- DL manuals

- Worcester

- Boiler

- Greenstar Ri

- Installation And Servicing Instructions

Worcester Greenstar Ri Installation And Servicing Instructions

UK/IE

INSTALLATION, COMMISSIONING AND SERVICING

INSTRUCTIONS

WALL HUNG RSF GAS FIRED CONDENSING BOILER

GREENSTAR Ri

6720644744-00.1W

o

FOR OPEN VENTED AND SEALED CENTRAL HEATING SYSTEMS AND

INDIRECT MAINS FED DOMESTIC HOT WATER

6 720

644

744a (

2010

/10)

The appliance is for use with Natural Gas or

L.P.G. (Cat II 2H3P type C13, C33 & C53)

Model

GC Number

Natural Gas

12 Ri

41-311-63

15 Ri

41-311-75

18 Ri

41-311-77

24 Ri

41-311-65

Liquid Petroleum Gas

12 Ri

41-311-64

15 Ri

41-311-76

18 Ri

41-311-78

24 Ri

41-311-66

Summary of Greenstar Ri

Page 1

Uk/ie installation, commissioning and servicing instructions wall hung rsf gas fired condensing boiler greenstar ri 6720644744-00.1w o for open vented and sealed central heating systems and indirect mains fed domestic hot water 6 720 644 744a ( 2010 /10) the appliance is for use with natural gas or ...

Page 2

Contents 6 720 644 744a (2010/10) 2 contents 1 key to symbols and safety precautions 3 1.1 explanation of symbols . . . . . . . . . . . . . . 3 1.2 safety precautions . . . . . . . . . . . . . . . . . 4 2 appliance information . . . . . . . . . . . . . . . . 6 2.1 appliance . . . . . . . . . . . . ....

Page 3

Key to symbols and safety precautions 6 720 644 744a (2010/10) 3 1 key to symbols and safety precautions 1.1 explanation of symbols warning symbols signal words indicate the seriousness of the hazard in terms of the consequences of not following the safety instructions. • notice indicates possible d...

Page 4

Key to symbols and safety precautions 6 720 644 744a (2010/10) 4 1.2 safety precautions if you smell gas: b call national gas emergency service on 0800 111 999 b lpg boilers call the supplier‘s number on the side of the lpg tank b turn off the ecv (emergency control valve) at the meter/regulator b d...

Page 5

Key to symbols and safety precautions 6 720 644 744a (2010/10) 5 british standards: where no specific instruction is given, reference should be made to the relevant british standard codes of practice. Bs7074:1 code of practice for domestic and hot water supply bs6891 installation of low pressure gas...

Page 6

Appliance information 6 720 644 744a (2010/10) 6 2 appliance information 2.1 appliance fig. 1 appliance 1 2 3 4 5 6720644744-01.1wo 390mm 270mm *600mm to top of case front 590mm* standard package: 1 wall hung gas fired condensing regular boiler for central heating and domestic hot water 2 tail pipes...

Page 7

Appliance information 6 720 644 744a (2010/10) 7 2.2 technical data description natural gas lpg unit 12ri 15ri 18ri 24ri 12ri 15ri 18ri 24ri gas flow rate - max. 10 minutes from lighting natural gas g20 m³/h 1.3 1.63 1.96 2.6 - - - - propane gas (lpg) kg/h - - - - 0.96 1.20 1.44 1.91 central heating...

Page 8

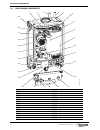

Appliance information 6 720 644 744a (2010/10) 8 2.3 boiler main components 1 air/gas manifold 16 wiring connections cover 2 sensor - boiler flow 17 burner indicator (green) 3 flow pipe 18 boiler on/off switch 4 return pipe 19 condensate connection 5 removable servicing panel 20 syphon / trap 6 elec...

Page 9

Pre-installation 6 720 644 744a (2010/10) 9 3 pre-installation 3.1 cleaning primary systems before cleaning the system: b ensure that the system and pipe work is in good working order. B where possible keep the existing boiler/circulating pump in place when flushing the system. Follow the guidance o...

Page 10

Pre-installation 6 720 644 744a (2010/10) 10 3.2 mains supply 3.2.1 electrical supply • supply: 230v - 50 hz, 140 watts • cable: pvc insulated 0.75 mm 2 (24 x 0.2 mm) temperature rated to 90 °c. • external 3a fuse to bs1362. • the appliance must be earthed. • this appliance must not be connected to ...

Page 11

Pre-installation 6 720 644 744a (2010/10) 11 3.3 water systems and pipe work plastic pipe work: • any plastic pipe work must have a polymeric barrier with 600mm (minimum) length of copper pipe connected to the boiler. • plastic pipe work used for underfloor heating must be correctly controlled with ...

Page 12

Pre-installation 6 720 644 744a (2010/10) 12 s and y plan systems: fully pumped sealed system: the central heating sealed system must be filled using a wras approved filling loop or comply with figure 2 for system fill. S plan layout fig. 3 s plan y plan layout fig. 4 y plan sealed system y plan lay...

Page 13

Pre-installation 6 720 644 744a (2010/10) 13 3.4 condensate pipe work 3.4.1 internal connections in order to minimise risk of freezing during prolonged cold spells, the following methods of installing condensate drainage pipe should be adopted, in order of priority. Wherever possible, the condensate...

Page 14

Pre-installation 6 720 644 744a (2010/10) 14 3.4.2 external connections if no other discharge method is possible then the use of an externally run condensate drainage pipe terminating at a suitable foul water discharge point, or purpose- designed soak away, may be considered. If this method is chose...

Page 15

Pre-installation 6 720 644 744a (2010/10) 15 condensate soak away • the condensate drainage pipe may be run above or below the ground to the soak away. • the examples shown on this page run above ground. • the soak away must use a 100mm Ø plastic tube with two rows of three 12 mm holes on 25 mm cent...

Page 16

Pre-installation 6 720 644 744a (2010/10) 16 3.5 pressure relief pipe work • the pressure relief drain pipe (1) from the boiler should be at least 15mm diameter copper pipe and run downwards, away from any electrical equipment or other hazard, preferably to an external drain or soak away. • pipe (1)...

Page 17

Pre-installation 6 720 644 744a (2010/10) 17 3.6 boiler location and clearances 3.6.1 installation this boiler is only suitable for installing internally within a property at a suitable location onto a fixed, rigid surface at least the same size as the boiler and capable of supporting the boiler wei...

Page 18

Pre-installation 6 720 644 744a (2010/10) 18 3.6.5 boiler clearances- unventilated compartments 3.6.6 installation clearances - unventilated compartments the tables below show the options for the minimum space required to install and service the boiler inside an unventilated compartment. Caution: cl...

Page 19

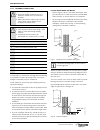

Pre-installation 6 720 644 744a (2010/10) 19 3.7 plumbing manifold 3.7.1 connections use the fittings supplied in the hardware literature pack: • use the 22mm copper pipes (1 & 2) provided with the appliance, as shown in the diagram opposite. • if the flow and return pipes are to be run behind the a...

Page 20

Pre-installation 6 720 644 744a (2010/10) 20 3.8 flue options the greenstar series has the option of two horizontal 60/100 rsf (telescopic and extended telescopic) and two horizontal 80/125 rsf (telescopic and extended telescopic) flue systems and two vertical rsf (60/100 or 80/125) flue systems: th...

Page 21

Pre-installation 6 720 644 744a (2010/10) 21 350 mm 570 mm 130 mm min flat roof 300 mm 500 mm pitched roof 2 3 4 5 6 10 9 8 7 1 6720643895-12.1wo.

Page 22

Pre-installation 6 720 644 744a (2010/10) 22 3.9 flue terminal positions fig. 18 flue terminal positions key to illustration 1. Flue clearance must be at least 300 mm from the ground. Terminal guards must be fitted if the flue is less than 2 metres from the ground or if a person could come into cont...

Page 23

Pre-installation 6 720 644 744a (2010/10) 23 3.10 plume terminal positions fig. 19 plume terminal positions key to illustration 1. 600 mm distance to a boundary, unless it will cause a nuisance. Bs 5440: part 1 recommends that care is taken when siting terminals in relation to boundaries. 2. Interna...

Page 24

Installation 6 720 644 744a (2010/10) 24 4 installation 4.1 unpacking the wall frame and ancillary items 1. System flow and return pipes - 22mm x 2 2. Wall mounting plate 3. Installer pack 4. Bottom panel 5. Inner wrap and wall template fig. 20 unpacking fig. 21 wall mounting template important hand...

Page 25

Installation 6 720 644 744a (2010/10) 25 4.2 wall mounting template & flue opening safety: all relevant safety precautions must be undertaken. Protective clothing, footwear, gloves and safety goggles must be worn as appropriate. Fixing the mounting frame: b the boiler template shows the relative pos...

Page 26

Installation 6 720 644 744a (2010/10) 26 4.3 outer case removal 1. Undo the two captive screws securing boiler casing at the bottom of the appliance. 2. Undo the two screws securing boiler casing at the top of the appliance. 3. Pull case upwards. 4. Remove cardboard packing piece from appliance. Wit...

Page 27

Installation 6 720 644 744a (2010/10) 27 4.4 boiler connection gas and water connections: b remove wall mounting template and secure the wall mounting frame to the wall with the appropriate fittings for the boiler weight and wall type. B if there is greater than 600mm clearance below the appliance i...

Page 28

Installation 6 720 644 744a (2010/10) 28 4.4.1 condensate connection never terminate or discharge into any open source, including; sink, bath, shower, bidet, toilet etc. Figure 27 gives the pipe work dimensions with respect to the mounting surface. A sealing washer (1) and 22mm adaptor (2) are suppl...

Page 29

Installation 6 720 644 744a (2010/10) 29 4.5 flue installation horizontal flue (60/100mm diameter) for vertical flues and 80/125mm horizontal flues, please refer to separate instructions supplied with the flue kit. Basic instructions for the 60/100mm diameter flue are shown below. Fig. 28 flue turre...

Page 30

Installation 6 720 644 744a (2010/10) 30 4.5.3 installing the telescopic flue: refer to figure 32. 1. Set the flue length to the distance required, secure with screws provided. 2. Seal the joint with the aluminium tape provided. 3. Slide the inner wall seal onto the terminal. 4. If fitting from insi...

Page 31

Installation 6 720 644 744a (2010/10) 31 4.5.4 flue terminal plume re-direction: the flue discharge can be re-directed allowing some plume redirection control, alternatively, a complete plume management system can be fitted to the flue terminal. Re-directing the flue discharge 1. Remove screws (1) a...

Page 32

Installation 6 720 644 744a (2010/10) 32 4.6 electrical connections the mains supply to the boiler must be either: b from a fused double pole isolator situated next to the appliance. The isolator must have a minimum of 3mm contact separation in both poles. Fig. 38 fused spur -or- b from a plug and u...

Page 33

Installation 6 720 644 744a (2010/10) 33 external wiring centre system components wired into terminal strip in accordance with system manufacturers instructions. Fig. 41 external wiring centre refit electric control panel covers: b refit panel and secure with screws. N e sw l wiring centre/junction ...

Page 34

Commissioning 6 720 644 744a (2010/10) 34 5 commissioning 5.1 pre-commissioning checks b check that the gas service pipe and water pipes are connected to the correct position on the manifold. 1. Gas inlet (22mm) 2. Flow (22mm) 3. Return (22mm) fig. 42 b check the gas type specified on the identifica...

Page 35

Commissioning 6 720 644 744a (2010/10) 35 5.2 filling the system open vented systems: b ensure all system and boiler drain points are closed. B open all radiator valves. B turn on the water supply to the system header tank and allow the system to fill. Sealed systems: b fill the system via a wras ap...

Page 36

Commissioning 6 720 644 744a (2010/10) 36 5.4 starting the appliance fig. 46 boiler controls switching the appliance on/off: b turn on mains power supply, the power on indicator (2) illuminates blue. B turn on any external controls b set the thermostatic radiator controls to maximum temperature b se...

Page 37

Commissioning 6 720 644 744a (2010/10) 37 5.5 commissioning having checked: b that the boiler has been installed in accordance with the installation instructions. B the integrity of the flue system and flue seals, as described in section 6.3 of this manual. B the integrity of the boiler combustion c...

Page 38

Commissioning 6 720 644 744a (2010/10) 38 5.6 finishing commissioning 5.6.1 replace the outer case: replace outer casing making sure that the securing points are properly located. 1. Replace top two screws. 2. Re-tighten bottom two screws. Fig. 50 replacing outer case 5.6.2 install the bottom panel ...

Page 39

Service and spares 6 720 644 744a (2010/10) 39 6 service and spares 6.1 inspection and service • to ensure the continued efficient operation of the appliance it must be checked at regular intervals. • the frequency of servicing will depend upon the particular installation conditions and usage howeve...

Page 40

Service and spares 6 720 644 744a (2010/10) 40 lowering the boiler controls to the service position: 1. Remove two screws securing the control. 2. Pull the control forward. 3. Lower the control to align the slots at the top of the control with the lugs on the boiler framework. 4. Hang control on two...

Page 41

Service and spares 6 720 644 744a (2010/10) 41 6.2 checking gas inlet pressure refer to section 5.5.1 for more information b check the gas supply working pressures in the system conform to the readings shown in the table below: 6.3 checking flue integrity the integrity of the flue system and perform...

Page 42

Service and spares 6 720 644 744a (2010/10) 42 6.4 fan pressure test setting the boiler to maximum 1. Remove the three screws retaining the control cover. 2. Remove the control cover. 3. Remove the plastic tool clipped inside the cover. 4. Insert the tool into the switch. 5. Using the tool set the m...

Page 43

Service and spares 6 720 644 744a (2010/10) 43 if the boiler fails the fan pressure test then before adjusting the air/gas ratio, try the following: b check the syphon is not blocked. 1. Remove the screws securing the sump cover. 2. Remove the sump cover. 3. Clean the sump with a suitable brush. B c...

Page 44

Service and spares 6 720 644 744a (2010/10) 44 6.6 setting the air/gas ratio 6.6.1 setting the co/co 2 b refer to section 6.2 and ensure that the gas inlet pressure is correct before continuing. B to adjust the co/co 2 it will be necessary to first operate the boiler at maximum output. B refer to se...

Page 45

Service and spares 6 720 644 744a (2010/10) 45 6.7 cleaning the heat exchanger b isolate the power to the appliance and remove outer case and base panel. 1. Refer to figure 62 and remove the clip from gas valve outlet. 2. Pull the gas outlet elbow free from the gas valve. Fig. 62 gas valve connectio...

Page 46

Service and spares 6 720 644 744a (2010/10) 46 burner removal refer to figure 65 1. Remove clamping plate. 2. Remove spark/flame electrode assembly and seal from the top of the heat exchanger. 3. Remove burner. Fig. 65 burner removal checking and cleaning the electrode assembly: b inspect the condit...

Page 47

Service and spares 6 720 644 744a (2010/10) 47 access cover removal refer to figure 67. 1. Remove the two pozi-drive screws 2. Remove the access cover 3. Remove the gasket. Fig. 67 access cover removal cleaning the primary heat exchanger refer to figure 68. B access the heat exchanger flue ways by i...

Page 48

Service and spares 6 720 644 744a (2010/10) 48 6.7.1 syphon removal and cleaning to release the syphon from the sump: 1. Undo the plastic nut on the bottom of the syphon and move the condensate pipe away from the syphon. 2. Remove the two screws retaining the syphon bracket. 3. Remove the bracket. 4...

Page 49

Service and spares 6 720 644 744a (2010/10) 49 6.8 replacement of parts 6.8.1 removing the outer casing b remove bottom tray by pressing the tabs (2) in, at the front underside of the boiler. B lower the panel. B pull the panel forward , off the retaining ledge (1) at the back of the boiler. Fig. 70...

Page 50

Service and spares 6 720 644 744a (2010/10) 50 6.8.2 primary sensor (ch ntc) refer to figure 72 for removal. 1. Remove electrical connection by pulling upwards. Squeeze retaining clip on plastic moulding of sensor and pull back and up until clear of pocket in heat exchanger. 2. Pull forward to remov...

Page 51

Service and spares 6 720 644 744a (2010/10) 51 6.8.5 lowering the boiler controls to the service position: 1. Remove two screws securing control. 2. Pull the control forward. 3. Lower the control to align the slots at the top of the control with the lugs on the boiler framework. 4. Hang control on t...

Page 52

Service and spares 6 720 644 744a (2010/10) 52 6.8.7 air/gas manifold and fan assembly b remove electrical connector and earth wire the from fan. B remove wire clip from gas valve outlet then pull gas pipe free from the gas valve (see figure 76). Fig. 78 b undo the securing nut at the top of the hea...

Page 53

Service and spares 6 720 644 744a (2010/10) 53 6.8.8 air pressure switch 1. Remove the electrical connections. 2. Slacken the top retaining screw and remove the bottom screw. 3. Disconnect the tube. 4. Remove the air pressure switch assembly fig. 80 air pressure switch 1. Remove the two screws retai...

Page 54

Service and spares 6 720 644 744a (2010/10) 54 flap valve assembly 1. Twist the mounting flange clockwise to release. 2. Pull mounting flange off the flap valve assembly. 3. Pull rubber flap off flap valve assembly. B to replace the flap valve: – press the two lugs on the back of the flap into the t...

Page 55

Service and spares 6 720 644 744a (2010/10) 55 6.8.11 heat exchanger b drain the system. B remove syphon. B remove the air/gas manifold and fan. Refer to figure 85. 1. Remove the clip from plastic elbow on the flow pipe. 2. Pull flow pipe away from heat exchanger. Fig. 85 flow pipe removal refer to ...

Page 56

Service and spares 6 720 644 744a (2010/10) 56 refer to figure 89. 1. Lift the heat exchanger up to clear. 2. Pull the heat exchanger forward from the case. Fig. 89 heat exchanger removal b reassemble and check combustion as stated in the air/gas ratio section. 6.6. 6.8.12 access to boiler control c...

Page 57

Service and spares 6 720 644 744a (2010/10) 57 6.8.15 transformer/pcb to change either the pcb, f2 fuse or transformer: b remove two screws securing the control. B pull the control forward. B lower the control to align the slots at the top of the control with the lugs on the boiler framework. B hang...

Page 58

Service and spares 6 720 644 744a (2010/10) 58 6.8.16 syphon removal to release the syphon from the sump: 1. Undo the plastic nut on the bottom of the syphon and move the condensate pipe away from the syphon. 2. Remove the two screws retaining the syphon bracket. 3. Remove the bracket. 4. Remove the...

Page 59

Service and spares 6 720 644 744a (2010/10) 59 6.9 short parts list fan 8 716 116 067 0 gc no. H26 536 burner 12 & 15ri: 8 718 120 616 0 gc no. H26 537 18 & 24ri: 8 716 120 619 0 gc no. H26-538 gas valve 12/15/18 & 24ri 8 716 111 325 0 gc no. H26 540 control board 8 718 687 164 0 h26-541 flue overhe...

Page 60

Fault finding and diagnosis 6 720 644 744a (2010/10) 60 7 fault finding and diagnosis 7.1 fault finding the electronic control system for this boiler incorporates a blue central indicator. This normally confirms the permanent mains supply but, by flashing at different rates during a fault, provides ...

Page 61

Fault finding and diagnosis 6 720 644 744a (2010/10) 61 7.1.1 circuit diagram external pump flue overheat stat l n lp np lr earth mains supply spark transformer st9 st6 st5 st2 st1 diagnostic interface code plug mode switch slow 2 a fuse, ac 230 v slow t1 .25 a fuse ch temperature control pressure s...

Page 62

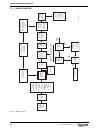

Fault finding and diagnosis 6 720 644 744a (2010/10) 62 7.2 boiler function fig. 94 boiler function no ye s mai n s po we r s u ppl y on boiler de man d f an to start speed. P ump o n. Ig n iti o n se qu e nce (see detai ) bl ue li g h t on burner l it? Green fl a m e li g h t on stop spark and gas....

Page 63

Fault finding and diagnosis 6 720 644 744a (2010/10) 63 7.3 protection function fig. 95 protection function internal boiler temperature between 8°c & 5°c boiler automatic frost function (monitors internal boiler primary temperature) internal boiler temperature below 5°c internal boiler temperature r...

Page 64

6 720 644 744a (2010/10) 64 notes.

Page 65

6 720 644 744a (2010/10) 65 notes.

Page 66

Failure to install and commission according to the manufacturer’s instructions and complete this benchmark commissioning checklist will invalidate the warranty. This does not affect the customer’s statutory rights. If yes, and if required by the manufacturer, has a water scale reducer been fitted? Co...

Page 67

Service record it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service record below, please ensure you have carried out the service as described in the manufacturer’s in...

Page 68

Worcester, bosch group cotswold way, warndon, worcester wr4 9sw. Tel. 0844 892 9900 worcester, bosch group is a brand name of bosch thermotechnology ltd. Worcester-bosch.Co.Uk 6 720 644 744a (2010/10) worcester, bosch group: technical support: 0844 892 3366 appointments: 0844 892 3000 spares: 01905 ...