- DL manuals

- Xerox

- Software

- Phaser 6100

- Service Manual

Xerox Phaser 6100 Service Manual

Summary of Phaser 6100

Page 1

Service manual x xer ox p h a s e r ® c o l o r l a s e r p r i n t e r 6100

Page 3: Service Manual

Phaser 6100 color laser printer service manual warning the following servicing instructions are for use by qualified service personnel only. To avoid personal injury, do not perform any servicing other than that contained in the operating instructions, unless you are qualified to do so. First printi...

Page 4

Copyright © 2004, xerox corporation. All rights reserved. Unpublished rights reserved under the copyright laws of the united states. Contents of this publication may not be reproduced in any form without permission of xerox corporation. Copyright protection claimed includes all forms of matters of c...

Page 5

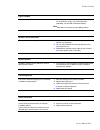

I contents 1 precautions 1. Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.1 service terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Ii front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 4.1.2 motor and fan layout . ....

Page 7

Iii 6.4.11 developer drive assembly (pl 9.1.8). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29 6.4.12 deve drive board (pl 9.13.20) and deve cover open switch (pl 9.15.36) (door a interlock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31 ...

Page 8

Iv 7.6.2.6 hvps tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17 7.6.2.7 regi.Set test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18 7.6.2.8 color calibration . . . . . . . . ...

Page 9

V 9.12 optional 500-sheet feeder (scf) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23 9.13 main frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26 9.14 front ...

Page 10

Vi.

Page 11: 1. Precautions

Precautions service manual 1-1 1. Precautions in order to prevent accidents and damage to the printer, please read all the precautions listed in this section carefully before servicing the printer. 1.1 service terms 1.1.1 manual terms various terms are used throughout this manual to either provide a...

Page 12

Precautions 1-2 1.2 symbols marked on the product danger high voltage. Protective ground (earth) symbol. Hot surface on or in the printer. Use caution to avoid personal injury. The surface is hot while the printer is running. After turning off the power, wait 30 minutes. Avoid pinching fingers in th...

Page 13: 1.3 Power Safety Precautions

Precautions service manual 1-3 1.3 power safety precautions 1.3.1 power source for 110 vac printers, do not apply more than 140 volts rms between the supply conductors or between either supply conductor and ground. Use only the specified power cord and connector. For 220 vac printers, do not apply m...

Page 14: 1.5Service Safety Summary

Precautions 1-4 1.4 electrostatic discharge (esd) precautions some semiconductor components , and the respective sub-assemblies that contain them, are vulnerable to damage by electrostatic discharge (esd). These components include integrated circuits (ics), large-scale integrated circuits (lsis), fi...

Page 15

Precautions service manual 1-5 1.5.2 warning labels read and obey all posted warning labels. Throughout the printer, warning labels are displayed on potentially dangerous components. As you service the printer, check to make certain that all warning labels remain in place. 1.5.3 safety interlocks ma...

Page 16

Precautions 1-6 1.5.6 servicing fuser components warning this printer uses heat to fuse the toner image to media. The fuser is very hot. Turn the printer power off, open door b, and wait at least 5 minutes for the fuser to cool before you attempt to service the fuser assembly or adjacent components....

Page 17: 2. Reference Information

Reference information service manual 2-1 2. Reference information this section contains a tools list, list of abbreviations used in this manual, and a clearance required specification when installing the phaser 6100 printer. 2.1 tools for troubleshooting the printer the following tools are recommend...

Page 18

Reference information 2-2 2.2 acronyms and abbreviations definition definition adc analog-to-digital conversion f/w firmware ap access point fcf/fct tray 1 or first cassette feeder ac alternating current fiso front in, side out asic circuit application specific integrated fpot first print out time a...

Page 19

Reference information service manual 2-3 lvps low voltage power supply or smps mb megabyte q’ty quantity mhz megahertz ram random access memory mpbf mean prints between failure rom read only memory mpf/mpt multi-purpose tray scf/sct tray 2 or second cassette feeder nic network interface card smps sw...

Page 20

Reference information 2-4 2.3 selecting a location for the printer ■ leave enough room to open the printer trays, covers, and allow for proper ventilation. ■ provide the proper environment ■ a sturdy, level surface ■ away from the direct airflow of air conditioners, heaters, or ventilators. ■ free f...

Page 21

Reference information service manual 2-5 2.4 printer serial number format changes to xerox products are made to accommodate improved components as they become available. It is important when ordering parts to include the following information: ■ component's part number ■ product type or model number...

Page 22

Reference information 2-6.

Page 23: Specifications

Specifications service manual 3-1 the specifiations in this manual are correct at the time of printing. Product specifications are subject to change without notice. 3.1 general specifications 3 specifications item description print method non-impact electro-photography developing system non-magnetic...

Page 24: 3.2 Controller Specification

Specifications 3-2 3.2 controller specification 3.3 electrical specification item description processor spgpm (samsung printer graphic processor) clock speed 120 mhz memory the controller has 64 mb sdram and 4 mb flash rom on board. 1 dimm expansion slot for sdram dimm package: dimm; 100-pin type: s...

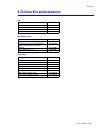

Page 25: 3.4 Environmental Range

Specifications service manual 3-3 3.4 environmental range 3.5 periodically replaced parts 3.5.2 consumables 3.5.3 options items operating storage (packaged) optimum temperature 15 ~ 30 o c (59 ~ 86 o f) 5 ~ 35 o c (41 ~ 95 o f) 20 - 25 o c humidity 20 - 80% rh 20 - 80 % rh 30 - 70% rh altitude 2,500...

Page 26: 3.6 Media Specifications

Specifications 3-4 3.6 media specifications 3.6.1 paper size and weights the supported media types for this printer include, but are not limited to: labels, envelopes, cardstock, plain paper, transparency, letterhead and colored paper. Paper type size tray support a4 210 x 297mm all trays letter 8.5...

Page 27

Specifications service manual 3-5 3.6.1 paper size and weights (cont’d) 3.6.2 print margins and skew 3.6.3 pc (host) specifications for reliable operation, the following pc configurations are recommended: ■ windows 98, me; pentioum 166 mhz; 64 mb ram ■ windows nt 4.0, 2000, xp, server 2003; pentium ...

Page 28

Specifications 3-6.

Page 29: 4.1 System Structure

Summary of product service manual 4-1 4.1 system structure 4.1.1 major assemblies of the printer 4 product summary hvps eraser lamp eraser lamp hvps dev . - black dev . - yellow pick-up roller dev . - magenta dev . - cyan cassette lsu feeder duplex fuser unit exit unit mpf mpt dev . - black dev . - ...

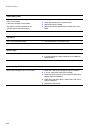

Page 30: Lvps

Summary of product 4-2 front view rear view deve oem board crum reader control panel waster toner sensor waster toner motor lvps lvps main drive main drive fuser fan fuser fan conrtoller board conrtoller board deve drive deve drive deve drive board deve drive board duplex cover open switch duplex co...

Page 31

Summary of product service manual 4-3 1) imaging unit the imaging unit creates the image using an electro-photo process. The imaging unit consists of the following: ■ an opc drum ■ waste toner assembly ■ charge roller assembly 2) transfer belt (itb) itb stands for image transfer belt. The image deve...

Page 32

Summary of product 4-4 7) feeder ■ paper arrangement: side registration. ■ drive: main motor dc ■ paper management: feed clutch 8) duplex unit the duplex unit is used to reverse paper feed to print the on backside of paper. The duplex unit is not an option. The transfer roller is part of the duplex ...

Page 33

Summary of product service manual 4-5 15) low voltage power supply (lvps or smps (switching mode power supply)) the lvps uses the ac supply voltage to generate the dc voltages used by the printer. ■ the lvps has 3 output channels (+3.3v, +5v, +24v). ■ the lvps sends ac power to the fuser and dc volt...

Page 34: 4.1.2 Motor and Fan Layout

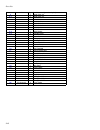

Summary of product 4-6 4.1.2 motor and fan layout no. Name description 1. Main motor drives the imaging unit, transfer belt, feed, fuser, exit and duplex unit. 2. Deve motor drives the toner cartridges and transfer belt cleaning cam. 3. Fuser fan cools the fuser. 4. Waste toner motor transfer collec...

Page 35

Summary of product service manual 4-7 4.1.3 clutch and solenoid layout no. Solenoid name description 1. Y deve solenoid controls high voltage to the yellow toner cartridge. 2. M deve solenoid controls high voltage to the magenta toner cartridge. 3. C deve solenoid controls high voltage to the cyan t...

Page 36

Summary of product 4-8 4.1.4 sensor and switch layout note the transfer belt home sensor and ctd sensor are located in the transfer belt. If these sensors become damaged or faulty, replace the transfer belt assembly. The sensors are not spared separately. No. Name description 1. Tray 1 paper empty s...

Page 37: 4.1.5 Main Board

Summary of product service manual 4-9 4.1.5 main board usb npc p arallel p or t cn26 cn27 cn2 8 cn29 cn30 cn30 cn32 cn33 t2 home bldc1 fsr_r oll fuser_f an smps mp empt mp sol feed cn25 pick_up cn23 cl t_feed cn21 empt cn9 cn1 cn16 scf cn12 lsu cn6 opc key cn5 deve_driverd e v e _d r iv e r deve_dri...

Page 38

Summary of product 4-10 ram dimm spgpm main control flash memory engine control.

Page 39

Summary of product service manual 4-11 1) cpu block a 120mhz - 32bit risc processor is used to manage commands and data supplied by the host. This is converted into a bitmap image which is passed to the engine block for printing. 2) spgpm (samsung printer graphics processor) overview ■ package: 272 ...

Page 40

Summary of product 4-12 ■ usb 2.0 interface usb 1.1 backward compatible udc (usb device controller) block and usb physical block are integrated both of high speed (480 mbps) and full speed (12 mbps) are supported 2 dma channels support: one rx channel and one tx channel 3) memory block the operating...

Page 41: 4.1.6 Lvps (Smps) Board

Summary of product service manual 4-13 4.1.6 lvps (smps) board the lvps board supplies dc power for driving the whole system, it also contains an ac heater control unit that supplies power to the fuser. 1) dc output main board, control panel, tray 1, developer drive board, interlocks, sensors imagin...

Page 42

Summary of product 4-14 4.1.7 hvps (high voltage supply) board the hvps uses the +24 volts supplied by the lvps to generate the high voltages used by the charge roller, toner cartridge, imaging unit (t1), transfer belt (t2), and transfer roller. For the best print-quality images, these hifh voltages...

Page 43

Summary of product service manual 4-15 1) charging voltage: charger ■ function: charges the surface of the drum to about -500 volt ~ 800 volt. ■ output voltage: -200 v~-2.0k v dc +/- 3% (duty is changeable, no loading) ■ error type: if the correct voltage was not present, the surface of the drum is ...

Page 44

Summary of product 4-16.

Page 45: System Outline

System outline service manual 5-1 5.1 color laser printing process 5.1.1 imaging unit (drum charge section) the imaging unit contains the drum, waste toner cleaning assembly and charge roller. 1) structure ■ opc drum: the laser light forms a latent electric image on the surface of the drum. ■ cleani...

Page 46

System outline 5-2 5.1.2 lsu (exposure) the latent image is formed on the drum using an image data stream to switch the laser beam on or off. Where no image is required the beam is off, where toner is required the beam is turned on. When the laser is on and the beam strikes the drum surface, the cha...

Page 47

System outline service manual 5-3 2) developing the latent image is formed as described below. Developing sequence: y, m, c, and k t1 process the image is created using a four color pass process. Each of the four colors is applied to the drum one at a time in the following order: y, m, c, and then k...

Page 48

System outline 5-4 5.1.4 image transfer the toner image formed on the drum and transferred to the transfer belt is called the primary image transfer or t1. When the final color image has been placed on the transfer belt it is then transferred onto the paper by the transfer roller, this is called the...

Page 49: Ptl

System outline service manual 5-5 1. Primary transfer (t1) 3. Ptl (pre-transfer lamp) 5. Transfer roller (t2) the transfer roller transfer the final toner image from the transfer belt to the paper. ■ the hvps applies the image transfer bias voltage to the transfer roller allowing transfer of the ima...

Page 50: Ctd Sensor

System outline 5-6 4. Ctd sensor 5) secondary image transfer, transfer roller (t2) opc drum transfer unit ctd sensor opc drum led pbs (polarized beam splitter) pd (photo diode) toner opc drum paper image transfer bias charge removal bias image transfer belt image transfer roller hvps.

Page 51

System outline service manual 5-7 5.1.5 fuser (fusing process) toner that has been through the primary and secondary image transfer processes is fused or fixed to the paper.. The fuser consists of two heat lamps, two heat rollers, one thermistor, and two thermostats. The fuser melts the toner onto t...

Page 52

System outline 5-8 5.1.6 exit after passing through the fuser, media is ejected into the output tray. Any static electrical charge is removed by static discharge brushes. When operating in duplex print mode, after printing the front side of the page, the paper exit roller reverses to feed the paper ...

Page 53: 5.2 System Start-Up Sequence

System outline service manual 5-9 5.2 system start-up sequence the printer uses 4 different colored toners (yellow, magenta, cyan, black) and is a color laser printer. Engine firmware controls the print processes, drives the print engine, paper feed, developer, fuser, and paper exit systems. It has ...

Page 54

System outline 5-10 5.2.3 ready 1) host interface is monitored for print commands 2) heat control ■ target temperature (165° c). ■ every 40 seconds, temperature value for the previous 250ms is read and a proportional control process is carried out. 3) printer is in “ready” mode entered after warm-up...

Page 55

System outline service manual 5-11 6) motor torque check 7) check and set a high voltage condition (t1, t2, charger) 8) initialize printing parameters ■ paper size, copies, trays ■ image pixels, image times, y-offset, x-offset ■ sensors ■ color print mode: ■ except legal & ohp/legal/ohp ■ simplex/du...

Page 56

System outline 5-12 5.2.6 post-print this is the last stage of the printing process. Its functions are described below. A. Clean transfer rollers. B. Stops all virtual timers. C. Re-initialize parameters used in the print process. D. Stops motors..

Page 57: Disassembly

Disassembly service manual 6-1 6.1.1 precautions for disassembly/reassembly ■ use only approved xerox spare parts. Ensure that the part number, product name, any voltage, current or temperature ratings are correct. Failure to do so could result in damage to the printer, circuit overload, fire or ele...

Page 58: 6.2 Maintenance and Supplies

Disassembly 6-2 6.2 maintenance and supplies there are parts in this printer that have a limited life compared to the life of the printer, these parts must be periodically replaced. The table shows the life of each part and is measured using a4/letter paper. When servicing a printer, always check th...

Page 59: 6.2.2 Printer Cleaning

Disassembly service manual 6-3 6.2.2 printer cleaning the printer should be cleaned regularly, especially if it is used in a dusty environment. This ensures that print-quality remains high and failures due to contamination are less likely to occur. ■ clean the printer with a soft, lint free, cloth d...

Page 60

Disassembly 6-4 6.3 information related to disassembly and reassembly before diassembling the printer: caution do not use a power screwdriver for reassembling the printer. The plastic screw holes in the chassis can become damaged or stripped. If holes are already damaged, use spare untapped holes. T...

Page 61

Disassembly service manual 6-5 7) fuser unit warning: the fuser melts toner onto the paper at a very high temperature, use care when handling the fuser or severe burns can result. When removing the fuser from a printer that has recently been operating, let the fuser cool before handling. Do not touc...

Page 62: 6.3.2 Removing Consumables

Disassembly 6-6 6.3.2 removing consumables this section shows you how to open the covers (front cover, deve cover, exit cover, and duplex cover) and how to remove and replace the consumable parts (toner cartridge, transfer belt, and imaging unit). Orientation of the printer doors 1. Pull the side ha...

Page 63

Disassembly service manual 6-7 caution do not damage the rollers. Keep the toner cartridges on a flat surface. 3. Open the exit cover by pressing the cover open button. Exit cover door b deve cover door a.

Page 64

Disassembly 6-8 4. Remove the transfer belt by releasing the lock levers on both sides. 5. To remove the imaging unit, carefully lift the unit using the handle provided. Caution ensure the drum surface is not scratched or damaged, while removing from the printer or after placing it on a flat surface...

Page 65

Disassembly service manual 6-9 6.3.4 replacing the waste toner cartridge (pl 9.1.57) 1. Push in the top corners of the front cover. 2. Lift the latch at the top of the waste toner cartridge and pull the top edge forward, then lift the cartridge out. Note do not spill toner from the waste toner cartr...

Page 66

Disassembly 6-10 3. Remove the toner caps and fit them to the inlets as shown below. Toner cap.

Page 67

Disassembly service manual 6-11 6.4.1 top cover (pl 9.1.17) and front cover (pl 9.1.15) 1. Remove tray 1. 2. Open deve cover (door a), exit cover (door b), and duplex (door c). 3. Remove 2 screws (3-10 silver) from the top cover. Deve cover door a exit cover door b duplex cover door c top cover scre...

Page 68

Disassembly 6-12 4. Rotate the top cover, towards door a, to release it from the two tabs at the base of the cover and remove as shown. 5. Open the front cover. 6. Remove 7 screws (3-10 silver) located inside the front cover. Note to access the bottom, right front screw, tray 1 needs to be removed f...

Page 69

Disassembly service manual 6-13 8. Close the front cover door. 9. Push the cover down, and using a flathead screwdriver remove the cover from the posts on the bottom to release it from the printer. 10. Remove the front cover. Post post.

Page 70

Disassembly 6-14 6.4.2 control panel (pl 9.2.19) 1. Remove the front cover (6.4.1). 2. Remove 3 ((a) 3-8 gold). 3. Disconnect the wiring harness connector. 4. Rotate the control panel to release it from the tabs and remove the control panel from the printer. Screw screw screw a a a a a a connector.

Page 71: 6.4.3 Rear Cover (Pl 9.1.16)

Disassembly service manual 6-15 6.4.3 rear cover (pl 9.1.16) 1. Open the duplex cover, the deve cover and the exit cover. (refer to 6.3.3) 2. Remove the top cover. (refer to 6.4.1) 3. Remove 10 screws. ■ a: top 2 ea (3 * 10 silver) ■ b: side 3 ea (3 * 10 silver) ■ c: bottom 3 ea (4 * 10 silver) ■ d:...

Page 72

Disassembly 6-16 6.4.4a duplex cover - door c (pl 9.6.0) 1. Remove the front and rear covers (6.4.3) 2. Open door c. 3. Remove the top 2 hinge screws (3*10 silver) on either side of each hinge rail. 4. Disconnect the links from the door. 5. Holding the door at a 90 o angle, snap the front hinge out....

Page 73

Disassembly service manual 6-17 6.4.4b duplex unit (pl 9.6.2) and transfer roller (pl 9.1.54) 1. Remove the duplex cover assembly (door c) (6.4.4a) 2. Release the 4 hooks on the right and left side of the duplex unit with a flat-blade screwdriver. 3. Remove the duplex assembly from the door. 4. Remo...

Page 74: 6.3.5A Fuser (Pl 9.1.9)

Disassembly 6-18 6.3.5a fuser (pl 9.1.9) warning if the printer has been printing recently, the fuser will be hot. Open the exit cover and let the fuser cool before removing it. 1. Open the deve cover (door a). Note before opening the exit cover, completely open the deve cover until it is at a 90 o ...

Page 75

Disassembly service manual 6-19 6.4.5b fuser base cover (pl 9.13.29) 1. Remove the fuser (6.4.5a). 2. Remove 3 screws (3-10 silver). 3. Lift the base cover off. Screws.

Page 76

Disassembly 6-20 6.4.6 exit cover - door b (pl 9.5.0) 1. Open the duplex cover (door c). 2. With the exit cover closed, remove the e-ring and the hinge pin. Caution do not lose the hinge pins. Note the diagram shows the door open and covers off for reference only. 3. Remove the exit cover. E-ring hi...

Page 77

Disassembly service manual 6-21 6.4.7a low-voltage power supply - lvps/smps (pl 9.1.19) 1. Remove the rear cover (6.4.3) 2. Remove 5 screws (3-6 machine, gold) from the main board shield. 3. Remove 2 screws (3-10 machine, silver) connected to the parallel port and then remove the main board shield. ...

Page 78

Disassembly 6-22 4. Remove 5 screws from the lvps. ■ a: right side 2ea (3 * 6 gold) ■ b: left side 1ea (3 * 10 silver) ■ c: bottom 1ea (4 * 10 silver) 5. Remove 2 screws (3*10 silver) from the harness guide and free the harness, then remove the guide. 6. Press the top of the lvps cage towards door c...

Page 79

Disassembly service manual 6-23 6.4.7b main controller board (pl 9.1.10) 1. Perform steps 1 and 2 from procedure 6.4.7a. Warning move the nvram chip from the old board to the new board. Failure to perform this step will result in the loss of important customer information, like page count and consum...

Page 80

Disassembly 6-24 6.4.8 fuser fan assembly (pl 9.1.27) 1. Remove the top cover. (6.4.1) 2. Remove the rear cover. (6.4.3) 3. Remove the main board shield. (6.4.7) 4. Remove 3 screws (3*10 silver). 5. Disconnect and free the harness from the main board and then remove the fuser fan. Fuser fan screw sc...

Page 81

Disassembly service manual 6-25 6.4.9 main drive assembly (pl 9.1.7) 1. Remove the rear cover. (6.4.3) 2. Remove the fuser. (6.4.5) 3. Remove the lvps. (6.4.7a) 4. Remove the fuser fan. (6.4.8) 5. Remove all harnesses from the harness guides. Two harnesses need to be freed from the bottom of the bra...

Page 82

Disassembly 6-26 9. Remove the washer and then remove the drum gear and pin. (the drum gear can be found inside the printer after removing the imaging unit.) note take care that the pin is not lost as you remove the gear. 10. Disconnect cn 23, 24, 27, and 32. 11. Remove 5 screws (3*10 silver) and th...

Page 83

Disassembly service manual 6-27 6.4.10 hvps (high voltage power supply) (pl 9.1.20) warning high voltage! Be sure to follow the steps outlined in section 1.5.4 when servicing this assembly 1. Remove the front cover and top cover. (6.4.1) 2. Remove the rear cover. (6.4.3) 3. Remove the main board shi...

Page 84

Disassembly 6-28 7. Remove 5 screws (3-6 machine gold) and then remove the hvps. Screw screw screw screw screw.

Page 85

Disassembly service manual 6-29 6.4.11 developer drive assembly (pl 9.1.8) 1. Remove the rear cover. (6.4.3) 2. Remove the main board. (6.4.7b) 3. Remove 5 screws securing the main board bracket. ■ left, 2 ea 3*6 machine screw, gold ■ top right, 2 ea 3*10 silver ■ bottom, 1 ea 4*10 silver note the b...

Page 86

Disassembly 6-30 5. Disconnect the harness from the deve motor. 6. Remove 4 harnesses connected to the deve drive board, then remove the deve drive assembly. 7. Remove 5 screws (3*10 silver) from the deve drive assembly. Screw screw screw screw.

Page 87

Disassembly service manual 6-31 6.4.12 deve drive board (pl 9.13.20) and deve cover open switch (pl 9.15.36) (door a interlock) warning high voltage! Be sure to follow the steps outlined in section 1.5.4 when servicing this assembly 1. Remove the rear cover. (6.4.3) 2. Remove the main board. (6.4.7b...

Page 88

Disassembly 6-32 8. Disconnect 8 harnesses from the deve drive board: cn1, cn10, cn5, cn9, cn4, cn8, and supply. 9. Remove 6 screws (3*10 silver) and then take out the deve drive board caution cn5, cn9, cn4, and cn8 are keyed the same and can be plugged in incorrectly. Start with cn8 which correspon...

Page 89

Disassembly service manual 6-33 6.4.13 deve drive motor (pl 9.7.16) and clutch cam solenoid (pl9.1.33) (t1 clean) 1. Remove the rear cover. (6.4.3) 2. Remove the main board shield. (6.4.7b) 3. Remove 4 screws (3*6 gold) and then remove the deve drive motor. 4. Unplug 1 harness from the deve drive bo...

Page 90

Disassembly 6-34 6.4.14 erase lamp (pl 9.13.12) 1. Remove all the consumables (6.3.3) 2. Remove the front cover and top cover (6.4.1) 3. Remove the waster toner cartridge (o 6.4.18) 4. Open the deve cover (door a) and the exit cover (door b). 5. Remove 2 screws (4*10 silver) from the laser unit cove...

Page 91

Disassembly service manual 6-35 6.4.15a laser brush (pl 9.1.49) 1. Remove all consumables (toner cartridges, transfer unit, and imaging unit (protect from light)) (6.3.3) 2. Remove the front cover and top cover. (6.4.1) 3. Remove the laser unit cover. (steps 1-3 of 6.4.14) 4. Remove 3 screws (4-15 s...

Page 92

Disassembly 6-36 6.4.15 deve cover - door a (pl 9.1.18) 1. Remove the laser brush (6.4.15a). 2. Remove the deve cover by pulling it in the direction of the arrows. Deve cover lsu cleaner.

Page 93

Disassembly service manual 6-37 6.4.16 laser unit (pl 9.1.21) 1. Remove the transfer unit and imaging unit (protect from light and damage). (6.3.3) 2. Remove the deve cover (door a). (6.4.15) 3. Remove the laser unit brush. (6.4.15.1) 4. Remove 4 screws (4*10 silver). 5. Remove 1 screw (3*8 yellow)....

Page 94

Disassembly 6-38 6. Disconnect 2 harnesses and remove the laser unit. Harness harness.

Page 95

Disassembly service manual 6-39 6.4.17 deve oem key board - crum reader board (pl 9.14.36) 1. Remove the front cover and the top cover. (6.4.1) 2. Disconnect the harness (cn1) from the hvps and free it from the channel. 3. Disconnect the harness (cn2) from the deve oem board. 4. 2) remove the 6 scre...

Page 96

Disassembly 6-40 6.4.18 waste toner auger assembly (pl 9.13.1) 1. Remove the front cover and the top cover. (6.4.1) caution it is very likely that waste toner will be spilled when removing the waste toner assemby. Have a toner vacuum when servicing this part. Never use a standard vacuum cleaner to c...

Page 97

Disassembly service manual 6-41 6.4.18a waste toner cartridge full sensor (pl 9.14.1) 1. Remove the front cover and the top cover. (6.4.1) 2. Remove the rear cover. (6.4.3) 3. Remove the fuser and fuser cover base. (6.4.5 and 6.4.5.1) 4. Remove the lvps. (6.4.7) 5. Remove the main drive assembly. (6...

Page 98

Disassembly 6-42 6.4.19 mpt (multi-purpose tray) feed assembly and roller (pl 9.17.0) 1. Remove all consumables (toner cartridges, transfer unit, and imaging unit (protect from light)) (6.3.3) 2. Remove the front cover and top cover. (6.4.1) 3. Remove the rear cover. (6.4.3) 4. Remove the duplex cov...

Page 99

Disassembly service manual 6-43 6.4.19 cont’d >> mpt feed roller 1. Place the mpt assembly on a flat surface and remove the e-ring and washer securing the pick roller shaft to the assembly. 2. Slide the shaft to the right to free the roller and remove it..

Page 100

Disassembly 6-44 >> on re-assembly: note the roller has 3 pieces; 2 collars and the roller. When re-assembling the roller, the collars fit with the long ends facing out. The hole through the roller is round on one end and d shaped on the other. The d shaped end needs to face the left. The black plas...

Page 101

Disassembly service manual 6-45 6.4.20 main frame (pl 9.13) and base frame (pl 9.16) 1. Remove the front cover and top cover. (6.4.1) 2. Remove the rear cover. (6.4.3) 3. Remove the duplex cover. (6.4.4) 4. Remove the lvps and lvps cover. (6.4.7a) 5. Remove the main board shield. (steps 1 and 2 of 6...

Page 102

Disassembly 6-46 6.4.21 pick roller assembly, tray1 (pl 9.18.0) 1. Remove the main frame and base frame. (6.4.20) 2. Remove the split ring from the white gear. 3. Remove the gear by rotating it to the no tooth portion. 4. Gently pull out on the outer bushing’s locking tab, where the gear was, to fre...

Page 103

Disassembly service manual 6-47 6.4.22 pick roller (pl 9.18.12) 1. Remove all consumables (toner cartridges, transfer unit, and imaging unit (protect from light)) (6.3.3) 2. Remove the rear cover. (6.4.3) 3. Remove the duplex cover. (6.4.4) 4. Remove the lvps cover. (6.4.7a) 5. Gently and slowly, ro...

Page 104

Disassembly 6-48 6.4.23 paper pickup solenoid (pl 9.16.22) 1. Remove all consumables (toner cartridges, transfer unit, and imaging unit (protect from light)) (6.3.3) 2. Remove the top cover. (6.4.1) 3. Remove the rear cover. (6.4.3) 4. Remove the lvps and lvps cover. (6.4.7a) 5. Remove the lvps inne...

Page 105

Disassembly service manual 6-49 6.4.24 temperature sensor (pl 9.16.23) 1. Remove the front cover and top cover. (6.4.1) 2. Remove the rear cover. (6.4.3) 3. Remove the duplex cover. (6.4.4) 4. Remove the lvps and lvps cover. (6.4.7a) 5. Remove the main board shield. (steps 1 and 2 of 6.4.11) 6. Remo...

Page 106

Disassembly 6-50 6.4.25 paper feed roller (pl 9.19.13) 1. Open door c and protect the transfer roller. 2. Remove the e-ring and slide the large black feed roller off the shaft. 3. This roller is a press-fit roller, so gently work the roller off the shaft using a small flat-blade screwdriver. >> on r...

Page 107

Disassembly service manual 6-51 6.4.26 paper feed roller mid (pl 9.19.9) 1. Open door c and protect the transfer roller. 2. Remove the e-ring from the shaft. 3. Remove the 2 screws from the bracket. Caution being careful not to lose the white bushing and black plastic washer, when removing the brack...

Page 108

Disassembly 6-52 6.4.27 feed sensor (pl 9.20.2) 1. Remove the waste toner assembly. (6.4.18) 2. Open door c and protect the transfer roller. 3. Unscrew the links from the door and lay the door down flat for more clearance. 4. Remove 3 screws (type) from the inner paper path cover and remove it. 5. R...

Page 109

Disassembly service manual 6-53 6.4.28 fuser exit sensor (pl 9.14.5) 1. Remove the front cover and top cover. (6.4.1) 2. Remove the rear cover. (6.4.3) 3. Remove the duplex cover (door c). (6.4.4) 4. Remove the fuser and fuser cover base. (6.4.5 and 6.4.5.1) 5. Remove the lvps and lvps cover. (6.4.7...

Page 110

Disassembly 6-54 6.4.29 500-sheet feeder (pl 9.1.44) 1. Turn the printer off and remove all cables. 2. Using 2 people, lift the printer off the 500 sheet feeder. Tray 2 sensor contacts door d front.

Page 111: 7.1 Paper Path and Paper Jam

Maintenance and diagnostics service manual 7-1 this chapter describes some of the main service procedures including: ■ using the engine diagnostic contol mode (edc) ■ clearing paper jams ■ test patterns. Much of this chapter is also included in the user’s guide. 7.1 paper path and paper jam 7.1.1 pa...

Page 112: 7.1.2 Jams

Maintenance and diagnostics 7-2 7.1.2 jams 1) jam at tray 1/tray 2 (jam in feed area) ■ after paper pick, paper was not fed any further. ■ paper did not reach the feed sensor in time. ■ feed sensor is faulty and does not detect paper. ■ tray 1 paper pick error: when paper is not picked from tray 1. ...

Page 113

Maintenance and diagnostics service manual 7-3 4) jam at c (jam in duplex area) ■ jams in the duplex area occur while printing the reverse side of the paper. After printing the front side, the duplex solenoid must operate in order to feed the paper back into the duplex path. If the solenoid fails, p...

Page 114: 7.2 Jam Removal

Maintenance and diagnostics 7-4 7.2 jam removal when a jam occurs while printing, a jam message is displayed on the control panel. * jam at tray 1: paper jam in tray 1. * jam at mpt: paper jam in the mpt. * jam at tray 2: paper jam in tray 2. * jam at c (inside printer): paper is jammed in the paper...

Page 115: 7.3 Sample Prints

Maintenance and diagnostics service manual 7-5 7.3 sample prints this product has the several sample patterns for maintenance. With the sample patterns, check the existence of the abnormality. The patterns help to regularly maintain the product. 7.3.1 printing a demo page print a demo page to make s...

Page 116

Maintenance and diagnostics 7-6 7.3.4 checking consumable life checking the remaining toner you can check the level of toner left in each cartridge. 1. In ready mode, press the menu button on the control panel until you see maintenance, then press ok. 2. Press the scroll button to access the check t...

Page 117: 7.4 Control Panel Functions

Maintenance and diagnostics service manual 7-7 7.4 control panel functions the control panel on the front of your printer has a display and seven buttons. 7.4.1 the display message description ready the printer is on-line and ready to print. If you press on line/continue, the printer switches to off...

Page 118

Maintenance and diagnostics 7-8 7.4.2 control panel buttons after 60 seconds of inactivity, no button has been pressed, the printer automatically returns to ready mode. Note print settings made from the printer driver, override settings on the control panel. Item description when an error occurs, a ...

Page 119: 7.4.3 Control Panel Menu Map

Maintenance and diagnostics service manual 7-9 7.4.3 control panel menu map information page layout color printer setup maintenance network setup* config page menu map demo page connection pg* duplex duplex margin calibration custom color language pwr save time auto continue jam recovery altitude ad...

Page 120: 7.5 Repeating Defects

Maintenance and diagnostics 7-10 7.5 repeating defects if an image defects appears at regular intervals on the printed-paper, it may be due to a faulty or damaged maintenance item or part. To identify which maintenance item is responsible for the defect, refer to the table below and check the condit...

Page 121

Maintenance and diagnostics service manual 7-11 7.6 how to use engine diagnostic control mode (edc) 7.6.1 what is edc mode edc mode is a feature that allows the service technician to check the condition of the print engine. It can check the operating condition of the motors, sensors, solenoids and c...

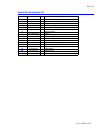

Page 122: 7.6.2 Edc Menu Map

Maintenance and diagnostics 7-12 7.6.2 edc menu map motor test main motor dev motor fan motor waste motor tray 2 motor test print select tray select pattern color bar 4x4 solid print pattern hvps print charger t1 t2 dev dc dev ac regi. Set yellow (+ / - 5) magenta (+ / - 5) cyan (+ / - 5) black (+ /...

Page 123

Maintenance and diagnostics service manual 7-13 7.6.2.1 motor tests this function allows the operation of the various motors to be checked. A. Press the scroll button until “motor test” is displayed. B. Press the ok button to select this function. C. Press the scroll button until you see the name of...

Page 124

Maintenance and diagnostics 7-14 7.6.2.2 solenoid tests this function allows the operation of the various solenoids and clutches to be checked. A. Press the scroll button until “solenoid” is displayed. B. Press the ok button to select this function. C. Press the scroll button until you see the name ...

Page 125

Maintenance and diagnostics service manual 7-15 7.6.2.3 sensor tests this function allows the operation of the various sensors to be checked. A. Press the scroll button until “sensor test” is displayed. B. Press the ok button to select this function. C. Press the scroll button until you see the name...

Page 126

Maintenance and diagnostics 7-16 7.6.2.5 test prints this function allows the printer to be checked by printing various test prints. A. Press the scroll button until “test print” is displayed. B. Press the ok button to select this function. C. Press the scroll button until you see “select tray” is d...

Page 127

Maintenance and diagnostics service manual 7-17 7.6.2.6 hvps tests this function provides an “acceptable range” specification for the hvps outputs. Note these are not actual readings. A. Press the scroll button until “hvps” is displayed. B. Press the ok button to select this function. C. Press the s...

Page 128

Maintenance and diagnostics 7-18 7.6.2.7 regi.Set test this function adjusts the vertical color registration for the printer. A. From the main menu, in customer mode go to “maintenance” , then “registration” . B. Press the ok button to select this function, a page will automatically print. C. Identi...

Page 129

Maintenance and diagnostics service manual 7-19 7.6.2.8 color calibration this feature controls the setting of the trc (tone reproduction curve). Note color calibration can be found on the control panel’s main menu, in normal customer mode, and is not part of the edc diagnostic tests. A. From the ma...

Page 130

Maintenance and diagnostics 7-20

Page 131: 8.1 Verifying Symptoms

Troubleshooting service manual 8-1 8.1 verifying symptoms before attempting to repair a problem with the printer, obtain a detailed description of the problem from the customer. 8 troubleshooting control panel on? See "8.1.1 basic check list" print print- quality is normal? End ready or power saver ...

Page 132

Troubleshooting 8-2 8.1.1 basic check list 1. Check power. A. Does “warming up” appear on the display ? If not, check the power cable, switch or lvps. (see section 8.1.2 below) verify the wall socket outputs the correct voltage. B. Do the motors or other components initialize (listen for the main mo...

Page 133

Troubleshooting service manual 8-3 8.1.2 initial inspection 1. Check printer power. A. The printer does not work at power on. Is the power switch (printer and wall socket) turned on? Is the power cord connected to the printer correctly? Is the power cord connected to the wall socket correctly? Is th...

Page 134

Troubleshooting 8-4 8.1.3 check the consumable life the length of life for consumables is indicated by the quantity of printed images and percent of life used, some consumables will continue to operate even at their end of life, but should be replaced as soon as possible to avoid print-quality issue...

Page 135: 8.2 Print-Quality Problems

Troubleshooting service manual 8-5 8.2 print-quality problems blank page completely black image example possible cause sequence of repair actions driver installation problem. Try printing a demo page. Check that the printer driver is installed correctly. Toner cartridge contacts are dirty or not mak...

Page 136

Troubleshooting 8-6 white spots / black spots / colored spots toner smudges on the reverse side of the page foggy background example possible cause sequence of repair actions contamination of the internal mechanism of the toner cartridge. Replace the toner cartridge. Imaging unit surface contaminate...

Page 137

Troubleshooting service manual 8-7 low image density, light in all colors black / white / colored lines and bands offset image example possible cause sequence of repair actions the image on the drum is light. Replace the toner cartridge. Poor toner transfer to the transfer belt. Check and clean the ...

Page 138

Troubleshooting 8-8 deterioration of print quality in all colors deterioration of print quality in one color uneven color density example possible cause sequence of repair actions problem transferring the intermediate images to the transfer belt. Check and clean the transfer belt contacts. Re-instal...

Page 139

Troubleshooting service manual 8-9 voids or white areas lateral lines - possible repeating defect evenly repeating defect example possible cause sequence of repair actions the paper is wet or moist. Use a fresh ream of dry paper and inspect the storage area for the media. Some parts of the image are...

Page 140

Troubleshooting 8-10 8.3 paper feed problems and troubleshooting 8.3.1 trouble with the top margin symptom: printing begins at the wrong position on the paper (mis-registration?) 8.3.2 jam at tray 1 / tray 2 symptoms: paper has not exited from the tray. This jam occurs even though the paper feeds in...

Page 141

Troubleshooting service manual 8-11 8.3.4 jam at b, c symptoms: paper is jammed inside the fuser. Paper is caught in the exit actuator. Paper is caught in the exit roller and fuser, but has not passed through the feed actuator. 8.3.5 jam at c (in the duplex area) symptoms: indicated a “jam at c” on ...

Page 142

Troubleshooting 8-12 8.3.6 jam at mpt symptoms: indicated jam at mpt on the control panel. 8.3.7 multi-feeding symptoms: multiple sheets are fed. 8.3.8 paper wrapped in the fuser symptoms: paper is wrapped in the fuser. Possible cause repair actions check the surface of the pick roller. Is it dirty ...

Page 143

Troubleshooting service manual 8-13 8.4 printer symptoms and general troubleshooting 8.4.1 fuser error warning the fuser is hot! Use caution and allow the fuser cool down before handling. Symptoms: “fuser error low/high temperature” is displayed on the control panel. 8.4.2 laser error symptoms: “las...

Page 144

Troubleshooting 8-14 8.4.4 paper empty symptoms: “tray1/mpt/tray2 [size] empty” is displayed on the control panel, even though paper is loaded. 8.4.5 paper empty not detected symptoms: the printer remains “ready”, even when the tray is empty. 8.4.6 cover open symptoms: “cover open” is displayed on t...

Page 145

Troubleshooting service manual 8-15 8.4.7 cover open not detected symptoms: “ready” is displayed on the control panel when a cover is open. 8.4.8 defective motor symptoms: “jam at tray1/mpt/tray2” is displayed on the control panel, the main motor does not work and paper does not feed when printing. ...

Page 146

Troubleshooting 8-16 8.4.10 curved or distorted vertical lines symptoms: curved, wavy or distorted vertical lines on prints. 8.4.11 low toner symptoms: “replace [color] toner soon” is displayed on the control panel. 8.4.12 replace toner [color] symptoms: “replace [color] toner soon” is displayed on ...

Page 147: 8.5 Error Message Handling

Troubleshooting service manual 8-17 8.5 error message handling adc not confirm error: the adc is defective. 1. Turn the printer off, wait 30 seconds then turn the printer back on. 2. Replace the main board if the error recurs. Cover open door a or door c is not properly closed. 1. Deve cover (door a...

Page 148

Troubleshooting 8-18 fuser error low temperature the temperature of the fuser is lower than the printing temperature. The fuser harness is not connected properly. 1. Verify the fuser is installed correctly. ■ if not, re-install. 2. Check the ac power to the fuser (copper contact.) ■ if bad, go to st...

Page 149

Troubleshooting service manual 8-19 main motor error the main motor that drives the imaging unit, the transfer belt and the pickup assembly is faulty. 1. Open the deve cover and top cover, then check the imaging unit and transfer unit. ■ reseat or replace if defective. 2. Open the rear cover and che...

Page 150

Troubleshooting 8-20 invalid imaging unit error cannot communicate with the imaging unit. This is caused by an incorrect value of the oem resistor in the imaging unit. Can be caused by mis-reading the value of the oem resistor because of contamination of the contact points. 1. Verify a xerox imaging...

Page 151

Troubleshooting service manual 8-21 ctd calibration error 1. Turn the printer off, wait 30 seconds, then turn it back on. 2. Clean the ctd sensor, located on the underside of the transfer belt. 3. Power cycle the printer to clear the error. 4. If the error recurs, reseat the imaging unit and transfe...

Page 152

Troubleshooting 8-22 jam at b, c paper is caught in the exit area 1. Check the exit sensor actuator. ■ replace the fuser if the exit sensor actuator is damaged or bent. 2. Check the paper guide rib of the output guide is clean and not damaged. ■ replace the fuser or exit assembly if damaged. 3. Chec...

Page 153

Troubleshooting service manual 8-23 page to complex the layout of the document is too complex 1. Try printing again after after simplifying and/or erasing any unnecessary images. If the message recurs repeatedly, you will need to add more memory. Note note note xerox does not currently support addin...

Page 154

Troubleshooting 8-24 install [color] toner occurs when the toner cartridge of the indicated color is not installed. If the toner cartridge is not installed. The resistor cannot be read due to the contamination of the contact points. 1. Verify the toner cartridge is installed. 2. Check the contact po...

Page 155: Contents

Parts list service manual 9-1 contents ■ 9.0 consumables, routine maintenance items and options ■ 9.1 main exploded view ■ 9.2 front cover ■ 9.3 top cover ■ 9.4 deve cover (door a) ■ 9.5 exit assembly ■ 9.6 duplex assembly ■ 9.7 deve drive assembly ■ 9.8 main drive assembly ■ 9.9 fuser assembly ■ 9....

Page 156

Parts list 9-2 9.0 consumables, routine maintenance items and options item life based on 5% coverage part no. Replaceable by black standard toner cartridge black high capacity 3,000 7,000 106r00679 106r00684 user replaceable cyan standard toner cartridge cyan high capacity 2,000 5,000 106r00676 106r...

Page 157

Parts list service manual 9-3 screws used in the printer (hardware kit) no description spec s1 screw-machine 2.6*4, gold s2 screw-tapping 4*15, gold s3 screw-tapping 3*8, gold s4 screw-taptite 2.6*6, gold s5 screw-taptite 3*8, black s6 screw-taptite 2*10, gold s7 screw-taptite 3*6, gold s8 screw-tap...

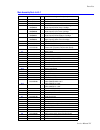

Page 158: 9.1 Main Exploded View

Parts list 9-4 9.1 main exploded view 17 12 23 40 56-1 56-2 s8 56 54 27 45 20 3 1 2 6 5 4 36 15 35 57 57-1 14 7 13 26 22 38 22 39 8 21 9 33 25 30 11 16-2 16-3 16-1 s8 19-2 s9 19 41 55 37 47 48 44 19-1 19-3 16 23 40 16-4 28 31 29 32 43-1 43-2 10 43 46 42 24 58 18 51 52 49 49-3 49-3 49-1 49-5 49-2 49-...

Page 159

Parts list service manual 9-5 main assembly parts list 9.1 no. Part number qty part name and (part description) 0 n/s set_xerox 1 108r00594 1 transfer belt 2 108r00593 1 imaging unit 3 106r00679 106r00684 1 1 standard capacity black toner cartridge high capacity black toner cartridge 4 106r00676 106...

Page 160

Parts list 9-6 32 116-1933-00 1 harness-main lvps (smps) 33 116-1934-00 1 clutch cam solenoid 34 1 bushing 8/5 35 116-1864-00 1 sheet cover front ope (control panel cover) 36 1 hvps shield 37 1 lvps (smps) cover 38 1 opc drive gear 2_z40 39 1 cam-t2 engage 40 2 shaft cover exit hinge 41 1 bracket gu...

Page 161: 9.2 Front Cover

Parts list service manual 9-7 9.2 front cover front cover 9.2 no. Part number qty part name and (part description) 0 1 xerox front cover 1 1 cover-front hinge f 2 2 cover front hinge r 3 116-1917-00 1 waste cartridge lock 5 116-1937-00 2 front cover lock 6 116-1918-00 1 waste cartridge lock spring 7...

Page 162: 9.3 Top Cover

Parts list 9-8 9.3 top cover top cover 9.3 no. Part number qty part name and (part description) 0 116-1856-00 1 top cover asm 1 1 cover top 2 1 spring-cs 3 1 cover top button 5 2 cover top opener 6 2 cover top stacker 7 1 stopper-stacker f 8 1 stopper-stacker r 9 1 lavel(p)-top s15 p/o screw kit 2 s...

Page 163: 9.4 Deve Cover (Door A)

Parts list service manual 9-9 9.4 deve cover (door a) deve cover (door a) 9.4 no. Part number qty part name and (part description) 0 116-1857-00 1 deve cover asm (door a) 1 1 spring ts 2 1 cover dev lock bar 3 1 label(p) deve cover 4 1 cover dup locker f 5 1 cover dup locker r 6 1 cover deve 7 1 cov...

Page 164: 9.5 Exit Assembly

Parts list 9-10 9.5 exit assembly exit assembly 9.5 no. Part number qty part name and (part description) 0 116-1853-00 1 exit asm 1 1 cover exit 2 1 c/exit lock cover 3 1 cover exit bar 4 1 cover dup locker f 5 1 cover dup locker r 6 2 spring ts 7 1 cover exit guide 8 1 cover exit f cap 0 5 6 2 4 6 ...

Page 165

Parts list service manual 9-11 9 1 cover exit r cap 10 1 cover exit hinge 11 116-1939-00 1 exit frame asm 11-1 1 guide exit upper 11-2 1 roller exit drive 11-2-1 1 roller exit drive idle 11-3 1 bearing large dp 11-4 1 ground exit 11-5 1 bearing large dp 11-6 1 gear duplex 11-7 p/o hardware kit 1 c-r...

Page 166: 9.6 Duplex Assembly

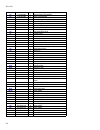

Parts list 9-12 9.6 duplex assembly 2-1 2-10 2-10 2-9 2-7 2-26 2-8 2-5 2-16 2-21 2-14 2-3 2-2 2-4 2-19 2-6 2-28 2-11 2-29 2-22 2-20 2 2-15 2-16 2-16 31 32 2-14 2-15 2-24 2-25 2-23 2-12 2-27 2-12-5 2-13 1 0 2-12-7 2-12-4 2-12-3 2-12-4 2-12-1 2-12-2 2-18 2-17 2-30 2-18 2-30 2-17 s8 s5 s8 s8 s8 2-12-8 ...

Page 167

Parts list service manual 9-13 duplex assembly 9.6 no. Part number qty part name and (part description) 0 116-1928-00 1 duplex asm 1 1 cover right 1-1 1 cover duplex 1-2 1 cover dup lock shaft 1-3 1 cover duplex handle 1-4 1 spring ts 1-5 1 cover dup locker f 1-6 1 cover dup locker r 1-7 1 cover dup...

Page 168

Parts list 9-14 2-18 2 fuser exit spring 2-19 1 bracket guide b 2-20 1 bracket guide duplex 2-21 1 bracket ground b 2-22 1 bracket ground a 2-23 1 bracket ground d 2-24 1 bracket ground c 2-25 1 cbf-harness control panel ground (ope) 2-26 1 bushing feed 2-27 1 guide lower duplex 2-28 p/o hardware ki...

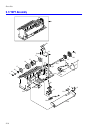

Page 169: 9.7 Deve Drive Assembly

Parts list service manual 9-15 9.7 deve drive assembly deve drive assembly 9.7 no. Part number qty part name and (part description) 0 116-1851-00 1 deve drive asm 1 1 bracket deve front 2 4 clutch spring deve 3 4 shaft deve clutch 4 12 bushing d6/l4 5 p/o hardware kit 12 e-ring 6 4 shaft deve drive ...

Page 170

Parts list 9-16 13 3 gear deve idle_z41 14 1 gear deve idle_z53 15 1 bracket deve rear 16 116-1880-00 1 motor bldc-deve (deve motor) 17 4 washer plain 18 12 pin adf 19 4 gear deve drive 1_z25 20 4 gear deve clutch 2_z33 s11 4 screw-taptite s17 5 screw-taptite no. Part number qty part name and (part ...

Page 171: 9.8 Main Drive Assembly

Parts list service manual 9-17 9.8 main drive assembly main drive assembly 9.8 no. Part number qty part name and (part description) 0 116-1850-00 1 main drive asm 1 116-1880-00 1 motor bldc-main drive (main motor) 2 1 duplex solenoid 3 116-1934-00 1 clutch cam solenoid 4 1 clutch electric feed 5 3 b...

Page 172

Parts list 9-18 11 1 gear idle z51 12 3 gear idle z53 13 1 gear itb (transfer belt) drive 1_z90 14 1 gear itb drive 2_z30 15 1 gear opc drive 1_z120 16 1 gear opc rdcn_z120/z60 17 1 gear rdcn z110/z37 18 1 gear rdcn z120/z60 19 1 gear swing drive 20 1 gear t2 drive z_25 21 1 shaft feed drive 22 1 sh...

Page 173: 9.9 Fuser Assembly

Parts list service manual 9-19 9.9 fuser assembly fuser assembly 9.9 no. Part number qty part name and (part description) 0 119-1579-00 116-1567-00 1 1 230v fuser assembly 110v fuser assembly 1 2 roller-heat 2 2 bearing fuser f 3 2 bearing fuser gear 4 2 gear fuser z35 5 2 spring-etc-pr 6 1 fuser up...

Page 174

Parts list 9-20 * 4 cover dime screws are included with a replacement fuser. 16 1 cover thermostat 17 1 cover cleaning 18 1 roller exit idle 19 2 roller exit f_up 20 1 guide dp side 21 1 npr electrode connector 22 1 halogen lamp 300w (110v/220v) 23 1 halogen lamp 500w (110v/220v) 24 1 actuator exit ...

Page 175

Parts list service manual 9-21 9.10 paper tray, tray 1 (fct) paper tray, tray 1 (fct) assembly 9.10 no. Part number qty part name and (part description) 0 116-1854-00 1 paper tray, tray 1 (fct) 1 1 frame cassette 2 1 cover cassette 3 1 guide side cst 4 1 guide front cst 5 1 guide rear 6 1 plate k/up...

Page 176

Parts list 9-22 9.11 paper tray, tray 2 (sct) paper tray, tray 2 (scf) assembly 9.11 no. Part number qty part name and (part description) 0 116-1940-00 1 paper tray, tray 2 (sct) 1 1 frame cassette 2 1 cover cassette 3 1 guide side cst 4 1 guide front cst 5 1 guide rear 6 1 plate k/up 7 1 finger 8 1...

Page 177

Parts list service manual 9-23 9.12 optional 500-sheet feeder (scf) (scf) optional 500-sheet feeder assembly 9.12 no. Part number qty part name and (part description) 0 119-6506-00 1 500-sheet feeder 1 1 hou-motor 1-1 1 ground_roller 1-2 p/o hardware kit 4 e-ring 11 3 0 1 6 s8 s5 s8 s8 s8 s8 s8 s9 s...

Page 178

Parts list 9-24 1-3 1 motor step 1-4 1 pick-up solenoid 1-5 1 gear p/up drv scf 1-6 1 gear idler option 1-7 1 gear idle z30 1-8 1 gear idle scf 1-9 1 bracket gear s9 5 screw_taptite 2 1 hou-guide lower scf 2-1 1 guide lower rail 2-2 2 spring cs 2-3 2 bushing idle roll-scf-16 2-4 1 holder idle roll-1...

Page 179

Parts list service manual 9-25 16 1 harness driver ground 17 1 harness scf_8p 18 1 board sub-scf s5 p/o screw kit 8 screw-taptite s8 p/o screw kit 26 screw-taptite no. Part number qty part name and (part description).

Page 180: 9.13 Main Frame

Parts list 9-26 9.13 main frame 5 15 3 8 29 23 7 6 30 4 26 14 18 27 25 28 5-2 5-3 5-1 3-3 3-6 3-7 3-2 3-1 11 10 24 9 12 2 31 3-5 3-4 1 1-18 1-3 1-17 1-10 1-14 1-15 1-20 1-11 1-4 1-8 1-3 1-5 1-13 1-19 1-16 1-12 1-7 1-6 1-9 1-1-2 1-1-3 s1 1-1-4 1-1-1 1-1 1-1-5 1-2 13 17-3 17-7 17-8 17-9 17-4 17-1 17-2...

Page 181

Parts list service manual 9-27 main frame 9.13 no. Part number qty part name and (part description) 1 116-1872-00 1 opc waste toner duct 1-1 116-1956-00 1 waste toner motor asm 1-1-s1 2 screw-machine 1-1-1 116-1957-00 1 e-ring (also in hardware kit) 1-1-2 116-1958-00 1 waste toner motor-dc 1-1-3 1 b...

Page 182

Parts list 9-28 9 1 frame base 10 1 frame rear 11 1 frame front 12 116-1874-00 1 erase lamp 13 1 shuttertension 14 p/o hardware kit 4 ring cs 15 1 cable clamp 16 116-1919-00 1 dust cover opc 17 116-1920-00 1 opc toner housing 17-1 1 vibration plate outlet 17-2 1 bushing waste cam m 17-3 1 cap shutte...

Page 183: 9.14 Front Frame Assembly

Parts list service manual 9-29 9.14 front frame assembly front frame assembly 9.14 no. Part number qty part name and (part description) 0 1 frame front 1 116-1879-00 1 waste toner sensor 1-1 p/o hardware kit 1 ring cs 1-2 1 holder m waste toner sensor 11 14 6 38 33 4 31 10 12 25 26 8 4 30 36 3 22 17...

Page 184

Parts list 9-30 1-3 116-1881-00 1 waste toner sensor actuator 1-4 1 sub waste sensor 2 1 transfer belt lifter 2-1 1 sponge duct toner transfer belt lift 2-2 1 duct toner transfer belt lifter 2-3 1 sponge transfer belt duct 3 116-1883-00 1 transfer belt waste toner housing 3-1 1 housing m waste toner...

Page 185

Parts list service manual 9-31 38 1 spring transfer belt lock (itb) 39 1 spring toner duct housing s5 p/o screw kit 6 screw-taptite s7 p/o screw kit 6 screw-taptite s8 p/o screw kit 26 screw-taptite no. Part number qty part name and (part description).

Page 186: 9.15 Rear Frame Assembly

Parts list 9-32 9.15 rear frame assembly 36a s8 s8 s5 s8 1 28 25 10 3 34 23 24 12 12 1 15 31 18 33 9 s8 s8 21 11 32 20 26 29 s5 s8 s8 35 22 s5 6 36a 2 s5 19 4 34 36* 12 1 s9 30 5 38 14 16 7 13 1 s8 s8 17 8 (36a+36b) 36b 1.

Page 187

Parts list service manual 9-33 rear frame assembly 9.15 no. Part number qty part name and (part description) 0 1 frame rear 1 p/o hardware kit 7 ring cs 2 116-1942-00 1 cbf harness hvps charge 3 116-1943-00 1 cbf harness hvps t1 4 116-1944-00 1 cbf harness hvps t2 5 1 feed unit 6 1 plate switch dupl...

Page 188: 9.16 Base Frame Assembly

Parts list 9-34 9.16 base frame assembly 16 15 14 23 13 6 12 8 3 3 7 4 5 19 10 9 20 18 22 17 1 2 24 25 26 11 21.

Page 189

Parts list service manual 9-35 base frame assembly 9.16 no. Part number qty part name and (part description) 0 116-1925-00 1 base frame 1 116-1889-00 1 mpt pickup asm 2 116-1890-00 1 tray 1 pickup asm 3 116-1891-00 1 harness scf 4 116-1926-00 1 assembly, ac switch 5 1 guide rail 6 2 foot ml80 7 1 gr...

Page 190: 9.17 Mpt Assembly

Parts list 9-36 9.17 mpt assembly 15 19 20 13 4 17 17 18 24 1 18 11 3 7 23 1 s5 6 2 s9 9 14 22 10 21 8 5 16 12 0

Page 191

Parts list service manual 9-37 mpt assembly 9.17 no. Part number qty part name and (part description) 0 116-1889-00 1 mpt pickup asm 1 p/o hardware kit 2 e ring 2 116-1894-00 1 mpt solenoid 3 1 spring cam mpt 4 1 spring pickup mpt 5 1 spring mpt 6 1 bracket solenoid 7 1 holer cam mpt 8 1 roller cam ...

Page 192: 9.18 Pickup Assembly

Parts list 9-38 9.18 pickup assembly pickup assembly 9.18 no. Part number qty part name and (part description) 0 116-1890-00 1 tray 1 pickup asm 1 1 pickup spring 2 1 ground feed 3 1 guide input 4 1 cap connector l 5 1 cap connector u 6 116-1897-00 1 actuator tray 1 empty 7 1 pickup shaft 8 1 guide ...

Page 193: 9.19 Feeder Assembly

Parts list service manual 9-39 9.19 feeder assembly feeder assembly 9.19 no. Part number qty part name and (part description) 0 1 feed unit 1 1 holder pinch c3 1-1 1 holder pinch c3 1-2 1 roller feed l 1-3 1 feed idler shaft 1 0 5 s8 5 6 7 8 8 9 10 12 11 1-1 22 s8 s8 23 1-2 14 3-1 25 8 11 15 13 4 3 ...

Page 194

Parts list 9-40 2 1 holder pinch c5 2-1 1 holder pinch c5 2-2 1 roller feed l 2-3 1 feed idler shaft 3 1 holder pinch m 3-1 1 holder pinch m 3-2 1 roller feed l 3-3 1 holder feed 3-4 1 roller feed s 3-5 2 feed idler shaft 4 1 frame feed 5 p/o hardware kit 4 e ring 6 1 bushing feed mid 7 1 bracket fe...

Page 195: 9.20 Paper Guide Assembly

Parts list service manual 9-41 9.20 paper guide assembly paper guide assembly 9.20 no. Part number qty part name and (part description) 0 1 paper guide 1 116-1901-00 1 feed sensor cover 2 116-1902-00 1 feed sensor 3 116-1903-00 1 feed sensor actuator 4 1 paper guide bracket 5 116-1952-00 2 sheet - p...

Page 196

Parts list 9-42 9.21 transfer belt cam assembly s18 9 0 8 s8 7 6 5 10 1 2 14 3 12 13 s8 11 4.

Page 197

Parts list service manual 9-43 transfer belt cam assembly 9.21 no. Part number qty part name and (part description) 0 116-1873-00 1 itb cam asm (transfer belt cam) 1 1 transfer belt cam lower 2 116-1904-00 1 ptl sensorupper erase lamp (ptl) 3 116-1905-00 1 ptl path 4 1 shaft transfer belt cleaning c...

Page 198: 9.22 Fuser Base Assembly

Parts list 9-44 9.22 fuser base assembly fuser base assembly 9.22 no. Part number qty part name and (part description) 0 1 fuser base 1 1 fuser base 2 116-1907-00 1 housing switch ac 3 116-1906-00 1 switch ac s8 p/o screw kit 2 screw 2 s8 1 3 0

Page 199

Parts list service manual 9-45 9.23 xerox kits and accessories kits miscellaneous items power cords description part number screw/washer kit (see page 9-3) 116-1908-00 hardware kit 116-1909-00 main drive hardware kit 116-1910-00 lvps fuse kit 116-1960-00 description part number network interface boa...

Page 200

Parts list 9-46.

Page 201: 10. Block Diagram

Block diagram service manual 10-1 10. Block diagram 10 block diagram control panel 16 x 2 l c d 16bi t ethernet (dn only) 32bi t ls u 8~ 16bi t hv p s pw m c o n tr o l *for engineering use only a nal og m u x - temp.(2 ea) - fusing temp. -h v p s x 3 -c t d - opc key - waste toner - waste auger * t...

Page 202

Block diagram 10-2 10.1 controller block diagram s c o nt ro ll e r b loc k d ia gr am p arallel (ieee) 12 84 us b 2. 0 u a r t (r x ,t x), r e s e t ethernet (dn onl y) de v e dr iv e de v e oe m t 1 , t 2(+ ), c harge, a c _vpp, a c _ f req/ d u ty su p p ly (p w m ) t 2 (- ), a c e n a b le st s ...

Page 203: Connection Diagram

Connection diagram service manual 11-1 11 connection diagram main motor dev motor power(ac input, 220v/1 10v) switch3(left cover) switch1(right cover) switch2(left cover) developer_1st developer_2nd developer_3rd developer_4th t1 roller t2 roller charger roller d eve lo p e r_ 1 s t d evel o p e r_ ...

Page 204

Connection diagram 11-2 1 ma in b d (c n 3 0 ) l v p s (c o n 4) pi n si g n a l n a m e di r pi n si g nal n a m e 1 +2 4 v f 2 +2 4 v f 2 +2 4 v f 1 +2 4 v f 3 +2 4 v f 4 +2 4 v f 4 +2 4 v f 3 +2 4 v f 5 ag n d 6 gn d 6 ag n d 5 gn d 7 ag n d 8 gn d 8 ag n d 7 gn d 9 +2 4 v 10 +2 4 v 10 +2 4 v 9 +...

Page 205

Connection diagram service manual 11-3 7 hv p s (cn2 ) d ev e o e m k e y (c n 1) pi n si g n a l n a m e di r pi n si g n al n a m e 1 24 v 2 24 v 2 ag n d 1 ag n d 3 reber ved 4 reber ved 4 nwst_agt 3 nwst_agt 5 deve_crum_scl 6 deve_crum_scl 6 +5vl 5 +5vl 7 dgnd 8 dgnd 8 deve_crum_sda 7 deve_crum_...

Page 206

Connection diagram 11-4 12a d e v e d ri v e (c n 6 ) s o le n o id (d eve 1st) c pi n si g n a l n a m e di r pi n si g n al n a m e 1 n s o l _d ev_1s t 2 nc 3 ag n d 12b d e ve d rive (c n 2) s o le n o id (d eve 2nd) m pi n si g n a l n a m e di r pi n si g n al n a m e 1 n s o l _d ev_2n d 2 nc...

Page 207

Connection diagram service manual 11-5 17 ma in b d (c n 3 ) parallel p o rt pi n si g n a l n a m e di r pi n si g n al n a m e 1 ns t b 2 da t a 0 3 da t a 1 4 da t a 2 5 da t a 3 6 da t a 4 7 da t a 5 8 da t a 6 9 da t a 7 10 na c k 11 bu sy 12 pe r r o r 13 sele c t 14 na u t o f d 15 nc 16 dg n...

Page 208

Connection diagram 11-6 20 m a in bd(cn9 ) ethernet (j1) (n e tw o rk p ri n t c a rd ) pi n si g n a l n a m e di r pi n si g n al n a m e 1 +3 .3 v 1 vd d 3 2 +3 .3 v 2 vd d 3 3 dgnd 3 gn d 4 nn p c _ c s 4 nx p c s 5 da t a (3 1 ) 5 xp d at a (3 1) 6 da t a (3 0 ) 6 xp d at a (3 0) 7 da t a (2 9 ...

Page 209

Connection diagram service manual 11-7 24 m a in bd(cn3 3 )s e n s o r( f e e d ) pi n si g n a l n a m e di r pi n si g n al n a m e 1 +3 .3 v 1 2 ns _ f e e d 2 3 dg n d 3 25 m a in bd(cn1 9 )s e n s o r( e x it ) pi n si g n a l n a m e di r pi n si g n al n a m e 1 +3 .3 v 1 2 ns _ e x it 2 3 dg...

Page 210

Connection diagram 11-8 34 m a in b d(cn1 2 ) l aser unit (lsu) >> ld part >> motor part pi n s ig nal n a m e di r pi n si g nal n a m e 1 nh s y n c 1 *h s y n c 2 +5 v l 2 +5 v 3 dg n d 3 gn d 4 nl d o n _ l s u 4 *l d o n 5 vd o _ l s u + 5 *v id e o + 6 vd o _ l s u - 6 *v id e o - 7 ns h _ l s...