- DL manuals

- Waukesha

- Water Pump

- 200 series

- Operation, Maintenance And Parts Manual

Waukesha 200 series Operation, Maintenance And Parts Manual

Summary of 200 series

Page 1

Read and understand this manual prior to installing, operating or maintaining this pump. Waukesha centrifugal pumps model 200 series operation maintenance & parts list effective date october 9,1999.

Page 2

95-03009 this page is intentionally left blank 7-12-96.

Page 3: Safety

2 95-03009 • always lock out power prior to servicing equipment. • ensure pump is isolated from system and pressure is relieved before disassembling pump, removing plugs, or disconnecting piping. • use proper lifting and supporting equipment to prevent injuries. • observe proper decontamination proc...

Page 4: Safety

3 95-03009 read and understand this manual prior to installing, operating or maintaining this pump. Warning to avoid serious injury, do not install or service pump unless all power is off and locked out. Warning to avoid possible serious injury, shut off and drain product from pump prior to disconne...

Page 5: Warranty

4 95-03009 waukesha cherry-burrell warranty seller warrants its products to be free from defects in materials and workmanship for a period of one (1) year from the date of shipment. This warranty shall not apply to products which require repair or replacement due to normal wear and tear or to produc...

Page 6: List of Contents

5 95-03009 list of contents waukesha 200 series centrifugal pumps safety ................................................. 2-3 general safety instructions ........................ 2 warnings, cautions, notes ........................ 3 warranty .......................................... 4 introductio...

Page 7: Introduction

6 95-03009 introduction the waukesha 200 series pump is built for extremely durable service. The casing, backplate and intrigal impeller/stub shaft are cast 316l stainless steel for extra strength and resistance to line shock and corrosion. Large bearings and shaft provide positive alignment and min...

Page 8: Introduction

7 95-03009 pump component and seal identification introduction motor shims deflector spring retainer *water cascade block 1/4-20 x 1/2 cap screws (4) type 1 seal assembly *type 1c seal assembly seat retainer stationary seal l-gasket figure 3 springs (3) tabbed washer rotary seal o-ring slinger 142-2...

Page 9: Specifications

8 95-03009 waukesha centrifugal 200 series pumps specifications 2045 2065lv 2065 2065hv 2085lv 2085 2105 capacities 200 series sanitary mode l industrial inlet outlet maximum maximum model size size impeller size capacity inch (mm) inch (mm) inch (mm) gpm (m3/hr) u2045 1.5 (40) 1.5 (40) 4.5 (115) to...

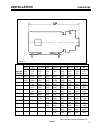

Page 10: Installation

9 95-03009 sanitary /industrial model/size (inlet x outlet) 2045 2065lv 2065 2065hv 2085lv 2085 2085 2105 2105 all all 2-1/2x2 3x2 2x1-1/2 3x2-1/2 4x2-1/2 4x4 6x4 cp cp cp cp cp cp cp cp cp motor inch inch inch inch inch inch inch inch inch frame (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) 145jm 18...

Page 11: Installation

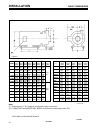

10 95-03009 a b d aa ab f e g frame inch inch inch inch inch inch inch inch (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) 145jm 8.56 6.87 3.5 .50 5.25 12.50 5.50 (218) (174) (89) (13) (133) (317) (140) 182jm 9.81 8.44 4.50 .75 5.87 12.50 7.50 (249) (214) (114) (19) (149) (317) (190) 184jm 9.81 8.44 4.50 ....

Page 12: Installation

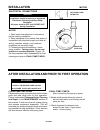

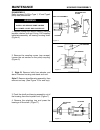

11 95-03009 installation figure 7 figure 8 figure 9 (length = 8 diameters) support legs (4) support set screw (2) per leg motor mount (page 34) location - piping preparation check quantities and inspect all parts of your equipment prior to beginning installation. Pump location 1. Locate pump as near...

Page 13: Installation

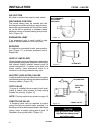

12 95-03009 installation figure 11 air suction all joints in suction line must be well sealed. Discharge position the pump casing may be rotated with the discharge connection pointing in any direction; best pump performance will be with the outlet up, to the left or positions in between; these posit...

Page 14: Installation

13 95-03009 figure 13 type 1c seal figure 14 type 4 flush housing in out housing hose fitting cascade block seal guard water cascade option type 1c seal a fitting for 1/4 inch o.D. Plastic tubing is supplied for directing a flow of water onto the backplate/seal area. Use cool and filtered water. (if...

Page 15: Installation

14 95-03009 electrical connections motor 1. Read motor manufacturer's instructions before making installation. 2. Read nameplate to be certain that motor is compatible with electrical supply and that all wiring, switches, starters, and overload protection are correctly sized. 3, following electrical...

Page 16: Operation

15 95-03009 operation pump must have been correctly installed as described in "installation" section. Seal flush 1. If pump has the flush seal option, start flow of flush water (approximately 5 us gallons per hour recommended rate). Prime pump 2. Flood pump casing with liquid before starting pump to...

Page 17: Operation

16 95-03009 caution caution stop pump 9. To stop pump, shut off power to pump motor. Liquid in system can flow freely through the pump; the pump does not act as a shut off valve. Shut off supply and discharge lines. Cleaning safety procedures see "disassembly for cleaning and repair" in maintenance ...

Page 18: Troubleshooting Guide

17 95-03009 troubleshooting guide this guide has been prepared on the assumption that the pump has been installed properly. If problems arise and are not listed in the chart, pump cavitation may be the problem. Symptoms of pump cavitation, such as noisy operation, insufficient discharge and vibratio...

Page 19: Troubleshooting

18 95-03009 motor overload conditions centrifugal pump motors may overload (draw excessive electrical current) under certain conditions. This will trip motor overload protection or burn out motor. Certain combinations will overload motor when operated with open, unrestricted discharge which results ...

Page 20: Maintenance

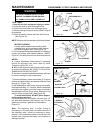

19 95-03009 figure 18 figure 19 figure 21 backplate retainer ring retainer bolt o-ring clamp casing o-ring cap screws guard cascade block shims deflector warning to avoid serious injury, do not install or service pump unless all power is off and locked out. Springs o-ring set screws rotary seal wash...

Page 21: Maintenance

20 95-03009 figure 23 figure 22 replace rotary seal if less than 1/32-inch or 1mm. 1/32" (1mm) minimum springs inspection of parts seal surfaces: examine and replace seals that become scratched, cracked and/or braised. Note: a. Stationary seals are revers- ible. Use both sides before replacing. B. R...

Page 22: Maintenance

21 95-03009 type 4 double seal the type 4 seal is essentially two type 1 seals assembled back to back in a chamber which bolts to the backplate in place of the stationary seat retainer. Except for the additional components, (e.G. Chamber, seals,) type 1 and type 4 components are interchangeable. (fi...

Page 23: Maintenance

22 95-03009 type 4 double seal the type 4 seal is essentially two type 1 seals assembled back to back in a chamber which bolts to the backplate in place of the stationary seat retainer. Except for the additional components, (e.G. Chamber, seals,) type 1 and type 4 components are interchangeable. (fi...

Page 24: Maintenance

23 95-03009 o-ring figure 34 figure 35 figure 36 retainer bolt .030 inches setscrew backplate o-ring casing assembly of type 4 seal 1. Clean all parts and lubricate all elastomer (rubber like) parts. 2. Install l-gaskets in backplate, flush housing and seat retainer. Install stationary seals in l-ga...

Page 25: Maintenance

24 95-03009 maintenance see page 34 motor mounts electric motors.

Page 26: Maintenance

25 95-03009 maintenance see page 34 motor mounts electric motors.

Page 27: Parts List

26 95-03009 complete seal kit - type 4 seal - sanitary - industrial pump model model kit contains qty 2045 2065* 2085* 2105 carbon seal 2 9-225a 9-225a 9-225a 9-225a seal o-ring 2 v70224 v70224 v70224 v70224 casing o-ring 1 v70252 v70439 v70446 v70450 impeller o-ring 1 v70214 v70220 v70220 v70220 ho...

Page 28: Parts List

27 95-03009 metric impellers part no. Model 5-224x 2045 5-230x 2065 5-242x 2085 5-234x 2065hv 5-238x 2085lv 5-226x 2065lv 5-246x 2105 metric motors frame size 200 180 160 132 112 100 90 using metric motors requires : * metric key metric impeller * metric adapter * metric fasteners **metric seal comp...

Page 29: Parts List

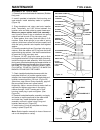

28 95-03009 seal components all pumps item part no. Name 1 69-1 deflector *2 23-17 stationary seal -purbide (1.75") 23-17a stationary seal -s/carbide (1.75") 23-17e stationary seal -ceramic (1.75") 23-17f stationary seal -t/carbide (1.75") 23-111 stationary seal -purbide (43mm) 23-111a stationary se...

Page 30: Parts Lists

29 95-03009 available seals for 200 series parts lists figure 38.

Page 31: Parts Lists

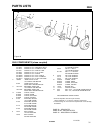

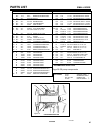

30 95-03009 2045 components (close-coupled) item part no. Name 1 301-57bx casing 1-1/2 x 1-1/2 beveled seat 301-57ex casing 40mm x 40mm din 301-57fx** casing 1-1/2 x 1-1/2 flanged 301-57hx casing 1-1/2 x 1-1/2 female i-line 301-57jx casing 1-1/2 x 1-1/2 male i-line 301-57kx casing 1-1/2 x 1-1/2 “s” ...

Page 32: Parts Lists

31 95-03009 figure 40 parts lists 5 6 seals 10 12 1 11 3 4 9 2 8 7 7 30-21 1/2-13 x 1-1/4 bolt 213-256jm motors 30-30 3/8-16 x 1 bolt 143-184jm motors 30-105 5/8-11 x 1-1/2 bolt 284-326jm motors 8 43-28 3/8 lock washer 43-16 1/2 lock washer 43-33 5/8 lock washer •9 v70439 o-ring, viton e70439 o-ring...

Page 33: Parts Lists

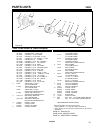

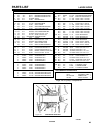

32 95-03009 parts lists 2065lv components (close coupled) item part no. Name 1 301-62-x casing 1-1/2 x 1-1/2 "s" clamp 301-62bx casing 1-1/2 x 1-1/2 beveled seat 301 -62ex casing 40mm x 40mm din 301-62nx** casing 1-1/2 x 1-1/2 n.P.T female 301-62mx** casing 1-1/2 x 1-1/2 n.P.T male 301-62fx** casing...

Page 34: Parts Lists

33 95-03009 figure 42 parts lists 5 6 seals 1 11 3 2 9 10 4 7 8 12 item part no. Name 5 2-171 adapter, motor 143-184jm frame 2-172 adapter, motor 213-215jm frame 2-173 adapter, motor 254-256jm frame 2-174 adapter, motor 284jm and larger motor 6 70-24 seal guard 143-215jm motor 70-26 seal guard 254-3...

Page 35: Parts Lists

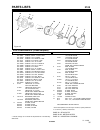

34 95-03009 parts lists figure 43 2085lv 5 6 seals 1 11 3 2 9 10 4 7 8 12 * trimmed impellers are same part number; specify diameter to 1/16-inch(1.59mm) increments. ** these casings do not meet the requirements of 3a sanitary standards page 26 - seals kits page 26-28 - metric notes page 34 - indust...

Page 36: Parts Lists

35 95-03009 parts lists 5 6 seals 1 11 3 2 9 10 4 7 8 12 ** these casings do not meet the requirements of 3a sanitary standards figure 45 item part no. Name 5 2-233 adapter, motor 143-184jm frame 2-230 adapter, motor 213-215jm frame 2-231 adapter, motor 254-256jm frame 2-232 adapter, motor 284jm and...

Page 37: Parts List

36 95-03009 301-28kxa 301-28bxa 301-28hxa 301-28jxa 301-28qxa 301-28wxa 301-28mxa 301-28nxa 301-28fxa 301-56kxa 301-56bxa 301-56hxa 301-56jxa 301 -56qxa 301-56wxa 301-56mxa 301-56nxa 301-56fxa u2105 4 x 4 industrial u2105 6 x4 industrial these casings do not meet the requirements of 3a sanitary stan...

Page 38: Waukesha 200 Series

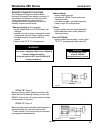

37 95-03009 description/specifications the waukesha 200 series modular base mounted centrigual pump design consists of 4 components (in addition to pump and motor). These components are used in various combinations and arrangements to provide flexibility to meet various needs: * bearing housing (pum...

Page 39: Installation

38 95-03009 motor sanitary & industrial models hp & rpm p2045 p2065lv p2065 p2065hv p2085lv p2085 p2105 up to 5hp 1750 rpm sm.B. Sm.B. Sm.B. Sm.B. Sm.B. Sm.B. Sm.B. Up to 5hp 3500 rpm sm.B. Sm.B. Sm.B. 7½hp 1750 rpm sm.B. Lg.B. 7½hp 3500 rpm sm.B. Sm.B. Sm.B. Sm.B. Sm.B. 10hp 1750 rpm sm.B. Lg. B. 1...

Page 40: Installation

39 95-03009 this page is intentionally left blank installation dimensions style a 7-12-96.

Page 41: Installation

40 95-03009 installation outlet 6.54 sm bore 10.47 lg bore x y z .56 dia. 4.5 sm bore 6.58 lg bore 3.35 sm bore 5.74 lg bore style "b" & "c" less base plate figure 5 b d model inlet outlet sm bore lg bore sm bore lg bore x y z p2045 1.5 1.5 16.39 --- 3.0 --- 3.88 1.81 2.25 p2045 2.0 1.5 16.39 --- 3....

Page 42: Maintenance

41 95-03009 maintenance housing disassembly retaining ring housing figure 4 impeller assembly housing casing retainer bolt o-ring figure 7 disassembly refer to pages 19-23 for type 1, 1c and type 4 pump seal procedures. 1. Release clamp and remove casing. Remove impeller retainer bolt and o-ring. Pu...

Page 43: Maintenance

42 95-03009 figure 8 setscrew seal assembly housing setscrew end cap figure 10 outer seal assemblies 5. Using an l/8" hex wrench, loosen set screws (opposite the grease fittings in the adapter or end cap) and the impeller end of the bearing housing. Remove the outer seal ring assemblies: (remove the...

Page 44: Cartridge Seals

43 95-03009 pre-assembled seals pre-assembled (cartridge) seals have all of the seal components mounted to a flange. They are pre adjusted at factory. Follow the seal manufacturers's (john crane, a. W. Chesterton, etc.) recommendations regarding application, operation and maintenance. The following ...

Page 45: Cartridge Seals

44 95-03009 4. Install the cartridge seal unit and use retaining bolts and flat washers to secure unit to the cartridge adapter. (figure 15) do not tighten-be sure the removable lugs/ spacers that position the rotating part of the seal in the housing are in place at this time. 5. Apply fda approved ...

Page 46: Parts Lists

45 95-03009 john crane cartridge seal- type 88s chesterton cartridge seal- model 123 chesterton cartridge seal model 241 durametallic cartridge seal model x 100 durametallic cartridge seal model x 200 figure 39 a b c bearing shaft a. Socket head capscrew to fasten seal adapter to backplate b. Cartri...

Page 47: Parts List

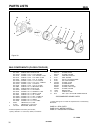

46 95-03009 9 7 6 17 13 19 5 3 2 4 27 28 29 25 24 30 19 23 32 33 34 14 27 28 29 23 22 26 20 23 32 33 34 14 1 17 6 7 9 18 16 15 14 13 11 9 7 6 17 13 21 5 3 2 4 14 1 17 6 7 9 18 parts list small bore assembly 16 15 11 13 style "c" small bore style "b" small bore figure 21 figure 22 7-7-96.

Page 48: Parts List

47 95-03009 1 b,c all 68-6 bearing housing 2045 b,c all 68-7 bearing housing 2065 b,c all 68-8 bearing housing 2085 2 b,c all 62-528x shaft •3 b,c all 23-101 bearing 6309 •4 b,c all 23-100 bearing 6209 •5 b,c all 43-139 retaining ring 6 b,c all 23-90 seal outer 7 b,c all 23-89 seal inner •9 b,c all ...

Page 49: Parts List

48 95-03009 9 7 6 17 13 19 5 3 2 4 parts list large bore assembly figure 25 27 28 29 25 31 24 30 19 23 32 33 34 16 15 11 13 14 27 28 29 23 22 26 21 23 32 33 34 14 1 17 6 8 10 18 16 15 14 13 11 9 7 6 17 13 20 5 3 2 4 14 1 17 6 8 10 18 style "c" large bore figure 26 style "b" large bore 7-12-96.

Page 50: Parts List

49 95-03009 1 b,c all 68-9 bearing housing 2065 1 b,c all 68-10 bearing housing 2085 1 b,c all 68-11 bearing housing 2105 2 b,c all 62-539x shaft •3 b,c all 23-98 bearing 6309 •4 b,c all 23-99 bearing 6209 •5 b,c all 43-138 retaining ring 6 b,c all 23-95 seal outer 7 b,c all 23-94 seal inner motor e...

Page 51: Parts Ordering

50 95-03009 parts ordering how to order parts by phone telephone your repair parts or fittings order to your distributor. To speed your order and avoid delays, please have your equipment model and serial number and the part numbers from the parts list before you call your distributor. If you do not ...

Page 52: Weights

51 95-03009 pedestal pump small bore/large bore -models b,c (less base & motor) pump model pedestal 2045 2065lv 2065 2065hv 2085lv 2085 2105 small bore 92 lbs. 106 lbs. 108 lbs. 110 lbs. 131 lbs. 125 lbs. Large bore 235 lbs. 240 lbs. Close coupled pump ( less motor and legs) motor pump model frame 2...

Page 53

611 sugar creek road delavan, wl 53115 u.S.A. Customer service telephone 1-800-252-5200 or 262-728-1900 toll free telefax 1-800-252-5012 or 262-728-4904 effective date: october 7, 1999 95-03009.