- DL manuals

- Webasto

- Water Heater

- Thermo 90

- Workshop Manual

Webasto Thermo 90 Workshop Manual

Summary of Thermo 90

Page 1

Water heaters 09/2001 workshop manual thermo 90 thermo 90-trs (transport of hazardous goods) thermo 90 s thermo 90 s-trs (transport of hazardous goods) type bw 80 (fuel) type dw 80 (diesel).

Page 2

Thermo 90 list of contents i list of contents 1 introduction 1.1 scope and purpose ............................................................................................................................... 101 1.2 meaning of warnings, cautions, and notes ...........................................

Page 3

List of contents thermo 90 ii 6 functional tests 6.1 general ................................................................................................................................................. 601 6.2 adjustments ............................................................................

Page 4

Thermo 90 list of contents iii 9 repair 9.1 general .................................................................................................................................................. 901 9.1.1 work on components after disassembly .........................................................

Page 5

List of figures thermo 90 iv list of figures 301 functional sequence ................................................................................................................................. 302 501 general failure symptoms .......................................................................

Page 6

Thermo 90 1 introduction 101 1 introduction 1.1 scope and purpose this repair shop manual is intended to support familiarised personnel in the repair of thermo 90 and thermo 90 s for the diesel and fuel type. The water heater may only be operated with the specified fuel (diesel or also fuel oil el) ...

Page 7

1 introduction 102 for the installation of the thermo 90-trs or thermo 90 s-trs in vehicles used for the transportation of dangerous goods, in addition to the stvzo, the requirements in trs 002 and trs 003 (technical guidelines for the transportation of dangerous goods on roads) must be met. The hea...

Page 8

Thermo 90 1 introduction 103 • installation instructions for webasto fuel tanks for the fuel supply of water heaters in vehicles: in busses the installation is not permitted in the passengers or driver's compartment. • the fuel filler neck must not be located in the passengers or driver's compartmen...

Page 9

1 introduction 104 page free for notes.

Page 10

Thermo 90 2 general description 201 2 general description the water heater webasto thermo 90 and thermo 90 s in combination with the vehicle's own heating system is used to: – heat the cabin – defrost the windshields – preheat water-cooled engines. The water heater operates independent from the vehi...

Page 11

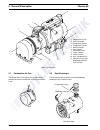

2 general description thermo 90 202 heater thermo 90 s 2.1 combustion air fan the combustion air fan delivers the air required for combustion from the combustion air inlet to the burner insert. 2.2 heat exchanger the heat exchanger dissipates the heat provided by combustion to the coolant circuit. H...

Page 12

Thermo 90 2 general description 203 2.3 temperature sensor the temperature sensor senses the coolant temperature in the heat exchanger of the heater unit as electrical resistance. This signal is fed to the control unit for processing. 2.4 temperature limiter the overheat protection (bimetal) protect...

Page 13

2 general description thermo 90 204 page free for notes.

Page 14

Thermo 90 3 functional description 301 3 functional description (fig. 301) 3.1 switch-on when operating the push button "immediate heating", the "operating indicator" on the timer illuminates or by activation with the switch, the operating indicator integrated in the switch illuminates. Circulation ...

Page 15

3 functional description thermo 90 302 3.4 switch-off when switching the heater off, the operation indicator on the timer/switch extinguishes. Combustion ends and run-down is initiated. Circulation pump and combustion air fan, however, continue operation to cool down the heater (run-down) and are au...

Page 16

Thermo 90 3 functional description 303 g vehicle blower setting of control temperatures thermo 90 on the standard wiring harness b6 is not in use. Note the selected control idle temperature of the heater should be below the opening temperature of the cooler thermostat! Setting of control temperature...

Page 17

3 functional description thermo 90 304 3.6.3 diagnosis after switch-off upon failure (thermo 90 s) when equipped with a standard timer an error will cause an output to the timer display: f 01 no start (after 2 start attempts) f 02 flame-out during operation (repeated > 5) f 03 voltage too low or too...

Page 18

Thermo 90 3 functional description 305 page free for notes.

Page 19

Thermo 90 4 technical data 401 4 technical data as long as no threshold values are given, the following technical data are understood to include tolerances of ±10% usual for heaters at an ambient temperature of +20° c and at nominal voltage and conditions. Electrical components: control unit, combus...

Page 20

4 technical data thermo 90 402 page free for notes.

Page 21

Thermo 90 5 troubleshooting 501 5 troubleshooting 5.1 general this section describes troubleshooting procedures for the water heater thermo 90 and thermo 90 s. Caution troubleshooting requires profound knowledge about structure and theory of operation of heater components and may only be performed b...

Page 22

5 troubleshooting thermo 90 502 5.3 failure symptoms after switch-off upon failure note when operated with a switch the type of failure is indicated by a flash code of the operation indicator light during heater run-down. After five short signals the long flash pulses are counted. The heater thermo ...

Page 23

Thermo 90 5 troubleshooting 503 fig. 502 failure symptoms after switch-off upon failure (sheet 2 of 2) 5.4 visual inspection for assessment of burner condition burner and evaporator have specific features indicating their need for replacement or their serviceable condition. The following describes t...

Page 24

5 troubleshooting thermo 90 504 5.4.2 rear wall with metal evaporator • the pilot flame exit bore (fig. 504) must not be clogged, otherwise there will be no start. Remedy replace burner • cracks, delaminations, as well as black or other discolorations of the evaporator do not cause a burner failure ...

Page 25

Thermo 90 6 functional tests 601 6 functional tests 6.1 general this section describes the on-vehicle and off-vehicle testing of the heater to check its proper operation. Warning the heater shall not be operated in enclosed areas like garages or workshops not provided with exhaust venting facilities...

Page 26

6 functional tests thermo 90 602 page free for notes.

Page 27

Thermo 90 7 circuit diagrams 701 7 circuit diagrams 7.1 general the circuit diagrams (figs. 702 and 703) show possible circuits of the heater thermo 90 with – 3-times-clock – trs equipment the circuit diagrams (figs. 704 through 706) show possible circuits of the heater thermo 90 s with – standard t...

Page 28

7 circuit diagrams thermo 90 702 fig. 702 circuit diagram automatic control for thermo 90, 12 and 24 v with triple timer ϑ ϑ bl br ge gn gr or rt sw vi ws wire colors blue brown yellow green gray orange red black violet white wire gauges 7.5 - 15 m 0.75 mm 2 1.0 mm 2 1.5 mm 2 2.5 mm 2 4.0 mm 2 1.5 m...

Page 29

Thermo 90 7 circuit diagrams 703 fig. 703 circuit diagram automatic control thermo 90-trs, 24 v ϑ ϑ for fuel heaters remove this connection temperature coding (temperature at water outlet): see table page 302 switch s6 must be installed so that plus or minus potential is applied to the relevant cont...

Page 30

7 circuit diagrams thermo 90 704 fig. 704 circuit diagram automatic control for thermo 90 s, 12 and 24 v with standard timer ϑ ϑ temperature coding (temperature at water outlet): see table page 302 timer p2: with plus at connection 10 = permanent operation in instant heating without plus at connecti...

Page 31

Thermo 90 7 circuit diagrams 705 fig. 705 circuit diagram automatic control for thermo 90 s-trs, 24 v ϑ ϑ temperature coding (temperature at water outlet): see table page 302 2 bl br ge gn gr or rt sw vi ws wire colors blue brown yellow green gray orange red black violet white wire gauges 7.5 - 15 m...

Page 32

7 circuit diagrams thermo 90 706 fig. 706 circuit diagram automatic control for thermo 90 s-trs, 24 v without auxiliary drive ϑ ϑ temperature coding (temperature at water outlet): see table page 302 2 bl br ge gn gr or rt sw vi ws wire colors blue brown yellow green gray orange red black violet whit...

Page 33

Thermo 90 8 servicing 801 8 servicing 8.1 general this section describes the servicing procedures that may be performed with the heater installed. 8.2 work on the heater prior to performing any work, it is mandatory to disconnect the vehicle battery main lead. As long as the heater is in operation o...

Page 34

8 servicing thermo 90 802 8.4 heater test run warning the heater must not be operated, not even with timer, in enclosed areas like garages or workshops not equipped with an exhaust venting facility. 8.5 servicing before or after each heating season the following servicing should be performed to main...

Page 35

Thermo 90 8 servicing 803 note manufacturer mounts control unit of heaters thermo 90 s to combustion air fan. With check valve and thermostat without check valve 1 heat exchanger, vehicle heating system 2 blower switch vehicle heating system 3 relay for vehicle blower 4 timer 5 fuse box in vehicle 6...

Page 36

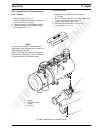

8 servicing thermo 90 804 fig. 801 example for heater installation in lorry 8.6 visual inspections and installation regulations 8.6.1 connection to the vehicle's cooling system in thermostat circuits only thermostats opening at are to be used. The installation of the heater should be in a location a...

Page 37

Thermo 90 8 servicing 805 8.6.2.1 fuel tapping fuel tapping must be from the fuel reservoir or from a separate tank (figs. 803, 804, and 805). This separate fuel tapping avoids an influence on the pressure. Fig. 803 webasto fuel tank tap * use fuel tank tap only on metal fuel tanks fig. 804 fuel tap...

Page 38

8 servicing thermo 90 806 the fuel tap should not be located in the engine compartment because the radiation of engine heat may cause gas bubbles to build up in the fuel lines causing malfunctions in the combustion operation. When installing the heater in vehicles with fuel injection system the fuel...

Page 39

Thermo 90 8 servicing 807 8.6.3.1 installation location it is advantageous to mount the dosing pump in a cool location as near as possible to the tank. The ambient temperature must never exceed +20° c for fuel and +40° c for diesel operated installations at any time while in operation. The maximum p...

Page 40

8 servicing thermo 90 808 8.7 removal and installation caution in installed condition, only the following removal and disassembly procedures are allowed as long as the top cover is accessible for removal and sufficient space for removal is available: – replacement of circulation pump – replacement o...

Page 41

Thermo 90 8 servicing 809 page free for notes.

Page 42

Thermo 90 9 repair 901 9 repair 9.1 general this section describes the repairs that may be performed on the heater thermo 90 when removed. Any further disassembly will void the warranty. For re-assembly only webasto-authorised spare parts kits are to be used. 9.1.1 work on components afterdisassembl...

Page 43

9 repair thermo 90 902 9.2 disassembly and assembly 9.2.1 electrical connections (fig. 901) 9.2.1.1 disconnecting electrical connections (connection x1) note all electrical connections are joined in the connector. Prior to removal of a component, the relevant electrical connections first have to be ...

Page 44

Thermo 90 9 repair 903 9.2.2 replacement of circulation pump 9.2.2.1 removal 1. Remove heater (see 8.7.1.1). 2. Disconnect electrical connections (see 9.2.1.1). 3. Remove screws (4, fig. 902). 4. Remove clamp (3) and circulation pump (2). 5. Perform procedures on components after disassembly (see 9....

Page 45

9 repair thermo 90 904 9.2.3 replacement of temperature limiter 9.2.3.1 removal note perform the following procedure only when the tempera- ture limiter needs replacement. A functional check has to be performed when the temper- ature limiter is installed. 1. Remove heater (see 8.7.1.1). 2. Disconnec...

Page 46

Thermo 90 9 repair 905 fig. 903 replacement of temperature limiter and temperature sensor thermo 90 6 5 1 2 3 4 1 protective cap 2 clamp 3 temperature limiter 4 heat exchanger 5 o-ring 6 temperature sensor note one of the newer models thermo 90 shown. Older models have the cable of the temperature l...

Page 47

9 repair thermo 90 906 9.2.5 replacement of combustion air fan 9.2.5.1 removal 1. Remove heater (see 8.7.1.1). 2. Disconnect electrical connections (see 9.2.1.1). 3. Remove screws (2, fig. 904). 4. Pull combustion air fan (1) from burner head (4) and remove together with profiled packing ring (3). N...

Page 48

Thermo 90 9 repair 907 9.2.6 replacement of burner, flame sensor, and glow plug 9.2.6.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove combustion air fan (see 9.2.5.1). 3. Remove screw (5, fig. 905) and washer (4). 4. Remove nuts (10) and withdraw bracket. 5. Withdraw grommets (11 and 12) from sl...

Page 49

9 repair thermo 90 908 fig. 905 replacement of burner, flame sensor, and glow plug thermo 90 1 burner 2 swirl ring 3 burner head 4 washer 5 screw 6 glow plug 7 flame sensor 8 bracket 9 insulation 10 nut (2) 11 grommet 12 grommet 13 grommet note one of the newer models thermo 90 shown. Older models h...

Page 50

Thermo 90 9 repair 909 9.2.7 replacement of burner head 9.2.7.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove combustion air fan (see 9.2.5.1). 3. Remove burner, flame sensor, and glow plug (see 9.2.6.1). 4. Remove attachment screw of v-clamp (2, fig. 906) and pull off clamp. 5. Withdraw burner ...

Page 51

9 repair thermo 90 910 9.2.8 replacement of heat exchanger 9.2.8.1 removal 1. Remove heater (see 8.7.1.1). 2. Remove circulation pump (see 9.2.2.1). 3. Remove temperature limiter (see 9.2.3.1). 4. Remove temperature sensor (see 9.2.4.1). 5. Remove combustion air fan (see 9.2.5.1). 6. Remove burner, ...

Page 52

Thermo 90 10 packaging/storage and shipping 1001 10 packaging/storage and shipping 10.1 general the heater and its components shipped to webasto thermosysteme gmbh for inspection or repair are to be cleaned and packaged so that they are protected against damage during handling, transportation, and s...

Page 53

10 packaging/storage and shipping thermo 90 1002 page free for notes.