- DL manuals

- Yamaha

- Motorcycle

- DRAG STAR XVS1100A

- Owner's Manual

Yamaha DRAG STAR XVS1100A Owner's Manual

WARNINGS, CAUTIONS

AND NOTES

The terms WARNING, CAUTION and NOTE

have specific meanings in this manual.

A WARNING emphasizes areas where injury or

even death could result from negligence. Mechani-

cal damage may also occur. WARNINGS should be

taken seriously.

A CAUTION emphasizes areas where equipment

damage could result. Disregarding a CAUTION

could cause permanent mechanical damage, though

injury is unlikely.

A NOTE provides additional information to

make a step or procedure easier or clearer. Disre-

garding a NOTE could cause inconvenience but

would not cause equipment damage or personal

injury.

SAFETY

Professional mechanics can work for years and

never sustain a serious injury or mishap. Follow

these guidelines and practice common sense to

safely service the motorcycle.

1. Do not operate the vehicle in an enclosed area.

The exhaust gasses contain carbon monoxide, a poi-

sonous gas that is odorless, colorless, and tasteless.

Carbon monoxide levels build quickly in a small

enclosed area, and it can cause unconsciousness and

death in a short time. Make sure the work area is

properly ventilated or operate the vehicle outside.

2. Never use gasoline or any extremely flammable

liquid to clean parts. Refer to Cleaning Parts and

Handling Gasoline Safely in this section.

3. Never smoke or use a torch in the vicinity of

flammable liquids, such as gasoline or cleaning sol-

vent.

4. When welding or brazing on the motorcycle, re-

move the fuel tank, carburetor and shocks to a safe

distance at least 50 ft. (15 m) away.

5. Use the correct type and size tool to avoid dam-

aging fasteners.

6. Keep tools clean and in good condition. Replace

or repair worn or damaged equipment.

7. When loosening a tight fastener, be guided by

what would happen if the tool slips.

8. When replacing fasteners, make sure the new

fasteners are of the same size and strength as the

original ones.

9. Keep the work area clean and organized.

10. Wear eye protection any time the safety of your

eyes is in question. This includes procedures in-

volving drilling, grinding, hammering, compressed

air and chemicals.

11. Wear the correct clothing for the job. Tie up or

cover long hair so it cannot be caught in moving

equipment.

12. Do not carry sharp tools in clothing pockets.

13. Always have an approved fire extinguisher

available. Make sure it is rated for gasoline (Class

B) and electrical (Class C) fires.

14. Do not use compressed air to clean clothes, the

motorcycle or the work area. Debris may be blown

into your eyes or skin. Never direct compressed air

at yourself or someone else. Do not allow children

to use or play with any compressed air equipment.

15. When using compressed air to dry rotating

parts, hold the part so it can not rotate. Do not allow

the force of the air to spin the part. The air jet is ca-

pable of rotating parts at extreme speed. The part

may be damaged or disintegrate, causing serious

injury.

16. Do not inhale the dust created by brake pad and

clutch wear. In most cases, these particles contain

asbestos. In addition, some types of insulating ma-

terials and gaskets may contain asbestos. Inhaling

asbestos particles is hazardous to health.

17. Never work on the vehicle while someone is

working under it.

18. When placing the vehicle on a stand, make sure

it is secure before walking away.

Handling Gasoline Safely

Gasoline is a volatile, flammable liquid and is one

of the most dangerous items in the shop.

Because gasoline is used so often, many people

forget that it is hazardous. Only use gasoline as fuel

for gasoline internal combustion engines. When

working on a vehicle, remember that gasoline is al-

ways present in the fuel tank, fuel lines and carbure-

tors. To avoid a disastrous accident when working

around the fuel system, observe the following

precautions:

1. Never use gasoline to clean parts. See Cleaning

Parts in this section.

2. When working on the fuel system, work outside

or in a well-ventilated area.

2

CHAPTER ONE

Summary of DRAG STAR XVS1100A

Page 1

Warnings, cautions and notes the terms warning, caution and note have specific meanings in this manual. A warning emphasizes areas where injury or even death could result from negligence. Mechani- cal damage may also occur. Warnings should be taken seriously. A caution emphasizes areas where equipme...

Page 2

3. Do not add fuel to the fuel tank or service the fuel system while the vehicle is near open flames, around sparks or near someone who is smoking. Gasoline vapor is heavier than air; it collects in low areas and is more easily ignited than liquid gasoline. 4. Allow the engine to cool completely bef...

Page 3

Record these numbers in the quick reference data section at the front of the book. Have these numbers available when ordering parts. If neces- sary, use table 1 and table 2 to identify a particular motorcycle. Fasteners proper fastener selection and installation is im- portant to ensure that the veh...

Page 4

Warning do not install fasteners with a strength classification lower than what was originally installed by the manufacturer. Doing so may cause equipment failure and/or damage. Torque specifications the components of the motorcycle may be sub- jected to uneven stresses if the fasteners of the vari-...

Page 5

To use a cotter pin, first make sure the pin’s diam- eter is correct for the hole in the fastener. After cor- rectly tightening the fastener and aligning the holes, insert the cotter pin through the hole and bend the ends over the fastener (figure 7). Unless instructed to do so, never loosen a torqu...

Page 6

Most often required. Make sure to follow the manu- facturer’s recommendations for lubricant types. Engine oils generally, all liquid lubricants are called oil. They may be mineral-based (including petroleum bases), natural-based (vegetable and animal bases), synthetic-based, or emulsions (mixtures)....

Page 7

Brake fluid will damage plastic, painted or plated surfaces. Use extreme care when working with brake fluid. Immediately clean up any spills with soap and water. Rinse the area with plenty of clean water. Hydraulic brake systems require clean and mois- ture-free brake fluid. Never reuse brake fluid....

Page 8

Gasket remover aerosol gasket remover can help remove stub- born gaskets. This product can speed up the re- moval process and prevent damage to the mating surface that may be caused by a scraping tool. Most of these products are very caustic. Follow the gasket remover manufacturer’s instructions for...

Page 9

The number stamped on the wrench refers to the distance between the work areas. This must match the distance across two parallel flats on the bolt head or nut. The box-end wrench is an excellent tool because it grips the fastener on all sides. This reduces the chance of the tool slipping. The box-en...

Page 10

Warning do not use hand sockets with air or impact tools. They may shatter and cause injury. Always wear eye protec tion when using impact or air tools. Various handles are available for sockets. The speed handle is used for fast operation. Flexible ratchet heads in varying lengths allow the socket ...

Page 11

Specifications in this manual provide an indication of the range required. A torque wrench is a precision tool that must be properly cared for to remain accurate. Store torque wrenches in cases or separate padded drawers within a toolbox. Follow the manufacturer’s in- structions for their care and c...

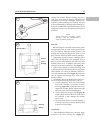

Page 12

General information 13 1 21 how to measure torque wrench effective length l l l l l + a = effective length l = effective length no calculation needed a a 22 23.

Page 13

Pliers. The sharp jaws will damage the objects they hold. Snap ring pliers snap ring pliers (figure 24) are specialized pliers with tips that fit into the ends of snap rings to re- move and install them. Snap ring pliers are available with a fixed action (either internal or external) or convertible ...

Page 14

Is easily felt. This feel for the equipment produces consistently accurate measurements and reduces the risk of damaging the tool or component. Refer to the following sections for a description of various measuring tools. Feeler gauge the feeler or thickness gauge (figure 26) is used for measuring t...

Page 15

Micrometers a micrometer is an instrument designed for linear measurement using the decimal divisions of the inch or meter (figure 29). While there are many types and styles of micrometers, most of the proce- dures in this manual call for an outside micrometer. The outside micrometer is used to meas...

Page 16

1. Read the upper half of the sleeve line and count the number of lines visible. Each upper line equals 1 mm. 2. See if the half-millimeter line is visible on the lower sleeve line. If so, add 0.50 to the reading in step 1. 3. Read the thimble mark that aligns with the sleeve line. Each thimble mark...

Page 17

Care micrometers are precision instruments. They must be used and maintained with great care. Note the following: 1. Store micrometers in protective cases or separate padded drawers in a toolbox. 2. When in storage, make sure the spindle and anvil faces do not contact each other or any other objects...

Page 18

Mounting bases: magnetic, clamp, or screw-in stud. When purchasing a dial indicator, select the mag- netic stand type (b, figure 36) with a continuous dial. Cylinder bore gauge a cylinder bore gauge is similar to a dial indica- tor. The gauge set shown in figure 37 consists of a dial indicator, hand...

Page 19

Electrical basics is necessary to perform simple diagnostic tests. Voltage voltage is the electrical potential or pressure in an electrical circuit and is expressed in volts. The more pressure (voltage) in a circuit, the more work can be performed. Direct current (dc) voltage means the electricity f...

Page 20

Starting the procedure. Perform each procedure in sequence. 10. Recommendations are occasionally made to re- fer service to a dealership or specialist. In these cases, the work can be performed more economi- cally by the specialist than by the home mechanic. 11. The term replace means to discard a d...

Page 21

Repairing damaged threads occasionally, threads are stripped through care- lessness or impact damage. Often the threads can be repaired by running a tap (for internal threads on nuts) or die (for external threads on bolts) through the threads (figure 42). To clean or repair spark plug threads, use a...

Page 22

Sulting from friction. Because bearings are preci- sion parts, they must be properly lubricated and maintained. If a bearing is damaged, replace it im- mediately. When installing a new bearing, take care to prevent damaging it. Bearing replacement proce- dures are included in the individual chapters...

Page 23

When installing a bearing onto a shaft, apply pres- sure to the inner bearing race (figure 48). 2. When installing a bearing as described in step 1, some type of driver is required. Never strike the bearing directly with a hammer or the bearing will be damaged. When installing a bearing, use a piece...

Page 24

2. Follow this step when installing a bearing in a housing. Bearings are generally installed in a hous- ing with a slight interference fit. Driving the bearing into the housing using normal methods may damage the housing or cause bearing damage. Instead, heat the housing before the bearing is instal...

Page 25

Seal replacement seals (figure 51) are used to contain oil, water, grease or combustion gasses in a housing or shaft. Improper removal of a seal can damage the housing or shaft. Improper installation of the seal can dam- age the seal. Note the following: 1. Prying is generally the easiest and most e...

Page 26

Riding time since the last service. Fill the engine with the recommended type of oil. 3. Drain all fuel from the fuel tank, run the engine until all the fuel is consumed from the lines and car- buretor. 4. Remove the spark plugs and pour a teaspoon of engine oil into the cylinders. Place a rag over ...

Page 27

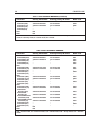

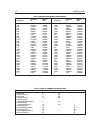

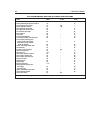

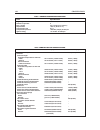

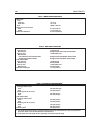

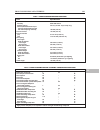

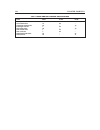

Table 1 xvs1100 serial numbers (continued) year/model starting vin number starting primary id number model code 2003 xvs1100r (usa) jyavp11e*3a034321 vp11e-0034321 5pbd xvs1100r c (ca) jyavp11y*3a004090 vp11y-0004090 5pbe xvs1100r (cdn) – – – xvs1100r (eur) – – – xvs1100r(aus) – – – 2004 n/a 2005 n/...

Page 28

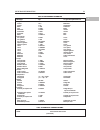

Table 3 model names and numbers model name model number usa, california and canada models v-star 1100 (1999 model) xvs1100 v-star 1100 custom (2000-on) xvs1100 v-star 1100 classic xvs1100a v-star 1100 silverado xvs1100a v-star 1100 classic cast wheel xvs1100a uk models xvs1100 drag star xvs1100 xvs1...

Page 29

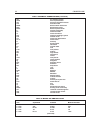

Table 6 decimal and metric equivalents decimal metric decimal metric fractions in. Mm fractions in. Mm 1/64 0.015625 0.39688 33/64 0.515625 13.09687 1/32 0.03125 0.79375 17/32 0.53125 13.49375 3/64 0.046875 1.19062 35/64 0.546875 13.89062 1/16 0.0625 1.58750 9/16 0.5625 14.28750 5/64 0.078125 1.9843...

Page 30

Table 8 conversion formulas multiply: by: to get the equivalent of: length inches 25.4 millimeter inches 2.54 centimeter miles 1.609 kilometer feet 0.3048 meter millimeter 0.03937 inches centimeter 0.3937 inches kilometer 0.6214 mile meter 0.0006214 mile fluid volume u.S. Quarts 0.9463 liters u.S. G...

Page 31

Table 9 technical abbreviations (continued) ais air induction system atdc after top dead center api american petroleum institute aus australia model bbdc before bottom dead center bdc bottom dead center btdc before top dead center c celsius (centigrade) ca california model cc cubic centimeters cdi c...

Page 32

Table 10 metric tap and drill size (continued) metric drill decimal size equivalent fraction nearest fraction 5 × 0.90 no. 20 0.161 5/32 6 × 1.00 no. 9 0.196 13/64 7 × 1.00 16/64 0.234 15/64 8 × 1.00 j 0.277 9/32 8 × 1.25 17/64 0.265 17/64 9 × 1.00 5/16 0.3125 5/16 9 × 1.25 5/16 0.3125 5/16 10 × 1.2...

Page 33

Chapter two troubleshooting begin any troubleshooting procedure by defining the symptoms as precisely as possible. Gather as much information as possible to aid diagnosis. Never assume anything and do not overlook the ob- vious. Make sure there is fuel in the tank, and the fuel valve is in the on po...

Page 34

Troubleshooting 35 2 four-stroke engine operating principles intake valve opens as piston begins downward, drawing air/fuel mixture into the cylinder through the valve. Compression intake intake valve closes and piston rises in cylinder, compressing air/fuel mixture. Exhaust power spark plug ignites...

Page 35

C. The engine can start when the sidestand is up and the transmission is in neutral. D. If the sidestand is up, the engine will also start if the transmission is in gear and the clutch le- ver is pulled in. 2. Before starting the engine, shift the transmission into neutral and make sure the engine s...

Page 36

If you smell gasoline after attempting to start the engine, the engine is probably flooded. To start a flooded engine: 1. Move the choke lever (figure 3) to the fully off position. 2. Turn the engine stop switch to the run position (a, figure 2). 3. Open the throttle completely and press the starter...

Page 37

Warning make sure the spark plug is away from the spark plug hole in the cylin der so the spark cannot ignite the mix ture in that cylinder. If the engine is flooded, do not perform this test. The firing of the spark plug can ignite fuel ejected from the opened spark plug hole. Warning during the ne...

Page 38

5. If the spark is good, check the following: a. Try starting the engine by following normal starting procedures. If the engine does not start, go to step 6. B. If the engine starts but then stops, check for an inoperative choke, incorrect carburetor ad- justment, leaking intake manifolds, improper ...

Page 39

A. Incorrect ignition timing due to a malfunc- tioning ignition component. B. Improperly adjusted valves or worn valve seats. C. Low engine compression. D. Clogged carburetor jet(s). E. Fouled spark plugs. F. Incorrect spark plug heat range. G. Oil level too low or too high. H. Contaminated oil. I. ...

Page 40

2. Carburetor adjustment incorrect; mixture too rich. 3. Choke not operating correctly. 4. Contaminants in the fuel. 5. Clogged fuel line. 6. Spark plugs fouled. 7. Ignition coil defective. 8. Ignitor unit or pickup coil defective 9. Loose or defective ignition circuit wire. 10. Short circuit from d...

Page 41

Engine lubrication an improperly operating engine lubrication sys- tem will quickly lead to engine seizure. Check the engine oil level before each ride, and top off the oil as described in chapter three. Oil pump service is described in chapter five. Oil consumption high or engine smokes excessively...

Page 42

Engine leakdown test perform an engine leakdown test to pinpoint en- gine problems caused by compression leaks. While a compression test (chapter three) can identify a weak cylinder, a leakdown test can determine where the leak occurs. A cylinder leakdown test is made by applying compressed air thro...

Page 43

Clutch slips if the engine speed increases without an increase in motorcycle speed, the clutch is probably slipping. Some main causes of clutch slipping are: 1. Incorrect clutch cable adjustment. 2. Weak clutch springs. 3. Worn clutch or friction plates. 4. Damaged pressure plate. 5. Clutch release ...

Page 44

5. Bent or damaged shift fork. 6. Worn gear dogs or slots. 7. Damaged shift drum grooves. Jumps out of gear 1. Loose or damaged shift drum stopper arm. 2. Bent or damaged shift fork(s). 3. Bent shift fork shaft(s). 4. Damaged shift drum grooves. 5. Worn gear dogs or slots. 6. Broken shift linkage re...

Page 45

7. Incorrect air/fuel mixture. 8. Plugged carburetor jets. 9. Partially plugged fuel tank breather hose. 10. Faulty fuel pump. 11. Faulty starting circuit cutoff relay. Incorrect fast idle speed a fast idle speed can be due to one of the follow- ing problems: 1. Idle adjust screw incorrectly set. 2....

Page 46

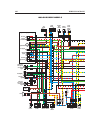

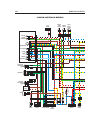

Shooting procedures listed below. Refer to the wir- ing diagram at the end of this book. Perform the troubleshooting test procedures in the listed sequence. Each test presumes the compo- nents tested in the earlier steps are working prop- erly. The tests can yield invalid results if they are perform...

Page 47

6. Check all electrical wires where they join with the individual metal terminals in both the male and female connectors. Note dielectric grease is special grease that can be used on electrical compo nents such as connectors and battery connections. Dielectric grease can be purchased at automotive p...

Page 48

3. Select two points within the circuit where there should be continuity. 4. Attach one lead of the self-powered test light to each point. 5. If there is continuity, the self-powered test light bulb will turn on. 6. If there is no continuity, the self-powered test light bulb will not come on indicat...

Page 49

Nection to ground is good so the problem is between the lamp and the power source. To isolate the problem, connect the jumper be- tween the battery and the lamp (b, figure 13). If it comes on, the problem is between these two points. Next, connect the jumper between the battery and the fuse side of ...

Page 50

4. The voltmeter should indicate 0 volts. If there is a drop of 1 volt or more, there is a problem within the circuit. A voltage drop reading of 12 volts indi- cates an open in the circuit. Continuity test a continuity test is used to determine the integrity of a circuit, wire or component. A circui...

Page 51

Is good, the cause must be in the wiring used only by the suspect circuit. If all related circuits are faulty at the same time, the probable cause is a poor ground connection or a blown fuse(s). As with all troubleshooting, analyze typical symptoms in a systematic manner. Never assume anything, and ...

Page 52

4. Test the starting circuit cutoff relay (sccr) by performing the continuity test described in chapter nine. 5. Test the starting system diode by performing the sccr diode test described in chapter nine. 6. Test the continuity of the starter relay (chapter nine). 7. Check the continuity of the main...

Page 53

A turn signal light and/or turn signal indicator fails to flash 1. Check the continuity of the affected turn signal bulb and socket. 2. Check the continuity of the bulb and socket for the turn signal indicator light. 3. Check the continuity of the turn signal switch (chapter nine). 4. Perform the tu...

Page 54

Soft suspension (front fork) 1. Insufficient tire pressure. 2. Insufficient fork oil level or fluid capacity. 3. Incorrect oil viscosity. 4. Weak or damaged fork springs. Soft suspension (rear shock absorbers) 1. Insufficient rear tire pressure. 2. Weak or damaged shock absorber spring. 3. Damaged s...

Page 55

Chapter three lubrication, maintenance and tune-up this chapter describes lubrication, maintenance and tune-up procedures. Minor problems found during periodic inspec- tions are generally simple and inexpensive to cor- rect. However, they could lead to major problems if not corrected promptly. Befor...

Page 56

For convenience, most of the procedures listed in table 1 are described in this chapter. Procedures that require more than minor disassembly or adjust- ment are covered in the appropriate chapter in the manual. Refer to the table of contents or index to locate a particular procedure. Cylinder number...

Page 57

5. Wipe the interior of the air filter housing with a shop rag dampened with cleaning solvent. Remove any debris that may have passed through a broken element. 6. Inspect the air filter element for tears or other damage that would allow unfiltered air to pass into the engine. Also check the element ...

Page 58

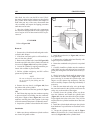

2. Remove the spark plugs as described in this chapter. 3. Insert each spark plug into its spark plug cap, and ground the spark plug against the cylinder head (figure 7). 4. Turn the compression gauge into one cylinder following the manufacturer’s instructions (figure 8). Make sure the gauge is prop...

Page 59

8. Shut off the engine, and disconnect the timing light and portable tachometer. Install the timing in- spection cover (a, figure 9). Valve clearance valve clearance measurement and adjustment must be performed with the engine at room temper- ature (below 35° c [95° f]). The exhaust valve is located...

Page 60

Note a cylinder at tdc on the compression stroke has free play in both rocker arms, which indicates that both valves are closed. 9. Make sure the cylinder is at tdc by pressing each rocker arm. The intake and exhaust rocker arms should have free play. If both rocker arms do not have free play, rotat...

Page 61

13. Perform steps 10 and 11 to check and adjust each valve in the front cylinder. 14. When the clearance of each valve is within specification, reinstall the removed parts by revers- ing the removal procedure. Note the following: a. Before installing the front-cylinder cam sprocket cover, install a ...

Page 62

Caution do not clean the spark plugs with a sand blasting device. This type of cleaning may leave abrasive material on the plug, which can enter the cylin der and cause damage. 6. Inspect the spark plug carefully. Look for a plug with broken center porcelain, excessively eroded electrodes, and exces...

Page 63

The spark plug post. If the cap does not completely contact the plug, the en gine may falter and cut out at high en gine speeds. 6. Install each plug cap onto the correct spark plug. Press the cap onto the spark plug and rotate the as- sembly slightly in both directions. Make sure it is attached to ...

Page 64

Carbon fouled soft, dry, sooty deposits covering the entire firing end of the plug are evidence of incomplete combus- tion. Even though the firing end of the plug is dry, the deposits decrease the plug’s insulation. The car- bon forms an electrical path that bypasses the elec- trodes resulting in a ...

Page 65

Blistered porcelain insulator surface. This condition is commonly caused by a spark plug with a heat range that is too hot. If the spark plug heat range is correct, consider the following causes: 1. Lean air/fuel mixture. 2. Improperly operating ignition component. 3. Engine lubrication system malfu...

Page 66

Oils are designed specifically for au tomotive applications. The additives added to these oils may cause engine and/or clutch damage in motorcycle applications. Note never dispose of engine oil in the trash, on the ground or down a storm drain. Many service stations and oil retailers accept used oil...

Page 67

In the hole with the small o-ring. See a, fig- ure 30 and b, figure 28. Torque the oil filter outer cover bolts to 10 n•m (89 in.-lb.). 9. Remove the oil filler cap (d, figure 9) and in- sert a funnel into the oil filler hole. Fill the crank- case with the correct weight and quantity of oil (table 4...

Page 68

4. Attach a portable tachometer to the no. 2 cylin- der (front cylinder) spark plug lead following the manufacturer’s instructions. 5. Remove the plug (figure 33) from the vacuum fitting on each cylinder’s intake manifold. On mod- els with an ais system, remove the ais hose (fig- ure 34) from the va...

Page 69

6. Rev the engine a couple of times to see if it set- tles down to the set speed. Readjust as necessary. 7. Shut off the engine and disconnect the portable tachometer. Throttle cable adjustment always check the throttle cables before making any carburetor adjustments. Too much free play causes delay...

Page 70

Routed incorrectly or there is insufficient cable free play. Make the necessary corrections. Control cables lubricate and adjust the control cables at the in- tervals specified in table 1. When lubricating a ca- ble, also inspect it for fraying and check the cable sheath for chafing. Cables can be l...

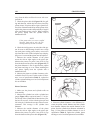

Page 71

4. Attach a cable lubricator to the cable following the manufacturer’s instructions. 5. Insert the nozzle of the lubricant can into the lu- bricator (figure 40), press the button on the can and hold it down until the lubricant begins to flow out of the other end of the cable. Note place a shop cloth...

Page 72

1. Securely support the motorcycle on a level sur- face. 2. Operate the sidestand, and check its movement and spring tension. Replace the spring if it is weak or damaged. 3. Lubricate the sidestand pivot surfaces with lith- ium soap grease. 4. Check the sidestand switch operation as follows: a. Park...

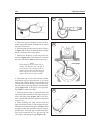

Page 73

Removal/installation 1. Securely support the motorcycle on a level sur- face. 2. Remove the battery cover as described in chap- ter fourteen. 3. Disconnect the negative cable (a, figure 46) from the battery. 4. Pull back the boot and disconnect the positive cable (b, figure 46). 5. Remove the batter...

Page 74

Charging a digital voltmeter and a charger with an adjust- able amperage output are required when charging a maintenance free battery. If this equipment is not available, have the battery charged by a shop with the proper equipment. Excessive voltage and am- perage from an unregulated charger can da...

Page 75

10. Install the battery into the motorcycle as de- scribed in this chapter. New battery initialization always replace a maintenance free battery with another maintenance free battery. Also make sure the battery is charged completely before installing it. Failure to do so will reduce the life of the ...

Page 76

Runout (side-to-side movement) or radial runout (up-and-down movement) exceeds the specifica- tion in table 5, remeasure both axial and radial run- out (figure 49) as described in chapter ten. Front suspension fork oil change yamaha does not provide an oil change interval for the front fork. Nonethe...

Page 77

2. The front fork makes a clicking or clunking noise when the front brake is applied. 3. The steering feels tight or slow. 4. The motorcycle does not want to steer straight on level road surfaces. Inspection 1. Securely support the motorcycle so that the front tire clears the ground. 2. Check the be...

Page 78

Ter twelve for correct tightening pro cedures and torque specifications. Shock absorber spring preload adjustment caution never turn the cam ring beyond the maximum or minimum position. The spring preload can be adjusted to seven dif- ferent positions to suit riding, load and speed condi- tions. The...

Page 79

Brakes brake hoses and seals replace the brake hoses and piston seals every two years. Check the brake hoses between the master cylin- der and each brake caliper. If there is any leak, tighten the connections and bleed the brakes as de- scribed in chapter thirteen. If this does not stop the leak or ...

Page 80

5. Add brake fluid from a sealed brake fluid con- tainer. 6. Reinstall the diaphragm, diaphragm plate and the top cover. Brake pad inspection inspect the brake pads for excessive or uneven wear, scoring and oil or grease on the friction sur- face. 1. Securely support the motorcycle on level ground. ...

Page 81

Clockwise to raise the brake pedal and coun- terclockwise to lower it. B. Tighten the locknut to 16 n•m (12 ft.-lb.). C. Check the end of the brake pushrod. It must be visible through the hole (c, figure 64) in the clevis. 4. After adjusting the brake pedal height, make sure the rear brake does not ...

Page 82

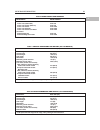

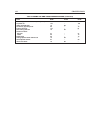

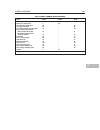

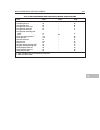

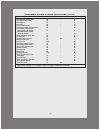

Table 1 maintenance schedule* (continued) 4000 miles (7000 km) or 7 months check the valve clearance; adjust as necessary check the condition of the spark plugs; clean and adjust the gap as necessary check the crankcase ventilation hose for cracks or damage; replace as necessary check the fuel lines...

Page 83

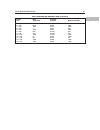

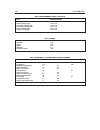

Table 2 tire specifications xvs1100 models front tire size 110/90-18 61s manufacturer bridgestone exedra l309, dunlop k555f rear tire size 170/80-15m/c 77s manufacturer usa, california and canada models bridgestone exedra g546g, dunlop k555 europe and australia models bridgestone exedra g546, dunlop...

Page 84

Table 4 recommended lubricants and fluids (continued) engine oil api classification se, sf or sg viscosity 5° c (40° f) or above sae 20w40 15° c (60° f) or below sae 10w30 capacity oil change only 3.0 l (3.2 u.S. Qt. [2.6 imp. Qt.]) oil and filter change 3.1 l (3.3 u.S. Qt. [2.7 imp. Qt.]) when engi...

Page 85

Table 6 maintenance and tune up torque specifications item n•m in.-lb. Ft.-lb. Air filter cover bolts 10 89 – brake pedal height adjuster locknut 16 – 12 cam sprocket cover bolts 10 89 – clutch adjuster locknut 12 106 – final gearcase drain bolt 23 – 17 final gearcase oil filler bolt 23 – 17 fork bo...

Page 86

Chapter four engine top end this chapter provides complete service and over- haul procedures for the engine top end components. This includes the camshafts, valves, cylinder heads, pistons, piston rings and the cylinder blocks. Refer to chapter three for valve adjustment procedures. Refer to basic s...

Page 87

During removal so it can be easily identified and in- stalled on the correct cylinder during assembly. Removal/installation 1. Securely support the motorcycle on level ground. 2. Remove the fuel tank, air filter housing, and surge tank and carburetor assembly as described in chapter eight. 3. The sm...

Page 88

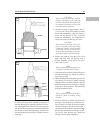

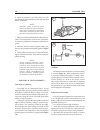

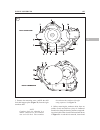

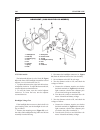

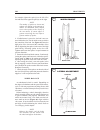

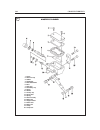

Engine top end 89 4 1. Cylinder head nut 2. Cylinder head cover bracket 3. Cylinder head cap nut 4. Washer 5. Cylinder bolt 6. Valve cover bolt 7. Intake valve cover 8. O-ring 9. Intake manifold 10. Intake manifold bolt 11. Dowel 3 12. Gasket 13. Rear cylinder head 14. Exhaust valve cover 15. Exhaus...

Page 89

90 chapter four 13. Front cylinder head 14. Cam sprocket 15. Cam sprocket plate 16. Washer 17. Cam sprocket bolt 18. Breather plate 19. O-ring 20. Cam sprocket cover 21. Cam sprocket cover bolt 22. Gasket 23. Dowel 4 1. Cylinder head cap nut 2. Washer 3. Cylinder head nut 4. Cylinder head cover brac...

Page 90

Mark. Take a photograph or make a drawing so you can correctly time the camshaft during assembly. 8a. When servicing the rear cylinder, set it to top dead center on the compression stroke as follows: a. Use the flywheel nut to turn the crankshaft clockwise until the t-mark on the flywheel (a, figure...

Page 91

9) on the flywheel aligns with the alternator cover cutout (b). B. Rotate the crankshaft another 290° clockwise until the i-mark on the flywheel (a, figure 11) aligns with the cutout in the alternator cover (b). C. Make sure the timing mark on the front cam sprocket plate (a, figure 12) aligns with ...

Page 92

Sprocket on the cam chain drive as sembly. If the chain is not held taut, the chain may become kinked, and cause damage to the crankcase, the cam chain, or cam chain drive assembly. 15. Tie a safety wire around the cam chain and se- cure the wire to the engine so the chain will not fall into the cra...

Page 93

24. If necessary, remove the intake manifold and its o-ring from the cylinder head. Note an exhaust manifold is not used on the front cylinder. 25. If necessary, remove the two manifold nuts (a, figure 19) and remove the exhaust manifold (b) from the rear cylinder. Also remove and discard the exhaus...

Page 94

Could be damaged if it is not tightened properly. 11. Following the tightening sequence shown in figure 15, torque the fasteners in 1/2 turn incre- ments and in two stages to the specifications. Torque the fasteners to 1/2 the given torque, then torque them to their final specifications: a. Cylinder...

Page 95

Cam chain tensioner hole and tension the chain. The timing mark on the cam sprocket (b, figure 14) should align with the pointer on the cylinder head (c) as noted during removal. 19. If the timing marks do not align, remove the sprocket. Use a screwdriver to walk the cam chain one way or the other a...

Page 96

25. Install the valve covers (figure 5) onto the cyl- inder head. Lubricate the new o-ring with lithium soap grease, and torque the valve cover bolts to 10 n•m (89 in.-lb.). 26. If the intake manifold was removed, install it. Lubricate a new o-ring with lithium soap grease, and torque the intake man...

Page 97

Use a spark plug thread tap (figure 30) to clean the threads. If the damage is severe, restore the threads by installing a steel thread insert. Thread insert kits can be purchased at automotive supply stores or they can be installed at a yamaha dealership. 5. After all carbon is removed from the com...

Page 98

Sprocket on the cam chain drive as sembly. 14. Check the sliding surfaces (b, figure 20) of the front cam chain guide and the rear chain guide (the bolted guide) for wear or damage. Replace the chain guide(s) as necessary. 15. If the exhaust manifold was removed, install it onto the rear cylinder. I...

Page 99

Bushing is severely worn, inspect the bushing bore in the cylinder head. The surface should be smooth with no visible marks. Replace the cylinder head if this surface is worn. 3. Visually inspect the camshaft bearing journals (a, figure 38) for wear and scoring. Replace as necessary. 4. Check the ca...

Page 100

Measure the cam lobe height (figure 41) and width (figure 42) with a micrometer. Replace the cam- shaft if a lobe is worn beyond the service limits specified in table 2. 6. Measure the camshaft runout with a dial indica- tor and v-blocks. Replace the camshaft if the runout exceeds the service limit....

Page 101

Shaft outside diameter from the bushing inside diameter. If the clearance is outside the range speci- fied in table 2, compare the camshaft journal out- side diameter and bushing inside diameter measurements to the specifications. Replace the camshaft and/or bushing, whichever is out of specificatio...

Page 102

7. Inspect the rocker arms and shafts as described in this section. Installation note each rocker arm and shaft have be come mated through wear. Unless a part is being replaced, install each rocker arm with its original shaft, and install them in their original locations (intake or exhaust side) in ...

Page 103

Pad is worn or damaged, also inspect the cam lobe for scoring, chipping or flat spots. 3. Inspect the valve adjuster (b, figure 51) where it rides on the valve stem. Replace the adjuster if it is scratched, pitted or shows signs of blue discolor- ation. 4. Measure the inside diameter of the rocker a...

Page 104

Tion. The cam chain drive assembly cannot be properly timed unless the flywheel is removed. Remove the fly wheel now in order to study the align ment of the timing marks. 3. Set the rear cylinder to top dead center on the compression stroke and remove the flywheel as de- scribed in chapter five. Not...

Page 105

B. Use a screwdriver or similar tool to pry the drive teeth on the gear until one set of teeth aligns with the other. C. Insert the 6-mm pin (figure 58) into the aligned hole to lock the gear. 3. Position the timing gear so the side with the 2 stamp faces the outboard side of the engine. Seat the ca...

Page 106

Removal (front cylinder) refer to figure 66 when performing this proce- dure. 1. Remove the front cylinder head as described in this chapter. 2. Remove the front chain guide by lifting it from its seat in the crankcase and pulling it from the cam chain tunnel in the cylinder. Note note that the timi...

Page 107

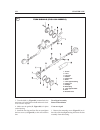

108 chapter four front 1. Rear chain guide 2. Chain guide bolt 3. Cam chain drive assembly 4. Cam chain 5. Front chain guide 6. Retainer bolt 7. Shaft retainer 8. Drive assembly shaft 66 9. Woodruff key 10. Primary drive nut 11. Lockwasher 12. Keyed washer 13. Timing gear 14. Pin 15. Spring 16. Prim...

Page 108

Cam chain drive assembly is installed in the correct cylinder. 2. Preload the cam chain drive assembly as follows: a. Cut a 6 × 15 mm pin from the shoulder (non-threaded portion) of a 6-mm bolt. B. Use a screwdriver or similar tool to pry the drive teeth on the gear until one set of teeth aligns wit...

Page 109

A. Remove the mounting bolts (figure 72) from the bracket, and pull the assembly from the crankcase. B. Fit the new cam chain assembly into place. Install the mounting bolts and torque them to 10 n•m (89 in.-lb.). 5. Replace any part that is worn or damaged. Valves and valve components complete valv...

Page 110

2. Perform the cylinder head leak test described in cylinder head in this chapter. 3. Remove the camshaft and rocker arms as de- scribed in this chapter. Note a bore protector can be made from a plastic 35 mm film canister (figure 74). Cut out the bottom of the canister and part of its side. Cut awa...

Page 111

Or into separate small boxes. Label the set so you will know what cylinder it came from and whether it is an in take or an exhaust valve. This keeps parts from getting mixed up and makes installation simpler. Do not mix components from different valve assemblies or excessive wear may occur. 13. Repe...

Page 112

Caution to avoid loss of spring tension, do not compress the springs any more than necessary to install the valve keepers. 9. Compress the valve springs with a valve spring compressor and install the valve keepers (figure 76). 10. When both valve keepers are seated around the valve stem, slowly rele...

Page 113

The valve guide if any measurement is outside the specified range. 7. Subtract the valve stem outside diameter (step 4) from the valve guide inside diameter (step 6). The difference is the valve stem-to-guide clearance. If the clearance exceeds the service limit, replace the valve and valve guide. N...

Page 114

1. 8 mm (0.31 in.) valve guide remover (ym-01200 or 90890-01211). 2. 8 mm (0.31 in.) valve guide installer (ym-01200 or 90890-01200). 3. 8 mm (0.31 in.) valve guide reamer (ym-01201 or 90890-04013). Procedure note the valve guide contracts when it is cooled, which reduces the overall di ameter of th...

Page 115

7. Remove and discard the valve guide and circlip. Never reinstall a valve guide or circlip. They are no longer true and are not within tolerance. 8. After the cylinder head cools, check the guide bore for carbon or other contamination. Clean the bore thoroughly. 9. Reheat the cylinder head as descr...

Page 116

18. Reface the valve seats as described in this chap- ter. 19. Install the intake manifold. Use new o-rings, and torque the intake manifold bolts to 10 n•m (89 in.-lb.). 20. When servicing a rear cylinder head, install the exhaust manifold with a new exhaust gasket. Torque the exhaust manifold nuts ...

Page 117

Ing the cylinder head and taking it to a yamaha deal- ership or machine shop to have the valve seats ground. The following procedure is provided if you choose to perform this task yourself. A valve seat cutter set (consisting of 30°, 45° and 60° cutters and the appropriate handle) is needed. These t...

Page 118

And then use the 45° cutter to center the contact area. 8. If the contact area is too narrow and down away from the valve head (figure 105), first use the 60° cutter and then use the 45° cutter to center the con- tact area. 9. After the desired valve seat position and width is obtained, use the 45° ...

Page 119

Inder head, the valve seat should be tested. Check the seat by performing the leakage test described in the cylinder head section earlier in this chapter. If fluid leaks past any of the seats, disassemble that valve assembly and repeat the lapping procedure until there are no leaks. 7. After the cyl...

Page 120

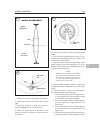

Engine top end 121 4 1. Cylinder bolt 2. Cylinder 3. Compression ring 4 oil ring 5. Piston pin circlip 6. Piston 7. Base gasket 8. Dowel 9. Front cam chain guide 10. Piston pin 108.

Page 121

12. Follow the break-in procedure in chapter five if the cylinder block was rebored or honed, or if a new piston or piston rings were installed. Inspection the following procedure requires the use of highly specialized and costly measuring instru- ments. If such equipment is not readily available, h...

Page 122

Pistons and piston rings the pistons are made of an aluminum alloy. The piston pins are made of steel and are a precision fit. The piston pin is held in place by a clip at each end. Refer to figure 108 when servicing the piston and rings. Piston removal 1. Remove the cylinder head and cylinder as de...

Page 123

The homemade tool shown in figure 119. Do not drive out the piston pin. This could damage the pis- ton pin, connecting rod or piston. 6. Remove the piston from the connecting rod and remove the remaining circlip from the piston. Dis- card both piston pin circlips. 7. Mark the piston pin and piston s...

Page 124

Note in the next step, install the second circlip with the gap away from the cut out in the piston. 8. Install the second piston pin circlip (figure 118) into the groove in the piston. Make sure the circlip’s end gap does not align with the notch in the piston (figure 120). Also, make sure both pist...

Page 125

Sary, clean the holes and blow them out with com- pressed air. 5. Check the piston skirt (b, figure 122) for gall- ing and abrasion, which may have been caused by piston seizure. If a piston shows signs of partial sei- zure (bits of aluminum build-up on the piston skirt), replace the piston to reduc...

Page 126

Piston pin inspection 1. Clean the piston pin in solvent and dry it thor- oughly. 2. Inspect the piston pin for chrome flaking or cracks. Replace the pin if necessary. 3. Measure the outside diameter of the piston pin with a micrometer (figure 126). If the measure- ment is outside the range specifie...

Page 127

3. Inspect the grooves carefully for burrs, nicks or broken and cracked lands. Recondition or replace the piston if necessary. 4. Roll each ring around its piston groove as shown in figure 131 to check for binding. Minor binding may be cleaned up with a fine-cut file. 5. Measure the thickness of eac...

Page 128

Piston ring installation note when installing any ring, liberally lu bricate the ring and piston groove with clean engine oil. 1. Install the oil control ring assembly into the bot- tom ring groove. Install the oil ring expander spacer first (a, figure 136), then install each ring rail (b). Make sur...

Page 129

Table 1 general engine specifications item specification engine type four-stroke, air-cooled, sohc, v-twin number of cylinders 2 bore × stroke 95 × 75 mm (3.74 × 2.95 in.) displacement 1063 cc (64.87 cu. In.) compression ratio 8.3 : 1 compression pressure 1000 kpa (142 psi) @ 400 rpm ignition timing...

Page 130

Table 2 engine top end specifications (continued) item new mm (in.) service limit mm (in.) valve head diameter intake 47.0-47.2 (1.850-1.858) – exhaust 39.0-39.2 (1.535-1.543) – valve face width (intake and exhaust) 2.1 (0.083) – valve seat width (intake and exhaust) 1.2-1.4 (0.047-0.055) 1.8 (0.071...

Page 131

Table 3 engine top end torque specifications (continued) item n•m in.-lb. Ft.-lb. Exhaust pipe-to-manifold bolts (rear cylinder) 20 – 15 flywheel nut 175 – 129 intake manifold bolts 10 89 – oil delivery pipe banjo bolt 20 – 15 primary drive nut 110 – 81 rear chain guide bolt 10 89 – rocker arm bolts...

Page 132

Chapter five engine lower end this chapter describes the service procedures for the following lower end components: 1. Crankcase assembly. 2. Crankshaft. 3. Connecting rods. 4. Flywheel and starter clutch. 5. Oil pump. 6. Transmission shaft assemblies (removal and in- stallation only). When inspecti...

Page 133

134 chapter five 1 13. Engine bracket upper through bolt 14. Rear frame member bolt 15. Engine bracket lower nut 16. Engine bracket 17. Engine bracket upper nut 8. Engine bracket lower through bolt 9. Upper rear engine mounting bolt 10. Engine mounting nut 11. Front frame member bolt 12. Removable f...

Page 134

Removal caution yamaha recommends removing the alternator cover before removing the engine from the frame. Though this is necessary, it also exposes the alterna tor cover mating surface on the crankcase, which could be damaged during engine removal. If this surface is marred and leaks oil, the crank...

Page 135

Note two types of rocker arm bolts are used in the cylinder head: one with a single oil hole (a, figure 5) and one with two oil holes (b). Note that the bolt with two oil holes (b, figure 5) se cures the oil pipe to the cylinder head. B. Remove the rocker arm bolt (figure 6) that secures the oil pip...

Page 136

18. Remove the removable frame member as follows: a. Remove the nuts from the upper frame mem- ber bolts (figure 13) and remove the bolts. B. Remove the lower frame member bolts (b, figure 3) and lift the removable frame mem - ber from the frame. 19. Remove the rear upper engine mounting bolt (c, fi...

Page 137

26. Pull back the universal joint boot. Roll the en- gine forward and disengage the universal joint from the driveshaft. 27. With an assistant, lift the engine off the jack and remove it from the right side of the frame. 28. While the engine is removed for service, check all of the frame engine moun...

Page 138

F. Torque the front frame member bolts (figure 13) and rear frame member bolts (b, figure 3) to 48 n•m (35 ft.-lb.). G. Torque the front engine bracket bolts (a, b and c, figure 12 and figure 11) to 48 n•m (35 ft.-lb.). 15. Pull the coolant hose from the left side of the frame and install the altern...

Page 139

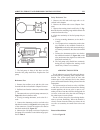

140 chapter five 17 alternator cover 1. Dowel 2. Gasket 3. Wire clamp 4. Stator/pickup coil assembly 5. Stator mounting bolt 6. Alternator cover 7. Alternator cover bolt 18 19.

Page 140

5. Remove the sidestand, toolbox cover and right side cover (chapter fourteen). 6. Roll the boot on the toolbox panel from the elec- trical connectors. Disconnect the three-pin stator connector (a, figure 21) and the two-pin pickup coil connector (b) from their respective mates on the wiring harness...

Page 141

A. Make sure the two dowels (c, figure 24) are in place in the crankcase. B. Install a new alternator cover gasket (b, fig- ure 24). C. Lubricate the shift shaft oil seal so it will not be damaged during installation. D. Install the clutch cable/ais bracket in its original location on the alternator...

Page 142

A. Remove the timing cover (c, figure 18) and the flywheel bolt cover (d) from the alterna- tor cover. B. Remove the cam sprocket cover from the rear cylinder head. C. Use the flywheel nut to rotate the crankshaft clockwise until the t-mark on the flywheel (a, figure 29) aligns with the cutout in th...

Page 143

E. If the timing mark on the rear cam sprocket does not align with the pointer on the rear head, rotate the engine one turn clockwise. 2. Remove the alternator cover as described in this chapter. Note install the sheave holder so it sits completely flat against the flywheel. Do not let the sheave ho...

Page 144

8. If necessary, lift the timing gear (a, figure 35) from the back of the flywheel. Remove each pin and spring (figure 36) from the slots in the flywheel. Installation 1. Insert a pin into each spring (figure 37). 2. Set the flywheel face down on the bench and in- stall two sets of pins/springs into...

Page 145

Sembly (b, figure 33) aligns with the woodruff key (or the crankshaft keyway) when the cylinder is at top dead center. 10. Position the flywheel so the two marked teeth (a, figure 41) align with the woodruff key in the crankshaft. Slide the flywheel onto the crankshaft so the keyway engages the wood...

Page 146

Starter clutch operational test 1. Set the flywheel on the bench so the starter clutch faces up as shown in figure 36. 2. Hold the flywheel and turn the starter wheel gear clockwise. The wheel gear should turn freely within the starter clutch. 3. Hold the flywheel and try to turn the starter wheel g...

Page 147

3. Inspect the teeth (a, figure 48) of the starter wheel gear. Replace the gear if any teeth are worn, broken or missing. 4. Inspect the bearing surface (b, figure 48) of the starter wheel gear for nicks or scratches. Replace the wheel gear if it shows signs of wear. 5. Inspect the starter wheel gea...

Page 148

6. If necessary, remove the oil delivery pipe mount- ing bolt (c, figure 53) at each end of the pipe, and remove the oil delivery pipe (d) from the crank- case. Watch for the o-ring (figure 54) behind the fitting on each end of the pipe. Note the oil pump drive sprocket is dam aged during removal. I...

Page 149

150 chapter five 55 oil pump 1. Primary body 2. Oil strainer 3. Indexing pin 4. Outer rotor 5. Inner rotor 6. Secondary body 7. Outer rotor 8. Inner rotor 9. Drive pin 10. Pump shaft 11. Snap ring 12. Washer 13. Oil pump cover 14. Screw 56 57.

Page 150

4. Turn the pump over and lift the primary pump body (figure 59) from the pump. Note this pump has two sets of rotors: a thick set that fits in the primary body and a thin set for the secondary body. Keep each set of rotors together with its respective body. 5. Remove the outer rotor (a, figure 60) ...

Page 151

11. Remove the shaft (figure 67) from the pump cover. Assembly 1. Coat all parts with fresh oil prior to assembly. 2. Install the pump shaft (figure 67) into the pump cover. The end with the holes enters from the out- board side of the cover. 3. Turn the cover over and install the washer (fig- ure 6...

Page 152

1. Clean all parts in solvent and dry them thor- oughly with compressed air. 2. Inspect the primary body (a, figure 68) for cracks and inspect the primary body rotors (b) for wear or abrasion. 3. Inspect the strainer (c, figure 68) for tears or other damage that will allow contaminants into the pump...

Page 153

13. Inspect the drive chain (b, figure 72) for ex- cessive wear or damage. If necessary, replace the chain along with both the drive and driven sprocket. Crankcase the following yamaha special tools, or their equivalents, are needed to service the crankcase: 1. Crankcase separating tool (part no. Yu...

Page 154

5. Remove the mounting screw, and lift the shift fork shaft stopper plate (figure 75) from the right crankcase half. Note crankcase bolts are identified by a number embossed on the crankcase near each bolt hole. These numbers also indicate the crankcase bolt tight ening sequence. See figure 76. 6. B...

Page 155

Any washer into its respective hole in the cardboard template so bolts can be quickly identified during assembly. Note bolts no. 15 and no. 16 are silver col ored. These bolts must be reinstalled in their original locations during as sembly. 7. Evenly loosen all the crankcase bolts 1/4 turn at a tim...

Page 156

A. Remove the two dowels (a figure 77) from the crankcase mating surface. B. Remove the o-ring and its short collar (b, figure 77) from the boss beneath the crank - shaft. C. Remove the o-ring from the crankcase mat- ing surface above the middle drive shaft. 13. Remove the oil pressure relief valve ...

Page 157

(b) from the left crankcase half. Store each individ- ual shaft assembly in a sealed and labeled plastic bag. 20. Use the crankcase separating tool to drive the crankshaft from the left crankcase half. Keep the tool centered over the crankshaft and follow the in- structions from the tool’s manufactu...

Page 158

Tion so the neutral knob (a, figure 89) on the drum aligns with the neutral switch (b) in the crankcase. 11. Install the center shift fork (figure 82) into the mainshaft second-third combination gear. Rotate the shift fork so its guide pin engages the groove in the shift drum. 12. Install the shift ...

Page 159

26. Turn the crankcase over and install the left crankcase bolts. Caution rotate the crankshaft frequently dur ing the tightening process. If there is any binding, stop and correct the cause before proceeding. 27. Evenly tighten the left crankcase bolts in 1/4-turn increments in the sequence shown i...

Page 160

6. Inspect the crankcase studs. Make sure they are straight and their threads are in good condition. Make sure they are tightly screwed into the crankcase. 7. Inspect the mating surfaces of both crankcase halves. They must be free of gouges, burrs or any damage that could cause an oil leak. 8. Inspe...

Page 161

Crankshaft refer to figure 94. Removal/installation remove and install the crankshaft as described in crankcase in this chapter. Inspection 1. Clean the crankshaft thoroughly with solvent and dry it with compressed air. Lightly oil the jour- nal surfaces immediately to prevent rust. 2. Blow the oil ...

Page 162

The clearance. If the side clearance is still outside the specified range, replace the crankshaft. 9. Use v-blocks and a dial gauge to check the crankshaft runout (figure 96). If the runout ex- ceeds the specification in table 1, replace the crankshaft. Connecting rods removal/installation note the ...

Page 163

Tab (b) on the bearing insert locks into the cutout in the rod cap or connecting rod. Caution each connecting rod has a y em bossed on one side (figure 100). The connecting rod must be installed so this side faces the left crankshaft end (the tapered end). B. Apply engine oil to the connecting rod b...

Page 164

Dial and lateral play (figure 102). If any play exists, replace the connecting rod (if piston pin outside di- ameter is within specification). 7. Check the connecting rod oil clearance as de- scribed in this chapter. Connecting rod oil clearance 1. Wipe the bearing inserts and crankpins clean. In- s...

Page 165

4. Refer to table 2 and use the bearing number to determine the color code for the bearing insert. In the above example, brown bearing inserts would be installed in the connecting rod. Note determine the bearing insert number for both connecting rods. Then take insert numbers and colors to a yamaha ...

Page 166

Table 3 engine lower end torque specifications item n•m in.-lb. Ft.-lb. Alternator cover bolts 10 89 – connecting rod nuts 48 – 35 crankcase stud 10 mm 20 – 15 12 mm 24 – 17 crankcase bolts 6 mm 10 89 – 10 mm 39 – 29 engine mounting hardware cylinder head bracket bolts 48 – 35 cylinder head bracket ...

Page 167

Chapter six clutch and primary drive gear this chapter includes service procedures for the clutch, clutch release mechanism and primary drive gear. When inspecting components, compare any measurement to the specifications in table 1 at the end of the chapter. Replace any part that is dam- aged, worn...

Page 168

7. Remove the clutch cover from the crankcase. Watch for the dowels (a, figure 3) behind the cover. Remove the dowels. 8. Remove and discard the clutch cover gasket (b, figure 3). 9. Inspect the clutch cover for cracks and other signs of wear. Replace the cover if necessary. 10. Installation is the ...

Page 169

C. Install the wire clamps behind the bolts (a, figure 2) noted during removal. D. Apply yamaha bond 1215 or an equivalent sealant to the threads of the two indicated bolts (c, figure 2). Oil will leak past these bolts if the threads are not sealed. E. Torque the clutch cover bolts to 10 n•m (89 in....

Page 170

Clutch and primary drive gear 171 6 7 8 9 clutch 1. Retaining wire 2. Clutch plate no. 1 3. Clutch boss spring 4. Plate seat 5. Clutch boss 6. Thrust washer 7. Clutch housing 8. Pushrod no. 2 9. Friction disc 10. Clutch plate 11. Clutch nut 12. Lock plate 13. Clutch spring bolt 14. Spring plate 15. ...

Page 171

5. Remove the pressure plate (b, figure 10). 6. Remove the washer (figure 11) and the release bearing (figure 12) from pushrod no. 1. 7. Remove pushrod no. 1 (figure 13) from the mainshaft, then remove pushrod no. 2 (figure 14). 8. Note that each friction disc is installed so the tab with the two se...

Page 172

The next step. However, do not use a steel washer. Steel will damage the gear teeth. 11b. If a clutch holder is not available, stuff a shop cloth, copper penny, or brass washer (figure 18) between the primary drive gear and the primary driven gear on the clutch housing. Remove the nut. The washer ho...

Page 173

B. Lift the other end from the hole and remove the retaining wire from the clutch hub. C. Remove clutch plate no. 1 (b, figure 21), the clutch boss spring and the plate seat from the clutch hub. Installation 1. Assemble the clutch boss damper assembly, if it was removed, as follows: a. Install the p...

Page 174

Two semi circular cutouts fits into the clutch housing slot with the two marks. See figure 15. This slot (a, figure 25) is cut down to the bottom of the clutch housing. 9. Install the first friction disc (figure 26) so the tab with the two semi-circular cutouts fit into the marked slot on the clutch...

Page 175

A. Check the inner splines (figure 30) on the clutch plates. Minor roughness can be cleaned with an oilstone or fine file. If any one plate has excessive roughness or wear, re- place all the clutch plates as a set. Note the clutch plate thickness does not apply to clutch plate no. 1. Clutch plate no...

Page 176

Or cracks. Replace the clutch housing if nec- essary. D. If the primary driven gear is worn or dam- aged, also inspect the primary drive gear as described in this chapter. E. Check the damper springs (b, figure 23) in the clutch housing. Replace the housing if any spring is damaged. 6. Inspect the c...

Page 177

1. Remove the alternator cover as described in chapter five. 2. Remove the clutch adjuster locknut (a, figure 38) and washer (b). 3. Disconnect the return spring (a, figure 39) from the post on the alternator cover, and remove the clutch lever (b). 4. Turn the alternator cover over and remove the pu...

Page 178

Assembly 1. Apply grease to the balls in the ball assembly (a, figure 41). 2. Lower the ball assembly (a, figure 41) onto the push screw (b). Seat the balls in the detents. 3. Invert the assembly and install it into the housing on the inboard side of the alternator cover (figure 40). 4. Turn the alt...

Page 179

A. Remove the mounting bolts (a, figure 45), and pull the clutch adjuster cover (b) from the alternator cover. B. Disconnect the clutch cable (figure 46) from the clutch lever. C. Pull the clutch cable end from the port in the alternator cover. 4. Remove any cable ties that secure the clutch ca- ble...

Page 180

Primary drive gear the yamaha sheave holder (part no. Yu-01880 or 90890-04131), or an equivalent flywheel holder, is needed to service the primary drive gear. Removal note when the front cylinder is set to tdc on the compression stroke, the timing mark on the cam sprocket plate may not precisely ali...

Page 181

2. Remove the cylinder head and the cam chain drive assembly from the front cylinder (chapter four). 3. Remove the clutch as described in this chapter. 4. Bend the ears of the lockwasher (a, figure 50) away from the primary gear nut. 5. Hold the flywheel with the sheave holder and re- move the prima...

Page 182

9. Remove the woodruff key (c, figure 53) from the crankshaft. 10. Set the assembly down on the bench. If neces- sary, remove the timing gear (a, figure 54) from the primary drive gear (b). 11. Remove each pin/spring assembly (figure 55) from the slots in the primary drive gear. A total of six pins ...

Page 183

Boss for the cam chain drive assembly shaft (c). See figure 48. 10. Install the cam chain drive assembly and the cylinder head as described in chapter four. 11. Install the clutch as described in this chapter. Inspection 1. Inspect the primary drive gear (figure 60) for broken or missing teeth. If i...

Page 184

Chapter seven transmission, shift mechanism and middle gear this chapter describes service procedures for the transmission, internal shift mechanism, external shift mechanism, middle drive shaft assembly and the middle driven shaft assembly. When inspecting these components, compare any measurement ...

Page 185

186 chapter seven 1 external shift mechanism 1. Washer 2. E-clip 3. Stopper lever spring 4. Stopper lever 5. Collar 6. Pin 7. Shift shaft spring 8. Shift shaft assembly 9. Shift lever 10. Clamp bolt 11. Locknut 12. Shift rod 13. Snap ring 14. Shift pedal (xvs1100a models) 15. Wave washer (xvs1100a m...

Page 186

C. Install the shift lever so the index mark (a, figure 2) on the shift shaft aligns with the slot in the shift lever. D. Torque the shift lever clamp bolt (b, figure 2) to 10 n•m (89 in.-lb.). E. Torque the footrest bracket bolts (figure 3) to 64 n•m (47 ft.-lb.). F. Adjust the shift pedal as descr...

Page 187

3. Slide the end of the shift shaft into the crankcase boss (b, figure 6) until the assembly bottoms. Note the following: a. The arms of the shift shaft spring (c, figure 4) must straddle the post in the crankcase. B. When the shift arm is released, the shift pawls must engage the pins on the shift ...

Page 188

Transmission, shift mechanism and middle gear 189 7 8 9 10 11 12 internal shift mechanism 1. Retainer screw 2. Shift fork shaft retainer 3. Shift fork shaft 4. Shift fork 5. Shift drum 6. Neutral pin 7. Bearing 8. Pin (20 mm) 9. Pin (16 mm) 10. Shift cam 11. Shift drum screw.

Page 189

8. Check the pins (b, figure 12) and shift cam ramps (c) for wear. A. If necessary, remove the shift drum screw (d, figure 12) to replace the shift cam, pins or bearing. B. During assembly, torque the shift drum screw to 4 n•m (35 in.-lb.). Transmission removal/installation remove and install the tr...

Page 190

The smallest diameter and fifth gear has the largest. On the countershaft, fifth gear has the smallest di- ameter and first gear has the largest. Mainshaft disassembly refer to figure 17. 1. Clean the assembled shaft in solvent. Dry all components with compressed air or let the assembly sit on rags ...

Page 191

1. Install fourth gear (a, figure 19) onto the mainshaft, and slide it up against first gear. Make sure the engagement dogs on the gear face away from first gear. 2. Install a splined washer (b, figure 19) and a new snap ring (c). The flat side of the snap ring must face away from the splined washer...

Page 192

2. If it is still installed, remove the middle drive gear (figure 23) from the countershaft. 3. Remove first gear, then remove fourth gear. 4. Remove the snap ring and the splined washer. 5. Remove the countershaft third gear. 6. At the opposite end of the countershaft (the short end), remove fifth ...

Page 193

8. Install first gear (figure 30) so its flat side faces out. 9. Install the middle drive gear (figure 23) so its splines engage those on the countershaft. 10. Mesh both assembled transmission shafts to- gether with the middle driven gear (figure 31). Make sure all gears mate properly. Transmission ...

Page 194

7. Inspect each shift fork groove (b, figure 36) for wear or damage. Replace the gear(s) if necessary. 8. Inspect the bearing (b, figure 35) in the middle driven gear. It should turn smoothly without rough- ness or binding. 9. Replace any washers that are worn. 10. Discard all snap rings and replace...

Page 195

196 chapter seven 37 middle drive shaft assembly 38 39 1. Bearing retainer 2. Spring retainer 3. Spring seat 4. Damper spring 5. Damper cam (male) 6. Damper cam (female) 7. Middle drive shaft nut 8. Bearing 9. Middle drive shaft shims 10. Middle drive shaft.

Page 196

2. Apply engine oil to the teeth of the middle drive shaft and install the middle drive shaft assembly into the crankcase. 3. Turn the bearing retainer (a, figure 40) until it is in place. 4. Using the bearing retainer wrench (figure 39), torque the bearing retainer to 110 n•m (81 ft.-lb.). 6. Stake...

Page 197

4. Install the middle drive shaft holder (a, figure 42) onto the middle drive shaft and secure the holder in a vise. 5. Install the middle drive shaft nut wrench (b, fig- ure 42) onto the nut. 6. Install a torque wrench at 90° to the middle drive shaft nut wrench and torque the nut to 110 n•m (81 ft...

Page 198

1. Remove the rear wheel and swing arm as de- scribed in chapter twelve. 2. Remove the bearing housing bolts (a, figure 45) from the middle driven shaft assembly. 3. Separate the universal joint as follows: a. Use a small screwdriver to drive the circlip (a, figure 46) from each side of the drive yo...

Page 199

Socket, press the bearing from each side of the drive yoke. C. Remove the driven yoke (c, figure 46) from the drive yoke (b). 4. Hold the drive yoke with the universal joint holder (a, figure 48) and loosen the middle driven shaft nut (b). 5. Remove the universal joint holder, and remove the middle ...

Page 200

6. Lubricate the splines of the middle driven shaft with lithium soap grease and slide the bearing hous- ing onto the shaft. 7. Seat the speed sensor bracket (c, figure 45), ro- tor (b) and the drive yoke on the bearing housing. 8. Lubricate a new o-ring with lithium soap grease and carefully roll t...

Page 201

F. Turn the universal joint over and repeat substeps d-f for the opposite bearing. 15. Install the bearing housing bolts (a, figure 45) and secure the speed sensor bracket and bearing housing to the crankcase. Apply yamaha bond 1215 or an equivalent sealant to the threads of the bolts and torque the...

Page 202

Chapter eight air/fuel, exhaust and emission control systems this chapter describes service procedures for the air/fuel, exhaust and emission control systems. Dur- ing inspection, compare measurements to the speci- fications in the tables at the end of this chapter. Replace any components that are w...

Page 203

8. Raise the fuel tank bracket and support the tank. Pull the meter connector (b, figure 5) from be- neath the ignitor panel and disconnect the 14-pin meter connector (a, figure 6) from its harness mate. 9. On california models, disconnect the evap hose (b, figure 6) from the fitting on the fuel tan...

Page 204

11. Pull the tank bracket rearward until the tank is free of the damper (a, figure 7) on each side of the frame. Remove the fuel tank. 12. Installation is the reverse of removal. Note the following: a. Set the tank on the frame and route the meter assembly cable and hoses along the paths noted durin...

Page 205

3. Drain the fuel from the tank into a clean, sealable container. 4. Position the tank so residual fuel will not spill from the tank when the fuel valve is removed. 5. Remove each fuel valve screw and washer (b, figure 3), and remove the valve and o-ring. 6. The packing and fuel valve seal are the o...

Page 206

Leaks. If there is a leak, solve the problem be- fore installing the fuel tank. Air filter housing note air filter service is described in chap ter three. Removal/installation refer to figure 9. 1. Securely support the motorcycle on level ground. 2. Remove the fuel tank as described in this chap- te...

Page 207

3. Remove the cover bolts (a, figure 10) and pull the air filter cover (b) from the housing. 4. Lift the air filter (a, figure 11) from the posts in the air filter housing. 5. Loosen the clamp (b, figure 11) that secures the surge tank duct to the back of the air filter housing. 6. Remove the air fi...

Page 208

Inspection 1. Remove the plug (a, figure 15) from the drain hose on the air filter housing. Clean out accumu- lated moisture or dirt. If necessary, blow the hose clear with compressed air. 2. Inspect all components of the air filter housing assembly. Look closely for cracks or other damage that woul...

Page 209

Installation 1. If removed, install the cylinder head breather hose (figure 20) onto the surge tank fitting so the dots on the hose face forward. 2. Make sure the clamp (a, figure 19) on each car- buretor duct is loose and the carburetor breather hose (b) faces up. 3. Apply soap to the male fittings...

Page 210

Carburetor operation the carburetor atomizes fuel and mixes it in cor- rect proportions with air that is drawn in through the air intake. At the primary throttle opening (idle), a small amount of fuel is siphoned through the pilot jet by the incoming air. When the throttle is opened further, the air...

Page 211

From the carburetor bracket and disconnect the ca- ble ends from the throttle wheel. If necessary, turn the pull cable adjuster (c, figure 26) to create addi- tional slack. 12. Loosen the cable clamp screw (a, figure 27) and disconnect the choke cable end (b) from the choke linkage. 13. Move the thr...

Page 212

D. Route the throttle cables and choke cable along their original paths. These cables must not be twisted, kinked or pinched. Secure the cables in the holder (b, figure 7). E. Connect each hose to the fitting noted during removal and route the hose along its original path. F. Adjust the throttle cab...

Page 213

7. Remove the cotter pin (a, figure 35) and washer. Remove the throttle arm (b, figure 35) from the throttle shaft on the front carburetor. 8. Remove the mounting screw (a, figure 36) and lift the choke linkage (b) from the starter plunger on the rear carburetor. 9. Remove the front carburetor (c, f...

Page 214

Air/fuel, exhaust and emission control systems 215 8 38 carburetor 1. Screw 2. Choke cable bracket 3. Top cover 4. Spring 5. Needle retainer 6. Jet needle 7. Vacuum piston 8. Pilot air jet no. 2 9. Choke linkage 10. Starter plunger 11. Carburetor body 12. Bracket bolt 13. Cover bracket 14. Coasting ...

Page 215

4. If the carburetors were not separated, disconnect the carburetor heater wires by performing steps 1-4 in separation in this section. 5. Remove the top cover as follows: a. Remove the top cover screws (a, figure 41). B. When servicing the rear carburetor, remove the choke cable bracket (b, figure ...

Page 216

11. Remove the carburetor heater (a, figure 48) and its washer from the bottom of the carburetor body. When servicing the rear carburetor, also re- move the heater ground terminal (b, figure 48). 12. Remove the mounting screws (a, figure 49) and lift the float bowl (b) from the carburetor body. Watc...

Page 217

15. Remove the screw (a, figure 53) and pull the valve seat (b) from the carburetor body. 16. Remove the pilot jet (figure 54). 17. Remove the starter jet (figure 55) and spacer. 18. Remove the main jet (figure 56). 19. Remove the jet holder (figure 57) and o-ring. 20. Insert a finger into the carbu...

Page 218

8. Install the float pin (b, figure 51) and secure it with the screw (a). 9. Install a new float bowl o-ring (figure 50) and set the float bowl onto the bottom of the carburetor (b, figure 49). Secure the float bowl in place with the mounting screws (a, figure 49). 10. Install the carburetor heater ...

Page 219

18. If removed, install the starter plunger (b, fig- ure 39). 19. Assemble the coasting enricher, if it was disas- sembled, as follows: a. Install the coasting enricher diaphragm (b, figure 40) onto the carburetor (figure 62). B. Install the spring (a, figure 40) into the cen- ter of the diaphragm. ...

Page 220

Replace any jet or holder if its holes cannot be unplugged. 5. Make sure all openings in the carburetor body are clear. Clean them out if they are plugged in any way. 6. Inspect the slide bore in the carburetor body. Make sure it is clean and free of any burrs or ob- structions that may cause the va...

Page 221

14. If removed, inspect the pilot screw (figure 70) for wear or damage that may have occurred during removal. Replace the pilot screw in both carbure- tors even if only one requires replacement. This is necessary for correct pilot screw adjustment as de- scribed in this chapter. 15. Replace all o-ri...

Page 222

Ble 1 provides the specification for fuel level, mea- sured from (figure 73) the upper edge of the float bowl with the carburetors mounted on the motorcy- cle. This measurement is more accurate than a float height measurement because the actual fuel level can vary between carburetors, even when the ...

Page 223

Idle speed adjustment refer to chapter three. Throttle cable adjustment refer to chapter three. Throttle position sensor testing perform the following test procedure whenever the self-diagnostic system (see chapter nine) flashes a tps error (code 3). Perform the test in the listed sequence. Each ste...

Page 224

B. Note the resistance while slowly opening the throttle. C. Replace the sensor if the r2 resistance is out- side the range specified in table 2. Adjustment adjust the throttle position sensor by turning the sensor until its resistance is within the specified range. Note the throttle position sensor...

Page 225

3. Disconnect the four-pin harness connector from the carburetor heater relay and remove the relay. 4. Installation is the reverse of removal. Thermo switch test 1. Disconnect the two-pin thermo switch connector (b, figure 75) from its harness mate. Caution the thermo switch is sensitive to shock. D...

Page 226

9. Turn the heat off and watch the continuity as the temperature decreases. A. While the temperature is above 12 ± 4° c (53 ± 7° f), there should be no continuity be- tween the switch terminals. B. When the temperature drops below 12 ± 4° c (53 ± 7° f), there should be continuity be- tween the switc...

Page 227

Note the piece of string in the next step is used to pull the new throttle cable through the frame so the cable will be properly routed. 10. Tie a piece of heavy string or cord to the ends of the throttle cable at the carburetor. Wrap this end with tape. Do not use an excessive amount of tape. Too m...

Page 228

2. Remove the fuel tank, air filter housing and the surge tank as described in this chapter. 3. Remove the neck covers (chapter fourteen). 4. Note how the choke cable is routed along the frame and through the fork legs. The new cable will have to follow the same path. 5. At the carburetor, loosen th...

Page 229

B. Position the filter so its arrow points toward the fuel pump. C. Check the hose clamps for damage; replace them if necessary. D. After installation is complete, thoroughly check for leaks. Fuel pump removal/installation 1. Disconnect the electrical lead from the negative battery terminal. 2. Remo...

Page 230

7. The fuel pump is faulty if fuel does not flow from the fuel pump outlet hose. Replace the fuel pump. Resistance test 1. Remove the toolbox cover and the side cover from the left side as described in chapter fourteen. 2. Roll the boot from the connectors on the toolbox panel. 3. Disconnect the two...

Page 231

232 chapter eight 95 air induction system 1. Vacuum hose (to rear cylinder intake manifold) 2. Orifice 3. Ais air filter 4. Air filter housing 5. Air cut valve 6. Reed valve 7. Housing 8. Bracket 9. Ais output hose 10. Ais pipe (to rear cylinder) 11. Ais pipe (to front cylinder) 12. Gasket.

Page 232

1. Remove the toolbox cover and the side cover from the left side as described in chapter fourteen. 2. Release the hose clamp (figure 96) and discon- nect the ais pipe from its fitting on each cylinder head. 3. Release the clamp and disconnect the output hose (a, figure 97) on the ais valve from eac...

Page 233

9. Replace any component that is worn, damaged or out of specification. Evaporative emission control (california models) all models sold in california are equipped with an evaporative emission control (evap) system, which reduces the amount of fuel vapors released into the atmosphere. The system con...

Page 234

Air/fuel, exhaust and emission control systems 235 8 101 1. Fitting 2. Solenoid valve 3. Rollover valve 4. Clamp 5. Canister.

Page 235