Summary of 2002 YZ250FR

Page 3: Yz250Fr

Yz250fr 5ul-28107-10 assembly manual lit-11666-16-39.

Page 4

Yz250fr assembly manual ©2002 by yamaha motor corporation, u.S.A. First edition, august 2002 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor corporation, u.S.A. Is expressly prohibited. Printed in u.S.A. Lit-11666-16-39 eaa00002 foreword this ...

Page 5

Eaa00008 symbols used in assembly manual in order to simplify descriptions in this assembly manuals, the following symbols are used: (1) coat with lithium-soap-based-grease. (2) tighten to 10 nm. (10 nm = 1.0mdkg = 7.2 ftdlb) (3) towards the front of the machine. (4) clearance required. (5) install ...

Page 6

(1) (2) (3) (4) eaa00040 preparation to assemble the machine correctly, sup- plies (e.G. Oils, greases, and shop rags) and sufficient working space are required. Workshop the workshop where the machine is assem- bled, should be clean, specious, and have a level floor. Self-protection protect your ey...

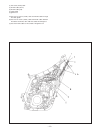

Page 7

Eaa00060 unpacking 1. Remove the frame cover (1). Note: to remove the frame cover, cut the vinyl bands around the cover using a cutter or scissors. 2. Remove the carton boxes (2), front tire (3). 3. Remove the packing frame bolt (4), and handlebar holder bolts (5). 4. Remove the packing frames (in o...

Page 8

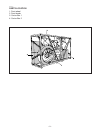

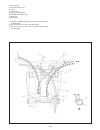

Eaa00070 parts location 1. Front wheel 2. Front fender 3. Carton box 1 4. Carton box 2 -2-.

Page 9

Packing frame 1. Front wheel 2. Front fender eaa00080 carton box 1 3. Handlebar 4. Side stand 5. Plastic bag 6. Handlebar upper holder 7. Flange bolt [d=8, l=35 (1.38)] 8. Master cylinder bracket 9. Flange bolt [d=6 (0.24), l=22 (0.87)] 10.Engine stop button holder (upper and lower) 11.Panhead screw...

Page 10

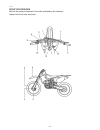

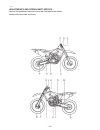

Eaa00100 setup procedures perform the setup procedures in the order indicated by the numbers. Always follow the order as shown. -4-.

Page 11

1 handlebar 1 c 2 collar 1 v 3 handlebar upper holder 2 v 4 flange bolt 4 v d=8 (0.31), l=35 (1.38) -5- eaa00200 1. Handlebar a: clean the right handlebar end. Apply light coat grease. B: before inserting the handle- bar into the throttle grip, make sure the collar is installed. Note: the upper hand...

Page 12

-6- eaa00030 4. Front brake hose holder a: remove the front fork cover bolts to slide the front fork cover upwards. B: note: d align the top (d) of the brake hose neck with the brake hose holder bottom (c). D pass the brake hose in front of the axle boss (a), then fit it into the brake hose groove (...

Page 13

-7- eaa00109 6. Front fender a: install the collars. B: tighten the bolts to specifica- tion. Bolt: 7 nm (0.7 mdkg, 5.1 ftdlb) caution: be careful not to scratch the front fender with the front fork outer tubes. W proper cable routing is essen- tial to assure safe motorcycle operation. Refer to "cab...

Page 14

-8- eaa00198 9. Hot starter (choke) cable a: install the boot to the hot starter (choke) lever. B: lubricate the pivoting part of the hot starter (choke) lever. Recommended lubricants: yamaha cable lube or motor oil c: insert the cable end into the lever hole, then squeeze the lever. While pulling t...

Page 15

-9- eaa01070 12. Number plate a: tighten the bolt to specifica- tion. Bolt: 7 nm (0.7 mdkg, 5.1 ftdlb) eaa00071 13. Fuel tank breather hose a: connect one end of the breather hose to the fuel tank filler cap, and insert the other end into the hole of the num- ber plate. Note: refer to "cable routing...

Page 16

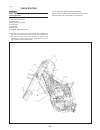

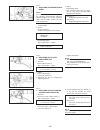

Caution: proper cable and lead routing are essential to insure safe machine operation. (1) fuel tank breather hose (2) clutch cable (3) hot starter (choke) cable (4) cable guide (5) hose guide (6) brake hose (7) “engine stop” button lead (a)pass the fuel tank breather hose between the handlebar and ...

Page 17

(1) hot starter (choke) cable (2) throttle cable (return) (3) throttle cable (pull) (4) cable guide (5) ignition coil (a)pass the hot starter (choke) cable and throttle cables through the cable guides. (b)pass the hot starter (choke) cable and throttle cables between the radiator and frame, then und...

Page 18

(1) throttle cable (2) fuel tank breather hose (3) clamp (4) clutch cable (5) hot starter (choke) cable (6) “engine stop” button lead (7) brake hose (8) hose guide (a)fasten the “engine stop” button lead to the handlebar with the plastic band. (b)pass the brake hose in front of the number plate. (c)...

Page 19

Eaa01100 adjustments and predelivery service perform the predelivery service in the order indicated by the letters. Always follow the order as shown. -13-.

Page 20

-14- eaa01005 a. Draining the fuel 1. Put a rag under the carburetor drain hose so fuel does not contact the crankcase. 2. Loosen the drain screw (1) and drain the standing fuel. W fuel is highly flammable: d always turn off the engine when draining fuel. D take care not to spill any fuel on the eng...

Page 21

B. Loosen the locknut (1). C. Turn the adjusting nut (2) in direction (a) or (b) until the specified throttle cable free play is obtained. Direction (a) throttle cable free play is increased. Direction (b) throttle cable free play is decreased. D. Tighten the locknut. W after adjusting the throttle ...

Page 22

-16- 2. Bleed: dhydraulic brake system a. Add the recommended brake fluid to the proper level. B. Install the brake master cylinder reser- voir diaphragm. C. Connect a clear plastic hose (1) tightly to the bleed screw (2). (a) front brake (b) rear brake d. Place the other end of the hose into a cont...

Page 23

-17- eaa01013 i. Checking the engine oil level 1. Stand the machine on a level surface. Note: d place the machine on a suitable stand. D make sure that the machine is upright. 2. Remove: dengine oil tank cap 3. Check: dengine oil level the engine oil level should be between the minimum level mark (a...

Page 24

-18- eaa01020 j. Adjusting the engine idling speed note: prior to adjusting the engine idling speed, the carburetor synchronization should be adjusted properly, the air filter should be clean, and the engine should have ade- quate compression. 1. Start the engine and let it warm up for several minut...

Page 25

-19- eaa01059 m. Adjusting the drive chain slack note: the drive chain slack must be checked above the drive chain guide bolt. Caution: a drive chain that is too tight will over- load the engine and other vital parts, and one that is too loose can skip and dam- age the swingarm or cause an accident....

Page 26

Rebound damping note: this is the position which is back by the specific number of clicks from the fully turned-in position. (which align the punch mark (c) on the adjuster with the punch mark (d) on the bracket.) caution: never go beyond the maximum or mini- mum adjustment positions. 1. Adjust: dre...

Page 27

-21- compression damping caution: never go beyond the maximum or mini- mum adjustment positions. 1. Remove: drubber cap 2. Adjust: dcompression damping a. Turn the adjusting screw (2) in direction (a) or (b). Direction (a) compression damping is increased (suspension is harder). Direction (b) compre...

Page 28

Eaa10000 appendices service data engine idling speed: 1,900~2,100r/min spark plug: type /manufacturer cr8e/ngk (resistance type) gap 0.7~0.8 mm (0.028~0.031 in) fuel: recommended fuel premium unleaded gasoline only with a research octane number of 95 or higher. Fuel tank capacity 7.0l (1.54 lmp gal,...

Page 29

-23- eaa10300 tightening torque engine: engine oil drain bolt (oil filter) m 6 x1.0 10 1.0 7.2 spark plug m10sx1.0 13 1.3 9.4 chassis: handle crown and outer tube m 8 x1.25 23 2.3 17 under bracket and outer tube m 8 x1.25 20 2.0 14 handle crown and steering shaft m24x1.0 145 14.5 105 handlebar holde...

Page 30

-24- rear wheel axle and nut m20x1.5 125 12.5 90 driven sprocket and wheel hub m 8 x1.25 42 4.2 30 nipple (spoke) - 3 0.3 2.2 disc cover and rear brake caliper m 6 x1.0 7 0.7 5.1 protector and rear brake caliper m 6 x1.0 7 0.7 5.1 chain puller adjust bolt and locknut m 8 x1.25 16 1.6 11 engine mount...

Page 31

Printed in u.S.A..