- DL manuals

- Waukesha

- Water Pump

- 200 series

- Operation And Maintenance Manual

Waukesha 200 series Operation And Maintenance Manual

Summary of 200 series

Page 1

Operation and maintenance manual 200 series liquid ring self-priming pumps read and understand this manual prior to installing, operating or servicing this equipment..

Page 2: Table of Contents

Table of contents issued: january 2003 95-03074 page 3 revised: june 2005 waukesha cherry-burrell warranty .........................................................4 shipping damage or loss .............................................................................4 warranty claim ...................

Page 3

Warranty waukesha cherry-burrell page 4 95-03074 january 2003 waukesha cherry-burrell warranty seller warrants its products to be free from defect in materials and workmanship for a period of one (1) year from the date of shipment. This warranty shall not apply to products which require repair or re...

Page 4: Safety

Waukesha cherry-burrell safety january 2003 95-03074 page 5 safety read and understand this manual prior to installing, operating or servicing this equipment waukesha cherry-burrell recommends users of our equipment and designs follow the latest industrial safety standards. At a minimum, these shoul...

Page 5: Care of Stainless Steel

Care of stainless steel waukesha cherry-burrell page 6 95-03074 issued: january 2003 revised: june 2005 care of stainless steel stainless steel corrosion corrosion resistance is greatest when a layer of oxide film is formed on the surface of stainless steel. If film is disturbed or destroyed, stainl...

Page 6: Introduction

Waukesha cherry-burrell introduction issued: january 2003 95-03074 page 7 revised: june 2005 introduction manual content maintenance procedures in this manual do not cover aseptic or high pressure pump applications. These are covered in special addendums available from your waukesha cherry-burrell r...

Page 7

Introduction waukesha cherry-burrell page 8 95-03074 issued: january 2003 revised: june 2005 pump characteristics the 200lr (liquid ring) self-priming pump handles products with entrained air as well as maintaining its prime when other pumps become air bound. This feature makes the 200lr the best ch...

Page 8

Waukesha cherry-burrell introduction issued: january 2003 95-03074 page 9 revised: june 2005 dimensions figure 2 - foot print dimensions item dimension for 2065lr 213jm and 215jm motor frame dimension for 2085lr 254jm and 256jm motor frame in mm in mm a 13.44 341 14.9 379 b 10.34 263 12 305 c 23.51 ...

Page 9: Installation

Installation waukesha cherry-burrell page 10 95-03074 january 2003 installation special requirements for liquid ring self-priming pump liquid ring self-priming pumps are designed for applications with large amounts of entrained air. Cip return pump applications involve intermittent flow from tank wi...

Page 10

Waukesha cherry-burrell installation january 2003 95-03074 page 11 installation safety procedures • any system throttling valves or similar devices controlling flow rate must be installed in discharge line. Do not install devices in supply line. Restriction in supply line may cause cavitation and pu...

Page 11

Installation waukesha cherry-burrell page 12 95-03074 january 2003 before first startup cleaning pump and piping disassemble pump and clean all product contact parts and seal parts prior to first operation. Follow instructions in “cleaning safety procedures” on page 12 and “scheduled routine mainten...

Page 12: Operation

Waukesha cherry-burrell operation january 2003 95-03074 page 13 operation before proceeding ensure pump has been correctly installed as described in “installation” on page 10. Starting pump 1. Start flow of filtered flush water (recommended rate is approximately 5 us gallons per hour) before operati...

Page 13: Maintenance

Maintenance waukesha cherry-burrell page 14 95-03074 issued: january 2003 revised: june 2005 maintenance scheduled routine maintenance a scheduled routine maintenance program can extend life of pump. Keep maintenance records to help pinpoint potential problems and causes. • check for unusual noise, ...

Page 14

Waukesha cherry-burrell maintenance issued: january 2003 95-03074 page 15 revised: june 2005 5. Remove front cover (figure 9, item a) from pump. Place front cover on a protected surface with ports up. 6. Remove backplate cover o-ring (figure 10, item a). 7. Remove shims, belleville washers and impel...

Page 15

Maintenance waukesha cherry-burrell page 16 95-03074 issued: january 2003 revised: june 2005 type 1 seal disassembly 1. Remove deflector (figure 14, item b). Note: drive key and shims (figure 14, item a) remain on motor shaft. If impeller is replaced, add or remove shims as necessary. 2. Loosen set ...

Page 16

Waukesha cherry-burrell maintenance issued: january 2003 95-03074 page 17 revised: june 2005 type 4 seal disassembly 1. Remove cap screws from seal housing. (figure 19, item a). 2. Carefully lift off seat retainer, o-ring, l-gasket, stationary seal and flush housing (figure 18, items p, r, t, s and ...

Page 17

Maintenance waukesha cherry-burrell page 18 95-03074 issued: january 2003 revised: june 2005 assembly of pump tools required soft-face hammer 3/4" socket wrench .020" feeler gage 3/4" open end wrench 1/8" allen wrench 1/2" open end wrench 1/4" allen wrench 7/16" open end wrench backplate assembly 1....

Page 18

Waukesha cherry-burrell maintenance issued: january 2003 95-03074 page 19 revised: june 2005 type 1 seal assembly 1. Carefully place rotary seal in position over impeller shaft and down against stationary seal. 2. Lubricate and slide seal assembly o-ring onto impeller shaft. (use the spring retainer...

Page 19

Maintenance waukesha cherry-burrell page 20 95-03074 issued: january 2003 revised: june 2005 5. Slide o-ring (figure 28, item f) onto shaft and use spring retainer to push o-ring into rotary seal (figure 30). 6. Place washer (figure 28, item g) over rotary seal with tabs in outside diameter notches....

Page 20

Waukesha cherry-burrell maintenance issued: january 2003 95-03074 page 21 revised: june 2005 2085lr: if end of shaft is not flush with impeller counter bore, add .015 shim washers (figure 34, item a) to end of shaft (figure 33). Assemble three belleville washers to impeller retainer with o-ring (fig...

Page 21: Parts Lists

Parts lists waukesha cherry-burrell page 22 95-03074 issued: january 2003 revised: june 2005 parts lists seal components all pumps figure 38 - type 1 seal assembly figure 39 - type 4 seal assembly.

Page 22

Waukesha cherry-burrell parts lists issued: january 2003 95-03074 page 23 revised: june 2005 *recommended spare parts. For item 22, see “motor shaft shims” on page 24. Item description type 1/1c seal qty type 4 seal qty material part # 1 deflector 1 - 69-1 2* stationary seal 1 2 purbide (1.75") 23-1...

Page 23

3duwv/lvwv :dxnhvkd&khuu\%xuuhoo 3djh ,vvxhg-dqxdu\ 5hylvhg-xqh /56hoi3ulplqj3xps3duwv 027256+$)76+,06 027251(0$)5$0(6,=( 47 3$57 7+. -0-0 $vuhtxluhg 7+. -0-0 $vuhtxluhg 7+. -0-0 $vuhtxluhg 7+. -0-0 $vuhtxluhg 7+. -0-0 $vuhtxluhg 7+. -0-0 $vuhtxluhg ,7(0 '(6&5,37,21 47 3$57 3oxj,qvshfwlrq 2ulqj)'$9l...

Page 24

Waukesha cherry-burrell parts lists issued: january 2003 95-03074 page 25 revised: june 2005 2085lr self-priming pump parts item description qty part # 1 plug inspection 1 115162 2 o-ring 215 fda viton ® 1 v70215 3 cover pump 1 115160 4 nut-impeller retainer 1 115163 5 belleville washer 1/2" 17-7ss ...

Page 25

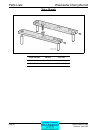

Parts lists waukesha cherry-burrell page 26 95-03074 issued: january 2003 revised: june 2005 motor mounts pump model frame leg kit s2065lr 213/215 110254 s2085lr 254/256 110253.

Page 26: Troubleshooting

Waukesha cherry-burrell troubleshooting january 2003 95-03074 page 27 troubleshooting problem possible cause suggested action not enough liquid delivered suction or discharge plugged or closed. Open suction. If plugged shutdown pump and remove blockage. Air leak in supply or at seal area. Check syst...

Page 27

Troubleshooting waukesha cherry-burrell page 28 95-03074 january 2003 problem possible cause suggested action vibration/noise pump not level. Ensure legs are touching floor. Level pump. Piping not supported. Support all piping as described in installation section. Starved suction/supply line blocked...