- DL manuals

- Yamaha

- Outboard Motor

- 6c

- Owner's Manual

Yamaha 6c Owner's Manual

Summary of 6c

Page 1

Q q q q read this manual carefully before operating this outboard motor. Owner’s manual 6c 8c 6m8-f8199-2d-e0

Page 2

Emu25052 read this manual carefully before operating this outboard motor. Keep this manual onboard in a waterproof bag when boating. This manual should stay with the outboard motor if it is sold..

Page 3: Important Manual Information

Important manual information emu25105 to the owner thank you for choosing a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you ob- tain maximum enjoyment from your ...

Page 4: Table of Contents

Table of contents safety information............................. 1 outboard motor safety .................... 1 propeller............................................ 1 rotating parts.................................... 1 hot parts ........................................... 1 electric shock ..........

Page 5: Table of Contents

Table of contents starting engine ................................ 28 checks after starting engine ......... 30 cooling water .................................. 30 warming up engine ....................... 30 choke start models ......................... 30 checks after engine warm-up ....... 31 shif...

Page 6: Safety Information

1 safety information emu33622 outboard motor safety observe these precautions at all times. Emu36501 propeller people can be injured or killed if they come in contact with the propeller. The propeller can keep moving even when the motor is in neutral, and sharp edges of the propeller can cut even wh...

Page 7: Safety Information

Safety information 2 death when inhaled. Symptoms include nau- sea, dizziness, and drowsiness. Keep cock- pit and cabin areas well ventilated. Avoid blocking exhaust outlets. Emu33780 modifications do not attempt to modify this outboard mo- tor. Modifications to your outboard motor may reduce safety...

Page 8: Safety Information

Safety information 3 operate defensively at safe speeds and keep a safe distance away from people, ob- jects, and other boats. ● do not follow directly behind other boats or waterskiers. ● avoid sharp turns or other maneuvers that make it hard for others to avoid you or un- derstand where you are go...

Page 9: General Information

4 general information emu25171 identification numbers record emu25183 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare ...

Page 10: General Information

General information 5 1. C-tick label location 1 zmu02838 zmu01697.

Page 11: General Information

General information 6 emu33520 read manuals and labels before operating or working on this motor: ● read this manual. ● read any manuals supplied with the boat. ● read all labels on the outboard motor and the boat. If you need any additional information, contact your yamaha dealer. Emu33831 warning ...

Page 12: General Information

General information 7 emu33912 contents of labels the above warning labels mean as follows. 1 warning ewm01691 emergency starting does not have start- in-gear protection. Ensure shift control is in neutral before starting engine. 2 warning ewm01681 ● keep hands, hair, and clothing away from rotating...

Page 13: General Information

General information 8 emu35132 symbols the following symbols mean as follows. Notice/warning read owner’s manual hazard caused by continuous rotation electrical hazard zmu05696 zmu05664 zmu05665 zmu05666.

Page 14: Specifications

9 specifications and requirements emu31480 specifications tip: “(al)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Likewise, “(sus)” represents the value for stainless steel propeller installed and “(pl)” for plastic propeller installe...

Page 15: Installation Requirements

Specifications and requirements 10 recommended gear oil: hypoid gear oil sae#90 gear oil quantity: 0.160 l (0.169 us qt, 0.141 imp.Qt) tightening torque for engine: spark plug: 25.0 nm (2.55 kgf-m, 18.4 ft-lb) propeller nut: 17.0 nm (1.73 kgf-m, 12.5 ft-lb) emu33554 installation requirements emu3356...

Page 16: Start-In-Gear Protection

Specifications and requirements 11 emu25770 start-in-gear protection yamaha outboard motors or yamaha-ap- proved remote control units are equipped with start-in-gear protection device(s). This feature permits the engine to be started only when it is in neutral. Always select neutral before starting ...

Page 17: Motor Disposal Requirements

Specifications and requirements 12 rine growth as possible. If necessary, the boat bottom can be coated with an anti-foul- ing paint approved for your area to inhibit marine growth. Do not use anti-fouling paint which includes copper or graphite. These paints can cause more rapid engine corrosion. E...

Page 18: Manufactured:

Specifications and requirements 13 1. Manufactured date label location 1 zmu02838 manufactured: zmu04346.

Page 19: Components

14 components emu2579m components diagram tip: * may not be exactly as shown; also may not be included as standard equipment on all mod- els. 6c, 8c emu25802 fuel tank if your model was equipped with a portable fuel tank, its function is as follows. Warning ewm00020 the fuel tank supplied with this ...

Page 20: Components

Components 15 tions. Emu25830 fuel joint this joint is used to connect the fuel line. Emu25841 fuel gauge this gauge is located on either the fuel tank cap or on the fuel joint base. It shows the ap- proximate amount of fuel remaining in the tank. Emu25850 fuel tank cap this cap seals the fuel tank....

Page 21: Components

Components 16 emu25961 throttle indicator the fuel consumption curve on the throttle indicator shows the relative amount of fuel consumed for each throttle position. Choose the setting that offers the best performance and fuel economy for the desired operation. Emu25975 throttle friction adjuster a ...

Page 22: Components

Components 17 emu26001 engine stop button to open the ignition circuit and stop the en- gine, push this button. Emu26011 choke knob for pull type to supply the engine with the rich fuel mix- ture required to start, pull out this knob. Emu26070 manual starter handle to start the engine, first gently ...

Page 23: Components

Components 18 to increase resistance, turn the adjuster clockwise. To decrease resistance, turn the adjuster counterclockwise. Warning ewm00040 do not overtighten the friction adjuster. If there is too much resistance, it could be difficult to steer, which could result in an accident. Emu26261 trim ...

Page 24: Components

Components 19 lock lever(s) to the lock position. 1. Cowling lock lever(s) zmu02862 1.

Page 25: Installation

20 installation emu26902 installation the information presented in this section is intended as reference only. It is not possible to provide complete instructions for every possible boat and motor combination. Prop- er mounting depends in part on experience and the specific boat and motor combinatio...

Page 26: Installation

Installation 21 notice ecm01631 ● check that the idle hole stays high enough to keep out water getting inside engine even if the boat is in stationary with maximum load. ● incorrect engine height or obstructions to the smooth flow of water (such as the design or condition of the boat, or ac- cessori...

Page 27: Installation

Installation 22 3. Secure the clamp bracket to the transom using the bolts provided with the out- board (if packed). For details, consult your yamaha dealer. Warning! Avoid using bolts, nuts or washers other than those contained in the engine packaging. If used, they must be of at least the same qua...

Page 28: Operation

23 operation emu36381 first-time operation emu30174 breaking in engine your new engine requires a period of break- in to allow mating surfaces of moving parts to wear in evenly. Correct break-in will help en- sure proper performance and longer engine life. Notice: failure to follow the break-in proc...

Page 29: Operation

Operation 24 emu36570 remove cowling for the following checks, remove the top cowling from the engine. To remove the en- gine top cowling, release the lock lever and lift off the cowling. Emu36442 fuel system warning ewm00060 gasoline and its vapors are highly flam- mable and explosive. Keep away fr...

Page 30: Operation

Operation 25 the way around the top cowling. 3. Place the top cowling on bottom cowl- ing. 4. Check to be sure the rubber seal fits cor- rectly all the way around the engine. 5. Move the lever to lock the cowling as shown. Notice: if the cowling is not installed correctly, water spray under the cowl...

Page 31: Operation

Operation 26 3. Remove the portable tank from the boat. 4. Be sure you are in a well-ventilated out- door area, either securely moored or trailered. 5. Do not smoke and keep away from sparks, flames, static electric discharge, or other sources of ignition. 6. If you use a portable container to store...

Page 32: Operation

Operation 27 2. Replace the fuel tank cap and close tightly. 3. Shake the fuel tank to mix the fuel thor- oughly. 4. Make sure that the oil and gasoline are mixed. If equipped with a built-in fuel tank 1. Pour oil into a clean fuel can, and then add gasoline. 2. Replace the fuel can cap and close ti...

Page 33: Operation

Operation 28 connect the fuel line to the joint. Then firmly connect the other end of the fuel line to the joint on the fuel tank. Tip: wipe up any spilled gasoline immediately with dry rags. Dispose rags properly accord- ing to local laws or regulations. 3. Squeeze the primer pump, with the ar- row...

Page 34: Operation

Operation 29 1. Place the gear shift lever in neutral. Tip: the start-in-gear protection device prevents the engine from starting except when in neu- tral. 2. Attach the engine shut-off cord to a se- cure place on your clothing, or your arm or leg. Then install the clip on the other end of the cord ...

Page 35: Operation

Operation 30 6. After the engine starts, slowly return the manual starter handle to its original po- sition before releasing it. 7. Slowly return the throttle grip to the fully closed position. Tip: ● when the engine is cold, it needs to be warmed up. For further information, see page 30. ● if the e...

Page 36: Operation

Operation 31 shorten engine life. Gradually return the choke knob to its home position as the en- gine warms up. Emu36530 checks after engine warm-up emu36540 shifting while tightly moored, and without applying throttle, confirm that the engine shifts smoothly into forward and reverse, and back to n...

Page 37: Operation

Operation 32 emu31742 stopping boat warning ewm01510 ● do not use the reverse function to slow down or stop the boat as it could cause you to lose control, be ejected, or im- pact the steering wheel or other parts of the boat. This could increase the risk of serious injury. It could also damage the ...

Page 38: Operation

Operation 33 emu27862 trimming outboard motor warning ewm00740 excessive trim for the operating condi- tions (either trim up or trim down) can cause boat instability and can make steering the boat more difficult. This in- creases the possibility of an accident. If the boat begins to feel unstable or...

Page 39: Operation

Operation 34 3. Reposition the rod in the desired hole. To raise the bow (“trim-out”), move the rod away from the transom. To lower the bow (“trim-in”), move the rod to- ward the transom. Make test runs with the trim set to different angles to find the position that works best for your boat and oper...

Page 40: Operation

Operation 35 the bow is greatly increased, heightening the danger of “bow steering” and making opera- tion difficult and dangerous. Tip: depending on the type of boat, the outboard motor trim angle may have little effect on the trim of the boat when operating. Emu27934 tilting up and down if the eng...

Page 41: Operation

Operation 36 equipped). 5. Hold the rear of the top cowling with one hand and tilt the engine up fully. 6. Push the tilt support knob into the clamp bracket. Or the tilt support bar will turn to the lock position automatically. Notice: do not use the tilt support lever or knob when trailering the bo...

Page 42: Operation

Operation 37 emu28110 procedure 1. Place the gear shift lever in neutral. 2. Slightly tilt the outboard motor up. Pull up the shallow water lever. 3. The shallow water lever will lock, sup- porting the outboard motor in a partially raised position. 4. When lowering the outboard motor, slightly tilt ...

Page 43: Maintenance

38 maintenance emu28227 transporting and storing outboard motor warning ewm00693 ● use care when transporting fuel tank, whether in a boat or car. ● do not fill fuel container to maximum capacity. Gasoline will expand consid- erably as it warms up and can build up pressure in the fuel container. Thi...

Page 44: Maintenance

Maintenance 39 lowing procedures. Notice ecm01411 ● do not place the outboard motor on its side before the cooling water has drained from it completely, otherwise water may enter the cylinder through the exhaust port and cause engine trou- ble. ● store the outboard motor in a dry, well- ventilated p...

Page 45: Maintenance

Maintenance 40 stops. 11. Drain the cooling water completely out of the motor. Clean the body thoroughly. 12. If the “fogging oil” is not available, re- move the spark plug(s). Pour a tea- spoonful of clean engine oil into each cylinder. Crank several times manually. Replace the spark plug(s). 13. D...

Page 46: Maintenance

Maintenance 41 11. Drain the cooling water completely out of the motor. Clean the body thoroughly. 12. If the “fogging oil” is not available, re- move the spark plug(s). Pour a tea- spoonful of clean engine oil into each cylinder. Crank several times manually. Replace the spark plug(s). 13. Drain th...

Page 47: Maintenance

Maintenance 42 tems on models affixed with an emission control label may be performed by any marine engine repair establishment or in- dividual. All warranty repairs, however, including those to the emission control system, must be performed by an autho- rized yamaha marine dealership. Emu28511 repl...

Page 48: Maintenance

Maintenance 43 emu34445 maintenance chart 1 tip: ● refer to the sections in this chapter for explanations of each owner-specific action. ● the maintenance cycle on these charts assume usage of 100 hours per year and regular flushing of the cooling water passages. Maintenance frequency should be adju...

Page 49: Maintenance

Maintenance 44 fuel line(low pres- sure) inspection or replace- ment as necessary fuel pump inspection or replace- ment as necessary fuel/engine oil leakage inspection gear oil replacement greasing points greasing impeller/water pump housing inspection or replace- ment as necessary impeller/water pu...

Page 50: Maintenance

Maintenance 45 emu34451 maintenance chart 2 item actions every 1000 hours exhaust guide/exhaust manifold inspection or replace- ment as necessary.

Page 51: Maintenance

Maintenance 46 emu28941 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) 6c, 8c emu28956 cleaning and adjusting spark plug the spark plug is an important engine com- ponent and is easy to inspect. The condition of the spark plug can ...

Page 52: Maintenance

Maintenance 47 1. Remove the spark plug caps from the spark plugs. 2. Remove the spark plug. If electrode ero- sion becomes excessive, or if carbon and other deposits are excessive, you should replace the spark plug with an- other of the correct type. Warning! When removing or installing a spark plu...

Page 53: Maintenance

Maintenance 48 the outboard motor is in the water. A flushing attachment or test tank can be used. If the boat is not equipped with a tachometer for the outboard motor, use a diagnostic ta- chometer for this procedure. Results may vary depending on whether testing is con- ducted with the flushing at...

Page 54: Maintenance

Maintenance 49 ● check the propeller shaft oil seal for dam- age. Emu30662 removing propeller emu29197 spline models 1. Straighten the cotter pin and pull it out using a pair of pliers. 2. Remove the propeller nut, washer, and spacer (if equipped). Warning! Do not use your hand to hold the propel- l...

Page 55: Maintenance

Maintenance 50 fastened to the transom or a stable stand. You could be severely injured if the outboard motor falls on you. ● never get under the lower unit while it is tilted, even when the tilt support lever or knob is locked. Severe injury could occur if the outboard motor accidental- ly falls. 1...

Page 56: Maintenance

Maintenance 51 drain screw. Emu29302 cleaning fuel tank warning ewm00920 gasoline is highly flammable, and its va- pors are flammable and explosive. ● if you have any question about properly doing this procedure, consult your yamaha dealer. ● keep away from sparks, cigarettes, flames, or other sourc...

Page 57: Maintenance

Maintenance 52 zmu02881.

Page 58: Trouble Recovery

53 trouble recovery emu29427 troubleshooting a problem in the fuel, compression, or igni- tion systems can cause poor starting, loss of power, or other problems. This section de- scribes basic checks and possible remedies, and covers all yamaha outboard motors. Therefore some items may not apply to ...

Page 59: Trouble Recovery

Trouble recovery 54 q. Is fuel system obstructed? A. Check for pinched or kinked fuel line or other obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have servic...

Page 60: Trouble Recovery

Trouble recovery 55 q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine power loss. Q. Is propeller damaged? ...

Page 61: Trouble Recovery

Trouble recovery 56 q. Is fuel joint connection incorrect? A. Connect correctly. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding...

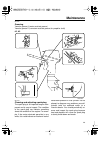

Page 62: Trouble Recovery

Trouble recovery 57 could result in an accident. ● attach the engine shut-off cord to a se- cure place on your clothing, or your arm or leg while operating the boat. ● do not attach the cord to clothing that could tear loose. Do not route the cord where it could become entangled, pre- venting it fro...

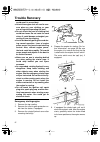

Page 63: Trouble Recovery

Trouble recovery 58 6. Insert the knotted end of the emergency starter rope into the notch in the flywheel rotor and wind the rope several turns around the flywheel clockwise. 7. Give a strong pull straight out to crank and start the engine. Repeat if neces- sary. Emu33501 treatment of submerged mot...

Page 64

Yamaha motor co., ltd. Printed in france april 2009–pdf × 1 !.