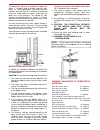

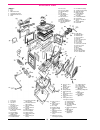

Waterford Trinity Mk II Installation & Operating Instructions Manual

SAFETY NOTICE

Please read this entire manual before you install and use your new room heater. Failure to follow instructions

may result in property damage, bodily injury or even death.

If this stove is not properly installed, a house fire may result. For your safety, follow the installation directions.

Contact local building or fire officials about restrictions and installation inspection requirements in your area.

This appliance is hot while in operation and retains its heat for a long period of time after use. Children, aged

or infirm persons should be supervised at all times and should not be allowed to touch the hot working surfaces

while in use or until the appliance has thoroughly cooled.

This stove must be connected to a UL/U.L.C. listed High Temperature residential chimney, Factory Built,

Residential Type and Building Heating Appliance, UL 103 or a code approved masonry chimney flue liner

constructed in accordance with NFPA 211 Chimney Vents and Solid Fuel Burning Appliances

Manufactured by Waterford Stanley (Marketing) Limited, Bilberry, Waterford, Ireland.

INSTALLATION & OPERATING INSTRUCTIONS

Trinity

Mk II

WOODBURNING STOVE