- DL manuals

- Xerox

- All in One Printer

- WorkCentre 3119

- Service Manual

Xerox WorkCentre 3119 Service Manual

Summary of WorkCentre 3119

Page 1

Part number 708p88471 06/06 workcentre 3119 service manual.

Page 2

06/06 workcentre 3119 service documentation 708p88471 june 2006 prepared by: xerox europe, global knowledge & language services, enterprise centre, p.O. Box 17, bessemer road, welwyn garden city, hertfordshire, al7 1bu, england. © copyright 2006 by xerox ltd. Xerox, and all identifying numbers used ...

Page 3

Introduction workcentre 3119 06/06 i introduction precautions .............................................................................................................................. Iii 1. Service call procedures section contents...................................................................

Page 4

Introduction ii 06/06 workcentre 3119 page intentionally blank.

Page 5

Introduction workcentre 3119 06/06 iii introduction precautions in order to prevent accidents and to prevent damage to the equipment, please read the precau- tions listed below carefully before servicing the machine and follow them closely. Warnings, cautions and notes warning a warning is used when...

Page 6

Introduction iv 06/06 workcentre 3119 warning avoid exposure to laser beam. Invisible laser radiation. Caution for safety toxic material this product contains toxic materials that could cause illness if ingested. 1. If the lcd control panel is damaged, it is possible for the liquid inside the displa...

Page 7

Introduction workcentre 3119 06/06 v electric shock and fire safety precautions failure to follow the following instructions could cause electric shock or potentially cause a fire. 1. Use only the correct voltage, failure to do so could damage the machine and potentially cause a fire or electric sho...

Page 8

Introduction vi 06/06 workcentre 3119 handling precautions the following instructions are for your own personal safety, to avoid injury and so as not to dam- age the machine 1. Ensure the machine is installed on a level surface, capable of supporting its weight. Failure to do so could cause the mach...

Page 9

Introduction workcentre 3119 06/06 vii releasing plastic latches many of the parts are held in place with plastic latches. The latches break easily; release them carefully. To remove such parts, press the hook end of the latch away from the part to which it is latched. Figure 1 disregarding this war...

Page 10

Introduction viii 06/06 workcentre 3119 2. After removing an electrical assembly equipped with esds, place the assembly on a conduc- tive surface, such as aluminium or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the assembly. 3. Use only a grounded tip...

Page 11

Introduction workcentre 3119 06/06 ix redistributing toner when the print cartridge is near the end of its life, white streaks or light print occurs. The lcd dis- plays the warning message, “toner low.” you can temporarily re-establish the print quality by re- distributing the remaining toner in the...

Page 12

Introduction x 06/06 workcentre 3119 health and safety incident reporting i. Summary this section defines requirements for notification of health and safety incidents involving xerox products (equipment and materials) at customer locations. Ii. Scope xerox corporation and subsidiaries worldwide. Iii...

Page 13

Introduction workcentre 3119 06/06 xi responsibilities for resolution: 1. Business groups/product design teams responsible for the product involved in the incident shall: a. Manage field bulletins, customer correspondence, product recalls, safety retrofits. B. Fund all field retrofits. 1. Field serv...

Page 14

Introduction xii 06/06 workcentre 3119 page intentionally blank..

Page 15

Service call procedures workcentre 3119 06/06 1-1 1. Service call procedures scp 1 service call actions .......................................................................................................1-3 scp 2 final actions ........................................................................

Page 16

Service call procedures 1-2 06/06 workcentre 3119 page intentionally blank.

Page 17: Scp 1 Service Call Actions

Service call procedures workcentre 3119 06/06 1-3 scp 1 service call actions procedure throughout this manual, observe the following warnings: warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. El...

Page 18: Scp 2 Final Actions

Service call procedures 1-4 06/06 workcentre 3119 scp 2 final actions final actions are used to evaluate the total operation of the system and to identify the actions re- quired to complete the service call. Procedure • exercise the machine in all modes. • make a proof copy or print of a customer do...

Page 19

Status indicator raps workcentre 3119 06/06 2-1 2. Status indicator raps 1 initial checks rap ..................................................................................................................2-3 2 jam 0 rap ...............................................................................

Page 20

Status indicator raps 2-2 06/06 workcentre 3119 page intentionally blank.

Page 21: 1 Initial Checks Rap

Status indicator raps workcentre 3119 07/06 2-3 1 initial checks rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Basic ...

Page 22

Status indicator raps 2-4 07/06 workcentre 3119 6. Check consumables (toner etc.). • using the keys print the test pattern. --> expected life of various consumable parts, compare this with the figures printed and install new parts as required, gp 7. If necessary, install a new toner cartridge, pl 1....

Page 23: 2 Jam 0 Rap

Status indicator raps workcentre 3119 07/06 2-5 2 jam 0 rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Description pap...

Page 24

Status indicator raps 2-6 07/06 workcentre 3119 5. Check the following parts: • cassette assembly, pl 9 • paper guides, pl 4 • spring-etc tr, pl 4 5. Adjust or install new parts as necessary: • guide paper, pl 4 • ipr-plate, pl 9 • rpr-friction pad, pl 9 • cassette assembly, pl 9 6. If the paper fee...

Page 25: 3 Jam 1 Rap

Status indicator raps workcentre 3119 07/06 2-7 3 jam 1 rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Description pap...

Page 26: 4 Jam 2 Rap

Status indicator raps 2-8 07/06 workcentre 3119 4 jam 2 rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Description pap...

Page 27: 5 Multi-Feeding Rap

Status indicator raps workcentre 3119 07/06 2-9 5 multi-feeding rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Descrip...

Page 28: 6 Fuser Jam Rap

Status indicator raps 2-10 07/06 workcentre 3119 6 fuser jam rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Descriptio...

Page 29

Status indicator raps workcentre 3119 07/06 2-11 7 paper rolled in the opc drum rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause...

Page 30: 8 Fuser Error Rap

Status indicator raps 2-12 07/06 workcentre 3119 8 fuser error rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Descript...

Page 31: 9 Lsu Error Rap

Status indicator raps workcentre 3119 07/06 2-13 9 lsu error rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Descriptio...

Page 32: 10 Melting Fuser Gear Rap

Status indicator raps 2-14 07/06 workcentre 3119 10 melting fuser gear rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. ...

Page 33: 11 Paper Empty Rap

Status indicator raps workcentre 3119 07/06 2-15 11 paper empty rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Descrip...

Page 34: 12 Cover Open Rap

Status indicator raps 2-16 07/06 workcentre 3119 12 cover open rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Descript...

Page 35: 13 No Power Rap

Status indicator raps workcentre 3119 07/06 2-17 13 no power rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Descriptio...

Page 36: 14 Spool Error Rap

Status indicator raps 2-18 07/06 workcentre 3119 14 spool error rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Descrip...

Page 37: 15 Abnormal Noise Rap

Status indicator raps workcentre 3119 07/06 2-19 15 abnormal noise rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. Desc...

Page 38: 16 Scanning Rap

Status indicator raps 2-20 07/06 workcentre 3119 16 scanning rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. 16a pc sca...

Page 39

Status indicator raps workcentre 3119 07/06 2-21 17 print cartridge problems rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause in...

Page 40: 18 Software Problems Rap

Status indicator raps 2-22 07/06 workcentre 3119 18 software problems rap warning switch off the electricity to the machine. Disconnect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury. 1...

Page 41

Status indicator raps workcentre 3119 07/06 2-23 18b the machine is not working (2) description after receiving the print command there is no response at all or print speed is low due to wrong setup of the environment rather than malfunction of the machine itself. Check and cause solution 1. Ensure ...

Page 42

Status indicator raps 2-24 07/06 workcentre 3119 18c abnormal printing description printing does not work – even after replacing the cable machine does not work at all or strange fonts are printed. Check and cause solution 1. Printer driver error. 1. Ensure that the correct driver is loaded. Use the...

Page 43

Image quality workcentre 3119 06/06 3-1 3. Image quality iq 1 vertical black lines and bands .........................................................................................3-3 iq 2 vertical white line ............................................................................................

Page 44

Image quality 3-2 06/06 workcentre 3119 page intentionally blank.

Page 45

Image quality workcentre 3119 06/06 3-3 iq 1 vertical black lines and bands description straight thin black vertical lines occur in the printing. Dark black vertical band occurs in the printing. Check and cause solution 1. Damaged developer roller or deformed doctor-blade in the toner cartridge, pl ...

Page 46: Iq 2 Vertical White Line

Image quality 3-4 06/06 workcentre 3119 iq 2 vertical white line description white vertical voids in the image. Check and cause solution 1. Contamination of the window or internal lenses of the lsu mirror 1. Clean the lsu window with rec- ommended cleaner (ipa). Clean the window with a clean cotton ...

Page 47: Iq 3 Horizontal Black Band

Image quality workcentre 3119 06/06 3-5 iq 3 horizontal black band description dark or blurry horizontal stripes on print periodically. Check and cause solution 1. Bad contacts on the toner car- tridge contacts, pl 1, mec-termi- nal and ipr-p-terminal con, pl 3. 1. Clean all the following parts: • t...

Page 48: Iq 4 Black/white Spot

Image quality 3-6 06/06 workcentre 3119 iq 4 black/white spot description dark or blurry black spots occur periodically on the print. White spots occur periodically on the print. Check and cause solution 1. If dark or blurry black spots occur periodically, the rollers in the devel- oper may be conta...

Page 49: Iq 5 Light Image

Image quality workcentre 3119 06/06 3-7 iq 5 light image description the printed image is light, with no ghost. Check and cause solution 1. Toner save mode enabled. 1. Ensure the toner save mode is off, gp 3. Check printer and driver settings. 2. Check shading profile in tech mode, gp 5. 2. Redo sha...

Page 50

Image quality 3-8 06/06 workcentre 3119 iq 6 dark image or black image description the printed image is dark. Check and cause solution 1. Check the connection between the cis and the main pba. 1. Ensure the cis harness, pl 7, is properly connected. 2. Check shading profile. 2.Redo shading profile in...

Page 51: Iq 7 Uneven Density

Image quality workcentre 3119 06/06 3-9 iq 7 uneven density description print density is uneven. Check and cause solution 1. The toner level is uneven on the developer roller due to a damaged blade. 1. Remove the toner cartridge, pl 1, gently shake it and replace. 2. The transfer roller, pl 1 is imp...

Page 52: Iq 8 Background

Image quality 3-10 06/06 workcentre 3119 iq 8 background description light or dark background on the print. Check and cause solution 1. The customer has been printing large quantities of low coverage prints or the printer has not been used for a long time. 1. Inform the customer that low area covera...

Page 53: Iq 9 Ghost (1)

Image quality workcentre 3119 06/06 3-11 iq 9 ghost (1) description ghost occurs at 75.5 mm intervals of the opc drum on the print. Check and cause solution 1. Abnormal low temperature (below 10°c). 1. Wait about 30 minutes after power on before using the machine. 2. The life of developer has expire...

Page 54: Iq 10 Ghost (2)

Image quality 3-12 06/06 workcentre 3119 iq 10 ghost (2) description ghost occurs at 75.5 mm intervals of the opc drum on the print. (when printing on card stock or transparencies using bypass feeder) check and cause solution when printing on card stock thicker than normal paper or transparen- cies ...

Page 55: Iq 11 Ghost (3)

Image quality workcentre 3119 06/06 3-13 iq 11 ghost (3) description white ghost occurs in the black image printing at 64mm intervals. Check and cause solution 1. Fuser contamination 1. Disassemble the fuser, rep 9 and remove any contamination on the rollers. Clean any contamina- tion from between t...

Page 56: Iq 12 Ghost (4)

Image quality 3-14 06/06 workcentre 3119 iq 12 ghost (4) description ghost occurs at 35.2mm intervals. Check and cause solution 1. The life of the developer may have expired. Install a new toner cartridge, pl 5. 2. Check the smps/hvps output using engine test mode, gp 4. 2. Clean the following parts...

Page 57

Image quality workcentre 3119 06/06 3-15 iq 13 contamination on the face of page description the background on the face of the printed page is contaminated. Check and cause solution 1. The transfer roller, pl 1 maybe contaminated. 1. Run clean drum, gp 3 several times. 2. Toner leakage due to improp...

Page 58

Image quality 3-16 06/06 workcentre 3119 iq 14 contamination on back of page description the back of the page is contaminated at 45.3mm or 75.3mm intervals. Check and cause solution 1. 45.3mm: transfer roller, pl 1, is contaminated. 1. Run clean drum, gp 3 several times. Install a new transfer rolle...

Page 59

Image quality workcentre 3119 06/06 3-17 iq 15 blank page print out (1) description blank page is printed. Check and cause solution 1. Room light is passing through a thin original while copying. 1. Ensure the cover platen, pl 7 is properly closed while copying. 2. Check shading profile. 2. Perform ...

Page 60

Image quality 3-18 06/06 workcentre 3119 iq 16 blank page print out (2) description blank page is printed. One or several blank pages are printed. When the machine turns on, several blank pages print. Check and cause solution 1. Abnormal solenoid hb (pickup), pl 3. 1. Check the solenoid hb (pickup) ...

Page 61

Image quality workcentre 3119 06/06 3-19 iq 17 defective image quality description the copied image is excessively light or dark check and cause solution check shading profile perform shading test in tech mode, gp 5. Check the gap between original and scanner glass, pl 7. A gap of more than 0.5mm ca...

Page 62

Image quality 3-20 06/06 workcentre 3119 iq 18 printed vertical lines not straight description when printing, vertical lines are not straight. Check and cause solution 1. Check the lsu operation usint engine test mode, gp 4. Check the stability of +24v supply to the lsu, pl 1. 1. 24v stable - instal...

Page 63: Iq 19 Blurred Image

Image quality workcentre 3119 06/06 3-21 iq 19 blurred image description image is blurred. Check and cause solution 1. Check the gap between original and platen glass, pl 7. 1. A gap of more than 0.5 mm can cause a blurred image. Ensure rollers and cover close correctly. Install new parts as necessa...

Page 64

Image quality 3-22 06/06 workcentre 3119 page intentionally blank.

Page 65

Repairs/adjustments workcentre 3119 06/06 4-1 4. Repairs/adjustments rep 1 front cover ....................................................................................................................4-3 rep 2 rear cover ...............................................................................

Page 66

Repairs/adjustments 4-2 06/06 workcentre 3119 page intentionally blank.

Page 67: Rep 1 Front Cover

Repairs/adjustments workcentre 3119 06/06 4-3 rep 1 front cover parts list on pl 2 switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause injury...

Page 68: Rep 2 Rear Cover

Repairs/adjustments 4-4 06/06 workcentre 3119 rep 2 rear cover parts list on pl 2 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause...

Page 69: Rep 3 Fuser Fan

Repairs/adjustments workcentre 3119 06/06 4-5 rep 3 fuser fan parts list on pl 2 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause ...

Page 70: Rep 4 Right Side Cover

Repairs/adjustments 4-6 06/06 workcentre 3119 rep 4 right side cover parts list on pl 2 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can...

Page 71: Rep 5 Left Side Cover

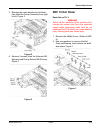

Repairs/adjustments workcentre 3119 06/06 4-7 6. If necessary, remove the cover open micro switch, figure 4. Figure 4 rep 5 left side cover parts list on pl 2 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not ne...

Page 72: Rep 6 Scan Assembly

Repairs/adjustments 4-8 06/06 workcentre 3119 4. Gently flex the left side cover in the direction of the arrows then remove the left side cover, figure 2. Figure 2 rep 6 scan assembly parts list on pl 7 warning switch off the electricity to the machine. Dis- connect the power cord from the customer ...

Page 73

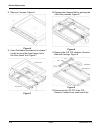

Repairs/adjustments workcentre 3119 06/06 4-9 4. Carefully lift the scan assembly in the direction of the arrows while threading the cables through the frame, figure 2. Figure 2 note: when replacing the scan assembly, push down the stopper-m-lever to ensure the scanassembly fits into the middle cove...

Page 74

Repairs/adjustments 4-10 06/06 workcentre 3119 8. Remove 2 screws, figure 6. Figure 6 9. Use a flat-bladed screwdriver to release 7 hooks securing the scan upper unit to the scan lower unit, figure 7. Figure 7 10. Release the scanner belt by pushing the idle pulley inwards, figure 8. Figure 8 11. Re...

Page 75

Repairs/adjustments workcentre 3119 06/06 4-11 cis. Release the cis in the direction of the arrow, figure 10. Figure 10 13. Remove the belt clip with a screwdriver to release the scanner belt, figure 11. Figure 11 note: take note of the position of the notch to ensure correct replacement when fittin...

Page 76: Rep 7 Ope Assembly

Repairs/adjustments 4-12 06/06 workcentre 3119 rep 7 ope assembly parts list on pl 8 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can ca...

Page 77: Rep 8 Middle Cover Unit

Repairs/adjustments workcentre 3119 06/06 4-13 4. Remove the keys, figure 4. Figure 4 rep 8 middle cover unit parts list on pl 2 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity ca...

Page 78: Rep 9 Fuser

Repairs/adjustments 4-14 06/06 workcentre 3119 rep 9 fuser parts list on pl 5 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause inj...

Page 79

Repairs/adjustments workcentre 3119 06/06 4-15 4. Remove 2 screws. Disconnect the fuser harness and the fuser joint harness from both sides of the thermostat, then remove the thermostat, figure 3. Figure 3 5. Remove 2 screws. Disconnect the fuser harness and the fuser joint harness from the halogen ...

Page 80: Rep 10 Lsu

Repairs/adjustments 4-16 06/06 workcentre 3119 8. Release the thermistor harness, figure 7. Figure 7 9. Remove 1 screw, then the thermistor, figure 8. Figure 8 rep 10 lsu parts list on pl 1 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while ...

Page 81: Rep 11 Toner Fan

Repairs/adjustments workcentre 3119 06/06 4-17 4. Disconnect the lsu connectors, figure 2. Figure 2 5. Remove 4 screws, then the lsu, figure 3. Figure 3 rep 11 toner fan parts list on pl 1 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while p...

Page 82: Rep 12 Engine Shield

Repairs/adjustments 4-18 06/06 workcentre 3119 rep 12 engine shield assembly parts list on pl 1 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving p...

Page 83: Rep 13 Main Pba

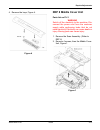

Repairs/adjustments workcentre 3119 06/06 4-19 note: when replacing the engine shield assembly, replace the paper empty actuator through the gap on the assembly. Ensure all the screws are properly fitted, figure 3. Figure 3 rep 13 main pba parts list on pl 1 warning switch off the electricity to the...

Page 84: Rep 14 Smps/hvps

Repairs/adjustments 4-20 06/06 workcentre 3119 rep 14 smps/hvps parts list on pl 1 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can caus...

Page 85: Rep 15 Crum Pba

Repairs/adjustments workcentre 3119 06/06 4-21 rep 15 crum pba parts list on pl 3 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can cause...

Page 86: Rep 17 Feed Roller

Repairs/adjustments 4-22 06/06 workcentre 3119 note: take note of the orientation of the ptl lens to ensure correct replacement. Figure 2 4. Unlatch the bush, then remove the bush. Remove the transfer roller in the direc- tion of the arrow, figure 3. Figure 3 rep 17 feed roller parts list on pl 4 wa...

Page 87

Repairs/adjustments workcentre 3119 06/06 4-23 3. Remove the feed idle bush and feed idle shaft, figure 2. Figure 2 4. Remove 3 screws then the feed bracket, figure 3. Figure 3 5. Remove the idle gear 23 and feed gear 2, figure 4. Figure 4 6. Remove the feed gear 1 assembly and feed roller 1, figure...

Page 88: Hb (Pickup) And Solenoid Hb

Repairs/adjustments 4-24 06/06 workcentre 3119 7. Remove the feed roller and feed roller 1, figure 6. Figure 6 rep 18 pickup roller, solenoid hb (pickup) and solenoid hb (bypass) parts list on pl 3 warning switch off the electricity to the machine. Dis- connect the power cord from the customer suppl...

Page 89: Rep 19 Exit Roller

Repairs/adjustments workcentre 3119 06/06 4-25 3. Release the notch attached to the bush, then slide the pickup assembly from right to left, figure 2. Figure 2 4. Remove 2 screws, then the solenoid hb (bypass) and pickup solenid hb (pickup), figure 3. Figure 3 rep 19 exit roller parts list on pl 3 w...

Page 90: Rep 20 Drive Assembly

Repairs/adjustments 4-26 06/06 workcentre 3119 rep 20 drive assembly parts list on pl 6 warning switch off the electricity to the machine. Dis- connect the power cord from the customer supply while performing tasks that do not need electricity. Electricity can cause death or injury. Moving parts can...

Page 91

Spare parts list workcentre 3119 06/06 5-1 5. Spare parts list pl 1 main assembly ..................................................................................................................5-2 pl 2 housing base assebly .............................................................................

Page 92: Pl 1 Main Assembly

Spare parts list 5-2 06/06 workcentre 3119 pl 1 main assembly.

Page 93

Spare parts list workcentre 3119 06/06 5-3 pl 1 main assembly item part number description remark 0 workcentre 3119 1 ela hou base-housing 2 usb cable refer to pl 10, item 5 3 105n02072 cbf-power cord 4 frame assembly refer to pl 3, item 0 5 127n07521 toner fan (dc_hawk) rep 11 6 062n00274 unit-humm...

Page 94: Pl 2 Housing Base Assembly

Spare parts list 5-4 06/06 workcentre 3119 pl 2 housing base assembly.

Page 95

Spare parts list workcentre 3119 06/06 5-5 pl 2 housing base assembly item part number description remark 0 housing base assembly 1 002n02610 middle cover unit rep 8 1-1 middle_cover-main_frame 1-2 spring etc-ts-charge apollo 1-3 stopper-m-lever 1-4 pmo-sub_m_stacker 1-5 038n00500 stacker-m-large 1-...

Page 96: Pl 3 Frame Assembly (1)

Spare parts list 5-6 06/06 workcentre 3119 pl 3 frame assembly (1).

Page 97

Spare parts list workcentre 3119 06/06 5-7 pl 3 frame assembly (1) item part number description remark 0 001n00487 ela unit-frame lower (220v) 001n00488 ela unit-frame lower (110v) 1 frame_m_base 2 015n00548 plate_p_saw 3 038n00408 plate-m-tr 4 gear-exit 5 holder bearing exit 6 e-clip 7 022n02269 ex...

Page 98: Pl 4 Frame Assembly (2)

Spare parts list 5-8 06/06 workcentre 3119 pl 4 frame assembly (2).

Page 99

Spare parts list workcentre 3119 06/06 5-9 pl 4 frame assembly (2) item part number description remark 1 spring ts 2 ipr-p-ground earth tr 3 spring ts 4 022n02127 feed sensor actuator 5 709n00007 bypass sensor actuator 6 121n01087 paper sensor actuator 7 frame ext 8 022n02128 feed roller 1 rep 17 9 ...

Page 100: Pl 5 Fuser Unit

Spare parts list 5-10 06/06 workcentre 3119 pl 5 fuser unit.

Page 101

Spare parts list workcentre 3119 06/06 5-11 pl 5 fuser unit item part number description remark 0 126n00259 fuser 220v rep 9 0 126n00260 fuser 110v rep 9 1 cover-m-fuser 2 stripper finger 3 stripper finger spring 4 pmo-roller_exit 5 spring etc-fuser exit 6 130n01485 thermostat 7 gear 25 8 gear 15 9 ...

Page 102: Pl 6 Drive Assembly

Spare parts list 5-12 06/06 workcentre 3119 pl 6 drive assembly.

Page 103

Spare parts list workcentre 3119 06/06 5-13 pl 6 drive assembly item part number description remark 0 007n01551 drive assembly rep 20 1 bracket-p-gear 1400 2 gear-drv fuser in 3 gear-hub clutch 4 gear-drv fuser out 5 washer plain 6 gear-rdcn 113/33 7 gear-rdcn 57/18 8 bracket-p-motor 1400 9 gear-rdc...

Page 104: Pl 7 Scan Assembly

Spare parts list 5-14 06/06 workcentre 3119 pl 7 scan assembly.

Page 105

Spare parts list workcentre 3119 06/06 5-15 pl 7 scan assembly item part number description remark 0 062n00275 scan assembly rep 6 1 002n02615 platen cover 1-1 002n02616 cover-m-platen 1-2 sheet-white sponge 1-3 hinge-m_pivot 2 ela unit- scan upper assembly 2-1 002n02617 ela-unit-scan upper 2-2 labe...

Page 106: Pl 8 Ope Assembly

Spare parts list 5-16 06/06 workcentre 3119 pl 8 ope assembly.

Page 107

Spare parts list workcentre 3119 06/06 5-17 pl 8 ope assembly item part number description remark 0 ope assembly rep 7 1 002n02619 cover-m-panel 2 002n02620 ope panel 3 003n01015 key-m-menu 4 003n01013 key-m-start 5 003n01014 key-m-stop 6 key-m-copies 7 021n02253 cap-m-led 8 101n01405 pba sub-panel ...

Page 108: Pl 9 Cassette Assembly

Spare parts list 5-18 06/06 workcentre 3119 pl 9 cassette assembly.

Page 109

Spare parts list workcentre 3119 06/06 5-19 pl 9 cassette assembly item part number description remark 0 050n00497 cassette assembly 1 adjust-m-cassette_l 2 adjust-m-cassette_r 3 gear-pinion 4 019n00820 ipr-plate 5 019n00821 rpr-friction pad 6 sheet-holder pad 7 019n00822 holder-m-pad 8 spring etc-l...

Page 110

Spare parts list 5-20 06/06 workcentre 3119 pl 10 common hardware & general service items pl 10 common hardware & general service items item part number description remark 0 038n00483 quick setup guide 1 095n00286 main packaging box 2 705n00022 elect user guide 3 705n00023 print drive cd 4 705n00024...

Page 111

General procedures / information workcentre 3119 06/06 6-1 6. General procedures/information gp 1 product specifications ......................................................................................................6-3 gp 2 system overview .......................................................

Page 112

General procedures / information 6-2 06/06 workcentre 3119 page intentionally blank.

Page 113: Gp 1 Product Specifications

General procedures and information workcentre 3119 06/06 6-3 gp 1 product specifications product overview general specifications table 1: item description remark basic model workcentre 3119 target user personal users key specification -18ppm(ltr. 19ppm), chorus2(cpu : use 16/32 bit risc processor) -...

Page 114

General procedures and information 6-4 06/06 workcentre 3119 print specifications scan specifications copy specifications table 3: item description method laser beam printing speed up to 20ppm in a4 (20ppm in letter) emulation gdi power save yes (interval option: 5, 10,15, 30, 45 minute) resolution ...

Page 115

General procedures and information workcentre 3119 06/06 6-5 paper handling specifications resolution scan 600 x 600 dpi print 600 x 600 dpi copy mode text, text/photo, photo callation copy n/a auto return to default mode yes (after 1 minute) - time out option: 15, 30, 60, 180 sec., off changeable d...

Page 116

General procedures and information 6-6 06/06 workcentre 3119 software package and pop accessories table 7: item description compatibility dos no win 2.X no win 95 no win 98/me yes win nt 4.0 no win 2000 yes win xp yes mac yes (10.3) linux yes driver printer gdi twain yes wia yes application rcp no p...

Page 117

General procedures and information workcentre 3119 06/06 6-7 consumables table 10: item description toner installation method front loading toner life 1k - initial 3k - running toner count level sensor no software count yes.

Page 118: Gp 2 System Overview

General procedures and information 6-8 06/06 workcentre 3119 gp 2 system overview system outline front view figure 1.

Page 119

General procedures and information workcentre 3119 06/06 6-9 rear view figure 2 control panel figure 3.

Page 120

General procedures and information 6-10 06/06 workcentre 3119 system layout figure 4 paper feed mechanism the printer has a 2 types of feeding methods, the universal cassette tray and a bypass feeder. The cassette has a friction pad which separates paper to ensure single sheet feeding as well as a s...

Page 121

General procedures and information workcentre 3119 06/06 6-11 transfer assembly this consists of the ptl (pre-transfer lamp) and the transfer roller. The ptl shines a light onto the opc drum. This lowers the charge on the drum’s surface and improves transfer efficiency. The transfer roller transfers...

Page 122

General procedures and information 6-12 06/06 workcentre 3119 scan assembly • scan image controller 1.Scan line time : 1.63ms 2.Scan resolution : color : max 600dpi 3.Scan width : 216mm 4.Function - white shading correction - gamma correction - cis interface - 256 gray scale cis operating part: cis ...

Page 123

General procedures and information workcentre 3119 06/06 6-13 toner cartridge the toner cartridge is an integral unit containing the opc unit and toner unit. The opc unit con- sists of the opc drum and charging roller, and the toner cartridge unit consists of the toner, supply roller, developing rol...

Page 124

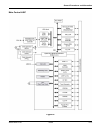

General procedures and information 6-14 06/06 workcentre 3119 hardware structure and descriptions the workcentre 3119 can be broken down to several elements which are; the main pba, ope assembly, scan assembly, print engine, copier and the power supply. Each element is a sepa- rated module which foc...

Page 125

General procedures and information workcentre 3119 06/06 6-15 main control-asic figure 8.

Page 126

General procedures and information 6-16 06/06 workcentre 3119 cpu the use of a 16/32bit risc processor, chorus 2,which is an exclusive controller to control the printer and to execute operation blocks using flash memory within the system program. It also controls the whole system. • main function bl...

Page 127

General procedures and information workcentre 3119 06/06 6-17 ope assembly 1) configuration the ope panel is consists of the micom controller, matrix part and lcd. 2) micom controller micom has rom, ram, built-in i/o port, displays and lcds which is controlled by the cpu com- mands of the main contr...

Page 128

General procedures and information 6-18 06/06 workcentre 3119 • optical resolution: 600 x 600 dpi • copy quality - h x v: text : 600 x 300 dpi (default) (user selectable via content button) :mixed : 600 x 300 dpi, photo : 600 x 600 dpi • supported media types: plain, label, cardstock, transparency •...

Page 129

General procedures and information workcentre 3119 06/06 6-19 • cleaning voltage (thv-) - the (+) transfer voltage is not outputted because the thv pwm is controlled with high. - the (-) transfer voltage is outputted because the thv-enable signal is controlled with low - the output fluctuation range...

Page 130

General procedures and information 6-20 06/06 workcentre 3119 • consumption power • length of power cord : 1830 +/- 50mm • power switch: use • features - insulating resistance: 100 or more (at dc 500v) - insulating revisiting pressure: must be no problem within 1 min. (at 1,000v-lv / 1,500vac-hv,10m...

Page 131

General procedures and information workcentre 3119 06/06 6-21 - turn on if current : 15ma - 50ma(design: 16ma) - high repetive peak off state voltage : min 600v software structure and descriptions architecture the following diagram shows the engine control system. Figure 3.

Page 132

General procedures and information 6-22 06/06 workcentre 3119 firmware overview the engine control firmware is executed every 10msec by the timer interrupt of the main system. And consists of 4 control modules. Power on initial, engine print processing control, print inter- face control and engine u...

Page 133

General procedures and information workcentre 3119 06/06 6-23 paper size the workcentre 3119 does not have a paper size sensor. If the paper width is narrow, the tem- perature of the fuser roller does not uniformly conform to the overall surface of the roller. So in this case, the engine controls th...

Page 134

General procedures and information 6-24 06/06 workcentre 3119 tions. For example, printers at cold and low marshy places are maintained at a higher temperature and vice versa. Temperature during warm-up mode when the engine executes warm-up mode, the temperature of the fuser is raised to stand-by te...

Page 135

General procedures and information workcentre 3119 06/06 6-25 air temperature sensor n/a environment recognition several reference voltages are supplied to the transfer roller to determine the environment. First, it supplies a low voltage to the transfer roller and then when a fixed time has elapsed...

Page 136

General procedures and information 6-26 06/06 workcentre 3119 one of pre-defined times as power save time from the driver ui. The setting value for power save time is off, 5min, 10min, 15min, 30min, 45min, and 60min. The default time is 5min. If off is selected, power save time is operated after 2 h...

Page 137

General procedures and information workcentre 3119 06/06 6-27 temperature open heat error if the fuser temperature is lower than a specified temperature during warm-up, the engine flags an open heat error. When this error occurs, the engine stops all functions and keeps the error state. The engine t...

Page 138: Gp 3 User Menu

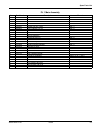

General procedures and information 6-28 06/06 workcentre 3119 gp 3 user menu table 1 shows the map of user settings available in the user mode. Full descriptions of these set- tings can be found in the user guide. Table 1: 1st level 2nd level 3rd level 4th level default value 1. Reduce / enlarge w x...

Page 139

General procedures and information workcentre 3119 06/06 6-29 settings reduce/enlarge this option allows the reduction or enlargement of a print. To access this option, press the menu button until ’reduce/enlarge’ appears on the display. Use the w and x buttons to scroll between the options availabl...

Page 140

General procedures and information 6-30 06/06 workcentre 3119 tons to scroll between the options available. Press the enter button to confirm selection. Or, to re- turn to standby mode, press stop/clear. Paper setting this option allows the user to set the paper size and type used in the cassette tr...

Page 141: Gp 4 Engine Test Mode

General procedures and information workcentre 3119 06/06 6-31 gp 4 engine test mode the engine test mode supplies useful functions to check the condition of the engine. It tests the condition of each device and displays the result of the test on the lcd. To enter the engine test mode to enter the en...

Page 142: Gp 5 Tech Mode

General procedures and information 6-32 06/06 workcentre 3119 gp 5 tech mode the engine tests mode supplies useful functions to check the condition of the engine. It tests the condition of each device and displays the result of the test on the lcd. To enter the tech mode to enter the engine test mod...

Page 143

General procedures and information workcentre 3119 06/06 6-33 machine test this option allows the you to perform several tests on the machine. To access this option, enter tech mode and press the menu button until ’machine test’ appears on the display. Press the en- ter button and use the w and x bu...

Page 144

General procedures and information 6-34 06/06 workcentre 3119 gp 6 paper path and clearing paper jams paper path figure 1 1) after receiving a print command, the printer feeds paper from the main cassette or bypass feed- er as required. 2) the paper being fed passes the paper feed sensor (jam 0 occu...

Page 145

General procedures and information workcentre 3119 06/06 6-35 clearing paper jams when a paper jam occurs, "paper jam" appears on the display. Refer to the table below to locate and clear the paper jam. To avoid tearing the paper, pull the jammed paper out gently and slowly. Follow the steps on the ...

Page 146

General procedures and information 6-36 06/06 workcentre 3119 3. Remove the jammed paper by gently pulling it straight out. If there is any resistance and the paper does not move when you pull or if you cannot see the paper in this area, go to the sec- tion “in the fuser area or around the toner car...

Page 147

General procedures and information workcentre 3119 06/06 6-37 4. Pull the paper out gently. Figure 5 5. Close the jam cover by pushing the support tab to the left and hold it down whilst lowering the cover carefully until the cover fully down, this will hold down the tab. If there is any resistance ...

Page 148

General procedures and information 6-38 06/06 workcentre 3119 1. Open the front cover and lightly push down on the cartridge then pull to take it out. Figure 7 2. Remove the jammed paper by gently pulling it straight out. Figure 8 3. Replace the toner cartridge and close the front cover. Printing au...

Page 149

General procedures and information workcentre 3119 06/06 6-39 occur when the paper is not properly fed into the machine through the bypass feeder. In that case, pull the paper out of the machine. Figure 9 in the toner cartridge remove the paper while turning the toner cartridge drum against the feed...

Page 150

General procedures and information 6-40 06/06 workcentre 3119 gp 7 consumables and replacement parts the cycle period outlined below is a general guideline for maintenance. The example list is for an average usage of 50 transmitted and received documents per day. Environmental conditions and actual ...

Page 151

General procedures and information workcentre 3119 06/06 6-41 gp 8 periodic defective image if a mark or other printing defect occurs at regular intervals down the page it may be caused by a damaged or contaminated roller. Measure the repetition interval and refer to the table below to identify the ...

Page 152: Gp 9 Error Messages

General procedures and information 6-42 06/06 workcentre 3119 gp 9 error messages table 1: display meaning suggested solutions door open the front cover is not securely latched close the front cover, pl 1 until it locks into place. Hsync error a problem has occured in the lsu (laser scanning unit) u...

Page 153: Gp 10 Led Status Indicator

General procedures and information workcentre 3119 06/06 6-43 gp 10 led status indicator table 1: led colour led status description off off power off / sleep mode green on ready blink when the job is in progress blinking slowly : priner data comm. Blinking fast : printing blinking normally : copy, s...

Page 154

General procedures and information 6-44 06/06 workcentre 3119 gp 11 system block diagram figure 1.

Page 155: Gp 12 Tools

General procedures and information workcentre 3119 06/06 6-45 gp 12 tools the following tools are recommended. Dvm (digital volt meter) standard: indicates more than 3 digits. Driver standard: "-" type, "+" type (m3 long, m3 short, m2 long, m2 short). Tweezers standard: for general home use, small t...

Page 156

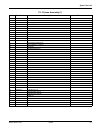

General procedures and information 6-46 06/06 workcentre 3119 gp 13 acronyms and abbreviations the table below explains the abbreviations and acronyms used in this service manual. Where ab- breviations or acronyms are used in the text please refer to this table. Table 1: acronyms and abbreviations a...

Page 157

General procedures and information workcentre 3119 06/06 6-47 lan local area network lb pound(s) lbp laser beam printer lcd liquid crystal display led light emitting diode liu line interface unit l/l low temperature and low humidity lsu laser scanning unit mb megabyte mhz megahertz mpf multi purpose...

Page 158

General procedures and information 6-48 06/06 workcentre 3119 gp 14 selecting printer locations leave enough room to open the printer trays, covers, and allow for proper ventilation. (see dia- gram below) provide the proper environment: - a firm, level surface - away from the direct airflow of air c...

Page 159: Gp 15 Sample Test Pattern

General procedures and information workcentre 3119 06/06 6-49 gp 15 sample test pattern the sample pattern shown below is the standard test pattern used in the factory. The life of the print cartridge, developer cartridge and printing speed are measured with the pat- tern shown below of 5% area cove...

Page 160

General procedures and information 6-50 06/06 workcentre 3119 gp 16 restriction of hazardous substances (rohs) purpose to give information on the rohs directive. The rohs directive restricts the use of certain hazardous substances in electrical and electronic equipment. It applies to equipment place...

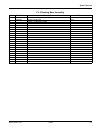

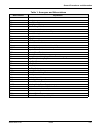

Page 161: Gp 17 Service Log

General procedures and information workcentre 3119 06/06 6-51 gp 17 service log service log use the service log to record all service procedures..

Page 162

General procedures and information 6-52 06/06 workcentre 3119 page intentionally blank.

Page 163

Wiring diagrams workcentre 3119 06/06 7-1 7. Wiring data wd 1 pj locations.....................................................................................................................7-3 wd 2 connection diagram (1/2) ..............................................................................

Page 164

Wiring diagrams 7-2 06/06 workcentre 3119 page intentionally blank.

Page 165: Wd 1 Pj Locations

Wiring diagrams workcentre 3119 06/06 7-3 wd 1 pj locations figure 1.

Page 166

Wiring diagrams 7-4 06/06 workcentre 3119 wd 2 connection diagram (1/2) figure 2.

Page 167

Wiring diagrams workcentre 3119 06/06 7-5 wd 3 connection diagram (2/2) figure 3.

Page 168: Wd 4 Main Pba (1/6)

Wiring diagrams 7-6 06/06 workcentre 3119 wd 4 main pba (1/6) figure 4.

Page 169: Wd 5 Main Pba (2/6)

Wiring diagrams workcentre 3119 06/06 7-7 wd 5 main pba (2/6) figure 5.

Page 170: Wd 6 Main Pba (3/6)

Wiring diagrams 7-8 06/06 workcentre 3119 wd 6 main pba (3/6) figure 6.

Page 171: Wd 7 Main Pba (4/6)

Wiring diagrams workcentre 3119 06/06 7-9 wd 7 main pba (4/6) figure 7.

Page 172: Wd 8 Main Pba (5/6)

Wiring diagrams 7-10 06/06 workcentre 3119 wd 8 main pba (5/6) figure 8.

Page 173: Wd 9 Main Pba (6/6)

Wiring diagrams workcentre 3119 06/06 7-11 wd 9 main pba (6/6) figure 9.

Page 174: Wd 10 Ope Pba

Wiring diagrams 7-12 06/06 workcentre 3119 wd 10 ope pba figure 10

Page 175: Wd 11 Smps-110V (1/4)

Wiring diagrams workcentre 3119 06/06 7-13 wd 11 smps-110v (1/4) figure 11.

Page 176: Wd 12 Smps-110V (2/4)

Wiring diagrams 7-14 06/06 workcentre 3119 wd 12 smps-110v (2/4) figure 12.

Page 177: Wd 13 Smps-110V (3/4)

Wiring diagrams workcentre 3119 06/06 7-15 wd 13 smps-110v (3/4) figure 13.

Page 178: Wd 14 Smps-110V (4/4)

Wiring diagrams 7-16 06/06 workcentre 3119 wd 14 smps-110v (4/4) figure 14.

Page 179: Wd 15 Smps-220V (1/4)

Wiring diagrams workcentre 3119 06/06 7-17 wd 15 smps-220v (1/4) figure 15.

Page 180: Wd 16 Smps-220V (2/4)

Wiring diagrams 7-18 06/06 workcentre 3119 wd 16 smps-220v (2/4) figure 16.

Page 181: Wd 17 Smps-220V (3/4)

Wiring diagrams workcentre 3119 06/06 7-19 wd 17 smps-220v (3/4) figure 17.

Page 182: Wd 18 Smps-220V (4/4)

Wiring diagrams 7-20 06/06 workcentre 3119 wd 18 smps-220v (4/4) figure 18.

Page 183

Wiring diagrams workcentre 3119 06/06 7-21 page intentionally blank.

Page 184

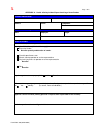

X page 1 of 2 form eh&s-700 (08nov2000) appendix a: health & safety incident report involving a xerox product customer identification customer name: name of customer contact person : telephone : address: e-mail: fax : customer service engineer identification name : employee : pager : location : phon...

Page 185

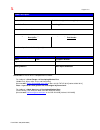

X page 2 of 2 form eh&s-700 (08nov2000) product description model no. Or product name : product serial : serial number(s) of accessory (ies): installation date: total copy meter : date of last service maintenance : list damaged and affected part(s) of the machine by description and part number : des...