- DL manuals

- Worcester

- Boiler

- 12/18

- Installation, Commissioning And Servicing Instruction Manual

Worcester 12/18 Installation, Commissioning And Servicing Instruction Manual

UK

Installation, Commissioning and Servicing instruction manual

Floor Standing oil-fired Condensing Boiler using Room Sealed Flue

Greenstar Danesmoor External Regular

ErP

& External System

ErP

12/18, 18/25 & 25/32

6720809437-00.1W

o

For fully pumped open vent or sealed central heating systems and domestic hot water cylinders.

These appliances are for use with Kerosene (Class C2) only.

6 72

0 813 288 (2014/09)

Summary of 12/18

Page 1

Uk installation, commissioning and servicing instruction manual floor standing oil-fired condensing boiler using room sealed flue greenstar danesmoor external regular erp & external system erp 12/18, 18/25 & 25/32 6720809437-00.1w o for fully pumped open vent or sealed central heating systems and do...

Page 2

Contents greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 2 contents 1 key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 3 1.1 key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.2 general safety instructio...

Page 3

Key to symbols and safety instructions greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 3 1 key to symbols and safety instructions 1.1 key to symbols warnings the following keywords are defined and can be used in this document: • notice indicates a situation that co...

Page 4

Installation regulations greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 4 the combustion air must be kept clear of chemically aggressive substances which can corrode the appliance and invalidate any warranty. Handling instructions and guidelines it is advised that...

Page 5

Installation regulations greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 5 bs 7291: thermoplastic pipes and associated fittings for hot and cold water for domestic purposes and heating installations in buildings. Bs 7074: part 1: application, selection and installa...

Page 6

Appliance information greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 6 3 appliance information 3.1 general information standard package: a - floor standing oil fired condensing boiler b - literature pack: • greenstar danesmoor external installation, commissioning ...

Page 7

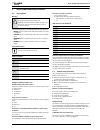

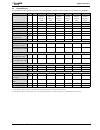

Appliance information greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 7 3.3 energy efficiency the following product data satisfy the requirements of the eu regulations no. 811/2013 and no. 812/2013 supplementing directive 2010/30/eu. Product data symbol unit 773160...

Page 8

Appliance information greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 8 3.4 layout and components - 18/25 regular appliance shown fig. 2 18/25 appliance shown figure 2 does not include the top, front, and right hand side panel. 1 control box assembly 18 primary hea...

Page 9

Appliance information greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 9 3.5 layout and components - 12/18 system appliance shown fig. 3 exploded system appliance view 1 control box assembly 24 primary heat exchanger drain 2 demand indicator 25 burner air intake - c...

Page 10

Pre-installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 10 4 pre-installation 4.1 cleaning primary systems 4.1.1 before cleaning the system: ▶ ensure that the system and pipe work is in good working order. ▶ where possible keep the existing appliance/circu...

Page 11

Pre-installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 11 4.2 mains supply 4.2.1 electrical supply • supply: 230v - 50 hz • cable: pvc insulated 0.75 mm2 (24 x 0.2mm) temperature rated to 90°c. • circuit breaker incorporating earth leakage protection. • e...

Page 12

Pre-installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 12 4.3.3 single pipe suction lift with de-aerator: maximum suction height 3.5 metres. The oil tank [1] must be positioned below the oil pump [9]. Create an inlet and return loop between the de- aerato...

Page 13

Pre-installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 13 open vent primary system (regular only) • the open vent pipe [f] and feed and expansion pipe [h must rise continuously from the appliance. • the feed and expansion cistern [e] must be positioned to...

Page 14

Pre-installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 14 filling primary sealed systems • where the system volume is more than 180 litres at 0.5 bar or exceeds 2.65 bar at maximum heating temperature an extra expansion vessel [b] figure 10 must be fitted...

Page 15

Pre-installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 15 fitting an external air break • refer to figure 13 when a rain water down pipe is used to dispose of condensate. • an air break must be installed in the 43mm pipe work, between the boiler condensat...

Page 16

Pre-installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 16 4.6 pressure relief pipework • the pressure relief discharge pipe [2]should be at least 15 mm diameter copper pipe and run downwards away from the boiler and discharge away from any electrical or o...

Page 17

Pre-installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 17 4.8 flue terminal positions fig. 21 external boiler flue terminal positions 1. An opening means an openable element, such as an openable window, or a permanent opening such as a permanently open ai...

Page 18

Pre-installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 18 4.9 flue options 4.9.1 cabinet mounted balanced horizontal flue options • the horizontal flue is fitted to the rear or either side of the cabinet. Fig. 22 flue options 4.9.2 plume management fittin...

Page 19

Installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 19 5 installation 5.1 unpacking the boiler unpacking it is advised that at least two or more persons are involved in the transfer of the packaged boiler from the van to the point of delivery. 1. Once the ...

Page 20

Installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 20 safety all relevant safety precautions must be undertaken. Protective clothing, footwear, gloves and safety goggles must be worn as appropriate. Pipework connections - regular • flow connections (optio...

Page 21

Installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 21 5.5 combustion chamber (18/25 regular shown) ▶ unscrew screws and remove flue manifold access cover [5]. ▶ check that all the baffles [2] and baffle retainer [3] are correctly fitted to the secondary h...

Page 22

Installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 22 water connections ▶ remove the transit bungs from the pipework connections on e boiler. ▶ ensure all of the pipework is clean. ▶ align the water pipework and connect. ▶ check that all the unused socket...

Page 23

Installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 23 5.7 oil burner and pump oil burner fig. 33 nozzle access ▶ check that the nozzle [1] and the electrode [2] alignment settings are correct as shown in figure 34. ▶ ensure that the nozzle [1] is aligned ...

Page 24

Installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 24 access to 230v connections ▶ remove the four cover panel retaining screws [2] from the control box [1]. ▶ release screws [4] from cable clamp [7]. ▶ pull inner clamp part [6] outwards. ▶ feed sufficien...

Page 25

Installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 25 regular appliance electrical connections. Fig. 38 regular wiring diagram key to components: [1] remote junction box (10 way). [2] high limit thermostat [3] frost thermostat [4] earth stud [5] terminal ...

Page 26

Installation greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 26 system appliance electrical connections. Fig. 39 system wiring diagram key to components: [1] remote junction box (10 way). [2] high limit thermostat [3] frost thermostat [4] earth stud [5] terminal co...

Page 27

Commissioning greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 27 6 commissioning 6.1 pre-commissioning checks - 18/25 regular shown ▶ check that the service and water pipes are connected correctly. ▶ check that all unused sockets are capped. ▶ check that the oil su...

Page 28

Commissioning greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 28 inhibitor (central heating) ▶ check drain cocks are closed and all radiator valves are open before adding a suitable inhibitor compatible with aluminium (or combined inhibitor/anti-freeze if the syste...

Page 29

Commissioning greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 29 double pipe sub-gravity feed system and single pipe suction lift with de-aerator: refer to figure 44. ▶ prime the oil supply pipework to prevent oil pump damage. ▶ to prime a de-aerator [2], disconnec...

Page 30

Commissioning greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 30 ▶ adjust the air shutter [3] figure 48 and pump pressure [2] figure 47 as shown in the table 8 on page 31. The burner should ignite following a pre-ignition period of approximately 15 seconds. ▶ if ch...

Page 31

Commissioning greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 31 ▶ turn off the electrical supply. ▶ isolate the oil supply to the burner. ▶ remove the oil pressure gauge. ▶ refit the blanking plug [4] figure 51. ▶ check and rectify any oil leaks. ▶ switch on the o...

Page 32

Commissioning greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 32 6.5 finishing commissioning ▶ refit the top panel [2] and press down to compress the seal when fitting the securing screws [1]. ▶ push the front panel [4] up behind the top panel and push in at the ba...

Page 33

Service and spares greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 33 7 service and spares 7.1 inspection and service - 18/25 regular shown routine servicing to maintain efficient boiler operation, the following should be carried out at least once a year, carry out...

Page 34

Service and spares greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 34 7.2 clean the appliance 7.2.1 accessing the flue manifold and secondary heat exchanger flue manifold access and secondary heat exchanger: refer to figure 56 ▶ remove flue manifold access cover[1]...

Page 35

Service and spares greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 35 7.2.4 condensate system ▶ check the discharge pipe for leaks or damage. Condensate trap removal. ▶ release the pipe locking tab [2] and lift connector [1] and flexible pipe away from the trap [4]...

Page 36

Service and spares greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 36 ▶ remove the nozzle [3]. ▶ check the nozzle holder is clear or any debris and clean if necessary. ▶ fit a new oil atomising nozzle [3]. Fig. 64 nozzle replacement ▶ check the electrodes [2] and r...

Page 37

Service and spares greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 37 ▶ plug burner lead [1] into control box. ▶ slide the burner into position in the heat exchanger and secure with the retaining nut [2] on top of the burner. ▶ reposition the flexible air supply tu...

Page 38

Service and spares greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 38 7.3 short parts list 12/18 7.4 short parts list 18/25 cleaning tool 8 716 109 428 0 service lead 7 716 192 760 cabinet key 8 716 114 013 0 oil nozzle (12kw) 0.35 80° sr 8 716 112 628 0 oil nozzle...

Page 39

Service and spares greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 39 7.5 short parts list 25/32 cleaning tool 8 716 109 428 0 service lead 7 716 192 760 cabinet key 8 716 114 013 0 oil nozzle (25 & 28.5kw) 0.75 80° es 8 716 109 387 0 oil nozzle (32kw) 0.85 80° eh ...

Page 40

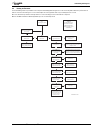

Fault finding and diagnosis greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 40 8 fault finding and diagnosis 8.1 burner functions these fault finding charts are provided to assist competent and suitably qualified engineers to locate and rectify faults. Whilst every...

Page 41

Fault finding and diagnosis greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 41 8.2 heating and hot water these fault finding charts are provided to assist competent and suitably qualified engineers to locate and rectify faults. Whilst every effort has been taken to...

Page 42

Fault finding and diagnosis greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 42 8.3 boiler function these fault finding charts are provided to assist com- petent and suitably qualified engineers to locate and rectify faults. Whilst every effort has been taken to ens...

Page 43

Fault finding and diagnosis greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 43 8.4 logic for the 535 se/ld rdb control box.

Page 44

Fault finding and diagnosis greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 44 8.5 oil supply vacuum testing a vacuum gauge can be attached to the oil pump vacuum test port [1] and the boiler operated to check the vacuum readings. Oil pumps can operate if readings ...

Page 45

Greenstar danesmoor external erp and external system erp - 6 720 813 288 (2014/09) 45 notes.

Page 46

Oil boiler commissioning checklist this commissioning checklist is to be completed in full by the competent person who commissioned the boiler as a means of demonstrating compliance with the appropriate building regulations and then handed to the customer to keep for future reference. Boiler make an...

Page 47

Service interval record it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service interval record below, please ensure you have carried out the service as described in the...

Page 48

Worcester, bosch group cotswold way, warndon, worcester wr4 9sw. Tel. 0330 123 9559 worcester, bosch group is a brand name of bosch thermotechnology ltd. Worcester-bosch.Co.Uk 6 720 813 288 (2014/09) worcester, bosch group: technical support: 0330 123 3366 appointments: 0330 123 9339 spares: 0330 12...