- DL manuals

- Webasto

- Heater

- DUAL TOP RHA-100

- Installation Manual

Webasto DUAL TOP RHA-100 Installation Manual

Summary of DUAL TOP RHA-100

Page 1

Integriertes heizgerät integrated heater riscaldatore integrato einbauanweisung installation instructions istruzioni di montaggio dual top rha 100 / 101 / 102.

Page 2

Improper installation or repair of webasto heating and cooling systems can cause fire or the leakage of deadly carbon monoxide leading to serious injury or death. To install and repair webasto heating and cooling systems you need to have completed a webasto training course and have the appropriate t...

Page 3

Dual top i inhalt 1 allgemeine informationen ............................................................... 1 2 gesetzliche bestimmungen für den einbau .................................... 2 3 verwendung des integrierten luft-/wasserheizgerätes ................ 5 4 weitere sicherheitsanweisungen .....

Page 4

General 63 1 general for installation and repair of a webasto dual top rha 100 / 101 / 102 in- tegrated heater you will need technical documentation, a special training by webasto, special tools and special equipment. You also have to be certified to work on 230 v electric systems. Installation and ...

Page 5

Statutory regulations governing installation 64 2 statutory regulations governing installation the dual top rha 100 / 101 / 102 heaters have been type-tested and ap- proved in accordance with ec directives 72/245/eec (emc) and 2001/56/ ec (heater) with the following ec permit numbers: e1 03 5000 e1 ...

Page 6

Statutory regulations governing installation 65 2.1. Extract from directive 2001/56/ec annex vii start of extract. Annex vii requirements for combustion heaters and their installation 1. General requirements 1.7.1. A clearly visible tell-tale in the operator's field of view shall inform when the com...

Page 7

Statutory regulations governing installation 66 2.6. Heating air inlet 2.6.1. The heating air supply may be fresh or recirculated air and must be drawn from a clean area not likely to be contaminated by exhaust fumes emitted either by the propulsion engine, the combustion heater or any other vehicle...

Page 8

Use of the integrated air / water heater 67 3 use of the integrated air / water heater the integrated dual top rha 100 / 101 / 102 air and water heaters from webasto are used for heating and to provide hot water in motorhomes and similar vehicles. The heaters operate independently of the vehicle eng...

Page 9

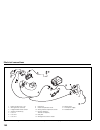

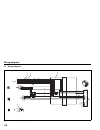

Installation example 68 5 installation example fig. 1: installation example for a dual top heater in a motorhome 1 2 3 4 5 6 7 8 9 10 12 13 15 14 16 11.

Page 10

Installation example 69 1 interior temperature sensor 2 water lines 3 dual top heater 4 dual top cooling-air intake cover 5 dual top rubber bellow (heating air adapter) 6 combustion air intake silencer 7 exhaust silencer 8 fuel tank connector 9 fuel tank 10 fuel pump 11 led dashboard 12 water pump 1...

Page 11

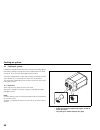

Heater installation 70 6 heater installation 6.1. General important the regulations specified in chapter 2, "statutory regulations governing installation" must be adhered to. Important the dual top may not be lifted at the heating air inlet! This offsets the air fan and causes the heating air impell...

Page 12

Heater installation 71 6.3. Installation location at all sides of the heater there should be at least 20 mm space. • space requirement for hot air outlet > 150 mm • length 530 mm • space requirement for air inlet > 200 mm • width 352 mm • height 256 mm • space requirement at sides > 20 mm • space ab...

Page 13

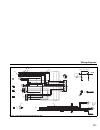

Heater installation 72 find a suitable location for the heater. Space for the heater: • make sure to have sufficient space at all sides of the heater. See fig. 3; • the heater must be fastened at a location in the vehicle which can with- stand a weight of 35 kg; • all parts above the water crossing ...

Page 14

Heater installation 73 6.4. Connecting wiring harness 1. Housing cover with inlet interfaces 2. Fastening screws for housing cover with inlet interfaces 3. Opening for dual top wiring harness 4. Opening for wiring harness of electric heater (dual top rha 101 / 102 only). Connect the wiring harness p...

Page 15

Heater installation 74 6.5. Installing the heater • the heater is fastened on the load-bearing parts of the vehicle frame using brackets and m8 t-bolts which are integrated in the heater guide rails. • to prevent breaks within the heater and noises, it is necessary to use vi- bration dampers. The m8...

Page 16

Heater installation 75 6.6. Additional information for exterior installation • install the heater in such a way that it will not fall from the vehicle in case the vibration dampers fail. • the brackets must be spaced at least 200 mm apart. See fig. 10. • to minimize energy loss, it is recommended th...

Page 17

Heater installation 76 6.7. Additional information for interior installation important both the dual top and the hot air hoses must be installed firmly closed off outside the range of the vehicle occupants and parts which are not tem- perature-resistant (e.G. In an installation box or behind furnitu...

Page 18

Heater installation 77 as the escaping exhaust gases can reach extremely high temperatures, a temperature-resistant (up to 90 °c) sealing compound should be used to seal off the floor. When installing the heater, the following must also be ensured for sealing off to the outside: • the seal is evenly...

Page 19

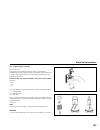

Identification plate 78 7 identification plate the type label must be positioned so that it cannot be damaged and is clearly legible after installing the heater (otherwise, a duplicate type label must be applied in a highly visible location or in the engine compartment next to the vehicle type label...

Page 20

Hot water system 79 8 hot water system the dual top complies with all applicable standards for this type of prod- uct. When installing the dual top heater and related components, make sure to follow all local regulations (e.G. 98/83/ec, din 2001-2, dvgw w 291). Note during and after installation of ...

Page 21

Hot water system 80 always use hoses, which are resistant to pressure (at least 4 bar) and hot water (90 ºc). For operating the heater it is possible to use all sanitary water pumps: – creating a pressure up to 2.5 bar; – closed when shut off; – min. Operating pressure 1 bar. When using immersion pu...

Page 22

Hot water system 81 8.1. Installation information for immersion pump systems the dual top application with an immersion pump system requires a “dual top diving pump” version and two additional ventilation hoses: • one ventilation hose for the cold water line so that no water is sucked in from the ve...

Page 23

Hot water system 82 fig. 20: dual top immersion pump version 2 4 10 9 11 5 2 cold water line 4 dual top ventilation hose 5 “dual top diving pump”heater 9 drain hose for pressure relief valve and solenoid valve 10 hot water line 11 housing cover with inlet in- terfaces (service cap).

Page 24

Hot air system 83 9 hot air system note the heater must not be integrated into the vehicle‘s front heating system. Only recirculation air mode is possible, with the heating air intake from the interior. The recirculation mode ensures frost protection of the coolant hoses with underfloor installation...

Page 25

Hot air system 84 9.1. Heating air intake 9.1.1. General note the heating air has to be drawn from the interior. Extracting heating air from an enclosure (e.G. Bottom of bed or seat box) will reduce noise coming from the heating air ventilator. Mounting the air intake in a central area will provide ...

Page 26

Hot air system 85 • identify the position of a hole in the floor for the pass through of the air intake hose. • drill a hole in the floor with a diameter of 100 mm. • seal off the joint between the floor and the hose with temperature-re- sistant sealing compound (up to 90 °c). • insulate the air hos...

Page 27

Hot air system 86 • in case hot air hoses inside the interior are not running through closed compartments or areas, cover them to prevent damaging the hose and accidental touching. • secure the hoses at all connection points with hose clamps. • fasten the hoses to the wall or floor using hose clips....

Page 28

Hot air system 87 dark colour = below interior, insulated bright colour = inside interior fig. 24: hot air distribution.

Page 29

Cooling air system 88 10 cooling air system cooling air is required to protect the heaters’ electronics and motor against overheating. Cooling air shall be taken from outside and not from inside the vehicle. The air has to be discharged outside the vehicle. The heater is equipped with a motor and a ...

Page 30

Boiler drainage and pressure relief system 89 11 boiler drainage and pressure relief system the heater is equipped with 1 a drainage system that drains the water contents automatically as a protection against frost (boiler water temperature below 6 ºc). It is also possible to drain the unit manually...

Page 31

Fuel supply 90 12 fuel supply 12.1. General the fuel is typically taken from the vehicle’s own fuel tank. It may also be taken from a separate fuel tank (accessory). The permissible values for the maximum pressure at the fuel pump entry side are shown in fig. 26. Note a notice, indicating that the h...

Page 32

Fuel supply 91 12.2. Fuel pump the dp40 fuel pump is a combined delivery, metering and a shut-off sys- tem and is subject to certain installation criteria (see fig. 26 and fig. 28). 12.2.1. Installation location the fuel pump and fuel lines must not be installed within the range of ra- diated heat f...

Page 33

Fuel supply 92 12.3. Fuel extraction for recommended fuel extraction solutions see webasto camping cata- logue. 1) installation into the vehicle’s fuel line. A) t-junction from the fuel line to the vehicle’s engine if no feeding pump is installed inside the tank. B) t-junction from the fuel return l...

Page 34

Fuel supply 93 12.4. Fuel lines only steel, copper and plastic lines of plasticised, light and temperature- stabilized pa 11 or pa 12 (e.G. Mecanyl rwtl) pursuant to din 73378 may be used as fuel lines. Since the lines normally cannot be routed with a con- stant rising gradient, the internal diamete...

Page 35

Fuel supply 94 12.4.2. Connecting two pipes with a hose the correct procedure for connecting fuel lines with hosing is shown in fig. 32. Ensure that there are no leaks. 1 = clip 2 = air or gas bubble 12.5. Fuel filter no fuel filter is to be used in the heater fuel system. Due to the danger of frost...

Page 36

Combustion air supply 95 13 combustion air supply 13.1. General the air for the combustion chamber of the heater may not be taken out of the vehicle passenger compartment (extract from 2001/56/ec). Note an intake silencer must be fitted to reduce noise levels. The combustion air must be taken from a...

Page 37

Combustion air supply 96 note the intake opening for combustion air must be located so that it cannot become clogged with dirt or snow. See fig. 34. Note the intake opening for combustion air must not point in the driving direc- tion. See fig. 35. Combustion air intake hose should point downwards fr...

Page 38

Exhaust system 97 14 exhaust system 14.1. General see chapter 2, "statutory regulations governing installation" for require- ments on exhaust system. Note an exhaust silencer must be fitted to reduce the noise level. The silencer should ideally be installed near the heater (not more than 0.20 m dist...

Page 39

Exhaust system 98 14.2. Exhaust line as exhaust lines use flexible piping of stainless steel or rigid pipes of stain- less steel with a minimum wall thickness of 1.0 mm. The exhaust pipe has to be connected to the heater using a webasto exhaust clamp. An exhaust assembly including a special bracket ...

Page 40

Exhaust system 99 • exhaust outlet should be on the opposite side of the entrance door of the living cell. • avoid that the exhaust pipe can touch ground or pavement, including traffic calming measures. Fig. 39: elbows, cast (left) and bent pipe (right) fig. 40: prevent the formation of condensate f...

Page 41

Exhaust system 100 fig. 42: location and direction of exhaust a: flow exhaust fumes 45 to 70º downwards and at side to avoid exhaust bag under vehicle. B: end exhaust line nearly aligned with side of vehicle body. C: end exhaust line cut horizontally to avoid that ambient wind can enter. 45 ~ 70º b ...

Page 42

Electrical connections 101 15 electrical connections carry out electrical connections in accordance with fig. 43 or fig. 44. Note when installing the dual top wiring harness in the vehicle, it should be ensured that no lines can be pinched. Fig. 43: schematic diagram of electrical connections for du...

Page 43

Electrical connections 102 fig. 44: schematic diagram of electrical connections for dual top rha 101 / 102 with programmable heater control 10 11 12 13 15 14 16 1 dual top rha 101 / 102 2 wiring harness (external) 3 programmable heater control 4 vehicle’s leisure battery 5 fuse 5 a 6 fuse 10 a 7 fus...

Page 44

Electrical connections 103 15.1. Supply voltage connection use 12 v dc only. Ensure that you take it directly from the vehicle‘s leisure battery. No additional switches may be used with the exception of the control pan- el switch. Switching the heater on and off shall only be done with the dual top ...

Page 45

Electrical connections 104 15.2. Interior temperature sensor the remote interior temperature sensor must be installed at medium height in the interior on vertical surfaces. Make sure that the inside temperature sensor is not positioned: • in the direct current of hot air (from the vehicle‘s own heat...

Page 46

Electrical connections 105 15.3. Connecting instrument panel led (only for programmable heater control) • make a hole where the control panel shall be placed, e.G. In the dash- board. The led must be located in the driver’s field of view. • connect the wiring. See fig. 48. Extend the wire from the l...

Page 47

Electrical connections 106 15.4. Connection to manual heater control • determine the best position of the control panel. The control panel must be located in the driver's field of view. It should be visible and accessible for the operator. However at the same time, it must not be accessible to child...

Page 48

Electrical connections 107 note: connector x2 is for: – webasto thermo test pc-diagnosis and – webasto telestart / thermo call (optional for programmable control panel). Note: the dual top rha 100 heater can easily be retrofitted with the program- mable heater control. This provides the user with ad...

Page 49

Electrical connections 108 note connector x2 is for: – webasto thermo test pc-diagnosis and – webasto telestart / thermo call (optional). Disassembly control panel place 1 or 2 suction cups on the control panel. Alternatively, slide flat, smooth material (e.G. Plastic card) under the control panel a...

Page 50

Electrical connections 109 15.5.1. 230 v connection 1 installation of the 230 v connection shall be carried out by personnel certified for 230 v electric systems. 2 installation must be in accordance with iec 60364. 3 connect to 230 v power supply. 4 install relay box in such a way that demanded pro...

Page 51

Wiring diagrams 110 16 wiring diagrams fig. 55: circuit diagram for dual top rha 100 1 3 4 7 6 5.

Page 52

Wiring diagrams 111 fig. 56: circuit diagram for dual top rha 101 / 102 1 3 4 to 8 6 2 5 to x5 8 7 not in scope of delivery!.

Page 53

Wiring diagrams 112 16.1. Legend for wiring diagrams 1 wiring harness (external) 2 wiring harness for electric heater (only for rha 101 / 102) 3 vehicle’s leisure battery 4 15 a fuse (red cable) 5 10 a fuse (red/black cable) 6 5 a fuse (red/blue cable) 7 interior temperature sensor 8 instrument pane...

Page 54

Starting the heater for the first time 113 17 starting the heater for the first time • after you have installed the heater, bleed the fuel supply line carefully. Note due to the low fuel consumption the heater may have to be switched on several times to fill the fuel line completely. • with dual top...

Page 55

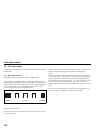

Fault code output 114 18 fault code output the heater is able to identify faults on individual components and during the operation. 18.1. Manual heater control the control panel gives out the fault code in a flashing mode. After a series of 5 fast green flashes, the fault code output will be a re- p...

Page 56

Fault code output 115 table 1: fault messages of manual heater control number of red flashes meaning remedy 00 no communication between control panel and heater, or error control panel first, remove fuses 15 a and 5 a. Then put in fuse 15 a, followed by fuse 5 a. Check connections of control panel. ...

Page 57

Fault code output 116 18.2. Programmable heater control the control panel gives out the fault message. Rectify the cause of the fault. To reset the fault, confirm message by pressing ok (if provided) or switch off the dual top for at least 5 seconds. If serious malfunctions such as overheating or fa...

Page 58

Fault code output 117 table 1: fault messages of programmable heater control message meaning remedy message 01 no data connection no communication between control panel and heater, or error control panel first, remove fuses 15 a and 5 a. Then put in fuse 15 a, followed by fuse 5 a. Check connections...

Page 59

Fault code output 118 message 14 failure cooling air ventilation overheating of heaters' control unit ensure that cooling air can flow freely, reset heater (by pressing ok or switching off for at least 5 sec.) message 15 failure combustion air motor combustion air motor interrupted ensure that cooli...

Page 60

Fault code output 119 note n/a = not available message 28 failure drain valve electrical drainage valve disconnection see message 20. Message 29 failure drain valve electrical drainage valve short circuit see message 20. Message 30 failure relay 230 v high or low power relay circuit interrupt- ed/sh...

Page 61

Validation and commissioning 120 19 validation and commissioning following completion of the installation and successful commissioning of the heater, the warranty card contained in the operating instructions must be filled out by the installation partner. Warranty card (see booklet operating instruc...

Page 62

Technical data 121 20 technical data except where limit values are specified, the technical data refer to the usual heater tolerances of ± 10 % at an ambient temperature of + 20 °c and at the rated voltage and in rated conditions. 20.1. Fuel for dual top the diesel according to din en 590 specified ...

Page 63

Technical data 122 20.2. Technical data heater operation dual top rha 100 dual top rha 101 dual top rha 102 type approval heater: emc: e1 00 0195 e1 03 5000 model air heater with evaporator burner air heater with evaporator burner and electric heating device heat output diesel electric control range...

Page 64

Technical data 123 overpressure valve 4.0 bar pressure water pump, central water supply maximum 2.5 bar heater dimensions length: 530 ± 2 mm width: 352 ± 1 mm height: 256 ± 1 mm weight (w/o water contents) 20 kg 21 kg heater operation dual top rha 100 dual top rha 101 dual top rha 102.

Page 66

Bei mehrsprachiger ausführung ist deutsch verbindlich. In multilingual versions the german language is binding. Nel caso di una versione plurilingue il tedesco è vincolante. Ident-n r. 9021215b • 01/11 • Ände rungen und irrtümer vorbehalten • gedruckt in deutschland • © w e basto ag, gcs 2011 webast...