- DL manuals

- Webasto

- Heater

- DUAL TOP RHA-100

- Workshop Manual

Webasto DUAL TOP RHA-100 Workshop Manual

Summary of DUAL TOP RHA-100

Page 1

Air heaters integrated heater 10/2009 9019782b 03/2003 workshop manual dual top rha-100 dual top rha-101/102.

Page 2

Improper installation or repair of webasto heating and cooling systems can cause fire or the leakage of deadly carbon monoxide leading to serious injury or death. To install and repair webasto heating and cooling systems you need to have completed a webasto training course and have the appropriate t...

Page 3

Dual top table of contents i table of contents 1 introduction .......................................................................................................................101 1.1 contents and purpose .............................................................................................

Page 4

Table of contents dual top ii 7 repair .................................................................................................................................701 7.1 general .......................................................................................................................

Page 5

Dual top 1 introduction 101 1 introduction 1.1 contents and purpose this workshop manual is designed to assist trained person- nel with repairing the dual top integrated heaters. 1.1.1 use of the integrated heaters the webasto dual top integrated air / water heaters are de- signed to heat and to pro...

Page 6

1 introduction dual top 102.

Page 7

Dual top 2 technical data 201 2 technical data except where limit values are specified, the technical data refer to the usual heater tolerances of ± 10 % at an ambient temperature of + 20 °c and at the rated voltage and in rated conditions. Fuel for dual top the diesel fuel specified by the manufact...

Page 8

2 technical data dual top 202 table 202: technical data rha 101/102 heater operation dual top rha 101 dual top rha 102 type approval heater: emc: e1 00 0195 e1 03 5000 e1 00 0195 e1 03 5000 model air heater with evaporator burner and electric heating device air heater with evaporator burner and elec...

Page 9

Dual top 3 fault code output 301 3 fault code output note this chapter describes the fault codes given out by the man- ual and programmable control panels. Replacement of parts, dismantling and assembly (e.G. For in- spection and cleaning) is described in chapter 7: "repair". 3.1 manual control pane...

Page 10

3 fault code output dual top 302 table 301: fault messages manual control panel number of red flashes meaning remedy 00 no communication between control panel and heater, or error control panel 1 first, remove fuses 15a and 5a. Then put in fuse 15a, followed by fuse 5a. 2 check connections of contro...

Page 11

Dual top 3 fault code output 303 note: n/a = not available 07 overheating or exceeding gradient hot air temperature sensor 1 ensure that hot air can flow freely, air intake and outlets are not blocked. Reset heater (by switching off for at least 5 sec.) 2 check fuel pump cable and connectors. 3 chec...

Page 12

3 fault code output dual top 304 3.2 programmable control panel fig. 303 programmable control panel the programable control panel can be used with all types dual top heaters. The heater is able to identify faults on individual components and during the operation. The control panel gives out the faul...

Page 13

Dual top 3 fault code output 305 message 08 failure heating air ventilator hot air motor fault: disconnection / short circuit / fan speed out of range / fan blocked 1 check power supply: fuse correct (fuse not damaged, 10a fuse used for pwm module) and functioning. All contacts are correct (no corro...

Page 14

3 fault code output dual top 306 message 17 failure control unit control unit (heater) fault / heater locked 1 put heater back into service (see above this table) and restart heater. 2 replace control unit. Message 18 failure cabin temperature sensor interior temperature sensor disconnection / short...

Page 15

Dual top 3 fault code output 307 note: n/a = not available message 34 system overheated or relay circuit disconnected one of the three overheating switches detects too high temperatures / overheating relay circuit interrupted rha 101/102: 1 check wiring harness relaybox to heater. 2 check the relay ...

Page 16

3 fault code output dual top 308 page for notes.

Page 17

Dual top 4 function tests 401 4 function tests 4.1 general this section describes the tests conducted on the heater when it is installed and not installed to verify that it is in working order. Warning the heater must not be operated in enclosed areas such as garages and workshops without an emissio...

Page 18

4 function tests dual top 402 4.2.1.4 air temperature switch the air temperature switch opens at 145 ± 5 °c. 4.2.1.5 water temperature switch the water temperature switch opens at 90 ± 5 °c. 4.2.1.6 overheating protector the overheating protector (temperature switch heat ex- changer) opens at 352 ± ...

Page 19

Dual top 5 circuit diagrams 501 5 circuit diagrams 5.1 general fig. 501 shows the heaters’ control unit. How the electrical connections are to be made: fig. 502 for rha 100, fig. 503 for rha 101/102. Electrical connections control panel: fig. 504 for manual version, fig. 505 for programmable version...

Page 20

5 circuit diagrams dual top 502 fig. 502 schematical electrical connection dual top rha 100 fig. 503 schematical electrical connection dual top rha 101/102 1 heater dual top 2 wiring harness 3 control panel 4 vehicle’s service battery 5 fuse 5 a 6 fuse 10 a 7 fuse 15 a 8 fuel pump 9 interior tempera...

Page 21

Dual top 5 circuit diagrams 503 fig. 504 electrical connections manual control panel fig. 505 electrical connections programmable control panel x0 (2 poles) of interior temperature sensor to control panel x2 is for: – webasto thermo test pc-diagnosis and – webasto telestart / thermo call (for option...

Page 22

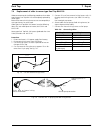

5 circuit diagrams dual top 504 fig. 506 wiring harness for dual top rha 100 (older type, heater ident. No. 9015314a and 9015314b) x3 x4 x0 1 3 4 6 7 to h eat ers’ cont rol unit pc-diagnosis t e lestart thermo c a ll.

Page 23

Dual top 5 circuit diagrams 505 fig. 507 external wiring harness for dual top rha 100 (newer type, heater ident. No. 9015314c) 1 3 4 5 6 7.

Page 24

5 circuit diagrams dual top 506 fig. 508 external wiring harness for dual top rha 101/102 x3 5 6 x5 x6 5 6 7 8 x0 x1 x1 x12 4 n o t in scope of de livery! 1 2 to x5 8 3 4 5 6 7 to 8.

Page 25

Dual top 5 circuit diagrams 507 fig. 509 internal wiring harness for dual top rha 100/101/102 y7 x3 gn rt b r rt/ b l ge/rt ge sw or sw/ws vi gn gn rt/ b l b r gr b r sw gr vi gn gn ge gr or gr vi or y11 y 8 y12 y9 y10 y6 y4 y5 y3 b r gn rt b r ge/rt ge gr gn sw/ws gn ge gr or 4 vehic le side vehic ...

Page 26

5 circuit diagrams dual top 508 5.2 legend for circuit diagram 1 wiring harness vehicle 2 wiring harness electric heater (not for rha 100) 3 vehicle’s service battery 4 fuse 15 a 5 fuse 10 a 6 fuse 5 a 7 interior temperature sensor 8 dashboard led (not for rha 100) item description comment x0 plug c...

Page 27

Dual top 6 servicing work 601 6 servicing work 6.1 general this section describes the servicing work that can be carried out on the heater when it is installed. Warning there is a potential danger of burns as the heater and its components may be very hot. 6.2 work on the heater disconnect the main p...

Page 28

6 servicing work dual top 602 6.7.1.2 installation see installation instructions. 6.7.2 control panel, removal and installation 6.7.2.1 manual version (for rha 100) 1. Disconnect the battery. 2. Remove control panel as shown (see fig. 601). 3. Disconnect the wiring harness plug x11. 4. Disconnect pl...

Page 29

Dual top 7 repair 701 7 repair 7.1 general this section describes the repair work that may be carried out on the dual top heater after it has been removed from the vehicle. Any further disassembly will void the warranty. Only use the spare parts from the appropriate spare parts kits for assembling t...

Page 30

7 repair dual top 702 remove foam gasket cooling shell and air intake grill. Loosen 8 screws t25 to remove end cap incl. Seal end cap boiler. Note loosen 2 screws t20 that hold metal plate (with air temper- ature sensor and air temperature switch) of sensor wiring harness to end cap. Loosen 2 screws...

Page 31

Dual top 7 repair 703 loosen 4 screws t30 on bottom of dual top. Push boiler incl. Insulation out of housing. Remove 2 parts insulation. Remove drain tube from air ventilation/overpressure valve, solenoid valve and cooling air outlet. Pull 2 plugs 1 pole out of solenoid valve. Remove insulation comb...

Page 32

7 repair dual top 704 use flat (-) screwdriver to push down ring of connector hot and cold water pipes and pull pipes up to remove them from boiler. In the same way, remove air ventilation/overpressure valve. Important avoid that screwdriver makes scratches on tubes. Scratches will cause leakage. Al...

Page 33

Dual top 7 repair 705 loosen 2 screws t10 that hold overheat switch to backside heat exchanger. Remove wires and cable fasteners from the ribs on the heat exchanger. Disconnect plug 2 poles of wiring overheating protector from internal wiring harness. For rha 101/102 only: disconnect 2 plugs x1 (2 p...

Page 34

7 repair dual top 706 disconnect 5 plugs of internal wiring harness from control unit. Loosen screw t20 that attaches brown wire to control unit. Remove internal wiring harness. Disconnect 2 remaining plugs 2 poles and loosen second screw t20 to remove control unit from thermo unit. Control unit: 1 ...

Page 35

Dual top 7 repair 707 loosen 2 screws t20 to remove clamping yoke from heat exchanger. Press grommet of wire glowplug inwards and guide plug through hole heat exchanger. Press grommet of fuel line inwards. Remove evaporator housing assy with fuel line and glow- plug from heat echanger. Pull holding ...

Page 36

7 repair dual top 708 7.3 assembling align straight sides of burner tube assy and metal crimp sealing with bottom of heat exchanger. Fix with 2 screws t20. Note position screws see drawing. Note gaskets must always be renewed. Guide glowplug into evaporator housing assy and fix with holding spring. ...

Page 37

Dual top 7 repair 709 attach flat gasket heat exchanger and drive assy to heat ex- changer and fix with 8 screws t20. Note align 2 holes in gasket with protrusions on the heat ex- changer. Put gasket cooling shell on the heat exchanger. Note align 2 holes in gasket with protrusions on the heat ex- c...

Page 38

7 repair dual top 710 put gasket exhaust on exhaust and cooling air outlet. For rha 101/102 only: slide electrical element from backside into the heat ex- changer. Note correct position of the electrical element. Fix tubular heaters to heat exchanger with holding plate coil and screw t10. Connect 2 ...

Page 39

Dual top 7 repair 711 connect plug 8 poles of sensor wiring harness to internal wiring harness. Put pink coloured silicon pad on 2 threaded studs m4 at backside boiler and fix water temperature switch and water temperature sensor of sensor wiring harness with hex nut sw 7mm. Note renew pink coloured...

Page 40

7 repair dual top 712 attach self-adhesive insulation combi-valve (top) and sole- noid valve (bottom). Note make sure that it’s possible to connect drain tube and wir- ing to valves. Connect 2 plugs 1 pole with solenoid valve. Use 2 parallel poles of valve. Doesn’t matter which wire colour is connec...

Page 41

Dual top 7 repair 713 connect plug 4 poles of internal wiring harness to pwm module. Attach heating air blower assy to housing dual top with 2 screws t30. Note – do not tighten screws yet! – make sure that wires don’t touch rotating parts. Fix hold metal plate (with air temperature sensor and air te...

Page 42

7 repair dual top 714 place foam gasket cooling shell and air intake fence. Push spout water expiration into service cap. Service cap shall fit into groove of spout. Guide connectors water pipes through spout. Fix service cap to dual top with 8 screws t25. Tightening torque: 6 nm. Note service cap s...

Page 43

Dual top 7 repair 715 7.4 replacement of older to newer type dual top rha 100 webasto recommends the following procedure when older types heaters dual top rha 100 are completely replaced by newer types. Because the external wiring harnesses are not compatible, a new type harness has to be used. Olde...

Page 44

7 repair dual top 716 page for notes.

Page 45

Dual top 8 packaging, storage and shipping 801 8 packaging, storage and shipping 8.1 general if the heater or its components are sent to webasto ag for testing or repair, it must be cleaned and packed in such a way that it is protected against damage during handling, transport and storage. An ambien...

Page 46

8 packaging, storage and shipping dual top 802 page for notes.

Page 48

Webasto ag kraillinger strasse 5 82131 stockdorf germany http://dealers.Webasto.Com http://www.Webasto.Com subject to modification © 2009 all rights reserved ident .- n r. 9 019 78 2b.