo

- Installation, operation & service manual

Water Right Clear Flo Installation, operation & service manual

Summary of Clear Flo

Page 1

Reverse osmosis drinking water system installation, operation & service manual drink with confidence!.

Page 2

Table of contents page section i. Introduction ...................................................................................3 section ii. Specifications ................................................................................4 section iii. Preparation .....................................

Page 3

3 important notices: this reverse osmosis system contains replaceable treatment components critical for effective performance. It is the user's responsibility to, and the manufacturer strongly recommends that the user, periodically test the product water to verify the system is performing satisfacto...

Page 4

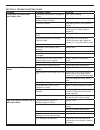

4 section ii. Specifications table a – recommended operating limits for feed water specifications t.F.C. Membrane water pressure 40–100 psig (280–690 kpa) tds 2000 ppm (also mg/l) max. Temperature 40–100°f (4–38°c) ph 4–11 (optimum rejection at ph 7.0 - 7.5) hardness less than 10 gpg (170 mg/l) or s...

Page 5

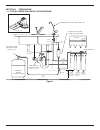

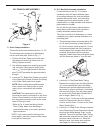

5 figure 1 dispensing faucet with air gap drain clamp drain (3/8" black) product (3/8" blue) drain (1/4" black) inlet (1/4" red) tank (3/8" yellow) drinking water holding tank holding tank shutoff valve (open position) feed water saddle valve (cold water line only) locate drain clamp above "p" trap ...

Page 6

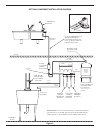

6 optional basement installation diagram dispensing faucet product (3/8” blue) note: for refrigerator water dispenser or ice maker hookup, tee into 3/8" blue tubing to dispensing faucet. Holding tank shutoff valve (open position) tank (3/8” yellow) drinking water holding tank mount holding tank on s...

Page 7

7 b. Tools recommended for installation the following tools will cover most of the installation sites encountered: 1. 3 / 8 " variable speed electric drill. 2. Extension work light with outlet. 3. Safety glasses. 4. Porcelain hole cutter kit. 5. Greenlee hole punch and 1 / 8 " and ½" metal drill bit...

Page 8

8 section iv. Installation steps all plumbing should be done in accordance with state and local plumbing codes. Note: some codes may require installation by a licensed plumber; check with the local plumbing authority prior to installation. In restricted under–sink areas, it may be easier to installt...

Page 9

9 3/8" drain clamp assembly drain clamp front plate drain pipe 1/4" nut 1/4" screw drain clamp back plate black drain tubing figure 4 c. Drain clamp installation choose the drain outlet location per sec. Iii, c.5. The following are instructions for discharging into the sink drain pipe. (refer to fig...

Page 10

10 4. Locate the ¼" yellow tubing with the tee attached to one end. Remove the yellow plug fromthefittinglabeled"out"onthemanifold and insert the tubing. E. Position the drinking water holding tank and make the final hose connections. 1. Check the tank precharge pressure. Make sure it is between 5 t...

Page 11

11 2. Installing the r.O. Membrane: •remove the r.O. Membrane housing, (the closest of the three to the in-out ports), and empty. •insert the membrane up into the manifold. (the o–rings should be up toward the manifold.) check the housing o–ring for proper position in its groove, engage and firmlyti...

Page 12

12 4. Tosanitizethesystemandreplacethefilters: note: the system should be sanitized beforeinstallingthesedimentprefilterand activatedcarbonprefilter. •use a good quality unscented 5¼% liquid chlorine household bleach. •add one capful of bleach (this is 2 tsp. Or 10ml)tothesedimentprefilterhousing an...

Page 13

13 notes:.

Page 14

14 notes:.

Page 15

15 notes:.

Page 16

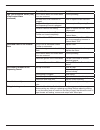

16 section vi. Trouble shooting guide problem possible cause solution low quantity of product water from holding tank feed water saddle valve is plugged or closed. Open valve or unclog. Cloggedsedimentprefilteror activatedcarbonprefilter. Replace filters. Low water pressure. Feed water pressure must...

Page 17

17 problem possible cause solution high total dissolved solids (tds) in the product water (continued) the product water and drain water lines are reversed. Correct plumbing. Nodrainflow,drainrestrictoris clogged. Clear or replace drain restrictor. Nodrainflow,thedrainorificein the dispensing faucet ...

Page 18

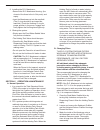

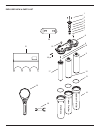

18 made in usa exploded view & parts list 19 1 2 3 4 5 6 7 8 9 10 11 12 13 14 18 16 17 out in 20 15 21 membr ane c arbon p ref ilt er sediment p ref ilt er.

Page 19

19 drawing no. Part no. Description 1 .................... Cs2009 ......................... Self tapping screw 2 .................... Cs2005 ......................... Aso cap 3 .................... Cs2013 .......................... Aso cap o–ring 4 .................... Cs2011 ..........................

Page 20

Form no. S1474wr-01 • 6/1/2015 r.O. Drinking water system five/one year limited warranty what does this warranty cover? This warranty covers any defects in materials and workmanship of the clearflo r.O. Drinking water system when installed and operated within recommended parameters, with the excepti...