- DL manuals

- Worcester

- Boiler

- Greenstar Ri

- User Manual

Worcester Greenstar Ri User Manual

THE APPLIANCE IS FOR USE WITH

NATURAL GAS OR L.P.G. (Cat II 2H3P TYPE C13 & C33)

NATURAL GAS: 24Ri GC NUMBER 41-311-65

18Ri GC NUMBER 41-311-77

15Ri GC NUMBER 41-311-75

12Ri GC NUMBER 41-311-63

LIQUID PETROLEUM GAS: 24Ri GC NUMBER 41-311-66

18Ri GC NUMBER 41-311-78

15Ri GC NUMBER 41-311-76

12Ri GC NUMBER 41-311-64

GB/IE

CHECKLIST & service

interval record is printed at the rear of

this manual

Summary of Greenstar Ri

Page 1

The appliance is for use with natural gas or l.P.G. (cat ii 2h3p type c13 & c33) natural gas: 24ri gc number 41-311-65 18ri gc number 41-311-77 15ri gc number 41-311-75 12ri gc number 41-311-63 liquid petroleum gas: 24ri gc number 41-311-66 18ri gc number 41-311-78 15ri gc number 41-311-76 12ri gc n...

Page 2

Installation & servicing instructions installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 1 worcester bosch: technical: 08705 266241 service: 08457 256206 spares: 01905 752571 literature: 01905 752556 training: 01905 752526 sales: 01905 752640 website: www.W...

Page 3

Safety & regulations safety precautions & symbols 3 installation regulations 3 appliance information general information 4 technical data 5 layout & components 6 pre-installation cleaning primary systems 7 mains supply 8 water systems & pipework 9 condensate pipework 10 boiler location & clearances ...

Page 4

Safety precautions & installation regulations installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 3 saf et y & re gul a t io n s safety precautions installation regulations if you smell gas: ✗ don’t smoke or strike matches ✗ don’t turn electrical switches on...

Page 5

General information standard package: a - wall hung gas fired condensing boiler for central heating and indirect domestic hot water b - wall plate c - hardware literature pack d - tail pipes - water e - bottom panel specifications: pre-wired and pre-plumbed galvanised steel inner frame digital contr...

Page 6

Technical data central heating max. Rated heat output net 40/30°c kw 12.85 16.06 19.28 25.67 12.85 16.06 19.28 25.67 max. Rated heat output net 50/30°c kw 12.74 15.92 19.11 25.45 24.74 15.92 19.11 25.45 max. Rated heat output net 80/60°c kw 12.0 15.0 18.0 24.0 12.0 15.0 18.0 24.0 max. Rated heat inp...

Page 7

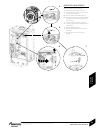

Layout & components the diagram opposite shows the controls in the servicing position and excludes the outer case, inner covers and fascia panel. 1 air / gas manifold 2 fan 3 air / gas adjustment screw 4 gas valve 5 inlet pressure test point 6 boiler power switch 7 flame indicator (green) 8 cover fo...

Page 8

Cleaning primary systems before cleaning the system: ensure the system and pipework is in good working order keep the existing boiler/ circulating pump where possible or use a power flushing machine to aid the cleansing procedure before installing a new boiler. Cleaning the primary system: 1 fill th...

Page 9

Mains supply electric supply: • supply: 230v - 50hz, 50 watts not including pump. • cable: pvc insulated 0.75mm 2 (24 x 0.2mm) temperature rated to 90°c. • external 3a fuse to bs1362. • the appliance must be earthed. • all pipes to the boiler must be cross-bonded. • mains supply to the boiler and sy...

Page 10

Water systems & pipework plastic pi pewor k & u n de r floor heating: • any plastic pipework must have a polymeric barrier with 600mm (minimum) length of copper or steel pipe connected to the boiler. • plastic pipework used for underfloor heating must be correctly controlled with a thermostatic blen...

Page 11

Condensate pipework installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 10 p r e - in st al la ti o n condensate pipework condensate pipework: • the condensate pipe must be a minimum of 22mmØ plastic pipe. • the condensate pipework must fall at least 50mm pe...

Page 12

Boiler location & clearances installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 11 p r e - in st al la ti o n boiler location & clearances this boiler is only suitable for installing internally within a property at a suitable location onto a fixed, rigid no...

Page 13

Boiler location & clearances installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 12 p r e - in st al la ti o n bathrooms: the boiler can be installed outside the shaded areas shown opposite. (zone 3 according to iee wiring regulations). (see technical data f...

Page 14

Plumbing manifold connections: heating system: 22mm compression fittings * gas: 22mm * use the 22mm copper pipes provided with the appliance. Use the fittings supplied in the lit/hardware pack. • if the flow and return pipes are to be run behind the appliance it maybe an advantage to connect the pip...

Page 15

Flue terminal positions installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 14 p r e - in st al la ti o n flue terminal positions • the flue must be fitted and terminated in accordance with the recommendations of bs5440 : part 1. • the flue must not cause an...

Page 16

P r e - in st al la ti o n flue options • the diagrams (opposite) show the components used and the maximum flue length for each configuration of 100mm and 125mm flues. • shaded flue components indicate the standard 100mm horizontal flue. • only straight flue sections can be reduced in length and cut...

Page 17

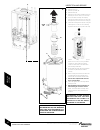

A - straps b - outer carton c - base tray d - inner wrap and wall template e - wall mounting plate f - installer pack g - base panel h - 22mm pipes (2) (system flow and return) important handling instructions • it is advised that two people are used to carry the carton from the van to the point of d...

Page 18

Safety: all relevant safety precautions must be undertaken. Protective clothing, footwear, gloves and safety goggles must be worn as appropriate. Fixing the mounting frame: • the boiler template shows the relative positions of the flue and pipes to the boiler. Also clearances around the appliance. F...

Page 19

1 2 3 4 b a outer case removal removing outer case 1. Undo and remove 2 screws (a) securing boiler casing at the top of the appliance. 2. Undo the 2 captive screws (b) securing boiler casing at the bottom of the appliance. 3. Pull case upwards. 4. Remove cardboard packing piece from appliance. With ...

Page 20

Gas and water connections: remove template and secure the wall mounting plate to the wall with the fixings supplied. • if there is greater than 600mm clearance below the appliance it is possible to fit the flow and return pipes, supplied, with the boiler installed on the wall. If clearance is less t...

Page 21

Flue installation horizontal flue (60/100mm diameter) for vertical flues and 80/125mm horizontal flues, please refer to separate instructions supplie with the flue kits. Note: to ease the assembly of flue components, apply silicone lubricant to sealing surfaces. The instructions for the 60/100mm dia...

Page 22

Flue installation installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 21 in st al la ti o n flue installation measuring the flue (extension flue kits): only cut extended flue lengths as with the standard flue measure from the outside wall to the centre line ...

Page 23

A b c d e a - standard flue b - internal wall seal c - external wall seal d - clamping plate e - extension duct flat at back flue installation assembling the flue 1 slide inner collar (b) onto terminal (a) 2 additional extensions or bends: push fit all extensions/bends/terminal together and secure c...

Page 24

Condensate connection: never terminate or discharge into any open source, including; sink, bath, shower, bidet, toilet etc. Note: any external condensate pipework should be protected with weather resistant insulation to help prevent freezing. • ensure that the condensate drain is 22mm diameter plast...

Page 25

Electrics caution: isolate the mains electricity supply before starting any work and observe all relevant safety precautions note: mains supply to the boiler and system wiring centre must be through a common fused double pole isolator situated adjacent to the appliance. The isolator must have a cont...

Page 26

Position of wired components position of wired components installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 25 in st al la ti o n c o mmi s s io n in g.

Page 27

Pre-commissioning checks caution: isolate the mains supplies before starting any work and observe all relevant safety precautions 1 check that the service and water pipes are connected to the correct position on the manifold. A - flow (22mm) b - return (22mm) c - gas inlet (22mm) 2 check the gas typ...

Page 28

Filling the system 1 ensure all system and boiler drain points are closed. 2 if connected to an open vented system turn on the water supply to system header tank and allow to fill the system. 3 for sealed systems fill the system using a wras approved filling loop to a pressure of 1 bar. 4 vent (a) a...

Page 29

Switching the appliance on/off: 1 turn on mains power supply turn on any external controls set the thermostatic radiator controls to maximum temperature set the clock/programmer to continuously on and the room thermostat to maximum temperature 2 turn control (a) from 0 (off position) to i (on positi...

Page 30

Water treatment ensure that the system has been cle an e d as on pag e 7 of th e s e instructions. Flushing (central heating): 1 switch off the boiler (a). If connected to an open vented system turn off the water supply to the system header tank open all drain cocks (b) and drain the system (c) whil...

Page 31

Commissioning the combustion for the appliance is factory set. No adjustment is required if the gas inlet pressure is correct. Checking gas inlet pressure: the inlet pressure to the appliance must be checked using the following proceedure: setting the boiler to maximum: 1 remove the three screws (a)...

Page 32

Finishing commissioning the boiler has been factory set, so there should be no need to adjust any controls. 1 install bottom panel. A the cut out in the bottom panel fits easily over the syphon elbow and outlet, however care should be taken not to disturb any sealed components. B hook the lip at the...

Page 33

Inspection and service to ensure the continued efficient operation of the appliance it must be checked at regular intervals. The frequency of servicing will depend upon the particular installation conditions and usage however, an annual service is recommended . The extent of the service required by ...

Page 34

Inspection and service component access 1. Removing outer case 1.1a undo and remove 2 screws (a) securing boiler casing at the top of the appliance. 1.1b undo but do not remove the 2 screws (b) securing boiler casing at the bottom of the appliance. 1.2 pull case forward and remove. It is necessary t...

Page 35

Inspection and service primary heat exchanger there is a special accessory kit availble specifically designed for cleaning the heat exchanger. If required order 7 716 192 312. 3 check fan pressure at the test point next to the fan using an electronic manometer the boiler must be run at maximum outpu...

Page 36

Inspection and service 1 a b 3 2 c d inspection and service installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 35 ser v ic in g & sp a res to clean the heat exchanger 1 with outer case and base panel removed and the power isolated from the appliance, remove...

Page 37

Inspection and service remove electrical connector from fan. Remove electrical connector from fan. 4 undo and remove securing nut (e) from the top of the heat exchanger. 5 remove stainless steel viewing mirror (f). 6 rotate fan and air/gas manifold assembly (g) around the top of the heat exchanger u...

Page 38

Inspection and service 8 l m n 0 p q r inspection and service installation & servicing instructions for worcester bosch greenstar ri 8 716 109 699a (05/05) 37 ser v ic in g & sp a res 8 remove burner (l). Remove top baffle (m). Remove baffle (n). Remove the two hexagon headed screws (o) retaining th...

Page 39

1.1 1.2 a b 1.1 remove 3 screws (a) and cover (b) from control box. Clipped inside the cover is a plastic tool used to change the mode switch setting. Re-connect mains electrical supply. 1.2 using the tool set the mode switch to maximum. The power indicator will flash and the boiler will stay in thi...

Page 40

1.4 remove covers from the air/gas outlet adjuster and gas valve adjuster. Connect manometer to inlet pressure point on the gas valve. The boiler should be run for 10 minutes before taking a co 2 measurement and compared with the figure in the table below. 1.5 if required, use a flat blade screwdriv...

Page 41

Caution: turn off the gas supply and isolate the mains s u p p li e s b e for e starti ng any wor k an d ob s e rve all relevant safety precautions. Important: after replacement of any components always check for gas soundness where relevant and carry out functional checks as described in commission...

Page 42

Replacement of parts 5. Moving boiler control to service position 5.1 remove two screws (a) securing control. 5.2 hang control on two lugs (b) on boiler framework. 6. Gas valve isolate gas supply at boiler gas cock. 6.1 remove wire clip from gas valve outlet then pull gas adjustment assembly free fr...

Page 43

Replacement of parts 9. Access to boiler control components move control to the service position. Remove 3 screws (a) and remove cover from control. 10. Pcb fuse remove fuse in plastic housing (b) from the pcb and replace. There is a spare fuse clipped into the cover. 11.Transformer / pcb disconnect...

Page 44

Replacement of parts 12. Air / gas manifold and fan assembly remove electrical connector from fan. Remove wire clip from gas valve outlet then pull gas adjustment assembly free from plastic connector and pull clear of case. See 6.1. 12.1 undo and remove securing nut (a) from the top of the heat exch...

Page 45

Replacement of parts 14. Fan 14.1 remove 3 screws (a) retaining mixing chamber. 14.2 remove 2 screws (b) retaining the fan to the air/gas manifold. 14.3 remove screw (c) retaining plate and remove. Re-assemble with new fan ensuring seals are correctly fitted. 15. Electrode assembly disconnect spark ...

Page 46

Short parts list 1 fan whs part no. 8 717 204 453 0 gc no. H26-536 2 burner 12ri whs part no. 8 718 120 616 0 12ri gc no. H26-537 15ri whs part no. 8 718 120 616 0 15ri gc no. H26-537 18ri whs part no. 8 718 120 619 0 18ri gc no. H26-538 24ri whs part no. 8 718 120 619 0 24ri gc no. H26-538 3 gas va...

Page 47

Gas conversion 12kw & 15kw conversion remove outer casing as described in servicing & spares section. 1 remove 3 screws (a) retaining cover. 2 remove cover (b) from control box. 3 gently pull code plug (c) from control box and replace with new one from lpg conversion kit. For code plug numbers see t...

Page 48

Electrical wiring diagram 1. St1, terminal block, 230vac mains supply. 1a. Control box earth connection. 2. Fuse f1 (t2a, h250v). 3. Boiler mains supply on/off switch. 4. Spark transformer. 5. Flame indicator. 6. St2, terminal block for pump & switched live. 7. Transformer connectors. 8. St5, fan 23...

Page 49

No light light on but boiler not operating during demand * slow flash (normally off, flashes on) * slow flash (normally on, flashes off) fast flash 2 pulses 5 pulses ignition lockout flue overheat heat exchanger overheat flue pressure switch volatile lockout (sensor, fan or code plug) permanent main...

Page 50

Main function no ye s p erm a nen t mai n s u p p ly t o boi l e r boi l e r de man d f rom s y ste m f an to start speed. P ump o n . P repurge then ignition spark 4 seconds bl ue li g h t on burner l it? Green f lam e li g h t on f an run 10 seconds then re-spark 5th attempt? L o ck out stabalisat...

Page 51

Controls to comply with the building regulations, each section must have a tick in one or other of the boxes time & temperature control to heating room t/stat & programmer/timer programmable roomstat time & temperature control to hot water cylinder t/stat & programmer/timer combi boiler heating zone...

Page 52: Service Interval Record

Service interval record it is recommended that your heating system is serviced regularly and that you complete the appropriate service interval record below. Service provider. Before completing the appropriate service interval record below, please ensure you have carried out the service as described...

Page 53

Instruction manual installation, commissioning & servicing excellence comes as standard worcester, bosch group cotswold way, warndon, worcester wr4 9sw. Tel. 01905 754624 fax. 01905 754619 worcester, bosch group is a trading name of bbt thermotechnology uk ltd. Www.Worcester-bosch.Co.Uk 8 716 109 69...