- DL manuals

- Xerox

- Printer

- 3150 - Phaser B/W Laser Printer

- Service Manual

Xerox 3150 - Phaser B/W Laser Printer Service Manual

Summary of 3150 - Phaser B/W Laser Printer

Page 1

Laser printer phaser ® 3150 service manual.

Page 3: Phaser 3150 Laser Printer

Phaser 3150 laser printer service manual warning the following servicing instructions are for use by qualified service personnel only. To avoid personal injury, do not perform any servicing other than that contained in the operating instructions, unless you are qualified to do so. First printing: ju...

Page 4

Copyright © 2004 xerox corporation. All rights reserved. Unpublished rights reserved under the copyright laws of the united states. Contents of this publication may not be reproduced in any form without permission of xerox corporation. Copyright protection claimed includes all forms of matters of co...

Page 5

1 precautions 1.1 safety warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.2 safety cautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 1.2.1 toxic material . . . . ...

Page 6

4.5 engine f/w. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15 4.5.1 feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15 5 disassembly 5.1 precautions for disassembly/re...

Page 7

7 troubleshooting 7.1 print quality problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 7.1.1 vertical black line and band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 7.1.2 vertical white lines. . . . . . . . . . . ...

Page 8

8 parts list 8.1 main assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2 main assembly parts list 8.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3 8.2 frame unit assemly . . . . . . . . . . . . ...

Page 9: 1.1 Safety Warnings

Precautions service manual 1-1 in order to prevent accidents and to prevent damage to the printer, please read the precautions listed below carefully before servicing the printer. 1.1 safety warnings 1. Only to be serviced by appropriately qualified service engineers. High voltages and lasers inside...

Page 10: 1.2 Safety Cautions

Precautions 1-2 1.2 safety cautions 1.2.1 toxic material this product contains toxic materials that could cause illness if ingested. 1. Please keep toner cartridges away from children. The toner powder contained in the toner cartridge may be harmful and if swallowed you should contact a doctor immed...

Page 11: 1.2.3 Handling Precautions

Precautions service manual 1-3 1.2.3 handling precautions the following instructions are for personal safety, to avoid injury, and to avoiddamage the printer 1. Ensure the printer is installed on a level surface, capable of supporting its weight. Failure to do so could cause the printer to tip or fa...

Page 12

Precautions 1-4 1.2.5 bodily injury warnings 1. Use caution around high temperature parts. The fuser unit works at a high temperature. Use caution when working on the printer. Wait for the fuser to cool down before disassembly. 2. Use caution when around rotating parts. When operating the printer, d...

Page 13: 1.3 Esd Precautions

Precautions service manual 1-5 1.3 esd precautions some semiconductor components, and the respective sub-assemblies that contain them, are vulnerable to damage by electro-static discharge (esd). These components include integrated circuits (ics), large-scale integrated circuits (lsis), field-effect ...

Page 14

Precautions 1-6.

Page 15: Reference Information

Reference information service manual 2-1 this section contains a tools list, list of abbreviations used in this manual, and a clearance required specification when installing the phaser 3150 printer. 2.1 tools for troubleshooting the printer the following tools are recommended for safe and easy trou...

Page 16

Reference information 2-2 2.2 acronyms and abbreviations definition definition adc analog-to-digital conversion f/w firmware ap access point fcf/fct tray 1 or first cassette feeder ac alternating current fiso front in, side out asic application specific integrated circuit fpot first print out time a...

Page 17

Reference information service manual 2-3 lvps low voltage power supply or smps mb megabyte q’ty quantity mhz megahertz ram random access memory mpbf mean prints between failure rom read only memory mpf/mpt multi-purpose tray scf/sct tray 2 or second cassette feeder nic network interface card smps sw...

Page 18

Reference information 2-4 2.3 selecting a location for the printer ■ leave enough room to open the printer trays, covers, and allow for proper ventilation. ■ provide the proper environment: ■ a sturdy, level surface. ■ away from the direct airflow of air conditioners, heaters, or ventilators. ■ free...

Page 19: 3.1 General Specifications

Specifications service manual 3-1 the specifiations in this manual are correct at the time of printing. Product specifications are subject to change without notice. 3.1 general specifications * print speed will be affected by the operating system used, computing performance, application software, co...

Page 20

Specifications 3-2 3.2 controller/software specifications 3.3 electrical specifications item description processor spgpm (samsung printer graphic processor) 166 mhz memory 32 mb, expandable to 144 mb, sdram emulation spl, pcl6 (firmware), epson, ibm proprinter, optional postscript 3 spl, pcl6 (firmw...

Page 21: 3.4 Environmental Range

Specifications service manual 3-3 3.4 environmental range 3.6 media specifications 3.6.1 approved paper size and weights the supported media types for this printer include, but are not limited to: labels, envelopes, cardstock, plain paper, transparency, letterhead and colored paper. 3.6.2 print marg...

Page 22

Specifications 3-4.

Page 23: 4.1 Printer Components

Summary of product service manual 4-1 this section describes the functions and operating principals of the printers main components. 4.1 printer components 4.1.1 front view 4 product summary output support top output tray (face down) control panel power switch paper level indicator tray multi purpos...

Page 24

Summary of product 4-2 4.1.2 rear view 4.1.3 control panel usb port parallel port power receptacle rear output tray (face up) top output tray (face down).

Page 25

Summary of product service manual 4-3 on line/error and toner save led’s led description the on line/error led is green, when the printer is ready to print. The on line/error led slowly blinks green when the printer is receiving data, and blinks rapidly while printing. The on line/error led is red i...

Page 26: 4.2.1 System Summary

Summary of product 4-4 4.2 printer theory of operation 4.2.1 system summary the printer consists of the following main functional components: 1) the firmware engine firmware controls the whole printing process. 2) the print engine 1. Engine frame 2. Paper feed the paper feed system consists of a 250...

Page 27: 4.2.2 System Layout

Summary of product service manual 4-5 4.2.2 system layout 4.2.3 paper feed the paper feed system consists of a 250- sheet main paper tray (tray 2), a multi-purpose paper tray (tray 1), pickup rollers, friction pads and feed rollers. The rollers and sensors in the paper feed path control paper regist...

Page 28: 4.2.4 Transfer Assembly

Summary of product 4-6 4.2.4 transfer assembly the transfer roller transfers toner from the opc drum to the paper. Toner is transferred from the opc drum onto the paper using a ptl (pre-transfer lamp) and a transfer roller. The ptl shines light onto the opc, reducing the electrical charge on the opc...

Page 29: 4.2.8 Toner Cartridge

Summary of product service manual 4-7 4.2.7 laser scanner unit (lsu) this is the core of the laser printer. It converts the video data received from the computer into an electrostatic latent image on the surface of the opc drum. This is achieved by controlling the laser beam and exposing the surface...

Page 30

Summary of product 4-8 4.3 main controller board (pba) the engine board and controller board have been integrated into a single board consisting of the cpu and printer control functions. The cpu functions as the bus controller, i/o handler, motor driver and pc interface. The main board sends the cur...

Page 31: 4.3.1 Asic (Spgpm)

Summary of product service manual 4-9 4.3.1 asic (spgpm) ■ arm946es ■ 32-bit risc embedded processor core ■ 16 kb instruction cache and 16 kb data cache ■ no tightly coupled memory ■ memory protection unit and cp15 control program ■ dual bus architecture for bus traffic distribution ■ amba high perf...

Page 32: 4.3.4 Sdram

Summary of product 4-10 4.3.4 sdram used as a swath buffer, systems working memory area, etc. When printing. ■ capacity: 32 mb, expandable up to 144 mb ■ optional additional dimm : 16 mb / 32 mb / 64 mb /128 mb ■ type : sdram 100 mhz/133 mhz, 16bit 4.3.5 sensor input circuit 4.3.5.1. Paper empty sen...

Page 33

Summary of product service manual 4-11 4.3.5.9 transfer the charging voltage, developing voltage, and the transfer voltage are controlled by pulse width modulation (pwm). Each output voltage is changeable according to the pwm duty cycle. The transfer voltage used when the paper passes the transfer r...

Page 34: Voltage Power Supply (Hvps)

Summary of product 4-12 4.4 switching mode power supply (smps) and high voltage power supply (hvps) the smps and hvps are on one integrated board. The smps supplies the dc power to the printer. It takes either 110 v or 220 v and outputs the +5 v and +24 v supplies to the main board. The hvps creates...

Page 35

Summary of product service manual 4-13 4.4.1 high voltage power supply 1) transfer high voltage (thv+) input voltage: 24 vdc ± 15% output voltage: max +5.0k v ± 5%, (duty variable, no loading 1.2 kv ±15% (when cleaning, 200 m output voltage trigger: 6.5 ua input contrast of the voltage stability deg...

Page 36

Summary of product 4-14 5) supply output voltage: -400 v ~ -800 vdc ±50 v (zener using, dev) input contrast of the output stability degree: under ±5% loading contrast: ±5% or less output voltage rise time: 50 ms maximum output voltage fall time: 50 ms maximum output loading range: 10 mž ~ 1000 mž ou...

Page 37: 4.5 Engine F/w

Summary of product service manual 4-15 4.5 engine f/w 4.5.1 feeding while feeding from the universal trays, the drive for the pickup roller is controlled by the pick-up solenoid. The printer feeds the paper from the tray1/mpt according to the information provided by the mp sensor, and by driving the...

Page 38

Summary of product 4-16.

Page 39: Disassembly

Disassembly service manual 5-1 5.1 precautions for disassembly/reassembly ■ use only approved xerox spare parts. Ensure that the part number, product name, any voltage, current or temperature ratings are correct. Failure to do so could result in damage to the printer, circuit overload, fire or elect...

Page 40

Disassembly 5-2 ■ do not touch the board with your bare hands or metal objects, this can create a short circuit or cause an electrical shock. Take extra care when handling boards containing sensors, motors or lamps as they may get hot. ■ take care when fitting, or removing, screws. Check for hidden ...

Page 41: 5.2 Front Cover

Disassembly service manual 5-3 5.2 front cover 1. Remove the paper tray. 2. Open the front door and remove the toner cartridge. 3. With the front cover fully open, carefully release the plastic hinge supports from the guide hooks by pulling inward. 4. Pull the front cover away from the printer to re...

Page 42: 5.3 Tray 1/mpt Assembly

Disassembly 5-4 5.3 tray 1/mpt assembly 1. Open the tray1/mpt assembly. 2. With the tray at a 45 o angle, carefully release the plastic hinge supports from the guide hooks. 3. Lift the tray1/mpt assembly off the hinge pins on the front cover. 45°.

Page 43: 5.4 Rear Cover

Disassembly service manual 5-5 5.4 rear cover note when disassembling the rear cover, move the power switch to the off position. When reassembling the rear cover, move the power switch to the on position. 1. Remove 2 screws securing the rear open cover and remove. 2. Open the face up cover. 3. Remov...

Page 44: 5.5 Top Cover

Disassembly 5-6 5.5 top cover 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the rear cover, see "5.4 rear cover" on page 5-5. 3. Remove 4 screws securing the top cover as shown below. Caution when removing the top cover, lift the front of the top cover slowly to avoid damag...

Page 45: 5.6 Middle Cover

Disassembly service manual 5-7 5.6 middle cover 1. Remove the rear cover, see "5.4 rear cover" on page 5-5. 2. Remove the top cover, see "5.5 top cover" on page 5-6. 3. Open the front cover. 4. Remove 4 screws securing the middle cover. 5. Disconnect and free the wiring harness from the middle cover...

Page 46

Disassembly 5-8 5.7 side cover (left and right) 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the rear cover, see "5.4 rear cover" on page 5-5. 3. Remove the top cover, see "5.5 top cover" on page 5-6. 4. Remove the 2 screws securing the right or left cover. 5. Slide the co...

Page 47: 5.8 Exit Roller

Disassembly service manual 5-9 5.8 exit roller 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the rear cover, see "5.4 rear cover" on page 5-5. 3. Remove the top cover, see "5.5 top cover" on page 5-6. 4. Remove the left and right covers, see "5.7 side cover (left and right)...

Page 48

Disassembly 5-10 5.9 engine shield assembly and exit board 1. Remove the rear cover, see "5.4 rear cover" on page 5-5. 2. Remove the top cover, see "5.5 top cover" on page 5-6. 3. Remove the right cover, see "5.7 side cover (left and right)" on page 5-8. 4. Remove the paper tray. 5. Remove 1 screw s...

Page 49

Disassembly service manual 5-11 8. Turn the printer onto its top to access and remove the 12 screws on the bottom of the printer securing the engine shield assembly. 9. Remove 2 screws securing the exit board to the print frame. Caution when reassembling the engine shield assembly, be sure the paper...

Page 50: 5.10.1 Smps

Disassembly 5-12 5.10.1 smps 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the rear cover, see "5.4 rear cover" on page 5-5. 3. Remove the top cover, see "5.5 top cover" on page 5-6. 4. Remove the left and right covers, see "5.7 side cover (left and right)" on page 5-8. 5. ...

Page 51: 5.10.2 Main Board

Disassembly service manual 5-13 5.10.2 main board 1. Remove the rear cover, see "5.4 rear cover" on page 5-5. 2. Remove the smps shield, see step 5 in "5.9 engine shield assembly and exit board" on page 5-10. 3. Disconnect all harnesses from the main board. 4. Remove the 8 screws securing the main b...

Page 52: Modules

Disassembly 5-14 5.10.3 removing the network card or optional memory modules you only need to open the rear open cover to access the memory modules and network card. Thumb screws memory board.

Page 53: 5.11 Fuser Assembly

Disassembly service manual 5-15 5.11 fuser assembly warning the fuser assembly is hot. Let the fuser cool before removing. 1. Remove the rear cover, see "5.4 rear cover" on page 5-5. 2. Unplug 2 connectors, one from the main board and one from the smps. 3. Remove 4 screws securing the fuser assembly...

Page 54

Disassembly 5-16 caution there are 2 securing nuts the screws go through that are not captured. These can fall out and get lost when tipping the fuser assembly. Caution hold the halogen lamp by the end terminals. Do not touch the lamp itself, this will damage it and cause the fuser to malfunction. 5...

Page 55

Disassembly service manual 5-17 7. Free the thermister harness as shown below. 8. Remove 1 screw securing the thermister and remove from the fuser assembly. Thermistor harness thermistor.

Page 56: 5.12 Fan

Disassembly 5-18 5.12 fan 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the rear cover, see "5.4 rear cover" on page 5-5. 3. Remove the top cover, see "5.5 top cover" on page 5-6. 4. Remove the right cover, see "5.7 side cover (left and right)" on page 5-8. 5. Disconnect th...

Page 57

Disassembly service manual 5-19 5.13 laser scanner unit (lsu) 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the rear cover, see "5.4 rear cover" on page 5-5. 3. Remove the top cover, see "5.5 top cover" on page 5-6. 4. Remove the left and right covers, see "5.7 side cover (...

Page 58: 5.14 Drive Assembly

Disassembly 5-20 5.14 drive assembly 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the rear cover, see "5.4 rear cover" on page 5-5. 3. Remove the top cover, see "5.5 top cover" on page 5-6. 4. Remove the left and right covers, see "5.7 side cover (left and right)" on page ...

Page 59: 5.15 Transfer Assembly

Disassembly service manual 5-21 5.15 transfer assembly 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the toner cartridge. 3. Remove the rear cover, see "5.4 rear cover" on page 5-5. 4. Remove the middle cover, see "5.6 middle cover" on page 5-7. 5. Remove the top cover, see...

Page 60: 5.16.1 Tray 1/mpt Assembly

Disassembly 5-22 5.16.1 tray 1/mpt assembly 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the rear cover, see "5.4 rear cover" on page 5-5. 3. Remove the middle cover, see "5.6 middle cover" on page 5-7. 4. Remove the top cover, see "5.5 top cover" on page 5-6. 5. Remove th...

Page 61: 5.16.2 Feed Roller

Disassembly service manual 5-23 5.16.2 feed roller 1. Remove the drive assembly, see "5.14 drive assembly" on page 5-20. 2. Remove the tray 1/mpt assembly, see "5.16.1 tray 1/mpt assembly" on page 5-22. 3. Remove the 3 screws (gold) from the feed bracket. Note the feed bracket screws are numbered an...

Page 62

Disassembly 5-24 5. Remove the screw from the right idler bushing plate. 6. Remove the plate, idler spring and bushing. 7. Slide the feed shaft idler to the right and out of the printer. 8. Remove the feed roller and feed roller 1 as shown below. Feed roller1 feed roller.

Page 63

Disassembly service manual 5-25 5.17 pick-up assembly, solenoids, and pick roller 1. Remove the front cover, see "5.2 front cover" on page 5-3. 2. Remove the rear cover, see "5.4 rear cover" on page 5-5. 3. Remove the middle cover, see "5.6 middle cover" on page 5-7. 4. Remove the top cover, see "5....

Page 64

Disassembly 5-26 13. Remove the pick roller as shown below on the right. Regi solenoid pick-up solenoid rubber pickup.

Page 65: Alignment and

Alignment and adjustments service manual 6-1 this chapter describes some of the main service procedures including: ■ using the dcu for diagnostics ■ clearing paper jam and test patterns much of this chapter is also included in the user's guide. 6.1 how to use the diagnostic control unit (dcu) 6.1.1 ...

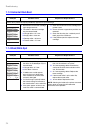

Page 66: 6.1.2 Status Monitoring Code

Alignment and adjustments 6-2 6.1.2 status monitoring code the dcu can be used in 2 modes: status monitoring and self diagnostic. To use the dcu in status monitoring mode, connect the dcu and turn printer power on. The 7 segment led display will show various codes that show the progress of the print...

Page 67: 6.1.3 Self Diagnostic Mode

Alignment and adjustments service manual 6-3 6.1.3 self diagnostic mode if an error appears, use the self diagnostic mode for fault finding as many safety features are disabled. To enter self diagnostic mode: a. Connect the dcu. B. Turn the printer on while holding down the [down], [shift] and [stop...

Page 68

Alignment and adjustments 6-4 08 feed and exit sensor test the off led indicates the status of the exit sensor. The 3rd led indicates the status of the feed sensor. Note: the feed sensor also detects the presensce of the toner cartridge. 09 cover open sensor test the on led indicates the status of t...

Page 69

Alignment and adjustments service manual 6-5 code function enter led stop remark 00 motor motor run motor stop 01 mhv mhv on mhv off -1550 v 02 thv(-) thv negative on thv negative off 03 thv(+) thv on thv off +1300 v 04 dev dev on dev off +430 v 05 lsu lsu run ● ● ● on off ready lsu stop 06 pick up ...

Page 70: 6.2 Paper Path

Alignment and adjustments 6-6 6.2 paper path after receiving the print command, the printer feeds paper from tray 1, 2, or optional tray 3. Jam0: if the paper does not pass the feed senosr in the specified amount of time a jam0 occurs. See the first illustration to the left. Jam1 a jam 1 will occur ...

Page 71: 6.3 Clearing Paper Jams

Alignment and adjustments service manual 6-7 6.3 clearing paper jams the leading causes of paper jams are: ■ the tray is loaded improperly or overfilled. ■ the tray has been pulled out during a print job. ■ the front cover has been opened during a print job. ■ paper that does not meet specifications...

Page 72

Alignment and adjustments 6-8 6.3.2 jam0: paper in the feed area 1. Slide out the tray to expose the jammed paper. 2. Remove any jammed paper by pulling the visible edge away from the tray. 3. Make sure that all of the paper is properly aligned in the tray. 4. Slide the tray back into the printer. O...

Page 73: 6.4 Sample Patterns

Alignment and adjustments service manual 6-9 6.3.4 tips for avoiding paper jams by selecting the correct paper types, most paper jams can be avoided. To help prevent paper jams always perform the following: ■ ensure that the adjustable guides are positioned correctly against the paper. ■ do not over...

Page 74

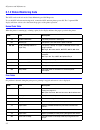

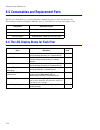

Alignment and adjustments 6-10 6.5 consumables and replacement parts the life cycle outlined below is a general guideline for maintenance purposes and is for reference only. Environmental conditions (temperature, humidity, dust, etc.) and actual use can cause these figures to vary. 6.6 the led displ...

Page 75

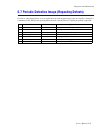

Alignment and adjustments service manual 6-11 6.7 periodic defective image (repeating defects) if a mark or other printing defect occurs at regular intervals down the printed page it may be caused by a damaged or contaminated roller. Measure the repeating defect and refer to the table below to ident...

Page 76

Alignment and adjustments 6-12.

Page 77: 7.1 Print Quality Problems

Troubleshooting service manual 7-1 7.1 print quality problems 7.1.1 vertical black line and band 7.1.2 vertical white lines 7 troubleshooting example possible cause sequence of repair actions there are straight, black, vertical lines or banding on the printed image. 1. Damaged developer roller, defo...

Page 78

Troubleshooting 7-2 7.1.3 horizontal black band 7.1.4 black/white spot example possible cause sequence of repair actions dark or blurry horizontal stripes periodically appear on the printed image. 1. Bad contacts on the toner cartridge high voltage terminals. 2. The rollers in the toner cartridge ma...

Page 79

Troubleshooting service manual 7-3 7.1.5 light image 7.1.6 dark image or completely black print example possible cause sequence of repair actions the printed image is too light, with no ghosting. 1. Toner save mode is enabled. 2. The developer roller is contaminated or the toner cartridge is almost ...

Page 80

Troubleshooting 7-4 7.1.7 uneven density 7.1.8 background contamination example possible cause sequence of repair actions print density is uneven from left to right. 1. The toner level is not even on the toner cartridge roller due to a damaged blade or low toner. 2. The life of the toner cartridge h...

Page 81

Troubleshooting service manual 7-5 7.1.9 ghosting 1 7.1.10 ghosting 2 example possible cause sequence of repair actions there is ghosting at 75.5 mm intervals from the opc drum while printing on card stock, transparencies or using the mpt. 1. When printing on card stock, thick paper or transparenice...

Page 82

Troubleshooting 7-6 7.1.11 ghosting 3 7.1.12 ghosting 4 7.1.13 stains on the front of the page example possible cause sequence of repair actions ghosting occurs at 78 mm intervals. 1. Fuser contamination or termperature control problem. A. Replace the fuser. Example possible cause sequence of repair...

Page 83

Troubleshooting service manual 7-7 7.1.14 stains on the back of the page 7.1.15 blank page is printed 1 7.1.16 blank page is printed 2 example possible cause sequence of repair actions the back of the page is stained at 47 mm intervals. 1. Transfer roller is contaminated. 2. Pressure roller is conta...

Page 84: 7.2 Paper Feed Problems

Troubleshooting 7-8 7.2 paper feed problems 7.2.1 wrong print position 7.2.2 jam 0 printing begins at the wrong position on the paper. Possible cause solution 1. Defective feed sensor. A. Replace the defective acutator/sensor. Description: paper does not leave the tray. Jam0 occurs if the paper is n...

Page 85

Troubleshooting service manual 7-9 7.2.3 jam 1 7.2.4 jam 2 description: there is a paper jam in front of or inside the fuser. There is a paper jam stuck in the discharge roller and in the fuser, just after passing the feed actuator. Possible cause solution 1. Defective exit sensor/actuator. 2. Defec...

Page 86

Troubleshooting 7-10 7.2.5 multiple pick 7.2.6 paper rolled in the fuser 7.2.7 paper rolled in the opc drum description: multiple sheets of paper are picked from the tray at the same time. Possible cause solution 1. The paper guides are set incorrectly. 2. The paper has a rough surface. 3. The frict...

Page 87: 7.3 Printer Faults

Troubleshooting service manual 7-11 7.3 printer faults 7.3.1 all leds blinking (fuser error) 7.3.2 all leds blinking (scan error) 7.3.3 fuser gear melted due to overheating, causing a paper jam description: ■ all the lamps on the control panel blink. ■ the fuser drive gear breaks or melts. ■ when pr...

Page 88

Troubleshooting 7-12 7.3.4 paper empty error 7.3.5 paper empty error without indication 7.3.6 cover open description: the paper empty led is lit even when paper is loaded in the tray. Possible cause sequence of repair actions 1. The paper empty sensor or actuator is damaged or faulty. 2. The main bo...

Page 89

Troubleshooting service manual 7-13 7.3.7 no error lamp when the cover is open 7.3.8 defective motor operation 7.3.9 no power description: the error led is not lit when the front cover is open. Possible cause sequence of repair actions 1. The interlock may be stuck or damaged. 2. The control panel l...

Page 90

Troubleshooting 7-14 7.3.10 printed vertical lines become curved description: when printing the vertical lines are not straight. Possible cause sequence of repair actions 1. The +24 v supply to the laser unit is faulty. A. Use the dcu test 05 to test the laser motor. B. If the voltage is stable, rep...

Page 91

Troubleshooting service manual 7-15 7.4 toner cartridge servicing use only xerox toner cartridges in the printer. Non-xerox toner or third party toner refills are not guaranteed to work with this printer and can cause malfunctions, print-quality problems, and jamming to occur. 7.4.1 precautions for ...

Page 92: 7.5 Software Problems

Troubleshooting 7-16 7.5 software problems 7.5.1 the printer is not responding to the print command the printer is on, but not operating in print mode. 1. Print a demo page: a. When the ready led lights, press and hold the [cancel] button until the leds flash then release. B. If the test print works...

Page 93

Troubleshooting service manual 7-17 7.5.3 spool error simultaneous peripheral operations online (spool) is the process windows uses to manage print jobs. Jobs are processed and then stored on the hard disk until the printer is ready to accept them. 1. Insufficient space on the hard disk in the direc...

Page 94

Troubleshooting 7-18.

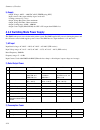

Page 95: Contents

Parts list service manual 8-1 contents ■ 8.1 main assembly ■ 8.2 frame unit assemly ■ 8.3 mp assembly ■ 8.4 fuser unit assembly ■ 8.5 main drive unit assembly ■ 8.6 tray 2 (cassette) unit assembly ■ 8.7 tray 3 (scf - optional cassette) unit assembly 8 parts list.

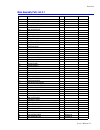

Page 96: 8.1 Main Assembly

Parts list 8-2 8.1 main assembly 0 toner cartridge 3 6 6-4 6-7 6-8 6-9 6-10 6-5 2 opt t ray 3 7 17 16 9 23 20 14 15 11 10 8 5 18 19 6-10 6-6 6-1 6-2 6-1 1 6-3 7-3 5-1 5-2 5-3 7-2 7-1 4 13 12 2-1 2-2 2-6 2-3 2-4 2-5 14-1 14-2 21 22.

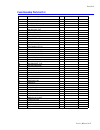

Page 97

Parts list service manual 8-3 main assembly parts list 8.1 no. Part name and (part description) qty part number remark 0 set 1 ela hou-frame-220v, hb2 1 1 ela hou-frame-110v, hb2 1 2 mea unit-cover top 1 002n02314 2-1 cover-m-top 1 2-2 pmo-stacker rx 1 2-3 key-m-on line 1 2-4 spring-cs 1 2-5 lens le...

Page 98

Parts list 8-4 19 cbf harness-engine 1 152n02012 20 mea unit-cassette (paper tray) 1 109r00749 21 plate channel 1 22 motor harness-drive 1 152n11566 23 toner cartridge 3.5k standard cap 1 109r00746 23 toner cartridge 5k high capacity 1 109r00747 no. Part name and (part description) qty part number r...

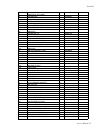

Page 99: 8.2 Frame Unit Assemly

Parts list service manual 8-5 8.2 frame unit assemly 15 16 72 18 13 10 11 12 60 70 35 8 9 14 58 24 25 43 44 45 47 39 46 17 26 42 47-1 46-1 46-2 47-2 47-3 47-4 47-5 45-1 45-2 45-3 40 41 51 5 62 5 5 2 48 4 3 65 25 33 19-1 19-2 50 7 6 37 36 38 49 49 28 29 30 34 31 32 t ransfer roller 56 23 61 63 73 61 ...

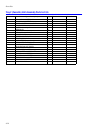

Page 100

Parts list 8-6 frame unit assembly parts list 8.2 no. Part name and (part description) qty part number remark 0 ela unit-frame 110v 1 110v ela unit-frame 220v 1 220v 1 frame-base r2 1 2 guide-p-tr 1 038n00407 3 plate-p-saw 1 4 guide-m-tr rib 1 038n00408 5 pmo-gear_exit_drv16 3 6 foot-back 2 7 foot-f...

Page 101

Parts list service manual 8-7 32 spring etc-tr l hawk 1 33 roller-feed 1 022n01607 34 bush-m-tr l 1 35 ground-fuser r2 1 36 shaft-feed idle 1 37 bush-m-feed idle 2 38 spring etc-tr 2 39 ground-drive2 r2 1 40 spring-ts 1 41 cam-m-pick_up 1 008n01738 42 ground-drive r2 1 43 solenoid-feed rocky2 1 121n...

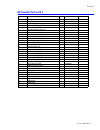

Page 102: 8.3 Mp Assembly

Parts list 8-8 8.3 mp assembly 0 11 18 24 31 10 2 12 15 29 16 17 13 19 27 19 5 4 8 22 6 7 14 26 14 23 28 23 1 30 20 9 3 21 25 25.

Page 103

Parts list service manual 8-9 mp assembly parts list 8.3 no. Part name and (part description) qty part number remark 0 ela unit-mp 1 022n02085 1 frame-17-mp 1 2 solenoid-mp 1 121n01075 3 cbf harness-mpf sen 1 4 bush-m-pick-up r 1 5 housing-m-pick up2_r2 1 6 stopper-m-pick up_r2 2 7 holder-m-pad_mp 1...

Page 104: 8.4 Fuser Unit Assembly

Parts list 8-10 8.4 fuser unit assembly 0 1 31 3 2 4 5 29 29 37 35 6 17 36 12 14 34 38 37 13 15 32 30 11 16 33 19 18 23 24 25 28 26 27 20 21 36 38 10 7 22 8 9.

Page 105

Parts list service manual 8-11 fuser assembly parts list 8.4 no. Part name and (part description) qty part number remark 0 ela hou-fuser 110v 1 126n00229 110v 0 ela hou-fuser 220v 1 126n00230 220v 1 cover-fuser r2 1 2 holder-plate claw r2 4 3 spring etc-claw 4 4 pmo-roller_exit 2 5 spring etc-fuser ...

Page 106: 8.5 Main Drive Unit Assembly

Parts list 8-12 8.5 main drive unit assembly main drive unit assembly parts list 8.5 no. Part name and (part description) qty part number remark 0 ela unit- drive 1 007n01270 1 bracket-gear main x 2 gear-rdcn 53/26 1 3 gear-rdcn 113/33 1 4 gear-rdcn 57/18 2 5 washer-plain 2 6 bracket-motor main 1 7 ...

Page 107

Parts list service manual 8-13 8.6 tray 2 (cassette) unit assembly 0 1 2 3 4 6 7 6-4 6-3 6-2 6-1 5 5 10 11 9 15 12 13 14 8 16.

Page 108

Parts list 8-14 tray 2 (cassette) unit assembly parts list 8.6 no. Part name and (part description) qty part number remark 0 mea unit-cassette, usa 1 109r00749 1 frame-m-cassette 1 2 guide-m-extension large 1 3 guide-extension small 1 4 plate-p-knock_up 1 5 spring-cs 2 6 mea unit-holder pad 1 6-1 ho...

Page 109

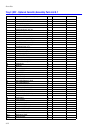

Parts list service manual 8-15 8.7 tray 3 (scf - optional cassette) unit assembly 0 5 4 2 3 31 15 16 36 34 34 35 24 21 20 22 23 19 18 17 39 39-2 39-1 39-9 39-5 39-4 39-7 39-6 39-3 39-8 27 33 32 25 26 28 27 1 30 37 38 39-10 41 1-1 1-2 40 39-11 39-12 42 11 13 10 14 6 9 7 12 8 29 43.

Page 110

Parts list 8-16 tray 3 (scf - optional cassette) assembly parts list 8.7 no. Part name and (part description) qty part number remark 0 ela hou-scf h2 1 097n01439 1 cover-m-front scf h2 1 1-1 spring-es 2 1-2 roller-idle feed 2 2 cover-m-left scf h2 1 3 cover-m-right scf h2 1 4 cover-m-rear scf h2 1 5...

Page 111

Parts list service manual 8-17 xerox options and accessories 39-6 gear 35 idle 1 39-7 gear-rdcn 57/18 1 39-8 gear-idle 23 1 39-9 motor step(scf) 1 39-10 screw-machine 5 39-11 core-ferrite 1 39-12 cable tie 1 40 bush cable 1 41 screw-taptite 14 42 guide-m-knockup 1 43 mea unit-cassette 1 109r00749 pa...

Page 112

Parts list 8-18.

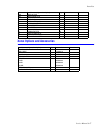

Page 113: Block Diagram

Block diagram service manual 9-1 9 block diagram popo wew er corco rd +24v mhvpwm biaspwm thvpw m cry st al 12mhz main clock po wer on re set f. G lsls u spgsp g pmpm panea ne l solenoid pt l thermistor heater-ac mhv opc gnd su ppl y de v thv sm ps blocl oc k fuser assyu se r a ss y ex it - sen sor ...

Page 114

Block diagram 9-2.

Page 115: Connection Diagram

Connection diagram service manual 10-1 10 connection diagram 36 pin host host computer computer ie ee1284 compatible cable m a i m a i n b o b oa r d a r d 4 l a y l a y e r e r f r f r 4 usb cable therm therm2 1 2 1 2 ther hermi mistor a a/ 1 2 3 4 1 2 3 4 b b/ motor motor 1 2 3 4 5 6 7 8 9 10 11 1...

Page 116

Connection diagram 10-2.