- DL manuals

- Yamaha

- Outboard Motor

- 40V

- Service Manual

Yamaha 40V Service Manual

Summary of 40V

Page 1

Lit-18616-01-81 290320 service manual 40v, 50h world wide 40w, 50w usa/canada.

Page 2: Notice

E a20000-0 notice this manual has been prepared by the yamaha motor company primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic under- standing of the...

Page 3: How to Use This Manual

E how to use this manual manual format all of the procedures in this manual are organized in a sequential, step-by-step format. The information has been complied to provide the mechanic with an easy to read, handy refer- ence that contains comprehensive explanations of all disassembly, repair, assem...

Page 4

E warnings, cautions and notes attention is drawn to the various warnings, cautions and notes which distinguish important information in this manual in the following ways. The safety alert symbol means attention! Become alert! Your safety is involved! Warning failure to follow warning instructions c...

Page 5

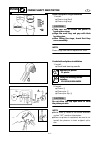

E how to read descriptions 1. A disassembly installation job mainly consists of the exploded diagram 1 . 2. The numerical figures represented by the number 2 indicates the order of the job steps. 3. The symbols represented by the number 3 indicates the contents and notes of the job. For the meanings...

Page 6: Gen

E a50001-1-4 symbols symbols 1 to 9 are designed as thumb- tabs to indicate the content of a chapter. 1 general information 2 specifications 3 periodic inspection and adjustment 4 fuel system 5 power unit 6 lower unit 7 bracket unit 8 electrical system 9 trouble-analysis symbols 0 to f indicate spec...

Page 7: Index

E index general information 1 specifications 2 spec periodic inspection and adjustment 3 fuel system 4 fuel power unit 5 powr lower unit 6 lower bracket unit 7 brkt electrical system 8 elec trouble-analysis 9 gen info insp adj – + trbl anls a30000-0

Page 9: Gen

E 1 2 3 4 5 6 7 8 9 gen info chapter 1 general information identification ............................................................................................. 1-1 serial number ..................................................................................... 1-1 starting serial numbers ...

Page 10: Gen

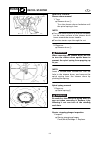

1-1 gen info e identification a60000-1* identification serial number the serial number of the outboard motor is stamped on a plate attached to the port side of the clamp bracket. Note: as an antitheft measure, a special label on which the outboard motor serial number is stamped is bonded to the port...

Page 11: Gen

1-2 gen info e safety while working safety while working the procedures given in this manual are those recommended by yamaha to be fol- lowed by yamaha dealers and their mechanics. Fire prevention gasoline (petrol) is highly flammable. Petroleum vapor is explosive if ignited. Do not smoke while hand...

Page 12: Gen

1-3 gen info e safety while working under normal conditions of use, there should be no hazards from the use of the lubricants mentioned in this manual, but safety is all-important, and by adopting good safety practices, any risk is mini- mized. A summary of the most important precau- tions is as fol...

Page 13: Gen

1-4 gen info e safety while working 3. Non-reusable items always use new gaskets, packings, o- rings, split-pins and circlips etc. On reassembly. Disassembly and assembly 1. Clean parts with compressed-air on dis- assembling them. 2. Oil the contact surfaces of moving parts on assembly. 3. After ass...

Page 14: Gen

1-5 gen info e special tools a80000-0* special tools the use of correct special tools recommended by yamaha will aid the work and enable accu- rate assembly and tune-up. Improvisations and use of improper tools can cause damage to the equipment. Note: ● for u.S.A. And canada, use part number startin...

Page 15: Gen

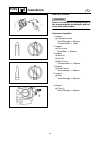

1-6 gen info e special tools measuring tool name tool no. Use for: usa and canada a except for usa and canada b 1 tachometer yu-08036-a 90890-06760 idle speed 2 dynamic spark tester ym-34487 90890-06754 ignition system 3 c.D.I. Tester yu-91022-b n.A. Ignition system 4 mity vac yb-35956 90890-06756 f...

Page 16: Gen

1-7 gen info e special tools.

Page 17: Gen

1-8 gen info e special tools removal and installation tool name tool no. Use for: usa and canada a except for usa and canada b 1 small end bearing needle installer yb-06106 90890-06526 small end 2 bearing separator yb-06219 90890-06534 crank shaft bearing reverse gear bearing forward gear inner bear...

Page 18: Gen

1-9 gen info e special tools.

Page 19: Gen

1-10 gen info e special tools tool name tool no. Use for: usa and canada a except for usa and canada b 23 bearing outer race puller n.A. 90890-06523 forward gear outer bearing 24 bearing outer race puller clow n.A. 90890-06532 forward gear outer bearing 25 bearing installer yb-41446 90890-06626 forw...

Page 21: Spec

E 1 2 3 4 5 6 7 8 9 spec chapter 2 specifications general specifications .......................................................................... 2-1 maintenance specifications ................................................................ 2-7 engine ................................................

Page 22: Spec

2-1 spec e general specifications general specifications item unit model worldwide 40vmh 40vmhd 40vmho 40vmo 40vwh usa, canada c40mh — 40mh — — dimension: over-all length mm (in) 1,281 (50.4) 670 (26.4) 1,281 (50.4) over-all width mm (in) 349 (13.7) 360 (14.2) over-all height s mm (in) 1,223 (48.1) ...

Page 23: Spec

2-2 spec e general specifications *1: pump octane number ; (research octane + motor octane)/2 fuel and lubrication: fuel type regular gasoline fuel rating p.O.N.* 1 min. 86 engine oil type/grade 2-stroke outboard motor oil / tc-w3 mixing ratio 50 : 1 — 50 : 1 engine oil tank capacity l (us qt, imp q...

Page 24: Spec

2-3 spec e general specifications item unit model worldwide 40ve 40veo 40vehto 40vet 40veto usa, canada c40er 40er p40th c40tr 40tr dimension: over-all length mm (in) 670 (26.4) 1,281 (50.4) 646 (25.4) over-all width mm (in) 349 (13.7) 360 (14.2) 350 (13.8) over-all height s mm (in) 1,192 (46.9) — 1...

Page 25: Spec

2-4 spec e general specifications *1: pump octane number ; (research octane + motor octane)/2 fuel and lubrication: fuel type regular gasoline fuel rating p.O.N.* 1 min. 86 engine oil type/grade 2-stroke outboard motor oil / tc-w3 mixing ratio 50 : 1 — 50 : 1 — engine oil tank capacity l (us qt, imp...

Page 26: Spec

2-5 spec e general specifications item unit model worldwide 50hmho 50hmhd 50hmo 50hmdo 50hwhd 50hedo 50het 50heto usa, canada — — — — — 50er c50tr 50tr dimension: over-all length mm (in) 1,281 (50.4) 670 (26.4) 1,281 (50.4) 670 (26.4) over-all width mm (in) 349 (13.7) 360 (14.2) 349 (13.7) 360 (14.2...

Page 27: Spec

2-6 spec e general specifications *1: pump octane number ; (research octane + motor octane)/2 fuel and lubrica- tion: fuel type regular gasoline fuel rating p.O.N.* 1 min. 86 engine oil type/grade 2-stroke outboard motor oil / tc-w3 mixing ratio — 50 : 1 — 50 : 1 — 50 : 1 — engine oil tank capacity ...

Page 28: Spec

2-7 spec e maintenance specifications maintenance specifications engine item unit model 40 hp 50 hp cylinder head: warpage limit mm (in) 0.1 (0.004) cylinder: bore size mm (in) 67.00 ~ 67.02 (2.638 ~ 2.639) wear limit mm (in) 67.10 (2.642) taper limi mm (in) 0.08 (0.003) out of round limit mm (in) 0...

Page 29: Spec

2-8 spec e maintenance specifications thermostat: opening temperature ˚c (˚f) 48 ~ 52 (118 ~ 126) full-opening temperature ˚c (˚f) 60 (140) valve lift mm (in) 3 (0.12) oil injection pump: identification mark 63d00 specified discharge cm 3 (us oz, imp oz) 1.60 ± 0.50 (0.054 ± 0.017, 0.056 ± 0.018) re...

Page 30: Spec

2-9 spec e maintenance specifications lower item unit model 40 hp 50 hp gear backlash: pinion - forward mm (in) 0.18 ~ 0.45 (0.007 ~ 0.018) pinion - reverse mm (in) 0.71 ~ 0.98 (0.028 ~ 0.039) pinion shims mm (in) 0.05, 0.08, 0.12, 0.30, 0.50 forward shims mm (in) 0.05, 0.08, 0.12, 0.30, 0.50 revers...

Page 31: Spec

2-10 spec e maintenance specifications electrical item unit model 40 hp 50 hp ignition timing: ignition timing (full retarded) degree a.T.D.C. 7 ± 1 (full advanced) degree b.T.D.C. 25 (cam roller pick-up) degree a.T.D.C. 7 piston position (full advanced) mm (in) b.T.D.C. 3.93 (0.155 ) starter motor:...

Page 32: Spec

2-11 spec e maintenance specifications charge coil resistance Ω (color) 368 ~ 552 (br — l) charging current (minimum)/rpm a/rpm 3/3,000 charging current (maximum)/rpm a/rpm 5 ~ 7/5,500 lighting voltage (minimum)/rpm v/rpm 12.0/3,000 lighting voltage (maximum)/rpm v/rpm 13.5 ~ 16.5/5,500 lighting coi...

Page 33: Spec

2-12 spec e maintenance specifications.

Page 34: Spec

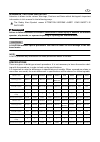

2-13 spec e maintenance specifications dimension 1.

Page 35: Spec

2-14 spec e maintenance specifications symbol unit model 40vmh 40vmho 40vwh 50hmho 40vmo 50hmo 40ve 40veo 50hmdo 40vmhd 50hmhd 50hwhd 40vehto 40vet 40veto 50hedo 50het 50heto l6 :s mm (in) 798 (31.4) — 822 (32.4) — 822 (32.4) :l 910 (35.8) 937 (36.9) :ul — 1,010 (39.8) — 1,040 (40.9) — 1,040 (40.9) ...

Page 36: Spec

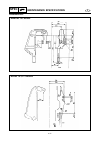

2-15 spec e maintenance specifications dimension 2 manual tilt model hydro tilt/ptt model.

Page 37: Spec

2-16 spec e maintenance specifications symbol unit model manual tilt hydro and ptt b1 mm (in) 62.5 (2.5) 126 (5.0) b2 mm (in) 208 (8.2) 254 (10.0) b3 mm (in) 121.5 (4.8) 163.5 (6.4) b4 mm (in) 32 (1.3) 50.8 (2.0) b5 mm (in) 131.5 (5.2) 180 (7.1) b6 mm (in) 245 (9.6) 355 (14.0) b9 mm (in) 25 (1.0) 18...

Page 38: Spec

2-17 spec e tightening torque tightening torque specified torque part to tightened part name thread size q‘ty tightening torque remarks nm m•kg ft•lb engine: engine unit bolt m8 8 21 2.1 15 flywheel nut m16 1 110 11 80 e intake manifold 1st bolt m6 12 4 0.4 2.9 2nd 8 0.8 5.8 reed valve bolt m3 12 1 ...

Page 39: Spec

2-18 spec e tightening torque general torque this chart specifies the torques for tighten- ing standard fastners with standard clean dry iso threads at room temperature. Torque specifications for special compo- nents or assemblies are given in applicable sections of this manual. To avoid causing war...

Page 41: Insp

E 1 2 3 4 5 6 7 8 9 insp adj chapter 3 periodic inspection and adjustment maintenance interval chart .............................................................. 3-1 periodic service ........................................................................................ 3-2 fuel system..............

Page 42: Insp

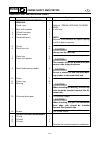

3-1 insp adj e maintenance interval chart maintenance interval chart the following chart should be considered strictly as a guide to general maintenance intervals. Depending on operating conditions, the intervals of maintenance should be changed. Item remarks initial every refer page 10 hours (break...

Page 43: Insp

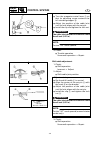

3-2 insp adj e fuel system/control system periodic service fuel system fuel line 1. Inspect: ● fuel line break/leak/damage → replace. Control system throttle link adjustment 1. Check: ● cdi unit indicator incorrect → adjust. Checking steps: ● turn the magneto control lever 1 so that its adjusting sc...

Page 44: Insp

3-3 insp adj e control system throttle cable adjustment note: before adjusting the throttle cable, the throttle link should be adjusted. 1. Check: ● full-open position incorrect → adjust. 2. Adjust: ● throttle cable joint position ● loosen the lock nut 2 . ● disconnect the magneto control rod 3 at t...

Page 45: Insp

3-4 insp adj e control system 3. Check: ● throttle operation unsmooth operation → repair. ● turn the magneto control lever 3 so that its adjusting screw contacts the full retarding stopper a . ● adjust the position of the cable joint until its hole aligns with the set pin. ● install the clip and tig...

Page 46: Insp

3-5 insp adj e control system start-in-gear protection adjustment 1. Check: ● start-in-gear protection operation incorrect → adjust. 2. Adjust: ● start-in-gear protection wire adjustment steps: ● set the shift lever in neutral. ● loosen the lock nut 1. ● adjust the start-in-gear protection wire adju...

Page 47: Insp

3-6 insp adj e control system/oil injection system ● turn in the pilot screw until it is lightly seated. ● turn out the pilot screw to specification. Pilot screw (turns out): 40 hp: 1-1/2 ± 1/4 50 hp (m model): 1-5/8 ± 1/4 50 hp (em, e model): 1-3/8 ± 1/4 ● start the engine and allow it to warm up f...

Page 48: Insp

3-7 insp adj e oil injection system/ power trim and tilt system 2. Adjust: ● oil pump link joint position power trim and tilt system power trim and tilt fluid 1. Check: ● fluid level fluid level is low → fill. Warning to prevent the hydraulic fluid from spurt- ing out by cancelling the internal pres...

Page 49: Insp

3-8 insp adj e lower unit lower unit gear oil 1. Check: ● gear oil milky oil → replace the oil seal. Slag oil → check the gear, bearing and dog. 2. Check: ● gear oil level oil level is low → add oil to proper level. 3. Replace: ● gear oil lower unit leakage check 1. Check: ● pressure holding pressur...

Page 50: Insp

3-9 insp adj e lower unit/general note: do not over-pressurize. Excess pressure may cause the air to leak out. General anode 1. Inspect: ● anode 1 ● trim tab 2 ● anode [(bracket bottom) except for manual tilt model] 3 scale → clean. Oil/grease → clean. Wear/excessively consumed → replace. Caution: d...

Page 51: Insp

3-10 insp adj e general note: ● batteries vary among manufacturers. Therefore the following procedures may not always apply. Consult your battery manufacturer’s instructions. ● disconnect the black negative lead first to prevent the risk of shorting. 1. Inspect: ● battery fluid level ● battery fluid...

Page 52: Insp

3-11 insp adj e general 4. Measure: ● electrodes gap a out of specification → regap. Gap: 0.9 ~1.0 mm (0.035 ~ 0.039 in) 5. Tighten: ● spark plug note: before installing the spark plug, clean the gasket surface and the plug surface. Note: if a torque wrench is not available, a good estimate of the c...

Page 53: Fuel

E 1 2 3 4 5 6 7 8 9 fuel chapter 4 fuel system fuel joint, fuel filter and fuel pump .............................................. 4-1 exploded diagram ............................................................................. 4-1 removal and installation chart .....................................

Page 54: Fuel

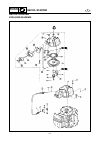

4-1 fuel e fuel joint, fuel filter and fuel pump fuel joint, fuel filter and fuel pump exploded diagram.

Page 55: Fuel

4-2 fuel e fuel joint, fuel filter and fuel pump removal and installation chart step procedure/part name q’ty service points fuel joint, fuel filter and fuel pump removal follow the left “step” for removal. Oil tank ass’y refer to “oil tank”. 1 clip 1 2 fuel hose (joint - filter) 1 3 bolt (with wash...

Page 56: Fuel

4-3 fuel e fuel joint, fuel filter and fuel pump fuel line layout m model 1 fuel pump 2 fuel filter w, e model 1 fuel pump 2 fuel filter 3 electrothermal valve.

Page 57: Fuel

4-4 fuel e fuel joint, fuel filter and fuel pump service points fuel joint inspection 1. Inspect: ● fuel joint crack/leak/damage → replace. 2. Measure: ● fuel joint operation impossible to maintain the specified pressure for 10 sec. → replace. Measuring steps: ● attach the mity vac. Mity vac: yb-359...

Page 58: Fuel

4-5 fuel e carburetor removal carburetor removal exploded diagram.

Page 59: Fuel

4-6 fuel e carburetor removal removal and installation chart step procedure/part name q’ty service points carburetor removal follow the left “step” for removal. Oil tank ass’y refer to “oil tank”. 1 screw 2 6 × 40 mm 2 screw 2 6 × 55 mm 3 washer 4 4 silencer 1 5 seal 3 6 clip 3 7 fuel hose (joint pi...

Page 60: Fuel

4-7 fuel e carburetor carburetor exploded diagram.

Page 61: Fuel

4-8 fuel e carburetor removal and installation chart step procedure/part name q’ty service points carburetor disassembly follow the left “step” for removal. Carburetor ass’y refer to “carburetor removal”. 1 drain screw 1 2 o-ring 1 3 screw (with washer) 3 4 × 14 mm 4 carburetor cover 1 5 cover packi...

Page 62: Fuel

4-9 fuel e carburetor service points caution: do not use steelwire for cleaning the jets as this may enlarge the jet diameters and seri- ously affect performance. Carburetor inspection 1. Inspect: ● carburetor body crack/damage → replace. Contamination → clean. 2. Inspect: ● pilot screw bend/wear → ...

Page 63: Fuel

4-10 fuel e carburetor carburetor assembly 1. Install: ● needle valve ● float 1 ● float pin 2 ● screw 3 note: ● the float pin should be fit in the slit the carburetor and locked with the screw. ● when installing the float in the carburetor, place the needle valve in the valve seat. ● after installin...

Page 64: Fuel

4-11 fuel e prime starter prime starter exploded diagram.

Page 65: Fuel

4-12 fuel e prime starter removal and installation chart step procedure/part name q’ty service points prime starter disassembly follow the left “step” for removal. Carburetor ass’y refer to “charburetor removal”. 1 screw (with washer) 2 4 × 10 mm 2 electrothermal valve 1 3 clip 1 4 fuel enrichment h...

Page 66: Fuel

4-13 fuel e prime starter service points fuel enrichment pump inspection 1. Inspect: ● body crack/leak/damage → replace. 2. Inspect: ● seat valve crack/distortion → replace. 3. Inspect: ● diaphragm damage → replace. Fuel enrichment valve inspection 1. Inspect: ● needle valve 1 ● piston valve 2 wear/...

Page 67: Fuel

4-14 fuel e prime starter.

Page 68: Fuel

4-15 fuel e oil tank oil tank exploded diagram.

Page 69: Fuel

4-16 fuel e oil tank removal and installation chart step procedure/part name q’ty service points oil tank removal follow the left “step” for removal. 1 clip 1 2 oil drain hose 1 3 clip 1 4 oil inlet hose 1 5 clip 1 6 oil return hose 1 7 oil level sensor lead coupler 1 8 bolt (with washer) 2 9 oil le...

Page 70: Fuel

4-17 fuel e oil tank oil line layout 1 electrothermal valve (em, e model) 2 oil level sensor 3 oil drain hose 4 oil tank 5 oil pump.

Page 71: Fuel

4-18 fuel e oil tank service points oil tank inspection 1. Inspect: ● oil tank crack → replace. Oil strainer inspection 1. Inspect: ● oil strainer crack/clog → replace. Contamination → clean. Check valve inspection 1. Check: ● check valve operation does not function → replace. Note: check the operat...

Page 72: Fuel

4-19 fuel e oil pump oil pump exploded diagram.

Page 73: Fuel

4-20 fuel e oil pump removal and installation chart step procedure/part name q’ty service points oil pump removal follow the left “step” for removal. Engine oil refer to “oil tank”. 1 clip 1 2 oil inlet hose 1 3 clip 1 4 oil return hose 1 5 clip 1 6 plate washer 1 7 link joint 1 8 clip 3 9 oil deliv...

Page 74: Powr

E 1 2 3 4 5 6 7 8 9 powr chapter 5 power unit power unit removal ............................................................................... 5-1 exploded diagram ............................................................................. 5-1 removal and installation chart ........................

Page 75: Powr

E 1 2 3 4 5 6 7 8 9 powr cylinder head, thermostat and exhaust cover ....................... 5-21 exploded diagram ........................................................................... 5-21 removal and installation chart ............................................. 5-22 service points ..........

Page 76: Powr

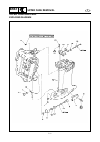

5-1 powr e power unit removal power unit removal exploded diagram.

Page 77: Powr

5-2 powr e power unit removal removal and installation chart step procedure/part name q’ty service points power unit removal follow the left “step” for removal. 1 bolt 1 m model 2 engine stop switch lead (black) 1 3 engine stop switch coupler (blue) 1 4 maine switch lead coupler 1 e model 5 oil leve...

Page 78: Powr

5-3 powr e recoil starter recoil starter exploded diagram.

Page 79: Powr

5-4 powr e recoil starter removal and installation chart step procedure/part name q’ty service points recoil starter removal follow the left “step” for removal. 1 lock nut 1 2 start-in-gear protection wire 1 3 bolt (with washer) 3 6 × 35 mm 4 recoil starter ass’y 1 5 dowel pin 1 recoil starter disas...

Page 80: Powr

5-5 powr e recoil starter service points sheave drum removal 1. Turn: ● sheave drum 1 turn the sheave drum clockwise until the spiral spring is free. Note: ● turn the sheave drum so that the cutaway on the outer surface of the sheave drum faces toward the starter handle. ● pass the starter rope thro...

Page 81: Powr

5-6 powr e recoil starter drive pawl and spring inspection 1. Inspect: ● drive pawl crack/wear/damage → replace. ● drive pawl spring broken/bent/damage → replace. Rope roller and collar inspection 1. Inspect: ● rope roller ● collar crack/wear/damage → replace them as a set. Bushing inspection 1. Ins...

Page 82: Powr

5-7 powr e recoil starter starter rope installation 1. Install: ● starter rope note: ● insert the rope through the rope holes and knot the end. ● wind the rope 1-9/10 turns around the sheave drum. ● place the rope at the cutaway. Sheave drum installation 1. Install: ● sheave drum 1 note: position th...

Page 83: Powr

5-8 powr e recoil starter.

Page 84: Powr

5-9 powr e flywheel magneto and magneto base flywheel magneto and magneto base exploded diagram.

Page 85: Powr

5-10 powr e flywheel magneto and magneto base removal and installation chart step procedure/part name q’ty service points flywheel magneto and magneto base removal follow the left “step” for removal. Recoil starter ass’y refer to “recoil starter”. 1 screw 1 6 × 40 mm 2 screw 2 6 × 35 mm 3 washer 3 4...

Page 86: Powr

5-11 powr e flywheel magneto and magneto base service points flywheel magneto removal 1. Remove: ● flywheel nut Å for usa and canada ı except for usa and canada caution: the major load should be carried in the direction of the arrows. If not, the holder may easily slip off. Flywheel holder: yb-06139...

Page 87: Powr

5-12 powr e flywheel magneto and magneto base.

Page 88: Powr

5-13 powr e electrical unit removal electrical unit removal exploded diagram Å.

Page 89: Powr

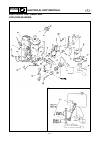

5-14 powr e electrical unit removal removal and installation chart step procedure/part name q’ty service points electrical unit removal follow the left “step” for removal. 1 thermo switch coupler 2 pink and black leads 2 wire harness coupler 1 3 electrothermal valve lead 1 blue lead 4 lighting coil ...

Page 90: Powr

5-15 powr e electrical unit electrical unit exploded diagram.

Page 91: Powr

5-16 powr e electrical unit removal and installation chart step procedure/part name q’ty service points electrical unit disassembly follow the left “step” for removal. Electrical unit refer to “electrical unit removal”. 1 fuse 1 2 clamp 1 3 bolt (with washer) 1 4 clamp 1 5 bolt (with washer) 1 6 rec...

Page 92: Powr

5-17 powr e reed valve and check valve reed valve and check valve exploded diagram.

Page 93: Powr

5-18 powr e reed valve and check valve removal and installation chart step procedure/part name q’ty service points reed valve and check valve removal follow the left “step” for removal. Oil tank ass’y refer to “oil tank” in chapter 4. Carburetor ass’y refer to “carburetor removal” in chapter 4. 1 cl...

Page 94: Powr

5-19 powr e reed valve and check valve service points reed valve inspection 1. Inspect: ● reed valve crack/damage → replace. 2. Measure: ● valve bending a out of specification → replace. 3. Measure: ● valve stopper height b out of specification → replace. Valve bending limit: 0.2 mm (0.01 in) valve ...

Page 95: Powr

5-20 powr e reed valve and check valve.

Page 96: Powr

5-21 powr e cylinder head, thermostat and exhaust cover cylinder head, thermostat and exhaust cover exploded diagram.

Page 97: Powr

5-22 powr e cylinder head, thermostat and exhaust cover removal and installation chart step procedure/part name q’ty service points cylinder head, thermostat and exhaust cover removal follow the left “step” for removal. Spark plug cap disconnect the cap from the plug. 1 spark plug 3 2 bolt (with was...

Page 98: Powr

5-23 powr e cylinder head, thermostat and exhaust cover service points cylinder head inspection 1. Inspect: ● water jacket material deposit/corrosion → clean. ● cylinder inner surface score marks → clean. Use #600 ~ 800 grit wet sandpaper. Caution: do not scratch the fitting surfaces of the cylinder...

Page 99: Powr

5-24 powr e cylinder head, thermostat and exhaust cover thermostat inspection 1. Inspect: ● thermostat stick/damage → replace. 2. Measure: ● valve opening temperature ● valve lift out of specification → replace. Water temperature valve lift below 48 ~ 52 ˚c (118 ~ 126 ˚f) 0 mm (0 in) above 60 ˚c (14...

Page 100: Powr

5-25 powr e crankcase and cylinder body crankcase and cylinder body exploded diagram.

Page 101: Powr

5-26 powr e crankcase and cylinder body removal and installation chart step procedure/part name q’ty service points crank case and cylinder body removal follow the left “step” for removal. Oil tank ass’y refer to “oil tank” in chapter 4. Oil pump refer to “oil pump” in chapter 4. Carburetor ass’y re...

Page 102: Powr

5-27 powr e crankcase and cylinder body exploded diagram.

Page 103: Powr

5-28 powr e crankcase and cylinder body removal and installation chart step procedure/part name q’ty service points d hose nipple 1 e hose joint 3 f check valve 2 g check valve 2 h hose joint 1 reverse the removal steps for installation..

Page 104: Powr

5-29 powr e crankcase and cylinder body service points cylinder body inspection 1. Inspect: ● water jacket material deposit/corrosion → clean. ● cylinder inner surface score marks → clean. Use #600 ~ 800 grit wet sandpaper. Note: do not scratch the fitting surfaces of the crank case and cylinder hea...

Page 105: Powr

5-30 powr e crankcase and cylinder body piston to cylinder clearance 1. Calculate: ● piston clearance out of specification → replace piston and piston ring and/or cylinder. Oil pump driven gear inspection 1. Inspect: ● oil pump driven gear crack/pitting/wear → replace. Cylinder body and crankcase in...

Page 106: Powr

5-31 powr e crank shaft and piston crank shaft and piston exploded diagram.

Page 107: Powr

5-32 powr e crank shaft and piston removal and installation chart step procedure/part name q’ty service points crank shaft and piston removal follow the left “step” for removal. Crank case refer to “crank case and cylinder body”. 1 bolt (with washer) 1 6 × 20 mm 2 oil seal housing 1 3 plane washer 1...

Page 108: Powr

5-33 powr e crank shaft and piston service points piston pin clip removal 1. Remove: ● piston pin clip note: take care not to damage piston pin hole edge. Piston pin and small end bearing removal 1. Remove: ● piston pin clip ● small end needle bearing note: when the piston pins, pistons, and small e...

Page 109: Powr

5-34 powr e crank shaft and piston measuring point “h” piston diameter standard 10 mm (0.4 in) 66.940 ~ 67.000 mm (2.6354 ~ 2.6378 in) over size piston diameter: 1*: 67.25 mm (2.648 in) 2: 67.50 mm (2.657 in) *: except for u.S.A. 2. Measure: ● piston pin boss inside diameter use a micrometer. Out of...

Page 110: Powr

5-35 powr e crank shaft and piston piston ring inspection 1. Inspect: ● piston ring breakage/damage → replace. 2. Measure: ● end gap use a feeler gauge. Out of specification → replace. Note: install the piston ring into the cylinder. Push the ring with the piston crown. End gap: top: 0.40 ~ 0.60 mm ...

Page 111: Powr

5-36 powr e crank shaft and piston crankshaft inspection 1. Measure: ● crank width a ● crank width b out of specification → replace. 2. Measure: ● runout use a v-blocks and dial gauge. Out of specification → replace. Crank width a: 53.90 ~ 53.95 mm (2.122 ~ 2.124 in) crank width b: 32.88 ~ 33.10 mm ...

Page 112: Powr

5-37 powr e crank shaft and piston piston and piston ring installation 1. Install: ● piston ring (2nd) ● piston ring (top) caution: ● take care not to scratch the piston or break piston rings. ● align the each ring end gap with their locating pins. ● after fitting the rings, check that they move smo...

Page 114: Lowr

E 1 2 3 4 5 6 7 8 9 lowr chapter 6 lower unit lower unit removal ............................................................................... 6-1 exploded diagram ............................................................................. 6-1 removal and installation chart ........................

Page 115: Lowr

E 1 2 3 4 5 6 7 8 9 lowr shimming .................................................................................................... 6-19 shim selection (for usa and canada) ..................................... 6-19 pinion gear shim ...................................................................

Page 116: Lowr

6-1 lowr e lower unit removal lower unit removal exploded diagram.

Page 117: Lowr

6-2 lowr e lower unit removal removal and installation chart step procedure/part name q’ty service points lower unit removal follow the left “step” for removal. 1 clamp 1 2 hose 1 3 cotter pin 1 4 propeller nut 1 5 plane washer 1 6 spacer 1 7 propeller 1 8 spacer 1 9 bolt (with washer) 1 8 × 25 mm 1...

Page 118: Lowr

6-3 lowr e water pump water pump exploded diagram.

Page 119: Lowr

6-4 lowr e water pump removal and installation chart step procedure/part name q’ty service points water pump removal follow the left “step” for removal. Lower unit ass’y refer to “lower unit removal”. 1 bolt 4 8 × 30 mm 2 washer 4 3 water pump housing 1 4 o-ring 1 5 insert cartridge 1 6 impeller 1 7...

Page 120: Lowr

6-5 lowr e propeller shaft and reverse gear propeller shaft and reverse gear exploded diagram.

Page 121: Lowr

6-6 lowr e propeller shaft and reverse gear removal and installation chart step procedure/part name q’ty service points propeller shaft and reverse gear removal follow the left “step” for removal. Gear oil refer to “lower unit” in chapter 3. Propeller refer to “lower unit removal”. 1 flange bolt 2 2...

Page 122: Lowr

6-7 lowr e propeller shaft and reverse gear service points propeller shaft housing removal 1. Remove: ● propeller shaft housing ass’y Å for usa and canada ı except for usa and canada bearing housing puller: yb-06234................................ 1 90890-06503........................... 3 universal...

Page 123: Lowr

6-8 lowr e propeller shaft and reverse gear 3. Remove: ● oil seal 1 ● needle bearing 2 driver rod: yb-06071/90890-06652 needle bearing attachment: yb-06112/90890-06614 reverse gear inspection 1. Inspect: ● tooth ● dog wear/damage → replace. Bearing inspection 1. Inspect: ● bearing pitting/rumbling →...

Page 124: Lowr

6-9 lowr e propeller shaft and reverse gear propeller shaft housing assembly 1. Install: ● needle bearing Å for usa and canada ı except for usa and canada depth a: 3.0 ~ 3.5 mm (0.12 ~ 0.14 in) depth b: 23.0 ~ 23.5 mm (0.91 ~ 0.93 in) driver rod: yb-06071................................ 1 90890-0660...

Page 125: Lowr

6-10 lowr e propeller shaft and reverse gear.

Page 126: Lowr

6-11 lowr e drive shaft, forward gear and shift rod drive shaft, forward gear and shift rod exploded diagram.

Page 127: Lowr

6-12 lowr e drive shaft, forward gear and shift rod removal and installation chart step procedure/part name q’ty service points drive shaft, forward gear and shift rod removal follow the left “step” for removal. Gear oil refer to “lower unit” in chapter 3. Lower unit ass’y refer to “lower unit remov...

Page 128: Lowr

6-13 lowr e drive shaft, forward gear and shift rod exploded diagram.

Page 129: Lowr

6-14 lowr e drive shaft, forward gear and shift rod removal and installation chart step procedure/part name q’ty service points f forward gear shim * g screw 1 h water inlet cover 1 1 i water inlet cover 2 1 j nut 1 k hose nipple 1 l bolt (with washer) 1 m anode 1 n lower case 1 reverse the removal ...

Page 130: Lowr

6-15 lowr e drive shaft, forward gear and shift rod service points pinion nut removal 1. Remove: ● pinion nut forward gear disassembly 1. Remove: ● taper roller bearing 1 ● forward gear 2 drive shaft holder: yb-06079/90890-06517 ......... 1 pinion nut wrench: 90890-06505........................... 2...

Page 131: Lowr

6-16 lowr e drive shaft, forward gear and shift rod 2. Remove: ● drive shaft needle bearing needle bearing attachment: yb-06063/90890-06614 ......... 1 driver rod: yb-06071/90890-06652 ......... 2 3. Remove: ● forward gear bearing outer race Å for usa and canada ı except for usa and canada slide ham...

Page 132: Lowr

6-17 lowr e drive shaft, forward gear and shift rod sleeve inspection 1. Inspect: ● sleeve wear/damage → replace. Lower case inspection 1. Clean: ● gear case use a soft brush and solvent. 2. Inspect: ● water passage mineral deposits/corrosion → clean. 3. Inspect: ● lower case crack/damage → replace....

Page 133: Lowr

6-18 lowr e drive shaft, forward gear and shift rod 3. Install: ● pinion gear shim ● drive shaft bearing outer race drive shaft oil seal housing assembly 1. Install: ● oil seal 1 bearing installer: yb-06110/90890-06627 ......... 1 driver rod: yb-06071/90890-06606 ......... 2 depth a: 0.0 ~ 0.5 mm (0...

Page 134: Lowr

6-19 lowr e shimming shimming note: shim selection requirement guide: ● not required when; reassembling with original case and inner parts. ● numeric calculation is required when; reassembling with original inner parts and the new case. (difference between original and new case) ● measurement and ad...

Page 135: Lowr

6-20 lowr e shim selection 2. Install: ● shimming gauge ● drive shaft ● bearing 1 ● shim(s) 2 note: ● attach the adapter plate to the gauge base using 4 bolts of appropriate sizes. ● fix the shimming gauge to the drive shaft so that the shaft is at the center of the hole. ● if the original shim(s) i...

Page 136: Lowr

6-21 lowr e shimming forward gear shim note: find forward gear shim thickness (t1) by selecting shims until the specified measure- ment (m) is obtained with the special tool. 1. Calculate: ● specified measurement (m) note: ● f is the deviation of the lower case dimen- sion from standard. It is stamp...

Page 137: Lowr

6-22 lowr e shimming 3. Check: ● specified measurement (m) out of specified measurement → adjust. Note: check the fit between the shimming gauge and lower surface of the press plate. Thickness gauge: yu-26900-9 4. Adjust: ● shim(s) remove or add. Available shim thickness: 0.05, 0.08, 0.12, 0.30 and ...

Page 138: Lowr

6-23 lowr e shimming shim selection (except for usa and canada) pinion gear shim note: find pinion gear shim thickness (t3) by selecting shims until the specified measure- ment is obtained with the special tool. 1. Install: ● pinion height gauge ● drive shaft ● bearing note: ● fix the pinion height ...

Page 139: Lowr

6-24 lowr e shimming note: ● find the average of the measurement (m). ● p is the deviation of the lower case dimen- sion from standard. It is stamped on the trim tab mounting surface of the lower case in 0.01 mm units. If the p mark is missing or unreadable, assume a p mark of “0”, and check the bac...

Page 140: Lowr

6-25 lowr e shimming forward gear shim note: find forward gear shim thickness (t1) by selecting shims until the specified measure- ment (m) is obtained with the special tool. 1. Measure: ● measurement (m) note: measure the length between the shimming plate and the bearing outer race after turn- ing ...

Page 141: Lowr

6-26 lowr e shimming 3. Select: ● forward gear shim example: if t1 is “0.45 mm”, then forward gear shim = 0.42 mm if t1 is “0.50 mm”, then forward gear shim = 0.48 mm calculated numeral at 1/100th place rounded numeral more than or less 0.00 0.02 0.00 0.02 0.05 0.02 0.05 0.08 0.05 0.08 0.10 0.08 ava...

Page 142: Lowr

6-27 lowr e shimming forward gear 1. Measure: ● forward gear backlash out of specification → adjust. Backlash: 0.18 ~ 0.45 mm (0.007 ~ 0.018 in) measuring steps: ● set the bearing housing puller for pushing the propeller shaft. Bearing housing puller: yb-6234/90890-06503 universal puller: yb-6117 st...

Page 143: Lowr

6-28 lowr e shimming 2. Adjust: ● forward gear shim(s) note: adjust the shim(s) to be added or removed according to specification. Forward gear backlash shim thickness less than 0.18 mm to be decreased by (0.31 – mea- surement) × 0.56 more than 0.45 mm to be increased by (measurement – 0.31) × 0.56 ...

Page 144: Lowr

6-29 lowr e shimming 2. Adjust: ● reverse gear shim(s) note: adjust the shim(s) to be added or removed according to specification. Backlash adjusting plate: yb-07003 dial gauge: yu-03097/90890-01252 magnet base: yu-34481/90890-06705 ● while pulling the drive shaft, slowly turn the drive shaft clockw...

Page 146: Brkt

E 1 2 3 4 5 6 7 8 9 brkt chapter 7 bracket unit tiller handle removal ........................................................................... 7-1 exploded diagram ............................................................................. 7-1 removal and installation chart .......................

Page 147: Brkt

E 1 2 3 4 5 6 7 8 9 brkt clamp bracket (hydro tilt, power trim and tilt) ................................... 7-17 exploded diagram ........................................................................... 7-17 removal and installation chart ............................................. 7-18 steeri...

Page 148: Brkt

7-1 brkt e tiller handle removal tiller handle removal exploded diagram.

Page 149: Brkt

7-2 brkt e tiller handle removal removal and installation chart step procedure/part name q’ty service points tiller handle removal follow the left “step” for removal. 1 bolt 2 steering friction model 2 clamp 1 e model 3 screw 1 steering friction model 4 bolt 1 5 collar 1 6 clamp 1 7 bolt 1 m model 8...

Page 150: Brkt

7-3 brkt e tiller handle tiller handle exploded diagram.

Page 151: Brkt

7-4 brkt e tiller handle removal and installation chart step procedure/part name q’ty service points tiller handle disassembly follow the left “step” for removal. Tiller handle ass’y refer to “tiller handle removal”. 1 screw 4 6 × 16 mm 2 screw 3 6 × 40 mm 3 cover 1 4 nut 1 5 engine stop switch ass’...

Page 152: Brkt

7-5 brkt e tiller handle exploded diagram.

Page 153: Brkt

7-6 brkt e tiller handle removal and installation chart step procedure/part name q’ty service points 35 collar 1 36 wave washer 1 37 bracket 1 38 steering handle 1 39 bushing 2 reverse the removal steps for installation. Service points control cable inspection 1. Inspect: ● throttle cable ● shift ca...

Page 154: Brkt

7-7 brkt e link ass’y disassembly link ass’y disassembly exploded diagram.

Page 155: Brkt

7-8 brkt e link ass’y disassembly removal and installation chart step procedure/part name q’ty service points link ass’y disassembly follow the left “step” for removal. 1 circlip 1 2 throttle arm shaft 1 3 throttle arm 1 4 screw (with washer) 2 6 × 16 mm 5 throttle shaft ass’y 1 6 screw 2 7 spring g...

Page 156: Brkt

7-9 brkt e shift actuator and bottom cowling shift actuator and bottom cowling exploded diagram.

Page 157: Brkt

7-10 brkt e shift actuator and bottom cowling removal and installation chart step procedure/part name q’ty service points shift actuator and bot- tom cowling removal follow the left “step” for removal. Power unit ass’y refer to “power unit removal” in chapter 5. 1 shift actuator ass’y 1 2 bolt (with...

Page 158: Brkt

7-11 brkt e upper case removal upper case removal exploded diagram.

Page 159: Brkt

7-12 brkt e upper case removal removal and installation chart step procedure/part name q’ty service points upper case removal follow the left “step” for removal. Power unit refer to “power unit removal” in chapter 5. Lower unit ass’y refer to “lower unit removal” in chapter 6. Bottom cowling refer t...

Page 160: Brkt

7-13 brkt e upper case and exhaust manifold upper case and exhaust manifold exploded diagram.

Page 161: Brkt

7-14 brkt e upper case and exhaust manifold removal and installation chart step procedure/part name q’ty service points upper case and exhaust manifold follow the left “step” for removal. Upper case ass’y refer to “upper case removal”. 1 bolt (with washer) 2 2 upper case 1 3 dowel pin 2 exhaust mani...

Page 162: Brkt

7-15 brkt e clamp bracket clamp bracket (manual tilt) exploded diagram.

Page 163: Brkt

7-16 brkt e clamp bracket removal and installation chart step procedure/part name q’ty service points clamp bracket removal (manual tilt) follow the left “step” for removal. Upper case ass’y refer to “upper case removal”. 1 spring 1 2 circlip 1 3 plane washer 2 4 tilt stop lever 1 5 pin 1 6 tilt pin...

Page 164: Brkt

7-17 brkt e clamp bracket clamp bracket (hydro tilt, power trim and tilt) exploded diagram.

Page 165: Brkt

7-18 brkt e clamp bracket removal and installation chart step procedure/part name q’ty service points clamp bracket removal (hydro tilt, power trim and tilt) follow the left “step” for removal. Upper case ass’y refer to “upper case removal”. 1 ptt motor lead 1 ptt model 2 trim sensor coupler 1 3 ban...

Page 166: Brkt

7-19 brkt e steering bracket steering bracket exploded diagram.

Page 167: Brkt

7-20 brkt e steering bracket removal and installation chart step procedure/part name q’ty service points steering bracket removal follow the left “step” for removal. Upper case ass’y refer to “upper case removal”. 1 flange bolt 1 manual tilt model 2 seal rubber 1 3 circlip 1 4 lower mount housing 1 ...

Page 168: Brkt

7-21 brkt e swivel bracket swivel bracket exploded diagram.

Page 169: Brkt

7-22 brkt e swivel bracket removal and installation chart step procedure/part name q’ty service points swivel bracket removal (manual tilt) follow the left “step” for removal. Upper case ass’y refer to “upper case removal”. Clamp bracket refer to “clamp bracket”. Steering bracket refer to “steering ...

Page 170: Brkt

7-23 brkt e swivel bracket disassembly swivel bracket disassembly exploded diagram.

Page 171: Brkt

7-24 brkt e swivel bracket disassembly removal and installation chart step procedure/part name q’ty service points swivel bracket removal (hydro tilt, power trim and tilt) follow the left “step” for removal. Upper case ass’y refer to “upper case removal”. Clamp bracket refer to “clamp bracket”. Stee...

Page 172: Brkt

7-25 brkt e tilt unit removal tilt unit removal exploded diagram.

Page 173: Brkt

7-26 brkt e tilt unit removal removal and installation chart step procedure/part name q’ty service points tilt unit removal follow the left “step” for removal. Tilt up 1 ptt motor lead 1 ptt model 2 band 3 ptt motor lead - trim sensor lead 3 bolt (with washer) 1 6 × 10 mm 4 wire lead 1 5 bolt (with ...

Page 174: Brkt

7-27 brkt e tilt cylinder, pump housing and motor removal tilt cylinder, pump housing and motor removal exploded diagram.

Page 175: Brkt

7-28 brkt e tilt cylinder, pump housing and motor removal removal and installation chart step procedure/part name q’ty service points tilt cylinder, pump hous- ing and motor removal follow the left “step” for removal. Power trim and tilt unit refer to “tilt unit removal”. 1 plug screw 1 drain hydrau...

Page 176: Brkt

7-29 brkt e tilt cylinder tilt cylinder exploded diagram.

Page 177: Brkt

7-30 brkt e tilt cylinder removal and installation chart step procedure/part name q’ty service points tilt cylinder disassembly follow the left “step” for removal. Tilt cylinder ass’y refer to “tilt cylinder, pump hous- ing and motor removal”. 1 tilt cylinder end screw 1 2 tilt cylinder 1 3 tilt rod...

Page 178: Brkt

7-31 brkt e tilt cylinder service points tilt cylinder disassembly 1. Loosen: ● tilt cylinder end screw tilt cylinder wrench: yb-06175-2b/90890-06544 inner cylinder disassembly 1. Loosen: ● inner cylinder end screw caution: vise the top of the inner cylinder with the tilt rod pulled out in its full ...

Page 179: Brkt

7-32 brkt e tilt cylinder inner cylinder assembly 1. Fill: ● atf (dexiron type 2) to inner cylinder. Note: depress the tilt rod fully and fill the inner cylinder with atf before installing the end screw. 2. Tighten: ● inner cylinder end screw tilt cylinder wrench: yb-06175-2b/90890-06544 tilt cylind...

Page 180: Brkt

7-33 brkt e pump housing pump housing exploded diagram.

Page 181: Brkt

7-34 brkt e pump housing removal and installation chart step procedure/part name q’ty service points pump housing disassembly follow the left “step” for removal. Pump housing ass’y refer to “tilt cylinder, pump hous- ing and motor removal”. 1 socket bolt 4 2 gear pump 1 3 o-ring 2 8.5 × 5.5 mm 4 bol...

Page 182: Brkt

7-35 brkt e ptt motor ptt motor exploded diagram.

Page 183: Brkt

7-36 brkt e ptt motor removal and installation chart step procedure/part name q’ty service points power trim and tilt motor disassembly follow the left “step” for removal. Power trim and tilt motor ass’y refer to “tilt cylinder, pump hous- ing and motor removal”. 1 screw 3 2 stator 1 3 armature ass’...

Page 184: Brkt

7-37 brkt e ptt motor service points motor inspection 1. Inspect: ● commutator dirty → clean with #600 abrasive paper. 2. Inspect: ● segment undercut clog → clean. Note: remove all particles of metal with com- pressed air. 3. Measure: ● commutator diameter out of specification → replace. Commutator ...

Page 185: Brkt

7-38 brkt e ptt motor 5. Inspect: ● circuit breaker discontinuity → replace. 6. Inspect: ● lead wire discontinuity → replace. 7. Measure: ● brush length a out of specification → replace. Brush length a: limit 3.5 mm (0.14 in) 8. Inspect: ● base crack/damage → replace. 9. Inspect: ● stator bushing ● ...

Page 186: Elec

E 1 2 3 4 5 6 7 8 9 – + elec chapter 8 electrical system electrical components ......................................................................... 8-1 oil injection model........................................................................... 8-1 mh, mho, mo, mdo model ........................

Page 187: Elec

E 1 2 3 4 5 6 7 8 9 – + elec starter motor ........................................................................................ 8-23 exploded diagram ........................................................................... 8-23 removal and installation chart .....................................

Page 188: Elec

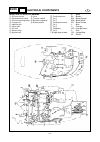

8-1 – + elec e electrical components electrical components oil injection model 1 electrothermal valve 2 oil level sensor l : blue b : black.

Page 189: Elec

8-2 – + elec e electrical components mh, mho, mo, mdo model 1 oil level sensor 2 warning lamp 3 charge coil 4 lighting coil 5 pulser coil 6 cdi unit 7 ignition coil 8 2p consent* 9 rectifier regulator* 0 thermo switch Å to engine stop switch ı to 6 Ç to 6 Î to 6 ‰ to 1 Ï to 2 Ì to 4 *: europe model ...

Page 190: Elec

8-3 – + elec e electrical components whd, wh, e, edo, eo model 1 oil level sensor 2 electrothermal valve 3 oil level warning lamp 4 charge coil 5 lighting coil 6 pulser coil 7 cdi unit 8 starter relay 9 ignition coil 0 fuse a thermo switch b rectifier regulator c starter motor b : black br : brown b...

Page 191: Elec

8-4 – + elec e electrical components et, eto model 1 p.T.T. Switch 2 oil level sensor 3 electrothermal valve 4 oil level warning lamp 5 charge coil 6 lighting coil 7 pulser coil 8 cdi unit 9 starter relay 0 p.T.T. Relay a ignition coil b fuse c thermo switch d rectifier regulator e starter motor Å t...

Page 192: Elec

8-5 – + elec e electrical components ehto model 1 main switch 2 main switch lead 3 engine stop switch lead 4 battery cable 5 extension wire harness 6 neutral switch b : black br : brown b/o : black/orange b/w : black/white b/y : black/yellow l : blue o : orange o/g : orange/green p : pink y/r : yell...

Page 193: Elec

8-6 – + elec e electrical unit components electrical unit components e, eo model 1 starter motor 2 rectifier regulator 3 ignition coil 4 fuse 5 starter relay a bracket b ground terminal b : black br : brown b/o : black/orange b/w : black/white b/y : black/yellow l : blue o : orange o/g : orange/gree...

Page 194: Elec

8-7 – + elec e electrical unit components et, eto model 1 starter motor 2 rectifier regulator 3 ignition coil 4 starter relay 5 p.T.T. Relay 6 fuse a bracket b ground terminal b : black br : brown b/o : black/orange b/w : black/white b/y : black/yellow l : blue o : orange o/g : orange/green p : pink...

Page 195: Elec

8-8 – + elec e electrical analysis electrical analysis inspection caution: all measuring instruments should be han- dled with special care, or the correct mea- surement is impossible. On an instrument powered by dry batter- ies, the latter should be checked for voltage periodically and replaced, if ...

Page 196: Elec

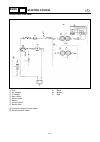

8-9 – + elec e ignition system ignition system 1 spark plug 2 ignition coil 3 charge coil 4 pulser coil 5 main switch 6 engine stop switch 7 10p coupler 8 7p coupler 9 cdi unit Å manual starter model ı electrical starter model br : brown l : blue w/r : white/red w/b : white/black w/g : white/green b...

Page 197: Elec

8-10 – + elec e ignition system ignition spark gap warning ● while checking the spark be careful not to touch any connection of lead wires of the “ignition spark gap tester”. ● when doing the spark test, take special care not to allow leakage from the plug cap which has been removed. ● this check is...

Page 198: Elec

8-11 – + elec e ignition system 1. Measure: ● cdi unit output (test #1) beyond specification → replace igni- tion coil. Below specification → measure charge coil output. Repeat checking two times. Cdi output: 125 v @ cranking 140 v @ 1,500 r/min 110 v @ 3,500 r/min measuring steps: ● disconnect the ...

Page 199: Elec

8-12 – + elec e ignition system 3. Measure: ● pulser coil output (test #3) beyond specification → replace cdi unit. Below specification → replace pulser coil. Spark plug refer to “general” in chapter 3. Pulser coil output: 3.0 v @ cranking 9.0 v @ 1,500 r/min 15.0 v @ 3,500 r/min measuring steps: ● ...

Page 200: Elec

8-13 – + elec e ignition system replacement steps: (except for canada and europe) ● remove the spark-plug cap by pulling the spark-plug cap. ● remove the plug-cap spring. ● strip the insulation cover 5 mm (0.2 in) a and spread the core wires outward. ● fit the plug-cap spring close to the spread cor...

Page 201: Elec

8-14 – + elec e ignition system main switch 1. Check: ● continuity out of specification → replace. Checking leads color switch position white black red yellow brown off on start.

Page 202: Elec

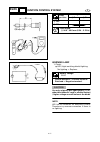

8-15 – + elec e ignition control system ignition control system 1 thermo switch 2 cdi unit 3 warning lamp 4 oil level sensor 5 oil level warning lamp 6 oil level sensor 7 meter Å pre-mixed model ı oil injection and warning lamp model Ç oil injection and oil level warning lamp model Î oil injection a...

Page 203: Elec

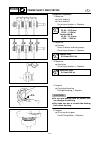

8-16 – + elec e ignition control system thermo switch 1. Measure: ● thermo switch continuity out of specification → replace. 1 discontinuity Å temperature 2 continuity ı time 3 discontinuity thermo switch continuity temperature: orange (o) — orange/green (o/g) a 38 ~ 52˚c (100.4 ~ 125.6˚f) b 26 ~ 34...

Page 204: Elec

8-17 – + elec e ignition control system float position checking leads color 1 p 2 b a off a on float length: a 56.8 ~ 59.8 mm (2.24 ~ 2.35 in) warning lamp 1. Check: ● led (light emitting diode) lighting no lighting → replace. Caution: use only originally pen light battery (1.5 v), other than batter...

Page 205: Elec

8-18 – + elec e ignition control system oil level warning lamp 1. Check: ● led (light emitting diode) lighting no lighting → replace. Caution: use only ordinally pen light battery (1.5 v), other than batteries such as alkaline battery / higher voltage one will be burnt the diode. Note: led has an di...

Page 206: Elec

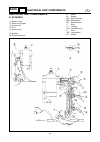

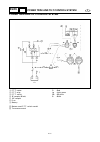

8-19 – + elec e starting system starting system 1 fuse 2 10p coupler 3 7p coupler 4 main switch 5 starter motor 6 battery 7 neutral switch 8 starter relay Å except for remote control model ı remote control model b : black br : brown r : red.

Page 207: Elec

8-20 – + elec e starting system battery refer to “general” in chapter 3. Wiring harness 1. Check: ● continuity discontinuity → replace. Wiring connection 1. Check: ● wiring connection poor connection → correct. Engine stop switch refer to “ignition system”. Main switch refer to “ignition system”. Ne...

Page 208: Elec

8-21 – + elec e starting system starter relay 1. Inspect: ● brown lead terminal ● black lead terminal loose → tighten. 2. Check: ● relay operation does not function → replace. Checking steps: ● connect the tester between the termi- nals of the starter relay as shown. ● connect a 12 v battery. Brown ...

Page 209: Elec

8-22 – + elec e starting system.

Page 210: Elec

8-23 – + elec e starter motor starter motor exploded diagram.

Page 211: Elec

8-24 – + elec e starter motor removal and installation chart step procedure/part name q’ty service points starter motor disassembly follow the left “step” for removal. Starter motor ass’y refer to “electrical unit removal” in chapter 5. 1 clip 1 2 pinion stopper 1 3 spring 1 4 pinion 1 5 through bol...

Page 212: Elec

8-25 – + elec e starter motor service points pinion removal 1. Remove: ● clip 1 note: using a pry-bar, pry off the clip. Pinion inspection 1. Inspect: ● pinion teeth wear/damage → replace. 2. Check: ● clutch movement damage → replace. Note: rotate the pinion clockwise, and check that it freely. Also...

Page 213: Elec

8-26 – + elec e starter motor 3. Check: ● commutator under cut clog/dirty → clean. Note: removal all particles of mica and metal by compressed air. 4. Measure: ● commutator under cut out of specification → replace. Commutator under cut: limit 0.2 mm (0.01 in) 5. Inspect: ● armature coil continuity o...

Page 214: Elec

8-27 – + elec e starter motor 2. Check: ● brush holder continuity out of specification → replace. Brush holder continuity: brush holder 1 - base 2 discontinuity cover inspection 1. Inspect: ● cover bushing wear/damage → replace the cover..

Page 215: Elec

8-28 – + elec e charging system charging system 1 rectifier regulator 2 lighting coil 3 battery 4 fuse g : green g/w : green/white r : red b : black.

Page 216: Elec

8-29 – + elec e charging system charging system peak voltage 1. Measure: ● rectifier regulator input below specification → lighting coil measurement. 2. Measure: ● lighting coil output beyond specification → replace recti- fier/regulator. Below specification → replace light- ing coil. Fuse refer to ...

Page 217: Elec

8-30 – + elec e enrichment control system enrichment control system 1 rectifier regulator 2 lighting coil 3 electrothermal valve g : green g/w : green/white l : blue b : black lighting coil refer to “charging system”. Electrothermal valve refer to “prime starter” in chap- ter 4. Rectifier regulator ...

Page 218: Elec

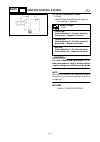

8-31 – + elec e power trim and tilt control system power trim and tilt control system 1 p.T.T. Motor 2 p.T.T. Relay 3 p.T.T. Switch 4 3p coupler (black) 5 10p coupler 6 fuse 7 battery Å bottom cowl p.T.T. Switch model ı to remote control r : red lg : light green sb : sky blue b : black.

Page 219: Elec

8-32 – + elec e power trim and tilt control system battery refer to “general” in chapter 3. Fuse refer to “starting system”. Ptt switch 1. Check: ● continuity out of specification → replace. Switch position checking leads color sky blue red light green up free dn ptt relay 1. Inspect: ● ptt relay co...

Page 220: Elec

8-33 – + elec e power trim and tilt control system ● connect the tester between the termi- nals of the ptt relay as shown. ● connect a 12 v battery. Sky blue (sb) lead → positive terminal black (b) → negative terminal ● check that there is continuity between the ptt relay terminals. Trim sensor 1. M...

Page 221: Trbl

E 1 2 3 4 5 6 7 8 9 trbl anls chapter 9 trouble-analysis trouble analysis ..................................................................................... 9-1 trouble analysis chart ................................................................. 9-1.

Page 222: Trbl

9-1 e trbl anls trouble analysis trouble analysis note: following items should be obtained before “trouble analysis”. 1. Battery is charged and its specified gravity is in specification. 2. There is no incorrect wiring connection. 3. Wiring connections are surely engaged and without any rust. 4. Lan...

Page 223: Trbl

9-2 e trbl anls trouble analysis lower unit neutral position 6 clutch 6 gear 6 water inlet 6 water pump 6 propeller shaft 6 shifter/pin 6 shift cam 6 shift shaft 6 lower case 6 bracket unit bracket 7 mount rubber 7 shift actuator 7 ptt unit fluid level 7 relief valve 7 fluid passage 7 ptt motor 7 pt...

Page 224

Yamaha motor corporation, usa printed in u.S.A. Printed on recycled paper.