- DL manuals

- Worcester

- Boiler

- 12/18

- Instruction Manual

Worcester 12/18 Instruction Manual

INSTRUCTION MANUAL

INSTALLATION COMMISSIONING

& SERVICING

GB

GREENSTAR CAMRAY UTILITY & UTILITY SYSTEM

12/18, 18/25, 25/32

FLOOR STANDING OIL FIRED CONDENSING BOILER

CONVENTIONAL FLUE & ROOM SEALED FLUE

FOR FULLY PUMPED OPEN VENT OR SEALED CENTRAL HEATING SYSTEMS AND DOMESTIC

HOT WATER CYLINDERS

THE APPLIANCE IS FOR USE WITH 28 SECOND KEROSENE

ONLY

INSTRUCTION MANUAL

GB

THE APPLIANCE IS FOR USE WITH 28 SECOND KEROSENE

ONLY

Summary of 12/18

Page 1

Instruction manual installation commissioning & servicing gb greenstar camray utility & utility system 12/18, 18/25, 25/32 floor standing oil fired condensing boiler conventional flue & room sealed flue for fully pumped open vent or sealed central heating systems and domestic hot water cylinders the...

Page 2: Check List

Installation & servicing instructions installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 1 symbols used in this manual: domestic hot water central heating installation & servicing instructions electricity supply important handling in...

Page 3

Safety & regulations important information and symbols 1 safety precautions and installation regulations 3 appliance information general information 4 technical data 5 layout & components utility 6 layout & components utility system 7 pre-installation cleaning primary systems 8 mains supply 9 oil su...

Page 4

Safety precautions & installation regulations installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 3 saf et y & re gul a t io n s safety precautions installation regulations oil smells, leaks or fumes from the appliance: extinguish any...

Page 5: Check List

General information installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 4 a ppl ia n c e inf o rm a t io n general information standard package: a - floor standing oil fired condensing boiler. B - literature pack. C - condensate trap ...

Page 6

Technical data installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 5 technical data central heating primary water capacity (total) utility litres primary water capacity (total) utility system litres maximum static head metres minimum ...

Page 7

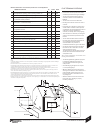

1 2 5 3 4 8 11 18 19 12 30 29 28 31 26 25 22 23 16 27 6 9 7 10 13 14 15 17 20 21 24 layout & components utility layout & components installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 6 a ppl ia n c e inf o rm a t io n the diagram opp...

Page 8

Layout & components utility system layout & components installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 7 p r e - in st al la ti o n 1 2 16 17 15 11 5 3 4 8 13 19 21 20 14 34 25 35 23 24 12 32 31 30 26 18 10 33 6 7 9 27 28 29 22 th...

Page 9

Cleaning primary systems before cleaning the system: ensure the system and pipework is in good working order. Flush the existing system with a power flushing machine or with a chemical cleaner before installing new components. Cleaning the primary system: cleanse the system in accordance with bs 759...

Page 10

Mains supply electric supply: • supply: 230v - 50hz. • cable: pvc insulated 0.75mm 2 (24 x 0.2mm) temperature rated to 90°c. • protection ip20. • external 5a fuse to bs1362. • the appliance must be earthed. • all pipes to the boiler must be cross-bonded. • it must be possible to isolate the applianc...

Page 11

Oil supply installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 10 p r e - in st al la ti o n oil supply oil supply : • this appliance is suitable for 28 second kerosene only, no other fuel must be used. • plastic or steel tanks should...

Page 12

Water systems & pipework installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 11 p r e - in st al la ti o n r typical open vent system: a - appliance. B - expansion vessel. C - automatic bypass valve. D - drain cock. E - feed and expan...

Page 13

Water systems & pipework filling primary sealed systems: • filling the system must comply with one of the methods shown opposite. • the filling point must be at low level and must never be a permanent direct fixing to the mains water supply. • filling loops must be wras approved. Heating return hose...

Page 14

Condensate & pressure relief pipework installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 13 p r e - in st al la ti o n condensate & pressure relief pipework condensate pipework: • all national and, where appropriate, local regulation...

Page 15

Boiler location & clearances • this boiler is only suitable for installing internally within a property at a suitable location onto a fixed rigid surface of the same size as the boiler and capable of supporting the boiler weight. • the boiler must be installed on a flat level surface to ensure conde...

Page 16

600mm 2250mm 600mm 750mm 1 1 2 3 2 3 a 0 600mm 2250mm 600mm radius 750mm a a - bath or shower cubicle (zone 0) 1 1 2 2 3 0 3 boiler location & clearances boiler location & clearances installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07)...

Page 17

P r e - in st al la ti o n flue terminal positions installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 16 minimum dimensions of flue terminal positions for oil-fired appliances: terminal position cf rs(h) rs(v) a 1 2 directly below an...

Page 18

Conventional flue c b a d e a - boiler b - flue c - max. 2 bends at 135° d - anti down-draught terminal e - chimney conventional flue installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 17 p r e - in st al la ti o n • open (convention...

Page 19

P r e - in st al la ti o n room sealed flue options installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 18 room sealed flue options the diagrams (opposite) show the components used and the maximum flue length (l) for each flue configu...

Page 20

Unpacking: it is advised that at least two or more persons are involved in the transfer of the packaged boiler from the van to the point of delivery. 1 once the packaged boiler has been delivered, the outer carton is removed first. Care should be taken when releasing the straps. If a sharp implement...

Page 21

Safety: all relevant safety precautions must be undertaken. Protective clothing, footwear, gloves and safety goggles must be worn as appropriate. Pipework positions: a - flow (utility models only) /open vent 1” bsp 12/18, 18/25. 1 1 / 4 ” bsp 25/32. B - primary drain/feed 3 / 4 ” bsp. C - return 22m...

Page 22

Boiler installation (all models): 1 lift the top panel (a) upwards to disengage the ball stud connections (b) and remove. Pull front panel (c) forward to disengage ball studs from their connections (d). (utility system only): in the case of the utility system boiler, remove the retaining tie at the ...

Page 23

Flue installation installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 22 in st al la ti o n the flue can exit the boiler from outlets a, b, c or d allowing vertical (rs) and horizontal (rs low or high level) flues to be fitted. (cf po...

Page 24

Combustion chamber: 1 remove the control box securing screws (a, bottom screw both sides) and loosen the pivot screws (b, top screw both sides). 2 pivot down control box. 3 release retaining nuts and washers (c). Remove combustion chamber access door (d). 4 release screws (e) on either side and remo...

Page 25

1m 50mm (min.) 500ml pipework connections cauti o n: i s o late th e o i l & wate r mains supply before starting any w o r k an d o b s e r ve all r e le vant safety precautions. A - flow (utility models only)/open vent 1” bsp (1 1 / 4 ” bsp for 25/32 models) a1 - flow utility system models only 22m...

Page 26

Oil burner & pump installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 25 in st al la ti o n caution: isolate the oil & water mains supply before starting any w o r k an d o b s e r ve all r e le vant safety precautions. Oil burner: 1 ...

Page 27

Refitting components 1 align burner combustion head into boiler collar. Locate the burner retainer (a) over the threaded lug on the collar (b), push the burner firmly onto the flange and secure in place with the retaining nut (c). Tighten sufficiently but do not overtighten. Check that the burner is...

Page 28

E d 2 g g b c a 3 1 2 3 = earth = live = neutral = switched live 230v 230v 1 2 3 230v a 1 f electrics danger - 230v: isolate the mains electricity supply before starting any work and observe all relevant safety precautions. Access to 230v connections: 1 release screws (a) and remove front panel (b) ...

Page 29

1 2 3 1 2 3 4 5 6 1 2 3 4 5 6 a b c d g h riello burner green/yellow green/yellow green/y ellow brown red 3 2 black red grey green/yellow m = earth = live = neutral orange f brown brown n l blue e j electrics utility model: 230v standard wiring diagram: key to components: a - earth stud. B - high li...

Page 30

Electrics 1 2 3 1 2 3 4 5 6 1 2 3 4 5 6 a b c d g h riello burner green/yellow green/yellow green/y ellow brown red 3 2 black red grey green/yellow m = earth = live = neutral orange brown brown n l blue e k f j n l danger - 230v: isolate the mains electricity utility system model: 230v standard wiri...

Page 31

Electrics 1 2 3 1 2 3 4 5 6 • = earth • = live • = neutral • = switched live k outside boiler inside boiler 3 2 e danger - 230v: isolate the mains electricity utility model: remote 2 or 3 port valve control set using remote programmer: key to components: k - remote junction box (10-way) to connect t...

Page 32

Electrics 1 2 3 1 2 3 4 5 6 • = earth • = live • = neutral • = switched live = pump feed k outside boiler inside boiler 3 2 e p p p m n l danger - 230v: utility system model: isolate t pre-wired remote 2 or 3 port valve control set using remote programmer: key to components: k - remote junction box ...

Page 33

1 2 3 4 pre-commissioning checks - appliance caution: isolate the mains supplies before starting any work and observe all relevant safety precautions. 1 check that the service and water pipes are connected correctly. Check that all unused sockets are capped. 2 check that the oil supply is 28 sec ker...

Page 34

1 open all system and radiator valves. Turn on the water main stop cock. Open vented systems only: turn on the water to the system feed and expansion cistern and allow the system to fill. 2 sealed systems only: check and if required, adjust the expansion vessel pressure using the schraeder type valv...

Page 35

A - bleed & pressure gauge port b - pressure adjustment c - vacuum gauge port d - retaining screws - cover burner lockout 1 c b a d riello rdb oil pump integral burner lockout indicator and reset button (h) h e f g return flow starting the appliance important: never run the appliance when the applia...

Page 36

5 4 k %co 2 nominal boiler rating at normal operating temperature using 28sec kerosene: nozzle boiler 12/18 rdb 1 oil pump pressure (p.S.I.) fuel flow rate kg/h l/h approx. Flue gas temp °c approx. Air setting input output kw kw 0.40 60 °es 0.45 60 °es 0.55 x 8 0 °eh 100 120 105 1.04 1.28 1.54 1.32 ...

Page 37

Starting the appliance installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 36 c o mmi s s io n in g a c d d b starting the appliance on 25/32 appliances: to achieve the mimimum output of 25kw from the 25/32 rdb 2.2 it is necessary to ...

Page 38

Starting the appliance installation & servicing instructions for worcester greenstar camray utility 12/18-18/25- 25/32 8 716 113 004b (05.07) 37 c o mmi s s io n in g 2 1 a starting the appliance central heating: 1 open all radiator valves. Set room thermostat to maximum. Set programmer to on. Turn ...

Page 39

Water treatment important: debris from the system can damage the boiler and reduce efficiency. Failure to comply with the guidelines for the use of water treatment with the appliance will invalidate the appliance warranty. Flushing (central heating): 1 switch off the boiler. Open vented systems only...

Page 40

Finishing commissioning - appliance 1 pivot the control box (a) up and into the boiler. Secure with screws (b). (utility system only): in the case of the utility system boiler, replace the expansion vessel securing bracket and and secure in place with the two screws (c ). Carefully replace the expan...

Page 41

Inspection and service inspection and service installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 40 ser v ic in g & sp a res caution: isolate the water, electricity and oil mains supplies before starting any work and observe all rele...

Page 42

1 clean the burner: remove the air intake cover (a) and clear any debris from the air intake and air damper. Disassemble the burner to allow access to the fan impeller. Check the condition of the gaskets between these parts and replace if necessary. Note the position of the air damper adjustment and...

Page 43

Inspection and service installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 42 ser v ic in g & sp a res inspection and service external oil filter: remove the paper element from the external oil filter and replace it. If the filter con...

Page 44

%co 2 nominal boiler rating at normal operating temperature using 28sec kerosene nozzle boiler 12/18 rdb 1 oil pump pressure (p.S.I.) fuel flow rate kg/h l/h approx. Flue gas temp °c approx. Air setting input output kw kw 0.40 60 °es 0.45 60 °es 0.55 x 8 0 °eh 100 120 105 1.04 1.28 1.54 1.32 1.63 1....

Page 45

Short parts list 12/18 1 burner - riello rdb 1 12/18 part number: 8 716 111 951 0 2 combustion head - ld2x sh12/18 part number: 8 716 112 731 0 3 control box 535 rse/ld part number: 8 716 109 203 0 4 photocell part number: 8 716 109 193 0 5 ignition electrode part number: 8 716 109 183 0 6 motor par...

Page 46

14 7 8 11 15 16 17 13 12 2 3 4 5 6 9 10 1 18 20 19 21 7a short parts list 18/25 installation & servicing instructions for worcester greenstar camray utility 12/18-18/25- 25/32 8 716 113 004b (05.07) 45 ser v ic in g & sp a res short parts list 18/25 1 burner - riello rdb 2.2 18/25 part number: 8 716...

Page 47

Short parts list 25/32 installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 46 ser v ic in g & sp a res short parts list 25/32 1 burner - riello rdb 2.2 25/32 part number: 8 716 112 347 0 2 combustion head - t2 lh25/32 part number: 8 7...

Page 48

F a ul t f ind in g & d ia g r a m s fault finding installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 47 fault finding boiler lockout : indicated by the illumination of the 'lockout' indicator on the burner. To reset, wait 2 minutes ...

Page 49

Fault finding fault finding installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 48 fa u lt f in d in g & d ia g r a m s problem cause remedy faulty boiler operation: noisy operation pump noise from air in pump or worn pump bleed air f...

Page 50

F a ul t f ind in g & d ia g r a m s fault finding installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 49 boiler not operating with a heating / hot water demand burner motor runs? L o ckout within 1 second? Replace control b o x repla...

Page 51: Service Interval Record

Service interval record it is recommended that your heating system is serviced regularly and that you complete the appropriate service interval record overleaf. Service provider. Before completing the appropriate service interval record below, please ensure you have carried out the service as descri...

Page 52

51 service 1 date engineer name company name tel no. Oftec reg no. Pump pressure: psi co 2 %: nozzle changed? Yes no f.G.T. °c flue pressure: comments signature service 3 date engineer name company name tel no. Oftec reg no. Pump pressure: psi co 2 %: nozzle changed? Yes no f.G.T. °c flue pressure: ...

Page 53

Notes installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 52 no t e s notes.

Page 54

No t e s notes installation & servicing instructions for worcester greenstar camray utility 12/18-18/25-25/32 8 716 113 004b (05.07) 53 notes.

Page 55

Baffle arrangement diagram 12/18 utility model shown baffle access door acoustic insulation insert (all models) remove last. Refit first. Restrictor plate (2 for 12/18 models, 1 for 18/25 models) remove and fit through baffle access door. 12/18 fitted into tubes 2 & 3. 18/25 fitted into tube 2. Baff...

Page 56

If in the unlikely event the boiler does not give complete satisfaction, before calling for a service engineer, the installer should check the following:- general checks 1. Is there 230v across the boiler live and neutral terminals? 2. Is the polarity correct? (230v across live and earth, 0v across ...