- DL manuals

- Xerox

- Printer

- DocuPrint N17

- Service Manual

Xerox DocuPrint N17 Service Manual

Summary of DocuPrint N17

Page 1

Xerox xerox docuprint n17 network laser printer service manual 721p50510 july, 1999 www.Printcopy.Info www.Printcopy.Info.

Page 2

3/99 product safety ii xerox docuprint n17 service manual this service manual contains information that applies to the xerox docuprint n17 network laser printers. Notice this manual is for use by xerox technicians and xerox-trained technicians only. Notice while every care has been taken in the prep...

Page 3

6/98 xerox docuprint n17 service manual iii product safety shock hazard this symbol indicates the presence of potentially hazardous voltages. Class 1 laser product the xerox docuprint n17 network laser printers are certified to comply with laser product performance standards, set by the u.S. Departm...

Page 4

6/98 product safety iv xerox docuprint n17 service manual (1) (2) www.Printcopy.Info www.Printcopy.Info.

Page 5

6/98 xerox docuprint n17 service manual v product safety the warning sticker illustrated below is affixed to the area identified with (3). (3) www.Printcopy.Info www.Printcopy.Info.

Page 6

6/98 product safety vi xerox docuprint n17 service manual this page intentionally blank. Www.Printcopy.Info www.Printcopy.Info.

Page 7

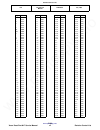

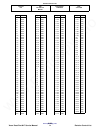

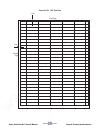

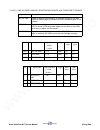

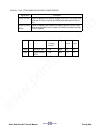

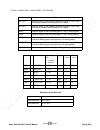

7/99 xerox docuprint n17 service manual vii revision control list revision control list product n17 title n17 service manual part number 721p50510 date july 1999 page rev. Cover 7/99 ii 3/99 iii 6/98 iv 6/98 v 6/98 vi 6/98 vii 7/99 viii 7/99 ix 6/98 x 6/98 xi 6/98 xii 6/98 1-1 6/98 1-2 6/98 1-3 6/98...

Page 8

6/98 revision control list viii xerox docuprint n17 service manual revision control list product n17 title n17 service manual part number 721p50510 date june 1998 page rev. 6-9 6/98 6-10 6/98 6-11 6/98 6-12 6/98 6-13 6/98 6-14 6/98 6-15 7/99 6-16 6/98 6-17 6/98 6-18 6/98 6-19 7/99 6-20 6/98 6-21 7/9...

Page 9

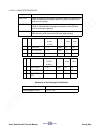

6/98 xerox docuprint n17 service manual ix revision control list revision control list product n17 title n17 service manual part number 721p50510 date june 1998 page rev. 9-1 6/98 9-2 6/98 9-3 6/98 9-4 6/98 9-5 6/98 9-6 6/98 9-7 6/98 9-8 6/98 9-9 6/98 9-10 6/98 9-11 6/98 9-12 6/98 9-13 6/98 9-14 6/9...

Page 10

6/98 revision control list x xerox docuprint n17 service manual revision control list product n17 title n17 service manual part number 721p50510 date june 1998 www.Printcopy.Info www.Printcopy.Info.

Page 11

6/98 xerox docuprint n17 service manual xi table of contents/introduction table of contents title page introduction ............................................. Xi organization ........................................... Xii service call procedures .......................1-1 printer specifications ...

Page 12

6/98 organization xii xerox docuprint n17 service manual organization this manual is divided into twelve sections. The title and description of each section of this service manual is as follows: section 1 - service call procedures this section is used to identify a suspected problem. It contains cal...

Page 13: Section 1

6/98 xerox docuprint n17 service manual 1-1 service call procedures section 1 service call procedures call flow diagram ......................................................................... 1-3 initial actions ................................................................................. 1-4 ...

Page 14

6/98 service call procedures 1-2 xerox docuprint n17 service manual www.Printcopy.Info www.Printcopy.Info.

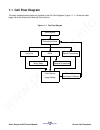

Page 15: 1.1 Call Flow Diagram

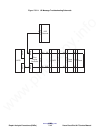

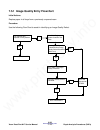

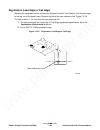

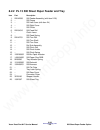

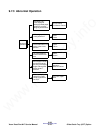

6/98 xerox docuprint n17 service manual 1-3 service call procedures 1 1.1 call flow diagram the basic troubleshooting steps are outlined in the call flow diagram (figure 1.1.1). All service calls begin with initial actions and end with final actions. Figure 1.1.1 call flow diagram initial actions co...

Page 16: 1.2 Initial Actions

6/98 service call procedures 1-4 xerox docuprint n17 service manual 1.2 initial actions 1 question the operator and verify the problem. 2 check that the printer paper path is clear of foreign matter such as staples, paper clips, and paper scraps. 3 after you have identified the problem symptom, chec...

Page 17: Section 2

6/98 xerox docuprint n17 service manual 2-1 printer specifications section 2 printer specifications electrical specifications ............................................................... 2-3 mechanical specifications............................................................ 2-3 minimum space re...

Page 18

6/98 printer specifications 2-2 xerox docuprint n17 service manual www.Printcopy.Info www.Printcopy.Info.

Page 19

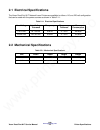

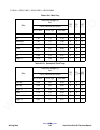

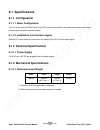

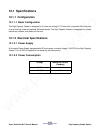

6/98 xerox docuprint n17 service manual 2-3 printer specifications 2 2.1 electrical specifications the xerox docuprint n17 network laser printers are available in either a 110 or a 220 volt configuration that can be used with the power sources as shown in table 2.1.1. Table 2.1.1 electrical specific...

Page 20

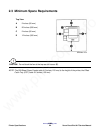

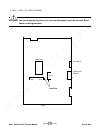

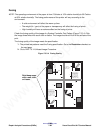

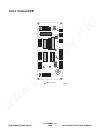

6/98 printer specifications 2-4 xerox docuprint n17 service manual 2.3 minimum space requirements caution do not block the fan at the top rear left corner (e). Note: the 500-sheet paper feeder adds 4.8 inches (120 mm) to the height of the printer; the offset catch tray (oct) adds 5.2 inches (130 mm)...

Page 21

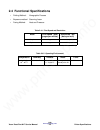

6/98 xerox docuprint n17 service manual 2-5 printer specifications 2.4 functional specifications • printing method: xerographic process • exposure method: scanning laser • fusing method: heat and pressure table 2.4.1 print speed and resolution table 2.4.2 operating environment mode print speed - ppm...

Page 22: 2.5 Paper Specifications

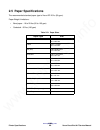

6/98 printer specifications 2-6 xerox docuprint n17 service manual 2.5 paper specifications the recommended standard paper type is xerox dp 20 lb. (80 gsm). Paper weight limitations: • bond paper - 16 to 28 lbs (60 to 105 gsm) • cardstock - 50 lbs (190 gsm) table 2.5.1 paper sizes paper type size a4...

Page 23

6/98 xerox docuprint n17 service manual 2-7 printer specifications table 2.5.2 standard tray capacity table 2.5.3 mbf tray capacity table 2.5.4 optional 500-sheet feeder paper type capacity (sheets) letter, b5, executive, a5, folio, and legal 250 a4 230 ohp film (transparency) 10 label paper 10 pape...

Page 24: 2.6 Options

6/98 printer specifications 2-8 xerox docuprint n17 service manual 2.6 options the customer can install the following options: • up to two 500-sheet high capacity paper decks or trays • high capacity envelope feeder • simms (ram) (sizes: 4, 8, 16, and 32mb) • flash simm (8mb) • i/o pwbs — 10/100 bas...

Page 25: Section 3

6/98 xerox docuprint n17 service manual 3-1 parts list section 3 parts list about the parts list ......................................................................... 3-3 pl 1 covers i .................................................................................... 3-4 pl 2 covers ii ..........

Page 26

6/98 parts list 3-2 xerox docuprint n17 service manual www.Printcopy.Info www.Printcopy.Info.

Page 27: About The Parts List

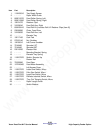

6/98 xerox docuprint n17 service manual 3-3 parts list about the parts list this section identifies all part numbers and the corresponding location of all spared subsystem components. Using the parts list: 1 each item number in the part number listing corresponds to an item number in the related ill...

Page 28

6/98 parts list 3-4 xerox docuprint n17 service manual pl 1 covers i s s 2 1 s s 6 s kl s 3 5 s s s 4 s s sas301fa www.Printcopy.Info www.Printcopy.Info.

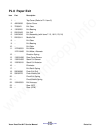

Page 29: Pl 1 Covers I

6/98 xerox docuprint n17 service manual 3-5 parts list pl 1 covers i item part description 1. 48k12916 rear cover 2. 48e09090 system controller cover 3. 48k12898 front cover assembly (exploded on pl 2) 4. 48e62070 left front cover 5. 48k12871 top cover 6. 48k29000 right cover www.Printcopy.Info www....

Page 30

6/98 parts list 3-6 xerox docuprint n17 service manual pl2 covers ii wsm3-07 7 8 13 4 3 2 5 9 11 s 1 (with 2 ~ 11) 12 6 10 sas302fe www.Printcopy.Info www.Printcopy.Info.

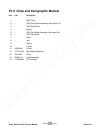

Page 31: Pl 2 Covers II

6/98 xerox docuprint n17 service manual 3-7 parts list pl 2 covers ii item part description 1. 48k12898 front cover assembly (with items 2-11)(see note ) 2. -- front cover 3. -- tray cover 4. -- tray stopper 5. -- holder guide 6. -- main tray 7. -- tray extender 8. 113e82630 catch holder 9. -- envel...

Page 32

6/98 parts list 3-8 xerox docuprint n17 service manual pl 3 paper tray 3 2 7 6 5 4 8 s s s 1 (with 2) s s sas303fb www.Printcopy.Info www.Printcopy.Info.

Page 33: Pl 3 Paper Tray

6/98 xerox docuprint n17 service manual 3-9 parts list pl 3 paper tray item part description 1. 130k83303 paper size sensor assembly (with item 2) 2. -- paper size harness 3. 109r306 250-sheet tray 4. -- front tray rail 5. -- rear tray rail 6. 48e09581 tray cover 7. -- right rail guide 8. -- left ra...

Page 34

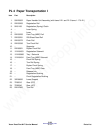

3/99 parts list 3-10 xerox docuprint n17 service manual pl 4 paper transportation i www.Printcopy.Info www.Printcopy.Info.

Page 35

3/99 xerox docuprint n17 service manual 3-11 parts list pl 4 paper transportation i item part description 1. 50k29302 paper handler unit assembly (with items 2-21 and pl 5 items 1-17 & 21) 2. 22k33263 registration roll 3. 5k81183 registration (spring) clutch 4. -- lever spring 5. -- lever 6. 22k3325...

Page 36

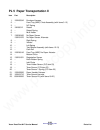

6/98 parts list 3-12 xerox docuprint n17 service manual pl 5 paper transportation ii s s s s s sas305fb s 22 19 20 20 18 17 16 15 21 14 7 6 4 3 12 13 1 9 8 10 5 2 (with3~13) 11(with12~13) www.Printcopy.Info www.Printcopy.Info.

Page 37

6/98 xerox docuprint n17 service manual 3-13 parts list pl 5 paper transportation ii item part description 1. 152k65342 envelope harness 2. -- front tray (mbf) chute assembly (with items 3-13) 3. -- n/f spring 4. 19k93012 retard 5. -- retard spring 6. -- multi holder 7. 130e80420 no paper sensor 130...

Page 38

6/98 parts list 3-14 xerox docuprint n17 service manual pl 6 paper transportation iii 2 s s s s 1 1 (with 2) s sas306fc www.Printcopy.Info www.Printcopy.Info.

Page 39

6/98 xerox docuprint n17 service manual 3-15 parts list pl 6 paper transportation iii item part description 1. 54k88353 btr (bias transfer roll) chute assembly (with item 2) 2. 600k99291 btr www.Printcopy.Info www.Printcopy.Info.

Page 40

6/98 parts list 3-16 xerox docuprint n17 service manual pl 7 fusing 20 40 3 31 s 4 s 32 32 s 7 8 5 6 s s 2 (with 3 ~ 12) 1 (with 2 ~ 40) s s 17 33 34 35 38 24 28 27 29 39 s 21 26 18 19 e s s 25 30 15 22 16 23 21 37 37 26 14 s s 13 s s s 36 34 38 9 (with 10 ~ 12) 12 s 11 10 (with 11) sas307fa www.Pri...

Page 41: Pl 7 Fusing

6/98 xerox docuprint n17 service manual 3-17 parts list pl 7 fusing item part description 1. 108r00092 fuser assembly (115v) (with items 2-40) 108r00093 fuser assembly (220v) (with items 2-40) 2. -- top cover assembly 3. -- top cover 4. -- thermostat 5. -- fuse plate 6. -- harness 1 plate 7. -- harn...

Page 42

6/98 parts list 3-18 xerox docuprint n17 service manual 11 19 21 13 s s s s 10 12 8 9 7 9 6 (with 7 ~ 13,18~21,23,24,25) 14 16 17 22 s 15 18 20 2 1 s s s s 3 4 5 4 24 23 s s sas308fb 25 pl 8 paper exit www.Printcopy.Info www.Printcopy.Info.

Page 43: Pl 8 Paper Exit

6/98 xerox docuprint n17 service manual 3-19 parts list pl 8 paper exit item part description 1. -- top cover (refer to pl1 item 5) 2. 48e09050 option cover 3. 7e88421 exit gear 4. 13e82261 exit bearing 5. 22k33422 exit roll 6. 54k04645 exit assembly (with items 7-13, 18-21, 23, 24) 7. 22k33411 midd...

Page 44

6/98 parts list 3-20 xerox docuprint n17 service manual pl 9 drive and xerographic module s s s s s 15 1 10 s 14 s s s s 5 (with 6 ~ 9) 3 9 8 7 9 8 7 2 (with 3 , 4) 6 s 4 13 s 12 s s s 11 s s sas309fc www.Printcopy.Info www.Printcopy.Info.

Page 45

7/99 xerox docuprint n17 service manual 3-21 parts list pl 9 drive and xerographic module item part description 1. -- ros plate 2. -- cru side guide assembly (with items 3-4) 3. -- cru side guide 4. -- spring 5. -- cru top guide assembly (with items 6-9) 6. -- cru top guide 7. -- roller 8. -- arm 9....

Page 46

6/98 parts list 3-22 xerox docuprint n17 service manual pl 10 electrical module i (with top cover) 2 4 3 s s 1 sas310fb 5 www.Printcopy.Info www.Printcopy.Info.

Page 47

6/98 xerox docuprint n17 service manual 3-23 parts list pl 10 electrical module i (with top cover) item part description 1. 48k71460 control panel (w/o item 5) 2. 53e91650 fan filter 3. 127k88510 fan 4. 162k05270 panel harness 5. 891e68700 control panel label - english 891e68730 control panel label ...

Page 48

6/98 parts list 3-24 xerox docuprint n17 service manual pl 11 electrical module ii (with chassis) 19 2 s s s s s s s s s 9 11 12 18 14 13 1 7 s s s 20 23 20 22 21 17 16 16 15 (with 16) 20 20 s s s s s s s 10 8 3 4 5 6 sas311fb 24 www.Printcopy.Info www.Printcopy.Info.

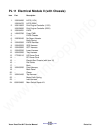

Page 49

6/98 xerox docuprint n17 service manual 3-25 parts list pl 11 electrical module ii (with chassis) item part description 1. 105k94260 lvps (115v) 105k94270 lvps (220v) 2. 160k18602 print engine controller (115v) 160k29060 print engine controller (220v) 3. 105k94291 hvps 4. 140k63780 fuser pwb 5. -- h...

Page 50

6/98 parts list 3-26 xerox docuprint n17 service manual 3 2 6 4 5 1 pl 12 system controller www.Printcopy.Info www.Printcopy.Info.

Page 51: Pl 12 System Controller

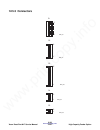

3/99 xerox docuprint n17 service manual 3-27 parts list pl 12 system controller item part description 1. 600k76090 system controller pwba w/ onboard ethernet 600k76100 system controller pwba parallel and serial only 2. 733w03660 memory simm (4mb) 733w03647 memory simm (8mb) 733w03642 memory simm (16...

Page 52

6/98 parts list 3-28 xerox docuprint n17 service manual notes www.Printcopy.Info www.Printcopy.Info.

Page 53: Section 4

6/98 xerox docuprint n17 service manual 4-1 repair/adjustment procedures section 4 repair/adjustment procedures overview............................................................................................ 4-5 notations in the rep text ....................................................... 4...

Page 54

6/98 repair/adjustment procedures 4-2 xerox docuprint n17 service manual paper transportation ii .................................................................. 4-24 toner sensor ......................................................................... 4-24 inlet chute assembly......................

Page 55

6/98 xerox docuprint n17 service manual 4-3 repair/adjustment procedures electrical module ii ......................................................................... 4-56 system controller chassis .................................................... 4-56 low voltage power supply (lvps) ..............

Page 56

6/98 repair/adjustment procedures 4-4 xerox docuprint n17 service manual www.Printcopy.Info www.Printcopy.Info.

Page 57: 4.1 Overview

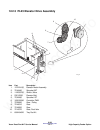

6/98 xerox docuprint n17 service manual 4-5 repair/adjustment procedures 4 4.1 overview this section contains xerox docuprint n17 network laser printers repair procedures (reps): 1) covers i 2) covers ii 3) paper tray 4) paper transportation i 5) paper transportation ii 6) paper transportation iii 7...

Page 58

6/98 repair/adjustment procedures 4-6 xerox docuprint n17 service manual 4.1.1 notations in the rep text locations given in the reps assume you are facing the control panel with the following orientation: figure 4.1.1.1 printer orientation the following notations apply: • arrows in the illustrations...

Page 59: 4.2 Covers I

6/98 xerox docuprint n17 service manual 4-7 repair/adjustment procedures 4.2 covers i 4.2.1 rear cover removal 1 open the rear cover. 2 remove the screw securing the stopper to the frame. (see figure 4.2.1.1). 3 press and unlatch the pivots on both ends of the rear cover and remove the cover. Figure...

Page 60: 4.2.2 Left Cover

6/98 repair/adjustment procedures 4-8 xerox docuprint n17 service manual 4.2.2 left cover removal 1 remove the three screws securing the cover to the frame. (see figure 4.2.2.1.) 2 pull the rear end of the cover to snap it off the frame. Figure 4.2.2.1 left cover removal replacement perform the remo...

Page 61: 4.2.3 Harness Cover

6/98 xerox docuprint n17 service manual 4-9 repair/adjustment procedures 4.2.3 harness cover removal 1 open the front cover. 2 press the latch on the left, and use a flat-slot screwdriver to free the latch on the right by slightly lifting upward. (see figure 4.2.3.1.) note: notice the routing of the...

Page 62

6/98 repair/adjustment procedures 4-10 xerox docuprint n17 service manual 4.2.4 front cover assembly removal 1 open the front cover assembly. 2 remove the harness cover ( rep 4.2.3 harness cover ). 3 disconnect p/j 130. 4 slide the cover stopper to the left to free it from the frame. (see figure 4.2...

Page 63: 4.2.5 Left Front Cover

6/98 xerox docuprint n17 service manual 4-11 repair/adjustment procedures 4.2.5 left front cover removal 1 open the front cover. 2 remove the two screws securing the front cover to the frame. (see figure 4.2.5.1). 3 remove the front cover from the top cover assembly by rotating the front cover and p...

Page 64: 4.2.6

6/98 repair/adjustment procedures 4-12 xerox docuprint n17 service manual 4.2.6 top cover assembly removal 1 open the front cover assembly. 2 remove the left cover ( rep 4.2.2 left cover ). 3 remove the left front cover ( rep 4.2.5 left front cover ). 4 remove the system controller chassis ( rep 4.1...

Page 65: 4.2.7 Right Cover

6/98 xerox docuprint n17 service manual 4-13 repair/adjustment procedures 4.2.7 right cover removal 1 open the front cover assembly. 2 remove the stopper securing the front cover assembly to the frame. 3 open the rear cover assembly. 4 remove the screw securing the stopper of the rear cover to the f...

Page 66: 4.3 Covers Ii

6/98 repair/adjustment procedures 4-14 xerox docuprint n17 service manual 4.3 covers ii 4.3.1 envelope feeder (ef) cover removal 1 press the top of the front tray cover to release the latch and open the tray. 2 open the ef cover by 90 degrees. (see figure 4.3.1.1.) 3 grasp the ef cover and remove it...

Page 67: 4.3.2 Inner Cover

6/98 xerox docuprint n17 service manual 4-15 repair/adjustment procedures 4.3.2 inner cover removal 1 press the top of the front tray cover assembly to release the latch and open the tray. 2 open the ef cover by 90 degrees. (see figure 4.3.2.1.) 3 release the latch on the top of the inner cover (1),...

Page 68: 4.3.3 Front Tray

6/98 repair/adjustment procedures 4-16 xerox docuprint n17 service manual 4.3.3 front tray removal 1 press the top of the front tray cover assembly to release the latch and open the tray. 2 remove the front tray cover ( rep 4.3.4 front tray cover ). 3 lift the front tray slightly and disengage the t...

Page 69: 4.3.4 Front Tray Cover

6/98 xerox docuprint n17 service manual 4-17 repair/adjustment procedures 4.3.4 front tray cover removal 1 press the top of the front tray cover assembly to release the latch and open the tray. 2 pull the front tray cover out fully. (see figure 4.3.4.1.) 3 lift the front tray with your fingers to cl...

Page 70: 4.3.5 Tray Extender

6/98 repair/adjustment procedures 4-18 xerox docuprint n17 service manual 4.3.5 tray extender removal 1 press the top of the front tray cover assembly to release the latch and open the front tray. 2 pull the front tray out fully. (see figure 4.3.5.1.) 3 unlatch the tray extender. 4 bend the right tr...

Page 71: 4.4 Paper Tray (Tray I)

6/98 xerox docuprint n17 service manual 4-19 repair/adjustment procedures 4.4 paper tray (tray i) 4.4.1 paper size sensor removal 1 remove the paper tray. 2 remove the rear cover ( rep 4.2.1 rear cover ). 3 remove the left cover ( rep 4.2.2 left cover ). 4 remove the front cover assembly ( rep 4.2.4...

Page 72: 4.5 Paper Transportation I

6/98 repair/adjustment procedures 4-20 xerox docuprint n17 service manual 4.5 paper transportation i 4.5.1 paper handling unit assembly removal 1 remove the left cover ( rep 4.2.2 left cover ). 2 remove the left front cover ( rep 4.2.5 left front cover ). 3 remove the front cover assembly ( rep 4.2....

Page 73: 4.5.2 Feed Roll Assembly

6/98 xerox docuprint n17 service manual 4-21 repair/adjustment procedures 4.5.2 feed roll assembly removal 1 remove the ep cartridge. 2 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 3 position the paper handling unit assembly on the gear side. 4 slightly push ba...

Page 74: 4.5.3 Duplex Refeed Roll

6/98 repair/adjustment procedures 4-22 xerox docuprint n17 service manual 4.5.3 duplex refeed roll removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 position the paper handling unit assembly on the gear side. 3 pull slightly on the latch; then remove the...

Page 75: 4.5.4 Front Tray Roll

6/98 xerox docuprint n17 service manual 4-23 repair/adjustment procedures 4.5.4 front tray roll removal 1 open the front cover assembly. 2 press the bottom tray assembly down. 3 pull slightly on the latch; then remove the front tray roll by sliding it to the right. (see figure 4.5.4.1.) figure 4.5.4...

Page 76: 4.6.1 Toner Sensor

6/98 repair/adjustment procedures 4-24 xerox docuprint n17 service manual 4.6 paper transportation ii 4.6.1 toner sensor removal note: carefully note the routing of the wiring harness. 1 pull the toner sensor assembly towards the front from the rear while lifting upward on the toner sensor assembly....

Page 77: 4.6.2 Inlet Chute Assembly

6/98 xerox docuprint n17 service manual 4-25 repair/adjustment procedures 4.6.2 inlet chute assembly removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 free the toner sensor wire harness from the inlet chute assembly. 3 remove the two screws securing the ...

Page 78: 4.6.3 Registration Sensor

6/98 repair/adjustment procedures 4-26 xerox docuprint n17 service manual 4.6.3 registration sensor removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 use a flat-slot screwdriver blade to unhook the front sensor registration clip. (see figure 4.6.3.1.) 3 ...

Page 79

6/98 xerox docuprint n17 service manual 4-27 repair/adjustment procedures 4.6.4 front tray chute assembly removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 remove the inlet chute assembly ( rep 4.6.2 inlet chute assembly ). 3 remove the screw securing th...

Page 80: 4.6.5 Tray Bottom

6/98 repair/adjustment procedures 4-28 xerox docuprint n17 service manual 4.6.5 tray bottom removal 1 remove the front tray chute assembly ( rep 4.6.4 front tray chute assembly ). 2 compress the tray bottom. 3 compress the tab on the right limiting the tray bottom upward travel. 4 raise the tray bot...

Page 81

6/98 xerox docuprint n17 service manual 4-29 repair/adjustment procedures figure 4.6.6.1 retard assembly removal replacement perform the removal steps in reverse order. Sas424f sas424f www.Printcopy.Info www.Printcopy.Info.

Page 82: 4.6.7 Multi Holder

6/98 repair/adjustment procedures 4-30 xerox docuprint n17 service manual 4.6.7 multi holder removal 1 remove the tray bottom ( rep 4.6.5 tray bottom ). 2 pull the multi holder upward out of the tray bottom. Figure 4.6.7.1 multi holder removal replacement perform the removal steps in reverse order. ...

Page 83

6/98 xerox docuprint n17 service manual 4-31 repair/adjustment procedures 4.6.8 front tray no paper actuator removal 1 remove the tray bottom ( rep 4.6.5 tray bottom ). 2 turn the tray bottom upside down, and pull and remove the front tray no paper actuator out of position. Figure 4.6.8.1 front tray...

Page 84: 4.6.9 No Paper Sensor

6/98 repair/adjustment procedures 4-32 xerox docuprint n17 service manual 4.6.9 no paper sensor removal 1 remove the tray bottom ( rep 4.6.5 tray bottom ). 2 use a flat-slot screwdriver blade. From the underside of the tray bottom, unhook the front no paper sensor clip. 3 lift the loosened no paper ...

Page 85: 4.6.10 Bottom Chute

6/98 xerox docuprint n17 service manual 4-33 repair/adjustment procedures 4.6.10 bottom chute removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 remove the registration sensor ( rep 4.6.3 registration sensor ). 3 remove the front tray chute assembly ( rep...

Page 86: 4.6.11 Supporter

6/98 repair/adjustment procedures 4-34 xerox docuprint n17 service manual 4.6.11 supporter removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 raise the paper handling unit assembly approximately 90 degrees. 3 remove the wire harnesses connected to the no ...

Page 87

6/98 xerox docuprint n17 service manual 4-35 repair/adjustment procedures figure 4.6.11.1 supporter removal replacement perform the removal steps in reverse order. Sas429f.Cdr 1 2 3 4 sas429fa www.Printcopy.Info www.Printcopy.Info.

Page 88: 4.6.12 Pinch Roll Assembly

6/98 repair/adjustment procedures 4-36 xerox docuprint n17 service manual 4.6.12 pinch roll assembly removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 remove the supporter ( rep 4.6.11 supporter ). 3 unclip the spring from the registration plate. 4 unlat...

Page 89

6/98 xerox docuprint n17 service manual 4-37 repair/adjustment procedures 4.6.13 turn pinch roll assembly removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 remove the supporter ( rep 4.6.11 supporter ). 3 unhook the spring on the registration plate side ...

Page 90

6/98 repair/adjustment procedures 4-38 xerox docuprint n17 service manual 4.6.14 registration solenoid/tray 1 solenoid/front tray solenoid removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 remove the three screws securing the registration solenoid, tray ...

Page 91

7/99 xerox docuprint n17 service manual 4-39 repair/adjustment procedures 4.6.15 registration clutch assembly removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 remove the supporter ( rep 4.6.11 supporter ). 3 remove the registration bushing. (see figure ...

Page 92

6/98 repair/adjustment procedures 4-40 xerox docuprint n17 service manual 4.7 paper transportation iii 4.7.1 bias transfer roll (btr) assembly removal 1 open the front cover assembly. 2 remove the ep cartridge. Warning! To prevent contamination of the btr, do not touch the foam portion of the roll. ...

Page 93: 4.7.2 Btr Chute Assembly

6/98 xerox docuprint n17 service manual 4-41 repair/adjustment procedures 4.7.2 btr chute assembly removal 1 remove the paper handling unit assembly ( rep 4.5.1 paper handling unit assembly ). 2 remove the two screws securing the btr chute assembly. (see figure 4.7.2.1.) 3 remove the two screws secu...

Page 94: 4.8 Fusing

6/98 repair/adjustment procedures 4-42 xerox docuprint n17 service manual 4.8 fusing 4.8.1 fuser assembly (cru) removal 1 remove the duplex module, if installed. ( rep 10.3.1 duplex module .) 2 remove the two fuser module anchor screws. (see figure 4.8.1.1.) 3 grasp the fuser assembly by the peach f...

Page 95: 4.9 Paper Exit

6/98 xerox docuprint n17 service manual 4-43 repair/adjustment procedures 4.9 paper exit 4.9.1 exit roll assembly removal 1 remove the top cover assembly ( rep 4.2.6 top cover assembly ). 2 remove the option cover (rep 4.9.6 option cover/eliminator assembly). 3 remove the three screws securing the e...

Page 96: 4.9.2 Middle Roll Assembly

6/98 repair/adjustment procedures 4-44 xerox docuprint n17 service manual 4.9.2 middle roll assembly removal 1 remove the top cover assembly ( rep 4.2.6 top cover assembly ). 2 turn the top cover assembly over. 3 pull the locking tab on the gear to unlatch the gear from the middle roll assembly. 4 p...

Page 97: 4.9.3 Exit Gate

6/98 xerox docuprint n17 service manual 4-45 repair/adjustment procedures 4.9.3 exit gate removal 1 remove the top cover assembly ( rep 4.2.6 top cover assembly ). 2 turn the top cover assembly over. 3 remove the four screws securing the exit assembly, and remove the assembly from the top cover asse...

Page 98: 4.9.4 Exit Motor Assembly

6/98 repair/adjustment procedures 4-46 xerox docuprint n17 service manual 4.9.4 exit motor assembly removal 1 remove the top cover assembly ( rep 4.2.6 top cover assembly ). 2 turn the top cover assembly over. 3 disconnect p/j24 (exit motor). 4 remove the two screws securing the exit motor assembly,...

Page 99: 4.9.5 Rear Cover Sensor

6/98 xerox docuprint n17 service manual 4-47 repair/adjustment procedures 4.9.5 rear cover sensor removal 1 remove the top cover assembly ( rep 4.2.6 top cover assembly ). 2 turn the top cover assembly over. 3 unhook the rear cover sensor clip by pressing it from the rear of the top cover assembly, ...

Page 100

6/98 repair/adjustment procedures 4-48 xerox docuprint n17 service manual 4.9.6 option cover/eliminator assembly removal 1 remove the option cover. (press the two hooks of the option cover plate from under the rear part of the top cover assembly.) 2 remove the three screws. 3 remove the eliminator a...

Page 101: 4.9.7 Stack Full Sensor

6/98 xerox docuprint n17 service manual 4-49 repair/adjustment procedures 4.9.7 stack full sensor removal 1 remove the rear option cover plate and the eliminator assembly. ( rep 4.9.6 option cover/ eliminator assembly .) 2 use a flat-slot screwdriver blade to unhook the stack full sensor clip. (see ...

Page 102: 4.9.8 Stack Full Actuator

6/98 repair/adjustment procedures 4-50 xerox docuprint n17 service manual 4.9.8 stack full actuator removal 1 remove the rear option cover plate and the eliminator assembly. ( rep 4.9.6 option cover/ eliminator assembly .) 2 lift the right end of the stack full actuator upward, and remove the actuat...

Page 103

6/98 xerox docuprint n17 service manual 4-51 repair/adjustment procedures 4.10 drive and xerographic modules 4.10.1 main motor assembly removal 1 remove the system controller chassis ( rep 4.12.1 system controller chassis ). 2 disconnect p14 from the print engine controller. (see figure 4.10.1.1.) 3...

Page 104: 4.10.2 Drive Assembly

6/98 repair/adjustment procedures 4-52 xerox docuprint n17 service manual 4.10.2 drive assembly removal 1 remove the btr chute assembly ( rep 4.7.2 btr chute assembly ). 2 remove the main motor assembly ( rep 4.10.1 main motor assembly ). Note: it is not necessary to completely remove the print engi...

Page 105: 4.10.3 Laser Assembly

6/98 xerox docuprint n17 service manual 4-53 repair/adjustment procedures 4.10.3 laser assembly removal 1 remove the top cover assembly ( rep 4.2.6 top cover assembly ). 2 remove the four screws (hexagon-shaped with a black flange) securing the laser assembly, and lift the laser assembly. 3 disconne...

Page 106: 4.11 Electrical Module I

6/98 repair/adjustment procedures 4-54 xerox docuprint n17 service manual 4.11 electrical module i 4.11.1 control panel assembly removal 1 remove the top cover assembly ( rep 4.2.6 top cover assembly ). 2 turn the top cover over. 3 disconnect p33 from the control panel. (see figure 4.11.1.1.) 4 open...

Page 107: 4.11.2 Fan Assembly

6/98 xerox docuprint n17 service manual 4-55 repair/adjustment procedures 4.11.2 fan assembly removal 1 remove the top cover assembly ( rep 4.2.6 top cover assembly ). 2 turn the top cover over. 3 remove the two screws securing the fan assembly, and remove the assembly. (see figure 4.11.2.1.) cautio...

Page 108

6/98 repair/adjustment procedures 4-56 xerox docuprint n17 service manual 4.12 electrical module ii 4.12.1 system controller chassis removal 1 remove the left cover ( rep 4.2.2 left cover ). 2 remove the left front cover ( rep 4.2.5 left front cover ). 3 remove the system controller pwb. 4 remove th...

Page 109

6/98 xerox docuprint n17 service manual 4-57 repair/adjustment procedures 4.12.2 low voltage power supply (lvps) removal 1 remove the system controller chassis ( rep 4.12.1 system controller chassis ). 2 disconnect p13 and p25 from the print engine controller. (see figure 4.12.2.1.) 3 disconnect p16...

Page 110

6/98 repair/adjustment procedures 4-58 xerox docuprint n17 service manual 4.12.3 print engine controller removal 1 remove the system controller chassis ( rep 4.12.1 system controller chassis ). 2 disconnect p13, p14, p15, p18, p19, p21, p22, p23, p24, p25, p28, and p32 from the print engine controll...

Page 111

6/98 xerox docuprint n17 service manual 4-59 repair/adjustment procedures 4.12.4 high voltage power supply (hvps) removal 1 remove the ep cartridge. 2 remove the btr chute assembly ( rep 4.7.2 btr chute assembly ). 3 remove the no paper actuator ( rep 4.12.6 no paper actuator ). 4 disconnect p115 an...

Page 112: 4.12.5 Fuser Pwb

6/98 repair/adjustment procedures 4-60 xerox docuprint n17 service manual 4.12.5 fuser pwb removal 1 remove the btr chute assembly ( rep 4.7.2 btr chute assembly ). 2 remove the system controller chassis ( rep 4.12.1 system controller chassis ). 3 disconnect p3 from the lvps. (see figure 4.12.5.1.) ...

Page 113: 4.12.6 No Paper Actuator

6/98 xerox docuprint n17 service manual 4-61 repair/adjustment procedures 4.12.6 no paper actuator removal 1 remove the btr chute assembly ( rep 4.7.1 bias transfer roll (btr) assembly ). 2 lift and remove the no paper actuator. Figure 4.12.6.1 no paper actuator removal replacement perform the remov...

Page 114: 4.12.7 Main Power Switch

6/98 repair/adjustment procedures 4-62 xerox docuprint n17 service manual 4.12.7 main power switch removal 1 remove the system controller chassis ( rep 4.12.1 system controller chassis ). 2 unplug the harness connector from the main power switch. (see figure 4.12.7.1.) 3 squeeze on the switch retain...

Page 115: Section 5

3/99 xerox docuprint n17 service manual 5-1 general procedures/information section 5 general procedures/information printer operations ......................................................................... 5-3 control panel ........................................................................ ...

Page 116

3/99 general procedures/information 5-2 xerox docuprint n17 service manual confirm tray 2 solenoid operation ........................... 5-36 confirm tray 3 solenoid operation ........................... 5-37 confirm envelope solenoid operation....................... 5-38 confirm direction solenoid ...

Page 117: 5.1 Printer Operations

3/99 xerox docuprint n17 service manual 5-3 general procedures/information 5 5.1 printer operations the information provided in this section is based on the standard functions of this model printer. The diagnostic procedures presented in this section are accessed at the printer control panel. 5.1.1 ...

Page 118: 5.1.2 Printer Modes

3/99 general procedures/information 5-4 xerox docuprint n17 service manual 5.1.2 printer modes the xerox docuprint n17 network laser printer has three modes of operation, each with a unique set of options: 1. Ready mode (see 5.1.3 ready mode ). 2. Menu mode (see 5.1.4 menu mode ). 3. Diagnostic mode...

Page 119

3/99 xerox docuprint n17 service manual 5-5 general procedures/information 5 the printer will display initializing..., then processing..., and ultimately ready when it is warmed up and ready to print. Ready www.Printcopy.Info www.Printcopy.Info.

Page 120: 5.1.4 Menu Mode

3/99 general procedures/information 5-6 xerox docuprint n17 service manual 5.1.4 menu mode the menu mode allows you to set, change, or adjust the various features/options available in the xerox docuprint n17 network laser printer. The menus displayed on any particular printer depend upon the options...

Page 121

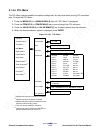

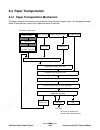

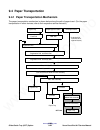

3/99 xerox docuprint n17 service manual 5-7 general procedures/information 5.1.4.1 menu tree the menu tree illustrates the twelve major menus that can be accessed from the menu mode. To access the menus: 1 press the menu up (1) or menu down (5) key to scroll through the major menus. 2 press the item...

Page 122

3/99 general procedures/information 5-8 xerox docuprint n17 service manual 5.1.4.2 main menu the main menu is a system of submenus, each containing options designed to configure the system. 1 press the menu up (1) key. 2 when “menus/jobs menu” is displayed, use the menu up (1) or menu down (5) key t...

Page 123

3/99 xerox docuprint n17 service manual 5-9 general procedures/information 5.1.4.3 job menu the complete job menu is illustrated below. To select the job menu: 1 press the menu up (1) or menu down (5) key until “job menu” is displayed. 2 press the item up (2) or item down (6) key to view the options...

Page 124

3/99 general procedures/information 5-10 xerox docuprint n17 service manual 5.1.4.4 password menu the password menu is available only when the hard disk drive is installed. This menu is used to print or delete secure jobs. To select the password menu: 1 press the menu up (1) or menu down (5) key unt...

Page 125

3/99 xerox docuprint n17 service manual 5-11 general procedures/information 5.1.4.5 tray menu the tray menu allows you to access tray settings that are common to all system languages (pcl and postscript). To select the tray menu: 1 press the menu up (1) or menu down (5) key until “tray menu” is disp...

Page 126

3/99 general procedures/information 5-12 xerox docuprint n17 service manual 5.1.4.6 pcl menu the pcl menu options establish the default configuration for the printer when printing pcl emulation jobs. To select the pcl menu: 1 press the menu up (1) or menu down (5) key until “pcl menu” is displayed. ...

Page 127

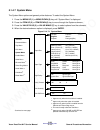

3/99 xerox docuprint n17 service manual 5-13 general procedures/information 5.1.4.7 system menu the system menu options set general printer features. To select the system menu: 1 press the menu up (1) or menu down (5) key until “system menu” is displayed. 2 press the item up (2) or item down (6) key...

Page 128

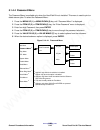

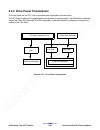

3/99 general procedures/information 5-14 xerox docuprint n17 service manual figure 5.1.4.7.1 system menu (continued) duplex draft mode edge-to-edge xie resolution output timeout output offset output dest alarm defaults power saver inches* millimeters off* on 600x600* 1200x600 off* on off* on standar...

Page 129

3/99 xerox docuprint n17 service manual 5-15 general procedures/information 5.1.4.8 parallel menu the parallel menu sets options for the parallel port connection. To select the parallel menu: 1 press the menu up (1) or menu down (5) key until “parallel menu” is displayed. 2 press the item up (2) or ...

Page 130

3/99 general procedures/information 5-16 xerox docuprint n17 service manual 5.1.4.9 serial menu the serial menu sets options for the serial port connection. To select the serial menu: 1 press the menu up (1) or menu down (5) key until “serial menu” is displayed. 2 press the item up (2) or item down ...

Page 131

3/99 xerox docuprint n17 service manual 5-17 general procedures/information 5.1.4.10 ethernet menu the ethernet menu set options for the ethernet port. To select the ethernet menu: 1 press the menu up (1) or menu down (5) key until “ethernet menu” is displayed. 2 press the item up (2) or item down (...

Page 132

3/99 general procedures/information 5-18 xerox docuprint n17 service manual figure 5.1.4.10.1 ethernet menu (continued) appsocket pdl appsocket bin ps ethertalk enable http enable ip address res ip address sub net mask default gateway port timeout xxx.Xxx.Xxx.Xxx 5 - 300 (60*) xxx.Xxx.Xxx.Xxx xxx.Xx...

Page 133

3/99 xerox docuprint n17 service manual 5-19 general procedures/information 5.1.4.11 token ring menu the token ring menu sets options for the token ring port. To select the token ring menu: 1 press the menu up (1) or menu down (5) key until “token ring menu” is displayed. 2 press the item up (2) or ...

Page 134

3/99 general procedures/information 5-20 xerox docuprint n17 service manual figure 5.1.4.11.1 token ring menu (continued) appsocket enable appsocket pdl appsocket bin ps ttalk enable http enable ip address res ip address sub net mask default gateway port timeout source routing speed laa on* off on* ...

Page 135

3/99 xerox docuprint n17 service manual 5-21 general procedures/information 5.1.4.12 novell menu the novell menu allows you to modify novell parameters. It appears only if novell is enabled from the ethernet menu. To select the novell menu: 1 press the menu up (1) or menu down (5) key until “novell ...

Page 136

3/99 general procedures/information 5-22 xerox docuprint n17 service manual 5.1.4.13 print menu the test menu options are used to generate printer reports. All options other than restart printer and hex mode cause the printer to generate a printed report. To select the test menu: 1 press the menu up...

Page 137

3/99 xerox docuprint n17 service manual 5-23 general procedures/information 5.1.4.14 reset menu the reset menu is used to reset various printer functions. The reset menu only appears in the main menu if the printer is powered on while simultaneously holding down the online and enter keys. To select ...

Page 138: 5.2 Diagnostic Mode

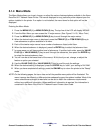

3/99 general procedures/information 5-24 xerox docuprint n17 service manual 5.2 diagnostic mode the diagnostics mode allows you to test various switches and sensors, turn on various output devices, adjust printer functions, and display the total number of prints produced. There are three different d...

Page 139: 5.2.1 Diagnostic Mode 1

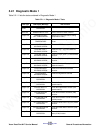

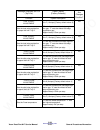

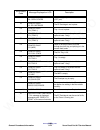

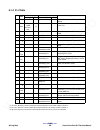

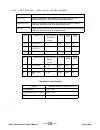

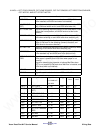

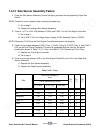

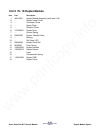

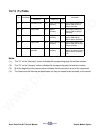

3/99 xerox docuprint n17 service manual 5-25 general procedures/information 5.2.1 diagnostic mode 1 table 5.2.1.1 lists the tests contained in diagnostic mode 1 table 5.2.1.1 diagnostic mode 1 tests test type lcd display message test function total print count print counter operation shows the total...

Page 140

3/99 general procedures/information 5-26 xerox docuprint n17 service manual output test hvps (c. Roll ac) operation tests the high voltage power supply (hvps) ac voltage to the charge roll output test hvps (c. Roll dc) operation tests the high voltage power supply (hvps) dc voltage to the charge rol...

Page 141

3/99 xerox docuprint n17 service manual 5-27 general procedures/information to enter diagnostic mode 1: 1 switch off the printer power 2 while switching on the printer, press and hold the item up (2) and the item down (6) keys until the lcd displays *iot?*. 3 press the value minus (7) key. The lcd d...

Page 142

3/99 general procedures/information 5-28 xerox docuprint n17 service manual 5.2.1.1 print counter operation this diagnostic displays the total number of print cycles. This print count is taken from the actuator signals sent to the feed solenoid. The total count increments even when paper jams in the...

Page 143

3/99 xerox docuprint n17 service manual 5-29 general procedures/information 5.2.1.2 sensor input test this diagnostic test allows you to check the function of the sensors and switches. In this mode, the num- ber on the lcd (at the rightmost position on the bottom line, (as shown in step 2 below), in...

Page 144

3/99 general procedures/information 5-30 xerox docuprint n17 service manual 3 check the function of the sensors and switches by manually actuating with your finger or a screw driver. If the sensor or switch is functioning correctly, the number at the position on the bottom line of the lcd increments...

Page 145

3/99 xerox docuprint n17 service manual 5-31 general procedures/information 5.2.1.3 reading fuser set temperature note: this diagnostic displays the current fuser setting. If you wish to change the fuser setting, you must enter diagnostic mode 3 and perform “fuser temp. Adjustment.” this diagnostic ...

Page 146

3/99 general procedures/information 5-32 xerox docuprint n17 service manual 5.2.1.4 reading fuser temperature this diagnostic displays the current temperature of the fuser. Execute reading fuser temperature: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the printer i...

Page 147

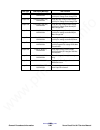

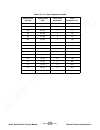

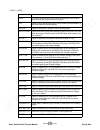

3/99 xerox docuprint n17 service manual 5-33 general procedures/information table 5.2.1.4.1 fuser temperature codes reading fuser set temp reading fuser temp fuser temp adjustment fuser temperature ( o c) af a8~b1 0 165 aa a4~ad 1 168 a6 a0~a9 2 171 a2 9c~a5 3 174 9e 97~a0 4 177 99 93~9c 5 180 95 8f...

Page 148

3/99 general procedures/information 5-34 xerox docuprint n17 service manual 5.2.1.5 confirm mbf solenoid operation this diagnostic tests the mbf feed solenoid. Execute confirm mbf solenoid operations: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the printer is in di...

Page 149

3/99 xerox docuprint n17 service manual 5-35 general procedures/information 5.2.1.6 confirm tray 1 solenoid operation this diagnostic tests the paper feed solenoid in tray 1. Execute confirm tray 1 solenoid operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the...

Page 150

3/99 general procedures/information 5-36 xerox docuprint n17 service manual 5.2.1.7 confirm tray 2 solenoid operation this diagnostic tests the paper feed solenoid in tray 2. Execute confirm tray 2 solenoid operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the...

Page 151

3/99 xerox docuprint n17 service manual 5-37 general procedures/information 5.2.1.8 confirm tray 3 solenoid operation this diagnostic tests the paper feed solenoid in tray 3. Execute confirm tray 3 solenoid operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the...

Page 152

3/99 general procedures/information 5-38 xerox docuprint n17 service manual 5.2.1.9 confirm envelope solenoid operation this diagnostic tests envelope tray feed solenoid function. Execute confirm envelope solenoid operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindicat...

Page 153

3/99 xerox docuprint n17 service manual 5-39 general procedures/information 5.2.1.10 confirm direction solenoid operation this diagnostic tests the exit direction solenoid function. Execute confirm direction solenoid operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindi...

Page 154

3/99 general procedures/information 5-40 xerox docuprint n17 service manual 5.2.1.11 confirm registration solenoid operation this diagnostic tests the registration solenoid execute confirm registration solenoid operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating...

Page 155

3/99 xerox docuprint n17 service manual 5-41 general procedures/information 5.2.1.12 main motor operation this diagnostic tests the main drive motor. Warning! This test switches on the main motor. Be careful around the motor and drive assembly. Execute main motor operation: 1 enter diagnostics mode ...

Page 156

3/99 general procedures/information 5-42 xerox docuprint n17 service manual 5.2.1.13 duplex motor h.S. (high speed) operation this diagnostic tests the duplex motor function (high speed rotation). Execute duplex motor h.S. Operation: 1 enter diagnostics mode 1. The lcd displays print counter operati...

Page 157

3/99 xerox docuprint n17 service manual 5-43 general procedures/information 5.2.1.14 duplex motor l.S. (low speed) operation this diagnostic tests the duplex motor function (low-speed rotation). Execute duplex motor l.S. Operation: 1 enter diagnostics mode 1. The lcd displays print counter operation...

Page 158

3/99 general procedures/information 5-44 xerox docuprint n17 service manual 5.2.1.15 exit motor cw (clockwise) operation this diagnostic tests the exit motor clockwise function. Execute exit motor cw operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the printe...

Page 159

3/99 xerox docuprint n17 service manual 5-45 general procedures/information 5.2.1.16 exit motor ccw (counter clockwise) operation this diagnostic tests the exit motor counterclockwise function. Execute exit motor ccw operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindi...

Page 160

3/99 general procedures/information 5-46 xerox docuprint n17 service manual 5.2.1.17 offset catch tray (oct) drive motor operation this diagnostic tests the oct motor function. Execute oct drive motor operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the print...

Page 161

3/99 xerox docuprint n17 service manual 5-47 general procedures/information 5.2.1.18 offset motor cw (clockwise) operation this diagnostic tests the offset motor clockwise function. Execute offset motor cw operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the ...

Page 162

3/99 general procedures/information 5-48 xerox docuprint n17 service manual 5.2.1.19 offset motor ccw (counter clockwise) operation this diagnostic tests the offset motor counter clockwise function. Execute offset motor ccw operation: 1 enter diagnostics mode 1. The lcd displays print counter operat...

Page 163

3/99 xerox docuprint n17 service manual 5-49 general procedures/information 5.2.1.20 hvps (charge roll ac) operation this diagnostic tests hvps ac voltage to the bias charge roll. Warning! This test switches on the hvps. Never touch the parts supplied with a high voltage from the hvps when running t...

Page 164

3/99 general procedures/information 5-50 xerox docuprint n17 service manual figure 5.2.1.20.1 test point locations 7 press the enter key to execute the test. The lcd displays the hvps (c. Roll ac) message. Note: voltage is present for approximately one second each time the enter key is pressed to ex...

Page 165

3/99 xerox docuprint n17 service manual 5-51 general procedures/information 5.2.1.21 hvps (charge roll dc) operation this diagnostic tests hvps dc voltage to the bias charge roll. Warning! This test switches on the hvps. Never touch the parts supplied with a high voltage from the hvps when running t...

Page 166

3/99 general procedures/information 5-52 xerox docuprint n17 service manual 5.2.1.22 hvps (developer bias dc) operation this diagnostic tests the hvps dc voltage to the developer bias charge roll. During this test the high voltage will be present for only a few seconds. Warning! This test switches o...

Page 167

3/99 xerox docuprint n17 service manual 5-53 general procedures/information 5.2.1.23 hvps (developer bias ac) operation this diagnostic tests hvps ac voltage to the developer bias charge roll. Warning! This test switches on the hvps. Never touch the parts supplied with a high voltage from the hvps w...

Page 168

3/99 general procedures/information 5-54 xerox docuprint n17 service manual 5.2.1.24 hvps (detack saw) operation this diagnostic tests hvps ac voltage to the detack saw. Warning! This test switches on the hvps. Never touch the parts supplied with a high voltage from the hvps when running the followi...

Page 169

3/99 xerox docuprint n17 service manual 5-55 general procedures/information 5.2.1.25 hvps (bias transfer roll -) operation this diagnostic tests hvps negative dc voltage to the bias transfer roll. Warning! This test switches on the hvps. Never touch the parts supplied with a high voltage from the hv...

Page 170

3/99 general procedures/information 5-56 xerox docuprint n17 service manual 5.2.1.26 hvps (bias transfer roll +) operation this diagnostic tests hvps positive dc voltage to the bias transfer roll. Warning! This test switches on the hvps. Never touch the parts supplied with a high voltage from the hv...

Page 171

3/99 xerox docuprint n17 service manual 5-57 general procedures/information 5.2.1.27 exit diagnostics operation this procedure is used to exit the diagnostic test currently running. Execute exit diagnostics operation: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the...

Page 172

3/99 general procedures/information 5-58 xerox docuprint n17 service manual 5.2.1.28 rom checksum this diagnostic displays the print engine controller rom checksum. Execute rom checksum: 1 enter diagnostics mode 1. The lcd displays print counter operationindicating the printer is in diagnostics mode...

Page 173

3/99 xerox docuprint n17 service manual 5-59 general procedures/information 5.2.1.29 paper tray size operation this diagnostic shows the contact actuation (combination of closed contacts) of each paper size sensor. Execute paper tray size operation: 1 enter diagnostics mode 1. The lcd displays print...

Page 174: 5.2.2 Diagnostic Mode 2

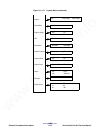

3/99 general procedures/information 5-60 xerox docuprint n17 service manual 5.2.2 diagnostic mode 2 to enter diagnostic mode 2: 1 switch off the printer power. 2 remove paper from all trays except the one under test. 3 while switching on the printer, press and hold the item up (2) and the item down ...

Page 175

3/99 xerox docuprint n17 service manual 5-61 general procedures/information figure 5.2.2.1 iot test print lead edge inboard edge 4 mm 4 mm 1003 www.Printcopy.Info www.Printcopy.Info.

Page 176: 5.2.3 Diagnostic Mode 3

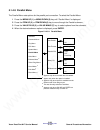

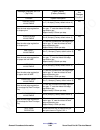

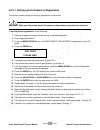

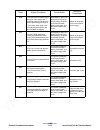

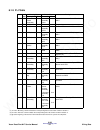

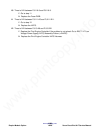

3/99 general procedures/information 5-62 xerox docuprint n17 service manual 5.2.3 diagnostic mode 3 to enter diagnostic mode 3: 1 switch off the printer power. 2 while switching on the printer, press and hold the item up (2) and the item down (6) keys until the lcd displays *iot?*. 3 press the enter...

Page 177

3/99 xerox docuprint n17 service manual 5-63 general procedures/information tray 2 proc. Adjustment 0 to f (16 steps) [factory default value: a] yes sets the lead edge registration for paper fed from tray 2. "0" sets the narrowest lead edge registra- tion gap. "f" sets the widest lead edge registrat...

Page 178

3/99 general procedures/information 5-64 xerox docuprint n17 service manual duplex proc. Adjustment to f (16 steps) [factory default value: a] yes sets the lead edge registration for duplex print. "0" sets the narrowest lead edge registra- tion gap. "f" sets the widest lead edge registration gap. Ap...

Page 179

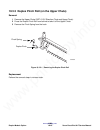

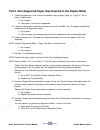

3/99 xerox docuprint n17 service manual 5-65 general procedures/information 5.2.3.1 setting and verification of registration this section covers setting and verifying registration of the printer. Warning! Make sure the printer has all the covers in place when you perform the test print. To set the p...

Page 180

3/99 general procedures/information 5-66 xerox docuprint n17 service manual the two methods to verify registration are: 1. Iot test print (see figure 5.2.2.1) • measure 4mm from the top edge (lead edge) of the paper to the top edge of the iot test print. • measure 4mm from the left edge of the paper...

Page 181

3/99 xerox docuprint n17 service manual 5-67 general procedures/information figure 5.2.3.1.1 system controller test print lead edge we conduct many of ever, these mail s coverage. Would yo your time to read survey has been de time and effort. T test pattern; a qu envelope are enclou we conduct many ...

Page 182

3/99 general procedures/information 5-68 xerox docuprint n17 service manual figure 5.2.3.1.1 lead edge-to-trail edge registration figure 5.2.3.1.1 side-to-side registration we conduct many of ever, these mail s coverage. Would yo your time to read survey has been de time and effort. T test pattern; ...

Page 183

3/99 xerox docuprint n17 service manual 5-69 general procedures/information 5.2.4 print engine controller test print there are three methods to produce a print engine controller test print. Note: the system controller must be installed to enter diagnostics. 1 enter diagnostic mode 2 and then press e...

Page 184

3/99 general procedures/information 5-70 xerox docuprint n17 service manual 5.2.5 system controller test print note: the system controller must be installed to produce system controller test prints. 1 press the online key to enter the offline mode. 2 press menu up (1) or menu down (5) key to scroll ...

Page 185

3/99 xerox docuprint n17 service manual 5-71 general procedures/information 5.3 diagnostic mode 2 error and status codes note: these error codes may be displayed on the printer control panel if a fault condition is detected during diagnostic mode 2 operation when the print engine cannot access the n...

Page 186

3/99 general procedures/information 5-72 xerox docuprint n17 service manual e6 printer fault e6: open covers there is a paper jam in the oct unit (oct jam). J3 printer fault j3: ep cartridge the ep cartridge is not in place. C3 printer fault c3: (tray 1) tray 1 is not in place. C3 printer fault c3: ...

Page 187: Recovery Procedures

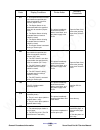

3/99 xerox docuprint n17 service manual 5-73 general procedures/information 5.3.1 error/status code display conditions, printer action, and recovery procedures table 5.3.1.1 error/status code display conditions, printer action, and recovery procedures code display conditions printer action recovery ...

Page 188

3/99 general procedures/information 5-74 xerox docuprint n17 service manual u5 the fan alm (fan alarm) signal becomes active (high) after a specified period of time from the printer power being switched on. * the active (high) state of the fan alm signal indicates that the fan motor is stopping. Imm...

Page 189

3/99 xerox docuprint n17 service manual 5-75 general procedures/information e4 1. The exit sensor is not deactu- ated in the specified time after the actuation of the registration sensor. 2. The exit sensor is being actu- ated when the printer is switched on. 3. The exit sensor is being actu- ated w...

Page 190

3/99 general procedures/information 5-76 xerox docuprint n17 service manual e1 1. The duplex sensor is not actu- ated within the specified time after the actuation of the exit sensor (duplex jam). 2. The duplex sensor is not deactuated within the specified time after its actuation (duplex jam). 3. T...

Page 191

3/99 xerox docuprint n17 service manual 5-77 general procedures/information paper size error the actual paper size is different from the paper size detected or set in the nonvolatile memory. In ready mode, the printer completes the cur- rent print cycle. In offline mode, the printer competes the cur...

Page 192

3/99 general procedures/information 5-78 xerox docuprint n17 service manual 5.4 supplemental tools, supplies, and hardware tools description ..........................................................Part number 150mm rule..........................................................600t41503 anacom g80 ...

Page 193

3/99 xerox docuprint n17 service manual 5-79 general procedures/information 5.5 service cleaning procedure proper diagnosis of printer problems requires that the printer be cleaned before troubleshooting begins. This section directs you in performing the cleaning and preliminary checkout procedures....

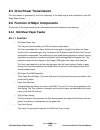

Page 194: 5.6.1 Printer Data Labels

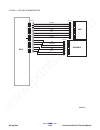

3/99 general procedures/information 5-80 xerox docuprint n17 service manual 5.6 printer data and tag information 5.6.1 printer data labels the printer serial number, data label, and retrofit (change) tag matrix are located on the printer as illustrated in figure 5.6.1.1 and figure 5.6.1.2. Figure 5....

Page 195

3/99 xerox docuprint n17 service manual 5-81 general procedures/information figure 5.6.1.2 printer data label and serial number plate www.Printcopy.Info www.Printcopy.Info.

Page 196

3/99 general procedures/information 5-82 xerox docuprint n17 service manual 5.6.2 retrofit (change) tag/mod matrix all important modifications are identified by a retrofit tag/mod number on the matrix card attached to the system controller chassis of each n17 printer (see rap 5.6.1 printer data labe...

Page 197: Section 6

6/98 xerox docuprint n17 service manual 6-1 wiring data section 6 wiring data wiring diagrams ............................................................................... 6-3 base engine connector locators ............................................ 6-3 base engine pwb connector locators ..........

Page 198

6/98 wiring data 6-2 xerox docuprint n17 service manual www.Printcopy.Info www.Printcopy.Info.

Page 199: 6.1 Wiring Diagrams

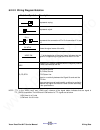

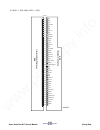

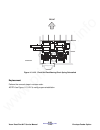

6/98 xerox docuprint n17 service manual 6-3 wiring data 6 6.1 wiring diagrams 6.1.1 base engine connector locators p202 j124 j125 p136 j136 p33 p17 p27 p16 p/j133 (blk) p/j134 (blu) p/j132 (wht) j122 p/j128 j137 p123 p114 p112 p113 p201 p130 j130 a b c d e f g h i j k l 1 2 3 4 5 6 7 8 9 10 11 12 13...

Page 200

6/98 wiring data 6-4 xerox docuprint n17 service manual 6.1.2 base engine pwb connector locators [sas602f.Cdr] hvps p115 p111 mcu p21 p23 p24 p28 p32 p13 p35 p31 p22 p14 p15 p25 p18 p19 p131 p17 p27 p12 p16 p3 lvps p1 p11 p117 p2 j2 p/j135 feeder pwb p118 p200 j118 m n o p q r s t u v w x 16 17 18 1...

Page 201

6/98 xerox docuprint n17 service manual 6-5 wiring data 6.1.3 hvps connector locators hvps bcr db btr dtc y z aa ab ac ad ae af ag ah ai aj 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 sas603fa www.Printcopy.Info www.Printcopy.Info.

Page 202

6/98 wiring data 6-6 xerox docuprint n17 service manual 6.1.4 p/j table (*1) pl in the “mounting” column indicates the corresponding parts list and item number in section 3. (*2) pl in the “harness” column indicates the corresponding parts list and item number in section 3. (*3) @ at the beginning o...

Page 203

6/98 xerox docuprint n17 service manual 6-7 wiring data 6.1.5 p/j table (*1) pl in the “mounting” column indicates the corresponding parts list and item number in section 3. (*2) pl in the “harness” column indicates the corresponding parts list and item number in section 3. (*3) @ at the beginning o...

Page 204

6/98 wiring data 6-8 xerox docuprint n17 service manual 6.1.6 p/j table (*1) pl in the “mounting” column indicates the corresponding parts list and item number in section 3. (*2) pl in the “harness” column indicates the corresponding parts list and item number in section 3. (*3) @ at the beginning o...

Page 205

6/98 xerox docuprint n17 service manual 6-9 wiring data 6.1.7 p/j table (*1) pl in the “mounting” column indicates the corresponding parts list and item number in section 3. (*2) pl in the “harness” column indicates the corresponding parts list and item number in section 3. (*3) @ at the beginning o...

Page 206: 6.2 Wiring

6/98 wiring data 6-10 xerox docuprint n17 service manual 6.2 wiring 6.2.1 general wiring diagram lvps hvps mcu m m m p/j 202 p/j 200 p/j 209 p/j 216 oct option deck 2 & deck 3 p/j 21 p/j 32 p/j 33 control panel p/j 112 ldd p/j 18 p/j 22 p/j 135 p/j 118 p/j 23 p/j 24 p/j 14 p/j 28 p/j 114 scanner p/j...

Page 207

6/98 xerox docuprint n17 service manual 6-11 wiring data 6.2.2 wiring for connection between components 6.2.2.1 organization the general connection and wiring diagram is divided into the following 19 blocks and the wiring and signals between the components in each blocks are described. 1. Lvps ↔ mcu...

Page 208

6/98 wiring data 6-12 xerox docuprint n17 service manual this page intentionally blank. Www.Printcopy.Info www.Printcopy.Info.

Page 209

6/98 xerox docuprint n17 service manual 6-13 wiring data 6.2.2.2 wiring diagram notation note: “ttl” in the “high level” and “low level” columns of the signal tables indicates that the signal is ttl_cmos compatible. The high and low levels of a ttl signal are as below. High level: 4 to 5 volts low l...

Page 210

6/98 wiring data 6-14 xerox docuprint n17 service manual 6.2.3 connection and wiring between components 1. Lvps ↔ mcu (xc specifications) 4 2 p/j136 1 3 p/j131 5v intlk 1 1 1 b1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 5 6 6 6 6 7 7 8 8 9 9 10 10 11 11 12 12 13 13 5v intlk 24v n.C 5v 24v (fan) 12v /heat on 2...

Page 211

7/99 xerox docuprint n17 service manual 6-15 wiring data 1. Lvps ↔ mcu (xc specifications) p11 p13 signal name signal direction l: lvps, m:mcu trigger high level low level 1 1 5v intlk l → m - +5v 0v 3 3 24v (fan) l → m - +24v 0v 4 4 heat on l ← m level ttl ttl 5 5 evn pres l → m level ttl ttl 6 6 n...

Page 212

6/98 wiring data 6-16 xerox docuprint n17 service manual this page intentionally blank. Www.Printcopy.Info www.Printcopy.Info.

Page 213

6/98 xerox docuprint n17 service manual 6-17 wiring data 1. Lvps ↔ mcu (xc specifications) warning! You can be shocked by electricity if you simultaneously touch the two heat sinks shown in the figure below. Transformer ld switch interlock switch d108 q101 q102 heat sink lvps www.Printcopy.Info www....

Page 214

6/98 wiring data 6-18 xerox docuprint n17 service manual 2. Lvps ↔ feed solenoid 1, turn clutch, and mbf solenoid 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 3 3 3 4 4 4 5 5 5 6 6 6 7 7 8 8 9 9 10 10 11 11 12 12 13 13 5v intlk 24v n.C feed sol 1 24v (fan) 24v /heat on turn clutch 1 /env pres 24v no paper en...

Page 215

7/99 xerox docuprint n17 service manual 6-19 wiring data 2. Lvps ↔ feed solenoid 1, turn clutch, and mbf solenoid resistance of the solenoids signal name description feed sol1 signal to actuate the feed solenoid which feeds paper on tray 1 (normally low level, and high level when paper is fed) turn ...

Page 216

6/98 wiring data 6-20 xerox docuprint n17 service manual 3. Lvps ↔ mbf no paper sensor, registration sensor, and toner empty sensor 1 1 1 1 1 1 1 2 2 2 2 2 2 2 3 3 3 3 3 3 3 4 4 4 5 5 5 6 6 6 7 7 7 8 8 8 9 9 9 10 10 11 11 12 12 13 13 5v intlk n.C 24v (fan) /heat on /env pres no paper env /env feed s...

Page 217

7/99 xerox docuprint n17 service manual 6-21 wiring data 3. Lvps ↔ mbf no paper sensor, registration sensor, and toner empty sensor signal name description no pap mbf signal for detecting the presence or absence of paper on the mbf (low level when paper is present and high level when paper is not pr...

Page 218

6/98 wiring data 6-22 xerox docuprint n17 service manual 4. Lvps ↔ envelope feeder unit 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 3 3 3 3 3 3 3 3 4 4 4 4 4 4 4 5 5 5 5 5 5 5 6 6 6 6 6 6 6 7 7 7 7 7 7 7 8 8 9 9 10 10 11 11 12 12 13 13 5v intlk n.C 24v (fan) /heat on /env pres env pres sg 5v no pap env ...

Page 219

6/98 xerox docuprint n17 service manual 6-23 wiring data 4. Lvps ↔ envelope feeder unit resistance of the envelope feed solenoid signal name description env pres signal for detecting if the optional envelope feeder is installed or not (low level when the envelope feeder is in place, and high level w...

Page 220

6/98 wiring data 6-24 xerox docuprint n17 service manual 5. Mcu ↔ hvps sas610f a12 b12 a1 b1 a11 b11 a2 b2 a10 b10 a3 b3 a9 b9 a4 b4 a8 b8 a5 b5 a7 b7 a6 b6 a6 b6 a7 b7 a5 b5 a8 b8 a4 b4 a9 b9 a3 b3 a10 b10 a2 b2 a11 b11 1 3 a1 b1 1 a12 b12 n.C /bcr ac on 5v-ld /d.B dc on /cru snr sg /exit snr 5v /d...

Page 221

6/98 xerox docuprint n17 service manual 6-25 wiring data 5. Mcu ↔ hvps signal name description 5v-ld +5v power source to the laser diode (0v when the front cover is open or when the fuser unit is not in place) sts signal from the temperature sensor which detects the temperature of the fuser heat rol...

Page 222

6/98 wiring data 6-26 xerox docuprint n17 service manual 5. Mcu ↔ hvps p15 p11 signal name signal direc- tion m: mcu h: hvps trigger high level low level a11 a2 5v-ld m ← h - +5v 0v a7 a6 sts m ← h - * * a6 a7 btr sig m → h - * * a5 a8 /refeed snr m ← h level ttl ttl a4 a9 no pap1 m ← h level ttl tt...

Page 223

6/98 xerox docuprint n17 service manual 6-27 wiring data 6. Hvps ↔ ep cartrige, bias transfer roll, and detack saw signal name description db hvps output to the magnet roll bcr hvps output to the bcr dts hvps output to the dts btr hvps output to the btr (+dc in transfer operation, and -dc when clean...

Page 224

6/98 wiring data 6-28 xerox docuprint n17 service manual 7. Hvps ↔ fuser pwb sas612f a12 b12 a1 b1 a11 b11 a2 b2 a10 b10 a3 b3 a9 b9 a4 b4 a8 b8 a5 b5 a7 b7 a6 b6 a6 b6 a7 b7 a5 b5 a8 b8 a4 b4 a9 b9 a3 b3 a10 b10 a2 b2 a11 b11 a1 b1 a12 b12 n.C /bcr ac on /btr on 5v-ld /d.B dc on /cru snr sg /exit s...

Page 225

6/98 xerox docuprint n17 service manual 6-29 wiring data 7. Hvps ↔ fuser pwb signal name description 5v-ld refer to “ 5. Mcu ↔ hvps” 5v-intlk refer to “ 1. Lvps ↔ mcu (xc specifications)” exit snr refer to “ 5. Mcu ↔ hvps” sts refer to “ 5. Mcu ↔ hvps” dup mot on refer to “ 5. Mcu ↔ hvps” dup mot cl...

Page 226

6/98 wiring data 6-30 xerox docuprint n17 service manual 8. Fuser pwb ↔ fuser unit sas613f a12 b12 a1 b1 a11 b11 a2 b2 a10 b10 a3 b3 a9 b9 a4 b4 a8 b8 a5 b5 a7 b7 a6 b6 a6 b6 a7 b7 a5 b5 a8 b8 a4 b4 a9 b9 a3 b3 a10 b10 a2 b2 a11 b11 a1 b1 a12 b12 n.C /bcr ac on /btr on 5v-ld /d.B dc on /cru snr sg /...

Page 227

6/98 xerox docuprint n17 service manual 6-31 wiring data 8. Fuser pwb ↔ fuser unit 1. The temperature at which the fuse melts: 141 o c (nominal temperature) 2. The temperature at which the contacts of the thermostat open: temperature of the contacts 150 o c (non-contact type) 3. The rated power of t...

Page 228

6/98 wiring data 6-32 xerox docuprint n17 service manual 9. Fuser pwb ↔ duplex pwb ↔ duplex motor, and refeed sensor a12 b12 a11 b11 a10 b10 a9 b9 a8 b8 a7 b7 a6 b6 a5 b5 a4 b4 a3 b3 a2 b2 a1 b1 a1 b1 a2 b2 a3 b3 a4 b4 a5 b5 a6 b6 a7 b7 a8 b8 a9 b9 a10 b10 a11 b11 a12 b12 n.C 24v (a-com) 24v (b-com)...

Page 229

6/98 xerox docuprint n17 service manual 6-33 wiring data 9. Fuser pwb ↔ duplex pwb ↔ duplex motor, and refeed sensor p117 p214 signal name signal direction f: fuser pwb d: duplex pwb trigger high level low level 4 4 d. Mot on f → d level ttl ttl 3 3 d. Mot clk f → d level ttl ttl 2 2 refeed snr f ← ...

Page 230

6/98 wiring data 6-34 xerox docuprint n17 service manual 10. Mcu ↔ ldd and scanner motor 3 8 7 9 10 11 12 13 7 6 6 6 5 5 5 4 4 4 3 3 2 2 2 1 1 1 p/j18 p/j112 p/j114 /p. Data 5v mo vl 2 vl 1 sg 5v-ld 24v 24v rtn /scn mot on sg spi 1 spi 2 ldd scanner mcu sas614f www.Printcopy.Info www.Printcopy.Info.

Page 231

6/98 xerox docuprint n17 service manual 6-35 wiring data 10. Mcu ↔ ldd and scanner motor signal name description /p. Data print image data (black dot: low level, white dot: high level) mo signal for monitoring the electric current of the ld (analog signal) vl2 sets the drive voltage for the ld (anal...

Page 232

6/98 wiring data 6-36 xerox docuprint n17 service manual 11. Mcu ↔ sos signal name description /sos sos detection signal (normally high level and low level when the laser light is detected) p2 p113 signal name signal direction m: mcu s: sos trigger high level low level 2 2 /sos m → s level ttl ttl 3...

Page 233

6/98 xerox docuprint n17 service manual 6-37 wiring data 12. Mcu ↔ control panel signal name description rd data data line for reading the information on the keys from the control panel (serial signal) /wr data data line for writing the display data for the lcd and leds on the control panel (serial ...

Page 234

6/98 wiring data 6-38 xerox docuprint n17 service manual 13. Mcu ↔ main motor 1 2 3 4 5 6 p/j14 /main mot on /mot ready 24v 24v rtn mcu main mot m www.Printcopy.Info www.Printcopy.Info.

Page 235

6/98 xerox docuprint n17 service manual 6-39 wiring data 13. Mcu ↔ main motor the main motor also rotates in the following conditions: 1) when the power is turned on (boom operation): 1 second 2) when the cover is closed after a paper jam is cleared (boom operation and erase cycle): 1 sec. (boom ope...

Page 236

6/98 wiring data 6-40 xerox docuprint n17 service manual 14. Mcu ↔ fan motor 1 2 3 4 p/j23 24v rtn fan ready 24v (fan) fan fast mcu fan m sas619xa www.Printcopy.Info www.Printcopy.Info.

Page 237

6/98 xerox docuprint n17 service manual 6-41 wiring data 14. Mcu ↔ fan motor signal name description fan ready signal for detecting a problem in the fan motor (low level when the motor is normal, and high level when the motor is abnormal) fan fast control signal for switching the motor speed (low le...

Page 238

6/98 wiring data 6-42 xerox docuprint n17 service manual 15. Mcu ↔ exit motor 1 2 3 4 5 6 p/j24 24v (a-com) a /a 24v (b-com) b /b mcu exit mot m sas620f www.Printcopy.Info www.Printcopy.Info.

Page 239

6/98 xerox docuprint n17 service manual 6-43 wiring data 15. Mcu ↔ exit motor signal name description a phase a drive signal for the stepping motor (low level when driving, and high level when not driving) b phase b drive signal for the stepping motor (low level when driving, and high level when not...

Page 240

6/98 wiring data 6-44 xerox docuprint n17 service manual 16. Mcu ↔ full stack sensor and rear cover sensor 1 1 1 2 2 2 3 3 3 4 5 6 7 p/j28 j125 j124 rear cover intlk full stack snr mcu sg sg 5v 5v n. C full stk snr /rear cover intlk www.Printcopy.Info www.Printcopy.Info.

Page 241

6/98 xerox docuprint n17 service manual 6-45 wiring data 16. Mcu ↔ full stack sensor and rear cover sensor signal name description fullstk snr signal for detecting the amount of paper on the exit tray (low level when the exit tray is not full, and high level when the exit tray is full) /rear cover i...

Page 242

6/98 wiring data 6-46 xerox docuprint n17 service manual 17. Mcu ↔ deck1 pwb ↔ deck2 pwb ↔ deck3 pwb 1 1 1 1 1 11 1 1 1 1 1 2 2 2 2 2 12 2 2 2 2 2 3 3 3 3 3 13 4 4 4 4 4 14 5 5 5 5 5 15 6 6 6 6 6 16 7 7 7 7 7 17 8 8 8 8 8 18 9 9 9 9 9 19 10 10 10 10 10 20 11 p/j216-1 p/j200-1 p/j22 p/j2 26-2 p/j2 16...

Page 243

6/98 xerox docuprint n17 service manual 6-47 wiring data 17. Mcu ↔ deck1 pwb ↔ deck2 pwb ↔ deck3 pwb resistance of the solenoid signal name function no pap2 detection signal on the presence/absence of paper in tray 2 (low when paper is present and high when out of paper) no pap3 detection signal on ...

Page 244

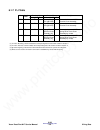

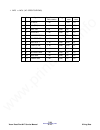

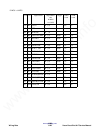

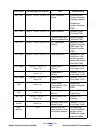

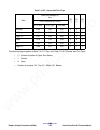

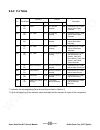

6/98 wiring data 6-48 xerox docuprint n17 service manual 17. Mcu ↔ deck1 pwb ↔ deck2 pwb ↔ deck3 pwba table 6.2.3.1 main tray table 6.2.3.1 second and third trays size size snr voltage (v) vsnr s2 (*) s1 (*) s0 (*) +5vdc measured at p/j22-6 4.77v min. 5.10v typ. 5.44 max. No cassette 0.00 0.00 0.00 ...

Page 245

6/98 xerox docuprint n17 service manual 6-49 wiring data this page intentionally blank. Www.Printcopy.Info www.Printcopy.Info.

Page 246

6/98 wiring data 6-50 xerox docuprint n17 service manual 18. Mcu ↔ oct stack sensor, oct home sensor, oct exit sensor, oct direct solenoid, oct motor, and oct offset motor 1 14 14 1 1 1 1 1 1 1 1 1 2 13 13 2 2 2 2 2 2 2 2 2 3 12 12 3 3 3 3 3 3 3 3 3 4 11 11 4 4 4 4 5 10 10 5 5 5 5 6 9 9 6 6 6 6 7 8 ...

Page 247

6/98 xerox docuprint n17 service manual 6-51 wiring data 18. Mcu ↔ oct stack sensor, oct home sensor, oct exit sensor, oct direction solenoid, oct motor, and oct offset motor signal name function /oct pres signal for detecting the presence of optional oct (low level when installed, and high level wh...

Page 248

6/98 wiring data 6-52 xerox docuprint n17 service manual 18. Mcu ↔ oct stack sensor, oct home sensor, oct exit sensor, oct direct sensor, oct motor, and oct offset motor signal name function oct stk snr signal for monitoring the amount of paper on the oct tray (low level when not full, and high leve...

Page 249

6/98 xerox docuprint n17 service manual 6-53 wiring data 19. Mcu ↔ ess and lvps ↔ ess p1 s9 p2 s10 p3 s11 p4 s12 s1 s13 s2 s14 s3 s15 s4 s16 s5 s17 s6 s18 s7 s19 s8 s20 s21 s22 s23 s24 s25 s26 s27 s28 s29 s30 s31 s32 s33 s34 s35 s36 s37 s38 s39 s40 sg 5v nc 12v txd m/b 12v rtn rsrv sg rsrv sg /led e...

Page 250

6/98 wiring data 6-54 xerox docuprint n17 service manual notes www.Printcopy.Info www.Printcopy.Info.

Page 251: Section 7

6/98 xerox docuprint n17 service manual 7-1 repair analysis procedures (raps) section 7 repair analysis procedures using raps ......................................................................................... 7-5 preliminary steps .................................................................

Page 252

6/98 repair analysis procedures (raps) 7-2 xerox docuprint n17 service manual toner low message (j5) ....................................................... 7-31 install print cartridge message (j3) ...................................... 7-32 error codes ................................................

Page 253

6/98 xerox docuprint n17 service manual 7-3 repair analysis procedures (raps) deletions ..................................................................... 7-81 fusing ......................................................................... 7-82 resolution ...........................................

Page 254

6/98 repair analysis procedures (raps) 7-4 xerox docuprint n17 service manual www.Printcopy.Info www.Printcopy.Info.

Page 255: 7.1 Using Raps

6/98 xerox docuprint n17 service manual 7-5 repair analysis procedures (raps) 7 7.1 using raps in each of the following repair analysis procedures (raps), you are instructed to perform certain actions and make observations. The instruction is followed by a statement. If your response to the statemen...

Page 256: 7.2 Preliminary Steps

6/98 repair analysis procedures (raps) 7-6 xerox docuprint n17 service manual 7.2 preliminary steps if the printer is displaying an obvious failure or fault, go immediately to the appropriate repair procedure or repair analysis procedure. If you are not sure where to begin troubleshooting, go to 7.2...

Page 257: 7.2.1 Entry Level Rap

6/98 xerox docuprint n17 service manual 7-7 repair analysis procedures (raps) 7.2.1 entry level rap 1 switch printer off then switch it on. Within 2 minutes the printer displays ready on the control panel display. Y: go to step 5. N: go to step 2. 2 the printer displays a fault message or error code...

Page 258