- DL manuals

- Xerox

- Printer

- 3130 - Phaser B/W Laser Printer

- Service Manual

Xerox 3130 - Phaser B/W Laser Printer Service Manual

Summary of 3130 - Phaser B/W Laser Printer

Page 1

Service laser printer phaser 3120 phaser 3130 manual laser printer contents 1. Precautions 2. Specifications 3. Disassembly and reassembly 4. Troubleshooting 5. Exploded views and parts list 6. Block diagram 7. Connection diagram 8. Schematic diagram.

Page 2: 1. Precautions

1 1 1-1 precautions service manual 1. Precautions the cautions in the below are items needed to keep in mind when maintaining and servicing. Please read carefully and keep the contents in mind to prevent accidents while servicing and to prevent that the machine gets damage. 1.1 warning for safety. (...

Page 3: 1.2 Caution For Safety

1-2 precautions service manual 1.2 caution for safety 1.2.1 precaution related noxious material the toner in a printer cartridge contains a chemical material, which might harm human body if it is swallowed. Please keep children out of the toner cartridge. 1.2.2 precaution related electric shock or f...

Page 4

1-3 precautions service manual 1.2.3 precaution related handling the machine. If you ignore this information, you could get harm and machine could be damaged. (1) do not install it on the different levels, or slanted floor. Please confirm whether it is balanced or not after installation. If it is un...

Page 5: 1.3 Esd Precautions

1-4 precautions service manual 1.3 esd precautions certain semiconductor devices can be easily damaged by static electricity. Such components are commonly called “electrostatically sensitive (es) devices”, or esds. Examples of typical esds are: integrated circuits, some field effect transistors, and...

Page 6

1-5 precautions service manual 1.4 tool for troubleshooting the following tools are recommended for safe and smooth troubleshooting described in this service manual. Dcu(diagnostic control unit) standard : test equipment to diagnose the laser printer supplied by samsung electronics. 1 driver standar...

Page 7: 2. Specifications

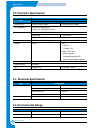

2 2 2-1 specifications service manual 2. Specifications 2.1 general specifications item description print technology non-impact electro-photograpic printing developing system non-magnetic, mono-component developing system print speed (1) 16 ppm : a4 size , 5% character pattern 17 ppm : letter size ,...

Page 8: 2.2 Controller Specification

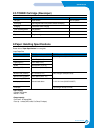

2-2 specifications service manual 2.3 electrical specification 2.2 controller specification item description phaser 3120 phaser 3130 processor(cpu) samsung jupiter4 90mhz samsung spgpm 166mhz os compatibility (1) win 98x/nt4.0/me/2000/xp, various linux os,mac(mac os 8.6 ↑ ) memory flash rom(program)...

Page 9

2-3 specifications service manual • input capacity cassette: 250 sheets manual : 1 sheet • output capacity face down : 50 sheets(20lb) face up : 1 sheet(ohp, lavbel, cut sheet, envelope) 2-paper handling specifications please refer to "paper specifications" on user guide • input paper size 2.5 toner...

Page 10

2-4 specifications service manual.

Page 11

3 3 3-1 disassembly and reassembly service manual 3. Disassembly and reassembly 3.1 general precautions on disassembly when you disassemble and reassemble compo- nents, you must use extreme caution. The close proximity of cables to moving parts makes proper routing a must. If components are removed,...

Page 12: 3.2 Top Cover

3-2 disassembly and reassembly service manual 1. Pull the cassette out of the printer. 2. Remove the front cover in the direction of arrow. 3. Remove four screws. 4. Unlatch the front ends of the top cover. 5. Remove the top cover in the direction of arrow. 6. Remove the rear cover from the top cove...

Page 13: 3.3 Fuser

3-3 disassembly and reassembly service manual 1. Before you remove the fuser, you should remove: - top cover(see page 3-2) 2. Unplug two connectors(block) from the boards, then remove four screws. 3. Remove two screws and take the thermostat out of the fuser. 4. Remove two screws and take the haloge...

Page 14: 3.4 Exit Roller

3-4 disassembly and reassembly service manual 1. Before you remove the fuser, you should remove: - top cover(see page 3-2) 2.Remove the exit gear, bearing and exit roller. Exit gear bearing exit roller 1 2 3.4 exit roller 3.5 lsu 1. Before you remove the fuser, you should remove: - top cover(see pag...

Page 15: 3.6 Fan

3-5 disassembly and reassembly service manual 1. Before you remove the fuser, you should remove: - top cover(see page 3-2) 2. Unplug the connector from the smps and remove the one screw. Then take out the fan. Dc fan 3.6 fan 3.7 driver ass’y 1. Before you remove the fuser, you should remove: - top c...

Page 16: 3.8 Engine Shield Ass’Y

3-6 disassembly and reassembly service manual 1. Before you remove the fuser, you should remove: - top cover(see page 3-2) - fuser connector(see page 3-3) 2. Remove the fourteen screws securing from the engine shield ass’y and unplug the all connec- tors. Then take the engine shield ass’y. Engine sh...

Page 17: 3.10 Smps

3-7 disassembly and reassembly service manual 3.10 smps 1. Before you remove the fuser, you should remove: - top cover(see page 3-2) - engine shield ass’y(see page 3-6) 2. Unplug one connector and remove three screws then take the inlet ass’y out. 3. Remove one screw and unplug one connector from th...

Page 18: 3.11 Transfer Roller

3-8 disassembly and reassembly service manual 3.11 transfer roller 1. Before you remove the fuser, you should remove: - top cover(see page 3-2) - lsu(see page 3-4) 2. Remove three screws and take the transfer earth out. 3. Unplug the ptl holder connector, then remove the ptl holder and ptl lens, as ...

Page 19: 3.12 Feed Roller

5-11 disassembly and reassembly service manual 3.12 feed roller 1. Before you remove the fuser, you should remove: - top cover(see page 5-2) - drive ass’y(see page 5-7) 2. Remove two screws from the guide paper and take it out. 3. Pull up the feed idle bush and feed idle shaft, as shown below. 4. Re...

Page 20: 3.13 Pick Up Roller

3-10 disassembly and reassembly service manual 1. Before you remove the fuser, you should remove: - top cover(see page 3-2) - drive ass’y(see page 3-5) - engine shield ass’y(see page 3-6) 2. Remove the pick up gear ass’y, as shown below. 3. Remove the pick up ass’y, as shown below. Pick up gear ass'...

Page 21: 4. Troubleshooting

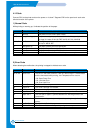

4-1 troubleshooting service manual 4 4 4. Troubleshooting 4.1 how to use dcu 4.1.1 dcu setup you can examine the malfunction of the printer. To perform dcu, open the front discharge cover and leave the connect the harness wire(10 pin/4 pin) to the cn10(4 pin) of the main control board. Ml series dia...

Page 22

4-2 troubleshooting service manual 4.1.2 code connect dcu to the printer and turn the power on. It show 7 segment fnd on the panel and each code tells the function of the printer. 1) normal code while printing or warming up, it indicate the position of the paper 2) error code when detecting the malf...

Page 23

4-3 troubleshooting service manual 4.1.3 self diagnostic mode if error code occurs due to malfunction of the printer, perform self diagnostic mode to solve the problem. The printer works only in the self-test mode to solve the malfunction problem. To enter the self-test mode, turn the power on press...

Page 24

4-4 troubleshooting service manual code description 07 paper empty sensor test : if activate the actuator of the pempty sensor, the left and right of the three leds are on. Paper empty sensor on/off 1st led on/off 08 feed & exit sensor test test the feed sensor and discharge sensor in the same way a...

Page 25

4-5 troubleshooting service manual 4.1.4 self test button if the self-test button pressed, vertical lines are printed. Turn the power on while pressing this button, '89' shows in the dcu and the printer is warming up. After warming-up the printer is in ready mode, and '88' shows in the dcu. In this ...

Page 26

4-6 troubleshooting service manual 4.2 bad image 4.2.1 vertical black line and band • description 1. Straight thin black vertical line occurs in the printing. 2. Dark black vertical band occur in the printing. Digital printer digital printer digital printer digital printer digital printer check and ...

Page 27

4-7 troubleshooting service manual 4.2.3 horizontal black band • description 1. Dark or blurry horizontal stripes occur in the printing periodically. (they may not occur periodically.) digital printer digital printer digital printer digital printer digital printer check and cause solution 1. Bad con...

Page 28

4-8 troubleshooting service manual 4.2.5 light image • description the printed image is light, with no ghost. Digital printer digital printer digital printer digital printer digital printer check and cause solution 1. Develop roller is stained when the toner of developer cartridge is almost con- sum...

Page 29

4-9 troubleshooting service manual 4.2.7 uneven density • description print density is uneven between left and right. Check and cause solution 1. The pressure force on the left and right springs of the transfer roller is not even, the springs are damaged, the transfer roller is improperly installed,...

Page 30: Digital Printer

4-10 troubleshooting service manual 4.2.9 ghost (1) • description ghost occurs at 75.5 mm intervals of the opc drum in the whole printing. Digital printer digital printer digital printer digital printer digital printer digital printer 75.5mm check and cause solution 1. Bad contacts caused by contami...

Page 31: Digital Printer

4-11 troubleshooting service manual 4.2.11 ghost (3) • description white ghost occurs in the black image printing at 32mm intervals. Digital printer digital printer digital printer digital printer digital printer digital printer 37mm check and cause solution 1. The life of the developer may be expir...

Page 32

4-12 troubleshooting service manual 4.2.14 satins on back of page • description the back of the page is stained at 47 mm intervals. Digital digital pri digital printer digital printer digital printer check and cause solution 1. Transfer roller is contaminated. 2. Pressure roller is contaminated. 1. ...

Page 33

4-13 troubleshooting service manual 4.3.1 wrong print position • description printing begins at wrong position on the paper. Check and cause solution wrong sense time caused by defective feed sensor actuator. Replace the defective actuator check and cause solution 1. Check the solenoid by using dcu ...

Page 34

4-14 troubleshooting service manual check and cause solution 1. If the recording paper is jammed in front of or inside the fuser. (perform dcu diagnostic code 08) 2. If the recording paper is stuck in the discharge roller and the fuser just after passing through the actuator- feed, feed actuator may...

Page 35

4-15 troubleshooting service manual 4.3.5 multi-feeding • description multiple sheets of paper are fed at once. Check and cause solution 1. Solenoid malfunction(the solenoid does not work properly): perform dcu diagnostic code 06. 2. Pad-friction is contaminated with foreign matter.(oil...) 3. The f...

Page 36

4-16 troubleshooting service manual 4.3.7 paper rolled in the toner cartridge (opc drum) • description paper is rolled up in the opc. Check and cause solution 1. Paper is too much thin. 2. The face of paper is curled. 1. Recommend to use normal paper. 2. How to remove the rolled in the opc drum. • r...

Page 37

4-17 troubleshooting service manual 4.4 malfunction 4.4.1 all leds blinking (fuser error) • description 1. All the lamps on the operator panel blink. 2. Gear of the fuser does not work and breaks away melt away. When printing, motor breaks away from its place due to defective fuser gear. Check and c...

Page 38

4-18 troubleshooting service manual 4.4.3 not function of the gear of the fuser due to melting away • description the motor breaks away from its place due to gear melting away. Check and cause solution dcu mode : check if the error states '60' '62' '68' occur. Check the operation of fuser erasing la...

Page 39

4-19 troubleshooting service manual 4.4.6 cover open • description the error lamp is on even when the print cover is closed. Check and cause solution 1. The hook lever in the top cover may be defective. 2. Check the connector (engine b’d ↔ hvps) and circuit of the cover switch department in the main...

Page 40

4-20 troubleshooting service manual 4.4.8 defective motor operation • description main motor is not driving when printing, and paper does not feed into the printer, resulting 'jam 0'. Check and cause solution 1. Motor harness or sub pcb may be defective. 2. Perform dcu diagnostic code 00 and check t...

Page 41

4-21 troubleshooting service manual 4.4.10 vertical line getting curved • description when printing, vertical line gets curved. Check and cause solution 1. If the supply of +24v is unstable in the main control board linking with lsu, check drive by dcu mode : lsu check -05- lsu motor on. 1. Replace ...

Page 42

4-22 troubleshooting service manual 4.5 toner cartridge service it is not guaranteed for the default caused by using other toner cartridge other than the cartridge supplied by the samsung electronic or caused by non-licensed refill production. 4.5.1 precautions on safe-keeping of toner cartridge exc...

Page 43

4-23 troubleshooting service manual 4.5.4 signs and measures at poor toner cartridge fault signs cause & check solution light image and partially blank image (the life is ended.) toner contamination • the printed image is light or unclean and untidy. • some part of the image is not print- ed. • peri...

Page 44

4-24 troubleshooting service manual fault signs cause & check solution white black spot recycled product • light or dark black dots on the image occur periodically. • white spots occur in the image period- ically. • poor appearance of the developer. • unclean and rough printouts. • bad background in...

Page 45

4-25 troubleshooting service manual 4.6 bad environment of the software 4.6.1 the printer is not working (1) • description while power turned on, the printer is not working in the printing mode. Check and cause solution 1. Run self-test mode : turn the power on while pressing the test printing butto...

Page 46

4-26 troubleshooting service manual 4.6.2 the printer is not working (2) • description after receiving the printing order, no response at all or the low speed of printing occurs due to wrong setup of the environment rather than malfunction of the printer itself. Check and cause solution 1. Secure mo...

Page 47

4-27 troubleshooting service manual 4.6.3 abnormal printing • description the printing is not working properly even when the cable has no problem. (even after the cable is replaced) if the printer won't work at all or the strange fonts are repeated, the printer driver may be defec- tive or wrong set...

Page 48

4-28 troubleshooting service manual 4.6.4 spool error • description to spool which stands for "simultaneous peripheral operations online" a computer document or task list (or "job") is to read it in and store it, usually on a hard disk or larger storage medium so that it can be printed or otherwise ...

Page 49

5 5 5-1 exploded views and parts list service manual 5. Exploded views and parts list 5.1 main assembly exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page(5-2) 5.2 frame assembly exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 50

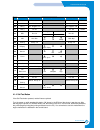

5-2 exploded views and parts list service manual 5.1 main assembly exploded view 0 9 6 7 8 2-2 2-3 2-4 2-5 2-6 2-6 15-1 15-2 5 2-1 2-7 2-10 1 2 10 4 1 1-1 11 1 1-2 1 1-3 11-4 1 1-5 1 1-3 12 13 14-1 14-2 14-3 14 14-4 3 15.

Page 51

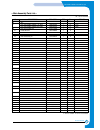

5-3 exploded views and parts list service manual sa. : service available no description sec code q’ty sa remark 0 set 1 ela unit-frame lower, 110v, xrx jc96-02732a 1 o 110v ela unit-frame lower, 220v, xrx jc96-02734a 1 o 220v 2 ela hou-cover top jc97-01748d 1 o 2-1 lens led-led jc67-00026a 1 x 2-2 c...

Page 52

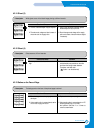

5-4 exploded views and parts list service manual 5.2 frame assembly exploded view 0 1 2 4 3 5 6 7 12 6 9 53 9 51 13 14 15 16 17 57 18 19 20 20 21 22 23 24 25 26 37 31 27 28 29 29 30 58 58-1 58-2 58-3 58-4 58-5 58-6 58-6 58-4 40 41 56 42 44 53 45 46 47 48 59 59-1 59-2 59-3 59-4 50 52 52 54 55 11 10 8...

Page 53

5-5 exploded views and parts list service manual sa. : service available o: service available x: service not available no description sec code q’ty sa remark 0 ela unit-frame assy jc96-02732a 1 x 1 frame-base jc61-00579a 1 x 2 guide-tr jc61-00607a 1 x 3 plate-saw jc61-00604a 1 x 4 guide-tr rib jc61-...

Page 54

5-6 exploded views and parts list service manual sa. : service available o: service available x: service not available no description sec code q’ty sa remark 40 shaft-feed idle jc66-00527a 1 x 41 bush-feed idle jc61-00585a 1 x 42 spring-feed idle jc61-70958a 1 x 43 ipr-p_ground_drive2 jc70-00335a 1 ...

Page 55

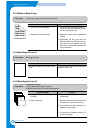

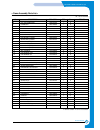

5-7 exploded views and parts list service manual 5.3 driver unit exploded view 0 1 2 3 4 4 5 6 7 8 9 harness-motor 5 sa. : service available o: service available x: service not available no description sec code q’ty sa remark 0 ela hou-rx drive 1400 jc96-02733a 1 o 1 bracket-gear 1400 jc61-00598a 1 ...

Page 56

5-8 exploded views and parts list service manual 5.4 fuser unit exploded view 0 1 2 3 4 5 32 32 6 33 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 31 22 23 24 25 26 27 30 28 29.

Page 57

5-9 exploded views and parts list service manual no description sec code q’ty sa remark 0 ela hou-fuser 110v tbd 1 o 110v ela hou-fuser 220v tbd 1 o 220v 1 cover-fuser jc63-00105a 1 x 2 holder-plate claw jc61-00584a 4 x 3 spring etc-claw jc61-00064a 4 x 4 pmo-roller exit jc72-60059a 2 x 5 spring-exi...

Page 58

5-10 exploded views and parts list service manual 5.5 cassette unit exploded view 0 1 2 3 4 5 5 6 7 8 9 10 11 12 13 14 15 16 18 17.

Page 59

5-11 exploded views and parts list service manual no description sec code q’ty sa remark 0 cassette jc97-01750a 1 o 1 frame-cassette jc61-00578a 1 x 2 pmo-extension large jc72-00970a 1 x 3 pmo-extension small jc72-00971a 1 x 4 plate-knock_up jc61-00603a 1 x 5 spring-knock_up 6107-001166 2 x 6 holder...

Page 60: 6. Block Diagram

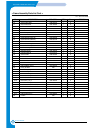

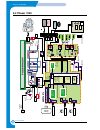

6 6 6-1 block diagram service manual 6. Block diagram 6.1 phaser 3130 fuser ass’y power cord in-let f. G thermist or to controller main mot or c-solenoid c-solenoid-mp scf (option) ieee1284 interface usb2.0 net2270 crystal 14.74 mhz freq. Spread v ideo clock vol tage detect or mot or driver power on...

Page 61: 6.2 Phaser 3120

6-2 block diagram service manual 6.2 phaser 3120 mhvpwm thvpwm f. G exit -sensor feed-sensor p/empty -sensor mp-sensor in-let - + gnd thv -rd biaspwm thv_ea hea ter-thermist or +24v +5v +3.3v fa n power cord crystal 12mhz main clock power on reset smps + main 26p cpu jupiter 4 +24v main motor c-clut...

Page 62: 7. Connection Diagram

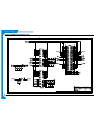

7 7 7-1 connection diagram service manual 7. Connection diagram 7.1 phaser 3130 host computer ieee1284 comopatiable cable cn5 pcl main board fr-4, 4layer 6 pin connector for usb usb cable cn14 1 2 1 2 thermistor 1 2 3 4 motor cn8 cn10 cn3 dcu +3.3v dcu_data 1 2 3 4 1 2 3 4 dcu_clk gnd 1 2 3 4 5 6 7 ...

Page 63: 7.2 Phaser 3120

7-2 connection diagram service manual 7.2 phaser 3120 the rm the rm2 1 2 1 2 thermistor motor dcu host computer a a/ 1 2 3 4 1 2 3 4 b b/ cn2 cn7 cn5 cn3 4p in conn-e ctor for us b usb cable + 3.3v d cu _d ata 1 2 3 4 1 2 3 4 d cu _c lk g nd spl main board fr-4, 2layer 1 2 3 4 5 6 lsu polygon motor ...

Page 64

8-1 schematic diagrams service manual 8 8. Schematic diagrams 8.1 phaser 3130 main circuit diagram (1/9).

Page 65

8-2 schematic diagrams service manual phaser 3130 main circuit diagram (2/9).

Page 66

8-3 schematic diagrams service manual phaser 3130 main circuit diagram (3/9).

Page 67

8-4 schematic diagrams service manual phaser 3130 main circuit diagram (4/9).

Page 68

8-5 schematic diagrams service manual phaser 3130 main circuit diagram (5/9).

Page 69

8-6 schematic diagrams service manual phaser 3130 main circuit diagram (6/9).

Page 70

8-7 schematic diagrams service manual phaser 3130 main circuit diagram (7/9).

Page 71

8-8 schematic diagrams service manual phaser 3130 main circuit diagram (8/9).

Page 72

8-9 schematic diagrams service manual phaser 3130 main circuit diagram (9/9).

Page 73

8-10 schematic diagrams service manual 8.2 phaser 3120 main circuit diagram (1/5).

Page 74

8-11 schematic diagrams service manual phaser 3120 main circuit diagram (2/5).

Page 75

8-12 schematic diagrams service manual phaser 3120 main circuit diagram (3/5).

Page 76

8-13 schematic diagrams service manual phaser 3120 main circuit diagram (4/5).

Page 77

8-14 schematic diagrams service manual phaser 3120 main circuit diagram (5/5).

Page 78

8-15 schematic diagrams service manual 8.3 hvps circuit diagram (1/2) r305 mgr1/2w 50m 5v q201 a708-y 4 r204 47k d202 d1nl20u tnr201 5n221k thv-pwm ¡ c210 6kv 221 r205 22k it301 q302 c2383 6 it201 it-01 c303 103 7 thv-ea ¡ d206 6kv r304 1/4w 4.7 zd301 2.7v c304 3kv 151 1 ¡ d205 6kv r212 1/2w 100k 5 ...

Page 79

8-16 schematic diagrams service manual hvps circuit diagram (2/2) d503 d1nl20u 5v r413 1/2w 100k c407 103 c505 104 d402 1n4148 opc 1 c402 102 r505 10k + c113 25v 47uf mhv-pwm ¡ r410 1/2w 560k bias-sen r513 1/2w 50k r407 100k zd401 2.7v 6 zd402 2.7v r501 47k r408 470 ¡ gnd zd501 2.7v c405 104 r404 10...

Page 80

8-17 schematic diagrams service manual 8.4 smps circuit diagram c110 nu 3 c105 50v 33uf d6 d1nl20u con2-22(led-data) c8 471 u101 tl431 2 3 1 r5 2w 100k 4 f101 con2-16(thv-pwm) 9 dss-401m c7 50v 33uf no marking resistor 1/8w-j(5%) c6 1kv 103 con2-25(fuser-on) r106 1/2w 3.3k c101 1kv 102 con2-14,16(+2...

Page 81

8-18 schematic diagrams service manual 8.5 other pba circuit diagrams r115 150 r117 150 con2-24(fan) 1 2 r118 47k 2 op102 itr-8406s con4 3 c111 104 con2-15(manual) 35301-0350 35303-0550 5 con2-23(key-demo) r120 5.6k 4 con2-26(exit) r119 2.2k 3 3 24vs 2 2 1 4 con2-21(led-error) op101 itr-8406s 1 3 3....