- DL manuals

- Water Right

- Water Filtration Systems

- UltroWater

- Installation, Operation & Service Manual

Water Right UltroWater Installation, Operation & Service Manual

Summary of UltroWater

Page 1

Tested and certified by nsf international against nsf/ansi standard 58 for the reduction of the claims specified on the performance data sheet. R.O. Drinking water system model no. Ultrowater installation, operation & service manual.

Page 2

Table of contents page section i. Introduction ...................................................................................3 section ii. Specifications ................................................................................4 section iii. Preparation .....................................

Page 3

3 section i. Introduction your new reverse osmosis (r.O.) drinking water system uses a combination of filtration technologies to reduce unwanted contaminants in a water supply. The following steps combine to give you the best in clear sparkling drinking water: mechanical filtration/activated carbon–...

Page 4

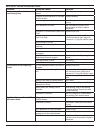

4 section ii. Specifications table a – qualified system performance because the performance of an r.O. Membrane is highly dependent upon pressure, temperature and tds, the following should be used for comparison purposes only. U.S. Metric membrane production 1 41-53 gpd 155–201 lpd membrane tds redu...

Page 5

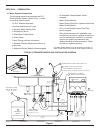

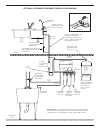

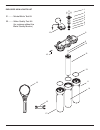

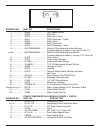

5 section iii. Preparation a. Major system components the following components comprise the r.O. Drinking water system. (refer to fig. 1, below for general system layout.) • an r.O. Manifold assembly. • housings and housing o–rings. • a drinking water holding tank. • a dispensing faucet. • a feed wa...

Page 6

6 optional ultrowater basement installation diagram dispensing faucet product (3/8” blue) note: for refrigerator water dispenser or ice maker hookup, tee into 3/8" blue tubing to dispensing faucet. Holding tank shutoff valve (open position) tank (3/8” yellow) drinking water holding tank mount holdin...

Page 7

7 b. Tools recommended for installation the following tools will cover most of the installation sites encountered: 1. 3 / 8 " variable speed electric drill. 2. Extension work light with outlet. 3. Safety glasses. 4. 1¼" porcelain hole cutter kit. 5. 1¼" greenlee hole punch and 1 / 8 " and ½" metal d...

Page 8

8 section iv. Installation steps all plumbing should be done in accordance with state and local plumbing codes. Note: some codes may require installation by a licensed plumber; check with the local plumbing authority prior to installation. In restricted under–sink areas, it may be easier to install ...

Page 9

9 4. Place the toggles of the monitor housing assembly through the mounting hole on the sink or counter top. Drop the handle of the wrench through the monitor housing opening. This will separate and orient the toggle wings. Position the monitor housing so that the display is facing forward. Tighten ...

Page 10

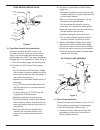

10 feed water saddle valve cold water line saddle valve handle insert plastic ferrule red tubing to manifold inlet compression nut tightening screw reversible back plate figure 3 b. Feed water saddle valve installation decide on location. Do not connect to a hot water feed line. If you are not sure ...

Page 11

11 2. Use a battery powered or properly grounded drill. Using the clamp port as a drill guide, drill a 7 / 32 " hole through the wall of the drain pipe. Do not penetrate the opposite side of the pipe. 3. Locate the 3 / 8 " black drain tubing connected to the dispensing faucet. Route to the tubing to...

Page 12

12 proper connections. The “out” port on the in–line filter should be towards the faucet. Firmly press in the tubing. The fittings will grab the tubing and hold and seal it in place. Make sure the tubing is pressed all the way in to create a pressure tight connection. E. Position the drinking water ...

Page 13

13 2. R.O. Systems produce drinking water at relatively slow rates; it can take up to 5 hours or more to fill the holding tank. Normal operation is to let the holding tank fill with water and then draw water as is needed. When the pressure in the holding tank falls to a given pressure (as the water ...

Page 14

14 c. Changing the in–line activated carbon post filter 1. Close the feed water saddle valve by turning fully clockwise. 2. Close the holding tank valve and then open the dispensing faucet to release the pressure. 3. Remove the in–line activated carbon post filter. Disconnect the used post filter by...

Page 15

15.

Page 16

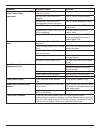

16 section vi. Trouble shooting guide problem possible cause solution low quantity of product water from holding tank feed water saddle valve is plugged or closed. Open valve or unclog. Clogged sediment module or activated carbon module. Replace modules. Low water pressure. Feed water pressure must ...

Page 17

17 problem possible cause solution high total dissolved solids (tds) in the product water (continued) the product water and drain water lines are reversed. Correct plumbing. No drain flow, drain restrictor is clogged. Clear or replace drain restrictor. No drain flow, the drain orifice in the dispens...

Page 18

18 made in usa exploded view & parts list 1 2 3 4 5 6 7 8 9 10 11 12 13 14 17 19 18 15 16 21......... Nitrate/nitrite test kit 22......... Water quality test kit (for systems without the water quality monitor).

Page 19

19 drawing no. Part no. Description 1 .................... S2009 .......................... Self tapping screw 2 .................... S2005 .......................... Aso cap 3 .................... S2013 .......................... Aso cap o–ring 4 .................... S2011 ............................

Page 20

Form no. S1474-01wc 12/18/2013 manufactured by: water-right, inc. 1900 prospect court • appleton, wi 54914 phone: (920) 682-6823 • fax: (920) 682-7673 r.O. Drinking water system five/one year limited warranty what does this warranty cover? This warranty covers any defects in materials and workmanshi...