- DL manuals

- Waterstage

- Heat Pump

- WG*G140DD6

- Installation And Operating Manual

Waterstage WG*G140DD6 Installation And Operating Manual

Installation and

operating manual

intended for professionals

To be saved for

future consultation

Split integrated DHW type

Document n° 1586-1 ~ 20/02/2013

Air to Water Heat Pump

Fujitsu General

(Euro) GmbH

Werftstrasse 20

40549 Düsseldorf - Germany

Subject to modifications without notice.

Non contractual document.

Outdoor unit

WO*G112LCT

WO*G140LCT

WO*K112LCT

WO*K140LCT

WO*K160LCT

Hydraulic unit

WG*G140DD6

WG*K160DD9

FR EN IT

NL DE

Summary of WG*G140DD6

Page 1

Installation and operating manual intended for professionals to be saved for future consultation split integrated dhw type document n° 1586-1 ~ 20/02/2013 air to water heat pump fujitsu general (euro) gmbh werftstrasse 20 40549 düsseldorf - germany subject to modifications without notice. Non contra...

Page 2

Contents package 4 definitions 4 specifications 5 description 9 operating principle 10 installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 regulation installation and maintenance conditions 12 unpacking and reservations 12 receipt 12 handling 12 containment of refri...

Page 3

Regulation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 user interface, remote control (option) and room thermostat (option) 36 description of the display 38 temperature control 38 set to 38 parametering the setting 40 general 40 setting parameters 40 list of function line...

Page 4: 1 Description of The Unit

1 description of the unit 1 .1 package • 1 package: outdoor unit. • 1 package: hydraulic unit and outdoor sensor. 1 .2 definitions -split: the heat pump consists of two elements (an outdoor unit for outdoor and a hydraulic unit for inside the dwelling). -air/water: the surrounding air is the energy ...

Page 5

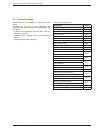

1 .3 specifications 1 sound pressure level in (x)m of the device, 1,5m of the ground, the open field. 2 the sound power level is a laboratory measure of the emitted sound power but contrary to the noise level, it doesn't correspond to the measure of the felt. 3 refrigerant r410a (as per the standard...

Page 6

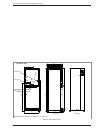

31 77 900 330 12 9 400 650 21 1290 147 170 196 370 99 3/8” 5/8” air overflow hole (Ø 20) 4 Ø 10) holes top view front view sight of lower part side view air air figure 1 - dimensions in mm 900 1290 9 21 650 370 air 31 12 330 400 air air overflow hole (ø 20) 4 holes (ø 10) sight of lower part front v...

Page 7

175 210 1840 47 244 1189 648 1296 698 103 1850 43 630 599 576 644 figure 2 - dimensions in mm blockage in the hydraulic unit, see figure 13, page 15 back view heating flow dhw dcw heating return side view front view " hydraulic unit installation and operating manual "1586 - en" - 7 - air to water he...

Page 8

Figure 3 - hydraulic pressures and flow rates available -50 1000 10000 43907 2490 338 -25 0 25 50 75 ° c 0 2500 5000 7500 10000 12500 15000 17500 20000 22500 25000 27500 30000 32500 0 10 20 30 40 50 60 70 80 90 100 °c outdoor sensor qac34 heat pump return sensor heat pump flow sensor figure 4 - ohmi...

Page 9

1 .4 description figure 6 - outdoor unit components legend : 1 - low-noise, high-output fan. 2 - electric variable speed "inverter" motor. 3 - "inverter" control module. 4 - vacuum start (pump down) and control light. 5 - connection terminal blocks (power and interconnection). 6 - refrigerant accumu...

Page 10

1 .5 operating principle the heat pump transmits the energy contained in the surrounding air into the dwelling to be heated. The heat pump consists of four main elements, in which a refrigerant fluid (r410a) circulates. -in the evaporator (ref. 13, figure 6, page 9 ) : the energy is taken from the s...

Page 11

• domestic hot water (dhw) operating principle two domestic hot water (dhw) temperatures can be parametered: nominal temperature (line 1610 to 55 °c) and reduced temperature (line 1612 to 40 °c). The default heat pump program (line 560, 561 and 562) is set for nominal temperature from 0:00 to 5:00 a...

Page 12: 2 Installation

2 installation 2 .1 regulation installation and maintenance conditions the appliance must be installed and the maintained by an approved professional in accordance with the prevailing regulations and code of practice, in particular: -the legislation on the handling of refrigerants. -heating installa...

Page 13

2 .3 installation position the choice of the position for installation is particularly important insofar as any later movement is a delicate operation requiring the intervention of a qualified person. Choose the site of the outdoor unit and the hydraulic unit after discussion with the customer. Obse...

Page 14

• water may drain away from the outdoor unit when it is operating. Do not install the appliance on a paved terrace; choose a well-drained place (e.G. Gravel or sand). If the installation is in an area where the temperature can be lower than 0°c for a long period, check that the presence of ice does ...

Page 15

Figure 13 - minimum installation clearances around the hydraulic module and distances to the combustible partitions front view 2 .5 installing the hydraulic unit 2 .5 .1 installation precautions • the room in which the appliance operates must comply with the prevailing regulations. • to facilitate m...

Page 16

2 .6 refrigeration connections " this appliance uses refrigerant r410a . Comply with the legislation for handling refrigerants. 2 .6 .1 rules and precautions • after every intervention on the refrigeration circuit and before final connection, take care to replace the plugs in order to avoid any poll...

Page 17

Figure 17 - flaring for flare connections flare nut flaring tool hose b l c ø hose dimensions in mm l b 0 / -0,4 c 9,52 (3/8") 2,5 to 2,7 13,2 22 15,88 (5/8") 2,9 to 3,1 19,7 29 figure 18 - tightening torque designation tightening torque flare nut 9,52 mm (3/8") 32 to 42 nm flare nut 15,88 mm (5/8")...

Page 18

Figure 19 - connecting the flared connections (pipe diameters and permissible lengths) “gas” refrigeration connection diameter d1 "liquid" refrigeration connection diameter d2 flare nut flare nut flare nut flare nut liquid valve gas valve hydraulic unit outdoor unit hp model high power single phase ...

Page 19

2.7 filling the installation with gas " this operation is reserved for installers familiar with the legislation for handling refrigerants. " creating a vacuum with a vacuum pump is essential (see annex 1). " never use equipment used beforehand with any refrigerant other than a hfc . " remove the ref...

Page 20

Figure 20 - connexion of the hose on the "gaz" valve refrigeration connexion plug (a) hex / allen key of 4 mm 3-way valve load orifice plug (b) service hose (blue) fitted with valve push-button high pressure hose (red) refrigeration connecxion (gas) • first seal test -remove the protective plugs ( b...

Page 21

2.7.3 additional charge 50 g of r410a per additional meter length of the connections 15 m 20 m max. Additional charge none 250 g the charge in the outdoor units corresponds to the maximum distances between the outdoor unit and the hydraulic unit defined in page 18 . If the distances are greater, an ...

Page 22

2 .8 hydraulic connecting 2 .8 .1 general the connection must comply with good trade practice according to local building regulations. The heating circulating pump is built into the hydraulic unit. Connect the central heating pipes to the appliance, complying with the direction of circulation. The p...

Page 23

2 .8 .2 connecting to the dhw circuit install dielectric fittings and dhw pipes on the tank (see figure 24) . Insulate dhw pipes with included insulation. " be sure to put the dhw sensor at the bottom of the thermowell dhw. On the cold water inlet, place a safety unit rated (from 7 to 10 bars - requ...

Page 24

P figure 26 - hydraulic module bleeder valve 2 .8 .3 rinsing out the installation before connecting the hydraulic unit to the installation, rinse out the heating system correctly to eliminate any particles that may affect the appliance's correct operation. Do not use solvents or aromatic hydrocarbon...

Page 25

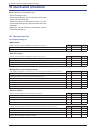

Ext. In 2 4 6 7 4 2 ext. In 2 4 6 7 4 2 2 .10 heating circulation pump speed settings figure 28 - hydraulic pressures and flow rates available circulation pump sticking or blocked: if the motor is blocked, a start cycle is launched. If the motor remains blocked it will be permanently stopped. " cut ...

Page 26

2 .11 electrical connections ensure that the general electrical power supply has been cut off before starting any repair work. 2 .11 .1 characteristic of the electrical supply the electrical installation must be conducted in accordance with the prevailing regulations. The electrical connections must...

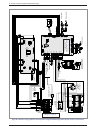

Page 27

2 .11 .3 overview of all the electrical connections the wiring diagram for the hydraulic unit is shown in detail on figure 50, page 56 2 .11 .4 cable section and protection rating the cable sections are given for information purposes only and do not exempt the installer from checking that these sect...

Page 28

2 .11 .5 electrical connections on the single phase outdoor unit side access to the connection terminals: -remove the front panel. Remove the screws and the front panel. Figure 31 - access to sinlge phase outdoor unit’s terminal block figure 32 - connections to sinlge phase outdoor unit’s terminal b...

Page 29

2 .11 .6 electrical connections on the 3- phase outdoor unit side access to the connection terminals. -remove the front panel. Remove the screws and the front panel. -make the connections in accordance with the diagram figure 37, page 26 -use cable clamps to prevent the conductors from being disconn...

Page 30

2.11.7 electrical connections on the hydraulic unit side access to the connection terminals: -remove the front panel. -open the power control box. -make the connections in accordance with the diagram ( figure 41, page 33 ). Do not place the sensor lines and the sector supply lines in parallel in ord...

Page 31

Figure 39 - connections to the heat pump regulator (accessories and options) ex1 ex2 ex3 x60 x86 l x84 x11 2 1 3 m b9 b2 m b1 3 2 1 1 2 1 3 2 b2 m b1 outdoor sensor room thermostat** room thermostat** remote control** wireless remote control** power shedding or ejp (peak day removal) tariffs, peak t...

Page 32

230 v l n l n 2 4 230 v l n l n 2 4 figure 40 - access to hydraulic model electric box and description relay + dhw terminal blocks relay + dhw terminal blocks hp regulator electrical back-up terminal blocks solid state relay safety thermostat cable grommet (power) interface card cable grommet (senso...

Page 33

Figure 41 - connection to terminal block and power relays 230 v l n l n 2 4 ln 1 2 3 4 5 6 l n l n 230 v l n l n 2 4 ln 1 2 3 4 5 6 1 2 3 l1 l2 l3 n l1 l2 l3 n 1 2 3 4 5 6 l1 l2 l3 commun l1 l2 l3 outdoor unit single phase outdoor unit 3-phase hydraulic unit hydraulic unit electricity supply 230 v s...

Page 34

2 .12 outdoor sensor the outdoor sensor is required for the heat pump to operate correctly. Consult the fitting instructions on the packaging. Place the sensor on the coldest part, generally the northern or north-eastern side. In any case, it must not be exposed to the morning sun. It must be instal...

Page 35

2 .15 configuring room thermostat (wireless) to configure the room thermostat and connect it to the appropriate heating zone: -hold down the presence key for more than 3 seconds. The room thermostat displays ru and a number flashes. -turn the wheel to choose the zone (1, 2). -if the installation is ...

Page 36: 3 Regulation System

3 regulation system 3 .1 user interface, remote control (option) and room thermostat (option) figure 42 - °c auto auto esc ok 0 4 8 12 16 20 24 1 2 3 4 5 6 7 8 11 5 2 10 11 remote control (option) room thermostat (option) 1 2 3 4 5 6 7 8 9 user interface installation and operating manual "1586 - en"...

Page 37

Ref. Function - definitions 1 selecting of the dhw operating mode (domestic hot water) on off -on: production of dhw according to the time program. -off: preparing the domestic hot water for stopping with the anti-frost function active. -manual start button: hold down the dhw key for 3 seconds. Swit...

Page 38

3 .3 temperature control the heat pump's operation is subject to the temperature control. The set temperature for the water in the heating circuit is adjusted according to the outdoor temperature. If there are thermostatic valves on the installation, these must be fully open or adjusted for higher t...

Page 39

Figure 46 - corrective actions in the case of discomfort figure 44 - heating curve slope (line 720) figure 45 - off-set of the heating curve (line 721) 40 50 60 70 -20 -15 -10 -5 5 10 -4,5 +4,5 20 0 10 30 0 30 heating flow temperature °c external temperature °c curve off-set heating curve slope 0,5 ...

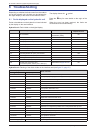

Page 40

3 .4 parametering the setting 3 .4 .1 general only the parameters accessible to levels: u – end user. I – commissioning level. S - engineer level. ... Are described in this document. The access levels are specified in the second column of the table by means of the letters u, i and s the oem paramete...

Page 41

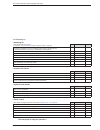

Line function setting range or display setting increment basic setting time program heating, circuit 1 500 u pre-selection (day / week) mon-sun, mon-fri, sat-sun, monday, tuesday, … mon-sun 501 u 1st phase on (start) 00:00... --:-- 10 min 6:00 502 u 1st phase off (end) 00:00... --:-- 10 min 22:00 50...

Page 42

Line function setting range or display setting increment basic setting time program 5 / cooling if the installation is fitted with the cooling kit (only with the cooling kit option). 600 u pre-selection (day / week) mon-sun, mon-fri, sat-sun, monday, tuesday, … mon-sun 601 u 1st phase on (start) 00:...

Page 43

Line function setting range or display setting increment basic setting 750 s room influence 1%... 100% 1% 50% if the installation is fitted with a room thermostat: this function enables you to choose the ambient temperature's influence on the setting. If no value is entered, the setting is made base...

Page 44

Line function setting range or display setting increment basic setting cooling circuit 1 if the installation is fitted with the cooling kit (only with the cooling kit option). 901 u operating mode off, automatic off 902 u comfort cooling setpoint 17 40 °c 0,5 °c 24 °c 907 u release 24h/day, time pro...

Page 45

Line function setting range or display setting increment basic setting 1041 s flow temp setpoint max 8 70 °c 1 °c 55 °c floor heating system = 50 °c / radiators = 65 °c. Important note : maximum temperature limitation is not a safety function as required by ground heating. 1050 s room influence 1 %....

Page 46

Line function setting range or display setting increment basic setting domestic hot water 1610 u nominal setpoint reduced setpoint (line 1612)… 65 °c 1 55 °c the backup electrical system is required to reach this level. 1612 u reduced setting 8 °c nominal setting (line 1610) 1 40 °c 1620 i release o...

Page 47

Line function setting range or display setting increment basic setting additional generator (boiler connection) 3692 s with dhw charging locked, substitute, complement, instantly substitute - dhw instantly : when dhw request, the hp and the boiler are put into operation. The hp will stop when the pr...

Page 48

Line function setting range or display setting increment basic setting 6220 s software version (rvs) 0 99 -- 6420 s function input h33 (= contact in x152) 1 56 1 (1) mode changeover hc+dhw - (2) mode changeover hc - (3) mode changeover hc1 - (4) mode changeover hc2 - (5) mode changeover hcp - (6) to...

Page 49

Line function setting range or display setting increment basic setting 7710 i output ux1 test (3-phase electrical back-up command) 0... 100% 1 -- 7712 i pwm signal ux1 0... 100% 1 0 7716 i output ux2 test 0... 100% 1 -- 7719 i pwm signal ux2 0... 100% 1 0 7722 i digital output do2 off, on off 7723 i...

Page 50

Line function setting range or display setting increment basic setting 8410 u return temp hp 0 140 °c -- setpoint (flow) hp -- 8412 u flow temp hp 0 140 °c -- setpoint (flow) hp -- 8413 u compressor modulation 0... 100% -- 8414 i modulation electric flow 0... 100% -- 8425 s temp diff condensor -50.....

Page 51

Line function setting range or display setting increment basic setting 8770 i room temperature 2 0 50 °c -- room setpoint 2 20 °c 8773 u flow temperature 2 0 140 °c -- flow temperature setpoint 2 -- 8820 i dhw pump off, on off 8821 i el imm heater dhw off, on off 8830 u dhw (domestic hot water) temp...

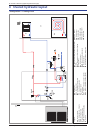

Page 52

4 overall hydraulic layout • configuration 1: 1 heating circuit se ssa sae ae r r pc ou sa1 sa2 sr ve c vd gs mt car sdp pg saec sse d legend: ae - back-up dhw av s - extension card, 2 circuits car - non-return valve c - hp circulation pump ccm - mixed-circuit heat pump d - shut-of f gs - safety uni...

Page 53

• configuration 2: 2 heating circuits legend: ae - back-up dhw av s - extension card, 2 circuits car - non-return valve c - hp circulation pump ccm - mixed-circuit heat pump d - shut-of f gs - safety unit k2c - 2nd circuit kit mt - thermostatic mixer valve pc - floor heating system pg - bleeder valv...

Page 54

5 electrical wiring diagrams figure 48 - electrical wiring of outside unit model high power integrated dhw (single phase type) woyg112lbt / woyg112lct woyg140lbt / woyg140lct thermistor (expansion) expansion valve coil (injecrtion) thermistor (pipe) thermistor (pipemid) thermistor (discharge) thermi...

Page 55

Figure 49 - electrical wiring of outside unit model high power integrated dhw (3-phase type) bk wh rd rd rd rd rd rd rd rd rd rd rd rd rd bn bn bn bn bn bn bn bn ye ye ye ye ye gn gn gn gn gn ye ye vt og og og og og og wh wh wh wh wh wh wh wh wh wh wh wh bk bk bk bk bk bk bk bu bu bu bu bu bu bu bu ...

Page 56

Figure 50 - electrical wiring, hydraulic unit high power integrated dhw single phase (except installer's connections) x10 x11 x12 x13 x14 x15 x30 x50 x70 x75 x80 x82 x83 x84 x86 x100 c.C x60 ou/ or ou/ or 0/i m 2a 1a 1b 2b ex1 ex2 ex3 bk bn bu l n b2 m b1 3 2 1 rp ecs l n l n 230v ac i l n 1 2 3 4 5...

Page 57

Figure 51 - electrical wiring, hydraulic unit high power integrated dhw 3-phase (except installer's connections) x10 x11 x12 x13 x14 x15 x30 x50 x70 x75 x80 x82 x83 x84 x86 x100 c.C x60 ou/ or ou/ or 0/i m 2a 1a 1b 2b ex1 ex2 ex3 bk bn bu l n b2 m b1 3 2 1 rp ecs l n l n 230v ac i l n 1 2 3 4 5 l n ...

Page 58: 6 Troubleshooting

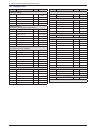

6 troubleshooting depending on whether the fault comes from the outdoor unit or the hydraulic unit, the fault may be indicated by the digital display or the diode on the interface cards. 6 .1 faults displayed on the hydraulic unit faults or breakdowns on the hydraulic unit are indicated by the displ...

Page 59

6 .2 information display various data can be displayed by pressing the info button. Depending on the type of unit, configuration and operating state, some of the info lines listed below may not appear. -possible error messages from the error code list (see table, page 58 ). -possible service message...

Page 60

6 .3 faults displayed on the single phase outdoor unit to access the electronic board, you must remove the front (right-hand) facing from the outdoor unit. Faults are coded by diode flashes. When an error occurs: -the diode " error" (2) blinks. -press once on the switch " enter" (sw3). -the " error"...

Page 61

6 .4 faults displayed on the 3-phase outdoor unit to access the electronic board, you must remove the front (right-hand) facing from the outdoor unit. Faults are coded by diode flashes. When an error occurs: -the diode " error" (2) blinks. -press once on the switch " enter" (sw4). -the " error" (2) ...

Page 62

Figure 55 - emptying the hydraulic unit and/or domestic hot water tank 7 maintenance of the installation ensure that the general electrical power supply has been cut off before starting any repair work. 7.1 hydraulic checks " warning : if frequent refills are required it is essential that you look f...

Page 63: 8 Maintenance

Figure 56 - fitting the distribution valve b a ab outlet to exchanger heating return outlet to dhw tank valve valve motor 8 maintenance 8 .1 emptying the hydraulic unit -remove the facade from the hydraulic unit. -place the distribution valve in the middle position. -open the emptying valve (ref. 5)...

Page 64: 10 Quick-Start Procedure

10 quick-start procedure before switching on the hydraulic unit: • check the electric wiring. • check the refrigeration circuit and make sure the gas supply has been performed. • check the pressure of the hydraulic circuit (1-2 bar), check that the heat pump is purged, and the rest of the installati...

Page 65

10 .1 .2 starting-up • switching on (see chapiter "star-up" page 28 & chapiter "list of function lines (settings, diagnosis, status)", page 40 ). Ok non compliant engage the installation's main circuit breaker (power supply to the outdoor unit) 2 hours before starting up the tests => preheating of t...

Page 66

10 .2 settings sheet setting description set to. Menus preliminary settings 20 language operator section 1 hour / minutes time & date 2 day / month time & date 3 year time & date 5700 installation config. Configuration heating circuit no . 1 if 2 circuits = the least warm one (e.G.: floor) 710 comfo...

Page 67

10 .3 start-up data sheet site installer outdoor unit serial no. Hydraulic unit serial no. Model model refrigerant type refrigerant charge kg checks operating voltage & current on outdoor unit compliance with positioning distances l/n or l1/n v condensate evacuation correct l2/n v electric connectio...

Page 68

Date of installation : contact of your heating technician or your after-sales service. This appliance is marked with this symbol. This means that electrical and electronic products shall not be mixed with general household waste. European community countries(*), norway, iceland and liechtenstein sho...