- DL manuals

- Water Tec

- Water Filtration Systems

- CP

- Operating Manual

Water Tec CP Operating Manual

Summary of CP

Page 1

Water tec int’l. Inc. Version 02a reverse osmosis systems operating manual models: cp / wmxl / wxl / vxl / hxl / hxxl / x water tec international, inc. Tucson, arizona 85714 www.Water-tec.Com.

Page 2: Table of Contents

Water tec int’l. Inc. Version 02a 2 this manual includes the most common components and installation specifications. Please keep in mind that water tec manufactures many units to customer specifications. If you do not find the information that you are looking for in this manual, please contact your ...

Page 3

Water tec int’l. Inc. Version 02a 3 introduction to reverse osmosis the application of reverse osmosis to the solution of problems in water treatment requires an understanding of the basic mechanisms involved in the process, the limitations of reverse osmosis and the pre-treatment requirements. How ...

Page 4

Water tec int’l. Inc. Version 02a 4 factors that affect the operation and the useful life of the membrane: there are five main factors that affect a reverse osmosis membrane: 1. Pressure: excessive pressure tends to deform or compact the membrane. The compaction causes the membrane to become less po...

Page 5

Water tec int’l. Inc. Version 02a 5 the reverse osmosis system the reverse osmosis unit is composed of two major parts: the high-pressure pump (200 psi max) and the membranes. The initial purified water production rate is measured at 200 psi. The system is carefully designed to make certain that min...

Page 6

Water tec int’l. Inc. Version 02a 6 purified water storage and delivery system as previously discussed the r.O. Product water is almost always delivered to an atmospheric storage tank. Normally, such a storage tank is sized to provide sufficient water to cope with the number of hours of continuous u...

Page 7

Water tec int’l. Inc. Version 02a 7 reverse osmosis component identification 1. Pre-filter pressure gauge 0-100 psi liquid filled panel mount gauge. Standard on all units 30,000 gpd and above. On smaller units this gauge is an option. Located on the front panel. This gauge measures the water pressur...

Page 8

Water tec int’l. Inc. Version 02a 8 9. Waste valve this valve is located on the front panel of units 1500 gpd and larger, and on other various locations of smaller units. Ex. The valve is located on the membrane housing of the compact unit. Its purpose is to meter or restrict the flow of concentrate...

Page 9

Water tec int’l. Inc. Version 02a 9 17. Time delay located inside of electrical system control box. The time delay is adjustable from 6-30 seconds. Its purpose is threefold: 1) when the on-off switch is turned to “on” the time delay starts after the feed water pressure is sensed at the low pressure ...

Page 10

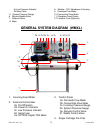

Water tec int’l. Inc. Version 02a 10 general system diagrams (cp) 1. Incoming feed water 2. #10 ps05-10 pre-filter 3. #10 c1 pre-filter 4. #10 cb10-10 pre-filter 5. Recycle needle valve 1 5 6 7 8 2 3 4 9&10

Page 11: General Systems Diagram (Wm)

Water tec int’l. Inc. Version 02a 11 6. Waste needle valve 7. Module – r.O. Membrane and housing 8. Powder coated steel frame 9. Electrical control box (not shown) 10. Rotary vane pump and motor (not shown) general systems diagram (wm) 1 . Incoming feed water 5. Rotary vane pump (pre-filter supplied...

Page 12

Water tec int’l. Inc. Version 02a 12 2c:low pressure indicator 2d:5amp fuse 3. System pressure gauge 6. Recycle needle valve 7. Solenoid valve 8. Module – r.O. Membrane & housing 9. Permeate flow meter 10. Concentrate flow meter 11. Fiberglass panel/frame 12. Pressure tank (optional) 4. Motor genera...

Page 13

Water tec int’l. Inc. Version 02a 13 5. High pressure multistage pump 5a. Solenoid valve 6. Module-r.O. Membrane & housing 7. Powder coated steel frame general system diagram (vxl) 1&2. Incoming feed water and pre-filter (not shown) 3. Electrical control box 3a. On/off switch 3b. Power on indicator ...

Page 14

Water tec int’l. Inc. Version 02a 14 6. Module-r.O. Membrane housing 7. Powder coated steel frame general system diagram (hxl & hxxl) 1. Incoming feed water 2. Single cartridge pre-filter 3. Electrical control box 3a. On/off switch 3b. Power on indicator 3c. Low pressure indicator 3d. 5amp fuse 4. C...

Page 15: General System Diagram (X)

Water tec int’l. Inc. Version 02a 15 containing two membranes per housing. 7. Powder coated steel frame general system diagram (x) 1. Incoming feed water 2. Pre-filter 1 and 2 3. Inlet ball valve 4. Pump a 5. Pump b (standard equipment has 1 pump) 6. Pump c (cleaning pump) optional 7. Control box 7a...

Page 16

Water tec int’l. Inc. Version 02a reverse osmosis set -up specifications inlet water supply inlet pipe size should never be smaller than equipment inlet. This is the inlet to the pre-filter. Sizing can range from ½” to 3” depending on each piece of equipment. General sizing is as follows: cp series:...

Page 17: Testing Procedures

Water tec int’l. Inc. Version 02a 17 reverse osmosis set -up, start-up and testing procedures it is very important to make sure you are aware of all plumbing and electrical codes in your area before you start the installation or set-up of these systems. As always, please follow proper plumbing and e...

Page 18: Membrane Installation

Water tec int’l. Inc. Version 02a 18 the brine seal direction consists of pre-treatment initial testing (continued) after the quality test you should also test all the electrical equipment. Disconnect the liquid level switch wires and look for these four things: the pump should automatically shut do...

Page 19: Trouble Shooting Guide

Water tec int’l. Inc. Version 02a 19 trouble shooting guide symptom possible cause solution ro unit will not start no electrical power to control circuit check power supply on/off switch check power / replace time delay not operating check power / replace fuse check / replace coil in magnetic motor ...

Page 20

Water tec int’l. Inc. Version 02a 20 reverse osmosis general pretreatment these are standard pieces of equipment necessary to help your reverse osmosis operate correctly. Individual circumstances, configurations and the type of system will determine if all the above equipment is necessary, if more i...