- DL manuals

- Waterax

- Water Pump

- STRIKER-2/3

- Owner's Manual

Waterax STRIKER-2/3 Owner's Manual

Summary of STRIKER-2/3

Page 1

Striker-2/3 owner's manual publication date: 09/2015 publication number: 701223, rev. 3.

Page 2

This document provides information proprietary to waterax inc. And cannot be used or disclosed without waterax’s written authorization. Waterax inc. Reserves the right to make changes without notice in its products or components as research and development or marketing conditions warrant. Changes af...

Page 3: Contents

Waterax striker-2/3 owner's manual 09/2015 1 contents important safety instructions ............................................................................................ 2 personal safety advisory ...................................................................................................

Page 4: Personal Safety Advisory

Waterax striker-2/3 owner's manual 2 09/2015 important safety instructions it is recommended that all information provided in this manual be carefully read and understood before performing any operation of or maintenance to the pump. The procedures listed in this manual are general operating and mai...

Page 5

Waterax striker-2/3 owner's manual 09/2015 3 do not ground the battery (if applicable) through the pump’s frame members; always ground to a bare metal (unpainted) part of the engine block to ensure proper ground. Preventing damage to equipment the following recommendations will help avoid damage to ...

Page 6: Introduction

Waterax striker-2/3 owner's manual 4 09/2015 introduction about this manual this manual contains general operation, care and servicing procedures for the following waterax striker-2/3 high pressure centrifugal pumps: pump designation engine used striker-2 honda gx390 13hp gasoline engine striker-3 h...

Page 7

Waterax striker-2/3 owner's manual 09/2015 5 about the striker-2/3 series features for full specifications and performance curves, see the product data sheet for your pump end model. Applications of the waterax striker-2/3 series include: slip-on units attack line firefighting long hose lay for remo...

Page 8: Parts Identification

Waterax striker-2/3 owner's manual 6 09/2015 parts identification striker-2/3 a. Pump intake (suction) b. Pump drain port (not shown) c. Priming valve d. Quick release pump clamp e. Discharge check valve* f. Pump discharge g. Hand primer* h. Ignition switch i. Recoil starter j. Fuel cap k. Throttle ...

Page 9

Waterax striker-2/3 owner's manual 09/2015 7 fastening to truck/apparatus when adding any equipment to a vehicle, follow all instructions and heed all warnings provided by manufacturers of the apparatus and any third-party accessories. Waterax provides certain accessories used in vehicle-mount confi...

Page 10: Pre-Operation Checklist

Waterax striker-2/3 owner's manual 8 09/2015 operating striker-2/3 series pumps pre-operation checklist before using your pump, follow this verification procedure: 1. Visually inspect product when you first receive your striker-2/3 pump, inspect the product and check for any damage. Notify the suppl...

Page 11: Drafting

Waterax striker-2/3 owner's manual 09/2015 9 drafting before you draft pumps should not be run dry, and therefore the pump ends require priming prior to operation. Use this procedure if you are drafting water from an open tank or natural water source. To maintain optimum performance from your pump, ...

Page 12: Priming The Pump

Waterax striker-2/3 owner's manual 10 09/2015 priming the pump before priming the pump, discharge hoses should be installed. Several options are available to prime a pump when you are drafting water, depending on the priming equipment you have. Note: the priming line must be connected to a port on t...

Page 13: Startup And Discharge

Waterax striker-2/3 owner's manual 09/2015 11 startup and discharge discharge hoses should be installed before starting the engine and priming the pump. 1. Fill fuel tank with recommended fuel grade. For models with an integral fuel tank, fill tank and securely replace cap. 2. Start the engine. A. W...

Page 14: Cold Weather Operation

Waterax striker-2/3 owner's manual 12 09/2015 cold weather operation the pump can be run in below freezing temperatures if certain precautions are taken to avoid the formation of ice in the pump. 1. After priming the pump, the unit should be run at low speed for a short period of time to allow all c...

Page 15: Troubleshooting

Waterax striker-2/3 owner's manual 09/2015 13 troubleshooting this section provides brief troubleshooting instructions for verifying the set-up and operation of the pump. Each section describes a condition and lists possible causes along with a list of items to check to identify the source of the pr...

Page 16

Waterax striker-2/3 owner's manual 14 09/2015 pump does not meet performance incompatible installation piping size and configuration may be too restrictive. Contact a waterax inc. Representative if assistance is needed in evaluating the unit’s piping. Gauge or instrument failure check that all gauge...

Page 17: Service

Waterax striker-2/3 owner's manual 09/2015 15 id item no description qty 1 600101 c-7221 speed increaser housing, alu. Painted 1 2 800512 fast-502 lockwasher 3/8 split zinc 8 3 800524 fast-23 screw 3/8-16x1-1/4 hex cap zinc 4 4 800803 part-1 timing belt,8mmp x 30w x 720lg 1 5 800825 part-2 pulley 64...

Page 18

Waterax striker-2/3 owner's manual 16 09/2015 id item no description qty 1 800538 part-8 retaining ring ext. 1 2 800541 part-9 ring retaining int. 1 3 800836 part-10 bearing, 4 point contact, sealed 2 4 700083 a-6956 spacer for c-7220, alu. 1 5 700086 a-7239 shaft assembly for c- 7220 1 6 600130 c-6...

Page 19

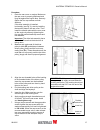

Waterax striker-2/3 owner's manual 09/2015 17 procedure 1. Place the rear cover on engine. Make sure the rear cover is properly positioned and lying flat against the engine face. Securely tighten the four cap screws and lock washers. If the drive assembly is installed horizontally (see fig. 2), star...

Page 20

Waterax striker-2/3 owner's manual 18 09/2015 8. Since tightening the cap screws will affect the axial position of the pulley, make sure pulleys are properly aligned: d r = w - d f if adjustment is required, determine the new position of the bushing and reposition the pulley assembly. See page 19 fo...

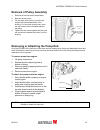

Page 21: Removal of Pulley Assembly

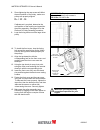

Waterax striker-2/3 owner's manual 09/2015 19 removal of pulley assembly 1. Remove all the cap screws sequentially. 2. Remove the set screw. 3. For the large driver pulley, insert the cap screws into the threaded holes of the bushing. For the small driven pulley, insert the cap screws into the threa...

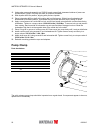

Page 22: Pump Tool Kit

Waterax striker-2/3 owner's manual 20 09/2015 pump tool kit 1 2 3 4 6 5 7 8 10 9 11 12 id item no description qty 1 700540 a-1884 pressing sleeve distributor 1 2 700531 a-4329 pressing sleeve rotary seal 1 3 700532 a-4097 protector shaft 1 4 700090 a-7644 seal puller for 12-28ns 1 5 700642 a-7711 se...

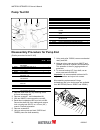

Page 23

Waterax striker-2/3 owner's manual 09/2015 21 assembly procedure for pump end (similar procedure for the 25-16s, will have fewer impeller and distributor) 13 14 15 16 17 18 19 20 25 21 22 23 24 26 19 (2/2) important: when reusing components, carefully inspect the parts. Ensure that key dimensions ar...

Page 24: Pump Clamp

Waterax striker-2/3 owner's manual 22 09/2015 13. Using arbor press and assembly tool 700540, apply several light, downward strokes of press ram until distributor "drops" into body and rests on previous distributor. 14. Slide impeller #22 into position, aligning with previous impeller. 15. Place loc...

Page 25: Striker-2/3 Wiring

Waterax striker-2/3 owner's manual 09/2015 23 striker-2/3 wiring standard waterax wiring configuration: all vehicle striker pumps are wired from the factory to work with an xcp control panel. To revert to the original engine controls, refer to the next section for instructions. Xcp vs. Engine contro...

Page 26: Fastwire Wiring Diagrams

Waterax striker-2/3 owner's manual 24 09/2015 fastwire wiring diagrams wiring for gasoline pumps *pins 7 & 8 connected on gx630 engine only..

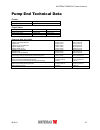

Page 27: Pump End Technical Data

Waterax striker-2/3 owner's manual 09/2015 25 pump end technical data threads discharge port 1-1/2” [38 mm] npsh male suction (intake) port 2” [51 mm] npsh male torque values retaining ring screw 22-25 in-lbs 2.5-2.8 nm shaft nose screw 32-36 in-lbs 3.6-4.1 nm suction cover screw 32-36 in-lbs 3.6-4....

Page 28: Notes

Waterax striker-2/3 owner's manual 26 09/2015 notes.

Page 29

Waterax striker-2/3 owner's manual 09/2015 27.

Page 30

Waterax striker-2/3 owner's manual 28 09/2015.

Page 31: Warranty

Waterax striker-2/3 owner's manual 09/2015 29 warranty whereas subject to the following general and specific terms and conditions, waterax inc. (the “seller”) hereby warrants to the original purchaser of the products from waterax, (the “purchaser”) that its products, including any pump parts product...

Page 32: Tf 855-616-1818

Waterax inc. 6635 henri-bourassa w. Montreal, qc h4r 1e1 tf 855-616-1818 t 514-637-1818 f 514-637-3985 info@ waterax .Com www. Waterax .Com all information contained in this document including drawings is proprietary to waterax and may not be copied, reproduced or used in whole or in part without ou...