- DL manuals

- Wood Stone

- Oven

- BISTRO 3030

- Installation And Operation Manual

Wood Stone BISTRO 3030 Installation And Operation Manual

Installation and

Operation Manual

Revised August 2010

Wood Stone Corporation

1801 W. Bakerview Rd.

Bellingham, WA 98226 USA

Tel (360) 650-1111

Fax (360) 650-1166

www.woodstone-corp.com

BiStro SerieS

Gas-Fired Stone Hearth Oven

BiStro 3030

WS-BL-3030-RFG-CE

BiStro 4343

WS-BL-4343-RFG-CE, WS-BL-4343-RFG-W-CE

BiStro 4355

WS-BL-4355-RFG-CE, WS-BL-4355-RFG-W-CE

CUStoM ModeLS

WS-CS-REC-11-RFG-CE

Commercial European Models

Summary of BISTRO 3030

Page 1

Installation and operation manual revised august 2010 wood stone corporation 1801 w. Bakerview rd. Bellingham, wa 98226 usa tel (360) 650-1111 fax (360) 650-1166 www.Woodstone-corp.Com bistro series gas-fired stone hearth oven bistro 3030 ws-bl-3030-rfg-ce bistro 4343 ws-bl-4343-rfg-ce, ws-bl-4343-r...

Page 2

This page intentionally left blank >.

Page 3

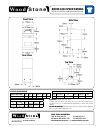

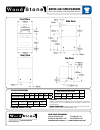

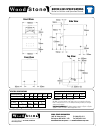

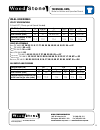

3 an ongoing program of product improvement may require us to change specifications without notice. Bl-rfg-ce, bl-rfg-w-ce revised august 2010 wood stone corporation 1801 w. Bakerview rd. Bellingham, wa 98226 usa tel (360) 650-1111 fax (360) 650-1166 info@woodstone-corp.Com or visit www.Woodstone-co...

Page 4

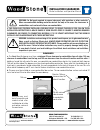

This appliance is for professional use by qualified personnel. This appliance must be installed by qualified persons in accordance with the regulations in force. This appliance must be installed with sufficient ventilation to prevent the occurrence of unacceptable concentrations of substances harmfu...

Page 8

A. The wood stone bistro oven must have a minimum 25 mm clearance to combustibles from all sides, 155 mm clearance to combustibles from the top, and 155 mm clearance from the exhaust transition and flue collar . If building a facade that will contact the oven, use completely non-combustible material...

Page 9

1. Use a forklift or other suitable lifting means to set the oven body onto blocks as shown. If the oven has the optional decorative logset, remove it before tipping the oven. 2. Install the side pieces of the tipping assembly. 3. Bolt the side piece to the oven as shown, and attach the cross-piece ...

Page 10

4. Using an appropriate hoist or lift, the oven may now be tilted (on its back) onto a pallet jack or suitable dolly. The oven can now be moved through a narrow doorway etc. Danger: never attempt to move the oven in this manner on any type of incline or sloped floor. Continue to the exploded diagram...

Page 11

Exhaust oven stand (6 pieces) oven body control module flame guard mantle burner tray front panel toe kick rear panel shipping panel (only on ovens shipped disassembled, discard once removed.) all parts shown above and provided with the oven (except the shipping panel) must be installed to ensure th...

Page 12

Use the 3/8" x 1"(9.5 mm x 25 mm) carriage bolts to assemble the stand on a level surface. Be sure to use the washers provided and to tighten nuts and bolts securely. Follow these instructions to assemble the oven. 1. 2. On 3030 models only: use 3/8"x 3/4"(9.5 mm x 19 mm) long carriage bolts as show...

Page 13

3. Using a forklift, carefully lower the body of the oven on to the stand so that the bolt holes line up. While supporting the oven with the lift, install the 3/8" x 1"(9.5 mm x 25mm) carriage bolts. Use the washers provided and tighten all nuts securely. Be sure to use the forklift pockets when lif...

Page 14

6. Attach the control box to the oven using 4) 1/4- 20 (6.35mm diameter) screws. The control box should be oriented so the knob is on the left side of the control box. 5. Remove the shipping panel from beneath the oven. The shipping panel is secured with 2 screws in the front, and 2 screws in the ba...

Page 15

7. Connect burner assembly components and thermocouple at the rear of the control box. Plug in thermocouple wire here. Remove the lower control box cover. Route the igniter wire through this hole and plug it into the terminal marked 'spark' on the ignition module. Attach flexible pilot tube here. Ti...

Page 16

16 spacer washers stainless steel washer stainless steel cap nut 9. Install the mantle. Install the 3 threaded studs into the clips on the front of the oven. Slide 2 spacer washers over each stud. Slide the mantle over the studs, then slip a stainless steel washer onto each stud. Install and tighten...

Page 17

17 11. Reinstall the burner guard, and optional logset if supplied. The lower tab of the guard fits into the front of the burner opening. The logset pieces fit onto the studs on the burner guard, behind the opening in the guard, so the logs sit at the rear of the burner opening. If the oven has been...

Page 19

Scope of approvals i 2h(20) for use in at , dk , es , fi , ie , it , pt , gb , se , ch , gr , ee , lv , si , cr , sk and cz i 2e(20) for use in: de and pl i 2l(25) for use in: nl and hu i 2ell(20) for use in: de i 3+(28-30/37/50) for use in: be , es , fr , ie , it , pt, gb , cr , gr , ch and cy i 3b...

Page 20

20 important: it is the responsibility of the installer to determine the best location for electrical and gas service to enter the stand enclosure of the oven, and to create the necessary aperture(s) for this entry. Gas and electrical routing to this appliance should be provided in a manner consiste...

Page 21

21 bistro models 4343/4355: 254 mm o.D. Duct collar bistro model 3030: 203 mm o.D. Duct collar wood stone ovens should be vented in accordance with pertinent national, regional and local codes concerning such appliances; check venting plans with the authority having jurisdiction before proceeding wi...

Page 22

First day 1. Make sure main gas supply is on (and has been purged), and that the individual shutoff valve (supplied by others ) is in the "flow" position. 2. Push i/o button on controller. It may take a while for the gas to purge all the air from the gas lines. 3. When the radiant flame ignites, mak...

Page 23

Detailed daily oven operation important: if at any time you feel that the burner is not operating properly, turn the oven off and call for service. Before servicing, disconnect the electrical supply at the breaker and turn off the gas supply at the appliance’s individual gas shutoff valve. In the ev...

Page 24

Gas fired models with a '-w' in the model number, ( ws-bl-4343-rfg-w and ws-bl-4355-rfg-w ) may burn up to 1.4 kg of wood per hour when properly vented as a solid fuel appliance. Build the fire on the side of the oven, 6-10 inches (150-250 mm) away from the doorway of the oven or use a smoker tray. ...

Page 25

Oven interior wood stone recommends the use of a long-handled, brass bristled or natural fiber brush for sweeping aside excess food particles that will accumulate on the floor of the oven during use. The oven floor can be cleaned with a damp rag. There is a stainless steel burner guard to prevent fo...

Page 26

O i f c power: press this button to turn the unit on or off. Temperature scale: press and hold this button to switch between celsius and fahrenheit. Temperature readout: when the power is on, the hearth temperature is displayed in this window. 26 an ongoing program of product improvement may require...

Page 27

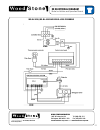

Ws-bl-3030, ws-bl-4343 and ws-bl-4355 ce models 230 vac 50/60 hz (wired by others) 27 an ongoing program of product improvement may require us to change specifications without notice. Bl-rfg-ce, bl-rfg-w-ce revised august 2010 wood stone corporation 1801 w. Bakerview rd. Bellingham, wa 98226 usa tel...

Page 28

Solution controller will not turn on 1. Incoming power to oven turned off. Check circuit breaker for circuit supplying the oven. Check that any wall switches external to the oven that control oven power are turned on. Check that any interlocks external to the oven are turned on. 2. Check for blown f...

Page 29

Exclusions the warranties provided by wood stone do not apply in the following instances: 1. In the event that the equipment is improperly installed. Proper installation is the responsibility of the installer; proper installation procedures are prescribed by the wood stone installation manual. 2. In...