Summary of 5KSJ

Page 2

Foreword this supplementary service manual has been prepared to introduce new service and data for the xvs1100a. For complete service information procedures it is necessary to use this supplementary service manual together with the following manual. Xvs1100l / xvs1100lc service manual: lit-11616-12-...

Page 3: Notice

Note: warning caution: eas00003 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manu- al. Therefore, anyone who uses this book to perform maintena...

Page 4: How To Use This Manual

1 2 6 3 5 4 7 8 eb002000 how to use this manual manual organization this manual consists of chapters for the main categories of subjects. (see “illustrated symbols”) 1st title 1 : this is the title of the chapter with its symbol in the upper right corner of each page. 2nd title 2 : this title indica...

Page 5: Gen

22 1 3 5 7 9 2 4 8 6 24 23 21 19 18 16 15 14 13 11 12 10 gen info spec eng carb elec chas chk adj trbl shtg 20 17 eb003000 illustrated symbols the following symbols are not relevant to every vehicle. Symbols 1 to 8 indicate the subject of each chapter. 1 general information 2 specifications 3 period...

Page 6: Contents

Contents specifications general specifications 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Maintenance specifications 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Engine 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

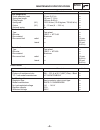

Page 7: Spec

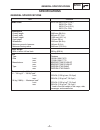

–1– general specifications spec specifications general specifications item standard model code xvs1100: 5ksj (for u.S.A.) 5ksk (for cal) 5ksu (for u.S.A.) 5ksv (for cal) dimensions overall length overall width overall height 2460 mm (96.9 in) 945 mm (37.2 in) 1,095 mm (43.1 in) seat height wheelbase...

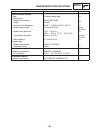

Page 8: Spec

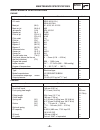

–2– maintenance specifications spec maintenance specifications engine item standard limit carburetor i.D. Mark main jet (m.J) main air jet (m.A.J) jet needle (j.N) needle jet (n.J) pilot air jet (p.A.J.1) (p.A.J.2) pilot outlet (p.O) pilot jet (p.J) bypass 1 (b.P.1) bypass 2 (b.P.2) bypass 3 (b.P.3)...

Page 9: Spec

–3– maintenance specifications spec item standard limit rear suspension shock absorber travel spring free length fitting length spring rate (k1) stroke (k1) optional spring 51 mm (2.01 in) 181 mm (7.13 in) 169 mm (6.65 in) 132.3 n / mm (13.49 kg / mm, 755.43 lb / in) 0 x 51 mm (0 x 2.01 in) no sss s...

Page 10: Spec

–4– maintenance specifications spec item standard limit electric starter system type starter motor: model / manufacturer output armature coil resistance brush overall length brush spring pressure commutator diameter mica undercut starter relay: model / manufacturer amperage rating constant mesh type...

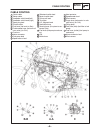

Page 11: Spec

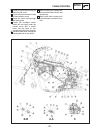

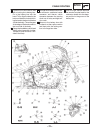

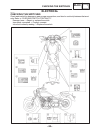

–5– cable routing spec 1 clutch cable 2 starter cable 3 handlebar switch lead (left) 4 handlebar switch lead (right) 5 spark plug lead 6 throttle cable 7 fuel hose (fuel cock to filter) 8 fuel breather hose (fuel tank roll over valve) (for cal) 9 fuse box 10 alarm connector 11 fuel pump lead 12 spee...

Page 12: Spec

–6– cable routing spec a fasten the handlebar switch lead (left and right) to the handle- bar with plastic locking tie and cut the end of tie. B lay out the throttle and starter cables in three rows and secure them with a clip. (two points at the front and rear.) care should be taken at this time so...

Page 13: Spec

–7– cable routing spec m fasten the lead with locking tie near the side cover. N position the all connectors inside of the connector cover. O route the clutch cable through the cable guide. P fasten the handlebar switch leads (left and right) under the handle crown with a plastic band. Set the band ...

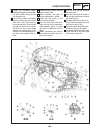

Page 14: Spec

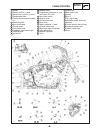

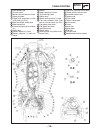

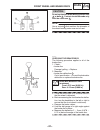

–8– cable routing spec 1 battery 2 battery positive (+) lead 3 starter motor positive (+) lead 4 speedometer lead 5 fuel hose (fuel pump to carbure- tor) 6 spark plug lead 7 main switch lead 8 throttle cable 9 front brake hose 10 handlebar switch lead (right) 11 headlight lead 12 ignition coil 13 br...

Page 15: Spec

–9– 36 rectifire / regulator and light (re- duce relay) lead cable routing spec a clamp the battery positive (+) lead to the battery with battery band. B connect the battery negative (–) lead and push it in to the space between battery box and battery. C push the wireharness into the space between f...

Page 16: Spec

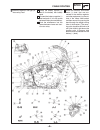

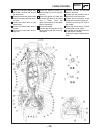

–10– o make sure to insert the rectifier regulator coupler sufficiently un- til the sound is heard. P to rear brake. Q fasten the rear brake switch lead with a band to down tube. (four point) r cutting part at the edge of the band. S 30 _ x 45_ cable routing spec j fasten the wire harness, starter m...

Page 17: Spec

–11– t fasten the oil level sensor lead with a locking tie to battery box. Fix to the battery box with the band. To fix, align the band to the bottom of the box’s hole while fix- ing the lead to the back of the box (inside the body). The cutting part at the edge of the band comes to the front side o...

Page 18: Spec

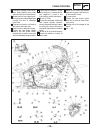

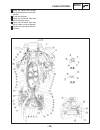

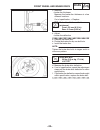

–12– 1 front brake hose 2 throttle cable 3 master cylinder reservoir hose 4 spark plug lead 5 purge hose (carburetor to sole- noid valve) (for cal) 6 rear brake light switch lead 7 rear brake hose 8 fuel hose (fuel pump to carbure- tor) 9 delay relay 10 battery negative (–) lead 11 battery negative ...

Page 19: Spec

–13– a clamp the throttle cables with the holder. Position the end of clip downword. B route the rear brake switch lead under the master cylinder reser- vor hose. C position the band end of right side bracket. D position the steel band end to forward. E position the steel band end to right side. Cab...

Page 20: Spec

–14– o route the igniter lead through the igniter plate hole to the wire- harness. P to the wire harness. Q clamp the tail / brake light lead with mud guard clamp. R clamp the tail / brake light lead with a holder on the mud guard. S position the locking tie upward. T forward. Cable routing spec.

Page 21: Chk

–15– introduction/periodic maintenance chart for the emission control system / general maintenance and lubrication chart chk adj eas00036 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these pre...

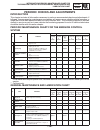

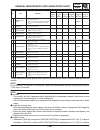

Page 22: Chk

–16– general maintenance and lubrication chart chk adj note: note: initial odometer readings no. Item remarks 600 mi (1,000 km) or 1 month 4,000mi (7,000 km) or 6 months 8,000 mi (13,000 km) or 12 months 12,000 mi (19,000 km) or 18 months 16,000 mi (25,000 km) or 24 months 20,000 mi (31,000 km) or 3...

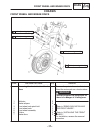

Page 23: Chas

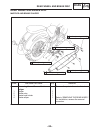

–17– order job name / part name q’ty remarks 1 2 3 4 5 6 7 removing the front wheel and brake discs reflector brake calipers front wheel axle pinch bolt front wheel axle front wheel assembly collars brake discs 2 2 1 1 1 2 2 remove the parts in the order listed. Stand the motorcycle on a level surfa...

Page 24: Chas

–18– front wheel and brake discs chas order job name / part name q’ty remarks disassembling the front wheel oil seals bearings collar 2 2 1 disassemble the parts in the order listed. For assembly, reverse the disassembly procedure. 1 2 3.

Page 25: Chas

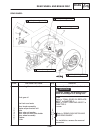

–19– front wheel and brake discs chas warning note: note: note: warning eas00521 removing the front wheel 1. Stand the motorcycle on a level surface. Securely support the motorcycle so that there is no danger of it falling over. Place the motorcycle on a suitable stand so that the front wheel is ele...

Page 26: Chas

–20– front wheel and brake discs chas warning note: 3. Measure: sfront wheel radial runout 1 sfront wheel lateral runout 2 over the specified limits ! Replace. Front wheel radial runout limit 1.0 mm (0.04 in) front wheel lateral runout limit 0.5 mm (0.02 in) 4. Check: scollars damage / wear ! Replac...

Page 27: Chas

–21– front wheel and brake discs chas caution: note: do not contact the wheel bearing center race 4 or balls 5 . Contact should be made only with the outer race 6 . Use a socket 3 that matches the diameter of the wheel bearing outer race and oil seal. Eas00531 checking the brake discs the following ...

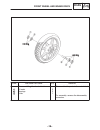

Page 28: Chas

–22– front wheel and brake discs chas note: 3. Measure: sbrake disc thickness measure the brake disc thickness at a few different locations. Out of specification ! Replace. Brake disc thickness limit (minimum) front: 4.5 mm (0.18 in) rear: 5.5 mm (0.22 in) 4. Adjust: sbrake disc deflection a. Remove...

Page 29: Chas

–23– front wheel and brake discs chas note: 59 nm (5.9 m skg, 29 ftslb) 20 nm (2.0 m skg, 14 ftslb) caution: 40 nm (4.0 m skg, 29 ftslb) warning eas00544 installing the front wheel the following procedure applies to both brake discs. 1. Lubricate: swheel axle soil seallips recommended lubricant lith...

Page 30: Chas

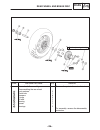

–24– order job name / part name q’ty remarks 1 2 3 4 removing the muffler and brake caliper muffler muffler stay brake hose holder brake caliper 1 1 1 1 remove the parts in the order listed. Refer to “removing the rear wheel”. For installation, reverse the removal procedure. 40 nm (4.0m skg, 29 ftsl...

Page 31: Chas

–25– order job name / part name q’ty remarks 1 2 3 4 5 6 7 removing the rear wheel final gear oil fuel tank and seats rear fender assembly brake caliper bracket bolt bolts rear axle nut / washer rear axle end nuts / axle holder rear wheel assembly washer collar 1 4 1 / 1 2 / 1 1 1 1 remove the parts...

Page 32: Chas

–26– rear wheel and brake disc chas order job name / part name q’ty remarks rear wheel disassembly disassembling the rear wheel lock washers clutch hub dampers o-rings oil seal bearing spacer bearings 2 1 6 2 1 1 1 2 remove the parts in the order listed. For assembly, reverse the disassembly procedu...

Page 33: Chas

–27– rear wheel and brake disc chas warning note: note: eas00562 removing the rear wheel 1. Stand the motorcycle on a level surface. Securely support the motorcycle so that there is no danger of it falling over. Place the motorcycle on a suitable stand so that the rear wheel is elevated. 2. Remove: ...

Page 34: Chas

–28– rear wheel and brake disc chas note: eas00567 checking the rear wheel drive hub 1. Check: srear wheel drive hub cracks / damage ! Replace. Srear wheel drive hub dampers damage / wear ! Replace. Eas00572 installing the rear wheel 1. Lubricate: sdrive shaft splines recommended lubricant molybdenu...

Page 35: Chas

–29– rear wheel and brake disc chas f. Tighten the rear axle holder with specified torque. Rear axle end nut 23 nm (2.3 m skg, 17 ftslb) g. Tighten the rear brake caliper bracket bolt with specified tightening torque. Brake caliper bracket bolt 40 nm (4.0 m skg, 29 ftslb) h. Install the rear brake c...

Page 36: Elec

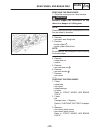

–30– checking the switches elec electrical eas00731 checking the switches check each switch for damage or wear, proper connections, and also for continuity between the termi- nals. Refer to “checking switch continuity”. Damage / wear ! Repair or replace the switch. Improperly connected ! Properly co...

Page 37: Elec

–31– checking the switches elec 7 engine stop switch 8 start switch 9 fuse 10 rear brake switch 11 sidestand switch 12 neutral switch 1 clutch switch 2 horn switch 3 dimmer switch 4 turn signal switch 5 main switch 6 front brake switch.

Page 38

Printed in u.S.A..

Page 39

Color code b black . . . . . . . . . Br brown . . . . . . . . Ch chocolate . . . . . . . Dg dark green . . . . . . . G green . . . . . . . . Gy gray . . . . . . . L blue . . . . . . . . . Lg light green . . . . . . . . O orange . . . . . . . . P pink . . . . . . . . . R red . . . . . . . . . Sb sky ...