- DL manuals

- Yamaha

- Outboard Motor

- F2.5C

- Owner's Manual

Yamaha F2.5C Owner's Manual

Summary of F2.5C

Page 1

Q q q q read this manual carefully before operating this outboard motor. Owner’s manual f25a ft25b f25c 65w-28199-2d-e0

Page 2

Emu25052 read this manual carefully before operating this outboard motor. Keep this manual onboard in a waterproof bag when boating. This manual should stay with the outboard motor if it is sold..

Page 3: Important Manual Information

Important manual information emu25105 to the owner thank you for choosing a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you ob- tain maximum enjoyment from your ...

Page 4: Table of Contents

Table of contents safety information............................. 1 outboard motor safety .................... 1 propeller............................................ 1 rotating parts.................................... 1 hot parts ........................................... 1 electric shock ..........

Page 5: Table of Contents

Table of contents flushing device ............................... 26 alert indicator .................................. 26 instruments and indicators ............ 27 indicators....................................... 27 low oil pressure-alert indicator ....... 27 engine control system...................

Page 6: Table of Contents

Table of contents checking propeller .......................... 68 removing propeller ......................... 68 installing propeller ........................... 69 changing gear oil ............................ 70 cleaning fuel tank ........................... 71 inspecting and replacing anode(s)...

Page 7: Safety Information

1 safety information emu33622 outboard motor safety observe these precautions at all times. Emu36500 propeller people can be injured or killed if they come in contact with the propeller. The propeller can keep moving even when the motor is in neutral, and sharp edges of the propeller can cut even wh...

Page 8: Safety Information

Safety information 2 emu33820 gasoline exposure and spills take care not to spill gasoline. If gasoline spills, wipe it up immediately with dry rags. Dispose of rags properly. If any gasoline spills onto your skin, immedi- ately wash with soap and water. Change clothing if gasoline spills on it. If ...

Page 9: Safety Information

Safety information 3 dling and lead to an accident, capsizing or swamping. Emu33771 avoid collisions scan constantly for people, objects, and other boats. Be alert for conditions that limit your visibility or block your vision of others. Operate defensively at safe speeds and keep a safe distance aw...

Page 10: General Information

4 general information emu25171 identification numbers record emu25183 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare ...

Page 11: General Information

General information 5 emu25203 ce marking outboard motors affixed with this “ce”mark- ing conform with the directives of; 98/37/ec, 94/25/ec - 2003/44/ec and 2004/108/ec. Emu25213 c-tick label engines affixed with this label conform to certain portion(s) of the australian radio communications act. 1...

Page 12: General Information

General information 6 emu33520 read manuals and labels before operating or working on this motor: ● read this manual. ● read any manuals supplied with the boat. ● read all labels on the outboard motor and the boat. If you need any additional information, contact your yamaha dealer. Emu33831 warning ...

Page 13: General Information

General information 7 emu33912 contents of labels the above warning labels mean as follows. 1 warning ewm01691 emergency starting does not have start- in-gear protection. Ensure shift control is in neutral before starting engine. 2 warning ewm01681 ● keep hands, hair, and clothing away from rotating...

Page 14: General Information

General information 8 emu33843 symbols the following symbols mean as follows. Notice/warning read owner’s manual hazard caused by continuous rotation electrical hazard remote control lever/gear shift lever operat- ing direction, dual direction engine start/ engine cranking zmu05696 zmu05664 zmu05665...

Page 15: Specifications

9 specifications and requirements emu34520 specifications tip: “(al)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Likewise, “(sus)” represents the value for stainless steel propeller installed and “(pl)” for plastic propeller installe...

Page 16

Specifications and requirements 10 spark plug gap: 0.8–0.9 mm (0.031–0.035 in) control system: f25aeht tiller f25aet remote control f25amh tiller f25cmh tiller ft25bet remote control starting system: f25aeht electric f25aet electric f25amh manual f25cmh manual ft25bet electric starting carburetion s...

Page 17: Installation Requirements

Specifications and requirements 11 (2.01 us qt, 1.67 imp.Qt) recommended gear oil: hypoid gear oil sae#90 gear oil quantity: f25aeht 0.320 l (0.338 us qt, 0.282 imp.Qt) f25aet 0.320 l (0.338 us qt, 0.282 imp.Qt) f25amh 0.320 l (0.338 us qt, 0.282 imp.Qt) f25cmh 0.320 l (0.338 us qt, 0.282 imp.Qt) ft...

Page 18: Remote Control Requirements

Specifications and requirements 12 emu33581 remote control requirements warning ewm01580 ● if the engine starts in gear, the boat can move suddenly and unexpectedly, pos- sibly causing a collision or throwing passengers overboard. ● if the engine ever starts in gear, the start-in-gear protection dev...

Page 19: Start-In-Gear Protection

Specifications and requirements 13 your yamaha dealer can help you select the right propeller for your boating needs. Select a propeller that will allow the engine to reach the middle or upper half of the operating range at full throttle with the maximum boat- load. Generally, chose a larger pitch p...

Page 20: Engine Oil Requirements

Specifications and requirements 14 emu37471 engine oil requirements if the recommended engine oil grades are not available, select an alternative from the following chart according to the average temperatures in your area. Emu36360 fuel requirements emu36770 gasoline use a good quality gasoline that...

Page 21: Anti-Fouling Paint

Specifications and requirements 15 motor in muddy or acidic water conditions. However, depending on the model it might not be required. Emu36330 anti-fouling paint a clean hull improves boat performance. The boat bottom should be kept as clean of ma- rine growth as possible. If necessary, the boat b...

Page 22: Components

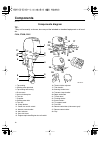

16 components emu2579j components diagram tip: * may not be exactly as shown; also may not be included as standard equipment on all mod- els. F25a, ft25b, f25c 27 24 1 3 4 5 6 10 9 11 8 7 25 23 12 13 14 17 21 19 20 18 22 26 2 15 16 28 zmu02818 1. Top cowling 2. Cooling water pilot hole 3. Top cowlin...

Page 23: Components

Components 17 emu25802 fuel tank if your model was equipped with a portable fuel tank, its function is as follows. Warning ewm00020 the fuel tank supplied with this engine is its dedicated fuel reservoir and must not be used as a fuel storage container. Com- mercial users should conform to relevant ...

Page 24: Components

Components 18 emu26201 neutral interlock trigger to shift out of neutral, first pull the neutral in- terlock trigger up. Emu26211 neutral throttle lever to open the throttle without shifting into ei- ther forward or reverse, put the remote con- trol lever in the neutral position and lift the neutral...

Page 25: Components

Components 19 emu25941 throttle grip the throttle grip is on the tiller handle. Turn the grip counterclockwise to increase speed and clockwise to decrease speed. Emu25961 throttle indicator the fuel consumption curve on the throttle indicator shows the relative amount of fuel consumed for each throt...

Page 26: Components

Components 20 when constant speed is desired, tighten the adjuster to maintain the desired throttle set- ting. Emu25993 engine shut-off cord (lanyard) and clip the clip must be attached to the engine shut- off switch for the engine to run. The cord should be attached to a secure place on the operato...

Page 27: Components

Components 21 emu26001 engine stop button to open the ignition circuit and stop the en- gine, push this button. Emu26070 manual starter handle to start the engine, first gently pull the han- dle out until resistance is felt. From that posi- tion, then pull the handle straight out quickly to crank th...

Page 28: Components

Components 22 set according to operator preference. An ad- juster lever is located on the bottom of the tiller handle bracket. To increase resistance, turn the lever to the port side “a”. To decrease resistance, turn the lever to the starboard side “b”. Warning ewm00040 do not overtighten the fricti...

Page 29: Components

Components 23 emu26143 power trim and tilt switch on remote control or tiller handle the power trim and tilt system adjusts the outboard motor angle in relation to the tran- som. Pressing the switch “ ” (up) trims the outboard motor up, and then tilts it up. Press- ing the switch “ ” (down) tilts th...

Page 30: Components

Components 24 will become ineffective as an anode. Emu26253 trim tab warning ewm00840 an improperly adjusted trim tab could cause difficult steering. Always test run after the trim tab has been installed or re- placed to be sure steering is correct. Be sure you have tightened the bolt after ad- just...

Page 31: Components

Components 25 emu30530 tilt lock mechanism the tilt lock mechanism is used to prevent the outboard motor from lifting out of the wa- ter when in reverse gear. To lock it, set the tilt lock lever in the lock po- sition. To release, push the tilt lock lever in the release position. Emu26321 tilt suppo...

Page 32: Components

Components 26 emu26372 top cowling lock lever(s) (turn type) to remove the engine top cowling, turn the lock lever(s) and lift off the cowling. When in- stalling the cowling, check to be sure it fits properly in the rubber seal. Then lock the cowling again by returning the lever(s) to the lock posit...

Page 33: Instruments and Indicators

27 instruments and indicators emu36014 indicators emu36023 low oil pressure-alert indicator if oil pressure drops too low, this indicator will light up. For further information, see page 28. Notice ecm00022 ● do not continue to run the engine if the low oil pressure-alert indicator is on and the eng...

Page 34: Engine Control System

28 engine control system emu26803 alert system notice ecm00091 do not continue to operate the engine if a alert device has activated. Consult your yamaha dealer if the problem cannot be located and corrected. Emu2681a overheat alert this engine has an overheat-alert device. If the engine temperature...

Page 35: Engine Control System

Engine control system 29 if the alert system has activated, stop the en- gine as soon as it is safe to do so. Check the oil level and add oil as needed. If the oil level is correct and the alert device does not switch off, consult your yamaha dealer..

Page 36: Installation

30 installation emu26902 installation the information presented in this section is intended as reference only. It is not possible to provide complete instructions for every possible boat and motor combination. Prop- er mounting depends in part on experience and the specific boat and motor combinatio...

Page 37: Installation

Installation 31 notice ecm01630 ● during water testing, check the buoy- ancy of the boat, at rest, with its maxi- mum load. Check that the static water level on the exhaust housing is low enough to prevent water entry into the power head when water rises due to waves when the outboard is not run- ni...

Page 38: Installation

Installation 32 3. Secure the clamp bracket to the transom using the bolts provided with the out- board (if packed). For details, consult your yamaha dealer. Warning! Avoid using bolts, nuts or washers other than those contained in the engine packaging. If used, they must be of at least the same qua...

Page 39: Operation

33 operation emu36380 first-time operation emu36390 fill engine oil the engine is shipped from the factory with- out engine oil. If your dealer did not fill the oil, you must fill it before starting the engine. No- tice: check that the engine is filled with oil before first-time operation to avoid s...

Page 40: Operation

Operation 34 heating and serious engine damage can occur. Emu36560 fuel level be sure you have plenty of fuel for your trip. A good rule is to use 1/3 of your fuel to get to the destination, 1/3 to return, and to keep 1/ 3 as an emergency reserve. With the boat level on a trailer or in the water, ch...

Page 41: Operation

Operation 35 ● turn the steering wheel full-right and full- left. Make sure operation is smooth and unrestricted throughout the whole range with no binding or excessive free play. ● operate the throttle levers several times to make sure there is no hesitation in their travel. Operation should be smo...

Page 42: Operation

Operation 36 emu27151 engine ● check the engine and engine mounting. ● look for loose or damaged fasteners. ● check the propeller for damage. ● check for oil leaks. Emu36490 flushing device check that flushing device’s garden hose connector is securely screwed on to the fit- ting on the bottom cowli...

Page 43: Operation

Operation 37 yamaha dealer. Emu34581 power trim and tilt system warning ewm01930 ● never get under the lower unit while it is tilted, even when the tilt support lever is locked. Severe injury could occur if the outboard motor accidentally falls. ● body parts can be crushed between the motor and the ...

Page 44: Operation

Operation 38 4. Do not smoke and keep away from sparks, flames, static electric discharge, or other sources of ignition. 5. If you use a portable container to store and dispense fuel, use only an approved gasoline container. 6. Touch the fuel nozzle to the filler open- ing or funnel to help prevent ...

Page 45: Operation

Operation 39 3. Squeeze the primer pump, with the ar- row pointing up, until you feel it become firm. During engine operation place the tank horizontally, otherwise fuel cannot be drawn from the fuel tank. Emu27492 starting engine warning ewm01600 before starting the engine, make sure that the boat ...

Page 46: Operation

Operation 40 3. Place the throttle grip in the “ ” (start) position. 4. Pull the manual starter handle slowly un- til you feel resistance. Then give a strong pull straight out to crank and start the engine. Repeat if necessary. 5. After the engine starts, slowly return the manual starter handle to i...

Page 47: Operation

Operation 41 tip: the start-in-gear protection device prevents the engine from starting except when in neu- tral. 2. Attach the engine shut-off cord to a se- cure place on your clothing, or your arm or leg. Then install the clip on the other end of the cord into the engine shut-off switch. 3. Place ...

Page 48: Operation

Operation 42 emu27664 electric start and remote control models warning ewm01840 ● failure to attached engine shut-off cord could result in a runaway boat if opera- tor is ejected. Attach the engine shut- off cord to a secure place on your cloth- ing, or your arm or leg while operating. Do not attach...

Page 49: Operation

Operation 43 warmed up. For further information, see page 43. ● if the engine is warm and fails to start, open the throttle slightly and try to start the engine again. If the engine still fails to start, see page 74. Emu36510 checks after starting engine emu36520 cooling water check for a steady flo...

Page 50: Operation

Operation 44 emu34530 shifting warning ewm00180 before shifting, make sure there are no swimmers or obstacles in the water near you. Notice ecm01610 warm up the engine before shifting into gear. Until the engine is warm, the idle speed may be higher than normal. High idle speed can prevent you from ...

Page 51: Operation

Operation 45 2. After the engine is at idle speed in gear move the remote control lever / gear shift lever firmly and crisply into the neu- tral position. Emu31742 stopping boat warning ewm01510 ● do not use the reverse function to slow down or stop the boat as it could cause you to lose control, be...

Page 52: Operation

Operation 46 2. After stopping the engine, disconnect the fuel line if there is a fuel joint on the outboard motor. 3. Tighten the air vent screw on the fuel tank cap (if equipped). 4. Remove the key if the boat will be left unattended. Tip: the engine can also be stopped by pulling the cord and rem...

Page 53: Operation

Operation 47 emu27872 adjusting trim angle for manual tilt models there are 4 or 5 holes provided in the clamp bracket to adjust the outboard motor trim an- gle. 1. Stop the engine. 2. Tilt the outboard motor up, and then re- move the trim rod from the clamp brack- et. 3. Reposition the rod in the d...

Page 54: Operation

Operation 48 emu27885 adjusting trim angle (power trim and tilt) warning ewm00753 ● be sure all people are clear of the out- board motor when adjusting the trim angle. Body parts can be crushed be- tween the motor and the clamp bracket when the motor is trimmed or tilted. ● use caution when trying a...

Page 55: Operation

Operation 49 bow up too much trim-out puts the bow of the boat too high in the water. Performance and econ- omy are decreased because the hull of the boat is pushing the water and there is more air drag. Excessive trim-out can also cause the propeller to ventilate, which reduces per- formance furthe...

Page 56: Operation

Operation 50 emu32661 procedure for tilting up (manual tilt models) 1. Place the gear shift lever in neutral. 2. Place the tilt lock lever (if equipped) in the release/up position. 3. Pull up the shallow water lever (if equipped). 4. Hold the rear of the top cowling with one hand and tilt the engine...

Page 57: Operation

Operation 51 3. Push the tilt support knob into the clamp bracket to support the engine. Warning! After tilting the outboard motor, be sure to support it with the tilt support knob or tilt support lever. Otherwise the outboard motor could fall back down suddenly if oil in the power trim and tilt uni...

Page 58: Operation

Operation 52 emu33120 procedure for tilting down (power trim and tilt models) 1. Push the power trim and tilt switch “ ” (up) until the outboard motor is support- ed by the tilt rod and the tilt support knob becomes free. 2. Pull out the tilt support knob. 3. Push the power trim and tilt switch “ ” ...

Page 59: Operation

Operation 53 2. Place the tilt lock lever in the release/up position. 3. Slightly tilt the outboard motor up. The tilt support bar will lock automatically, supporting the outboard motor in a par- tially raised position. This outboard mo- tor has 2 positions for shallow water cruising. 4. To return t...

Page 60: Operation

Operation 54 2. Slightly tilt the outboard motor up to the desired position using the power trim and tilt switch. Warning! Using the power trim and tilt switch on the bot- tom cowling while the boat is moving or engine is on could increase the risk of falling overboard and could distract the operato...

Page 61: Maintenance

55 maintenance emu28226 transporting and storing outboard motor warning ewm00692 ● use care when transporting fuel tank, whether in a boat or car. ● do not fill fuel container to maximum capacity. Gasoline will expand consid- erably as it warms up and can build up pressure in the fuel container. Thi...

Page 62: Maintenance

Maintenance 56 the attitude shown when transporting and storing it. If storing or transporting the outboard motor on its side (not up- right), put it on a cushion after draining the engine oil. ● do not place the outboard motor on its side before the cooling water has drained from it completely, oth...

Page 63: Maintenance

Maintenance 57 cessively and almost stall. 8. Remove the outboard motor from the test tank. 9. Install the silencer cover/cap of fogging hole and top cowling. 10. If the “fogging oil” is not available, run the engine at a fast idle until the fuel sys- tem becomes empty and the engine stops. 11. Drai...

Page 64: Maintenance

Maintenance 58 off the water and disconnect the garden hose adapter from the garden hose con- nector. 4. Reinstall the garden hose connector onto the fitting on the bottom cowling. Tighten the connector securely. No- tice: do not leave the garden hose connector loose on the bottom cowl- ing fitting ...

Page 65: Maintenance

Maintenance 59 genuine yamaha parts or parts of equivalent design and quality. Any part of inferior quality may malfunction, and the resulting loss of control could endanger the operator and passengers. Yamaha genuine parts and ac- cessories are available from your yamaha dealer. Emu34150 severe ope...

Page 66: Maintenance

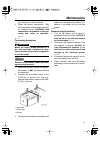

Maintenance 60 emu34445 maintenance chart 1 tip: ● refer to the sections in this chapter for explanations of each owner-specific action. ● the maintenance cycle on these charts assume usage of 100 hours per year and regular flushing of the cooling water passages. Maintenance frequency should be adju...

Page 67: Maintenance

Maintenance 61 fuel filter (can be dis- assembled) inspection or replace- ment as necessary fuel line(high pres- sure) inspection fuel line(high pres- sure) inspection or replace- ment as necessary fuel line(low pres- sure) inspection fuel line(low pres- sure) inspection or replace- ment as necessar...

Page 68: Maintenance

Maintenance 62 emu34451 maintenance chart 2 emu28910 tip: when using lead or high-sulfur gasoline, inspecting valve clearance may be required more frequently than every 500 hours. Water inlet inspection main switch/stop switch/choke switch inspection or replace- ment as necessary wire harness connec...

Page 69: Maintenance

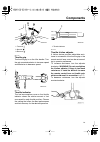

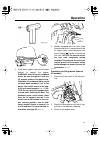

Maintenance 63 emu28941 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) f25amh, f25aeht, f25cmh zmu02891.

Page 70: Maintenance

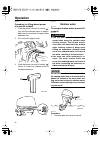

Maintenance 64 f25aet, ft25bet emu28955 cleaning and adjusting spark plug the spark plug is an important engine com- ponent and is easy to inspect. The condition of the spark plug can indicate something about the condition of the engine. For exam- ple, if the center electrode porcelain is very white...

Page 71: Maintenance

Maintenance 65 otherwise the engine may not operate properly. Before fitting the spark plug, measure the electrode gap with a wire thickness gauge; adjust the gap to spec- ification if necessary. 4. When fitting the plug, wipe off any dirt from the threads, and then screw it in to the correct torque...

Page 72: Maintenance

Maintenance 66 or other qualified mechanic. 2. Verify whether the idle speed is set to specification. For idle speed specifica- tions, see page 9. Emu29077 changing engine oil change the engine oil several minutes after the engine has been stopped, so that the oil is still warm, but not hot. Warning...

Page 73: Maintenance

Maintenance 67 age or damage. If the oil level is above the upper level mark, drain un- til the level meets the specified ca- pacity. [ecm01850] 5. Start the engine and watch to make sure the low oil pressure-alert indicator (if equipped) turns off. Make sure that there are no oil leaks. Notice: if ...

Page 74: Maintenance

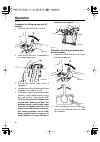

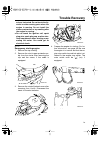

Maintenance 68 emu32111 checking propeller warning ewm01880 you could be seriously injured if the en- gine accidentally starts when you are near the propeller. ● before inspecting, removing, or install- ing the propeller, place the shift control in neutral, turn the main switch to “ ” (off) and remo...

Page 75: Maintenance

Maintenance 69 3. Remove the propeller, washer (if equipped), and thrust washer. Emu30671 installing propeller emu29233 spline models notice ecm00500 be sure to use a new cotter pin and bend the ends over securely. Otherwise the propeller could come off during opera- tion and be lost. 1. Apply yamah...

Page 76: Maintenance

Maintenance 70 emu29287 changing gear oil warning ewm00800 ● be sure the outboard motor is securely fastened to the transom or a stable stand. You could be severely injured if the outboard motor falls on you. ● never get under the lower unit while it is tilted, even when the tilt support lever or kn...

Page 77: Maintenance

Maintenance 71 6. Put a new gasket on the oil level plug. When the oil begins to flow out of the oil level plug hole, insert and tighten the oil level plug. 7. Put a new gasket on the gear oil drain screw. Insert and tighten the gear oil drain screw. Emu29302 cleaning fuel tank warning ewm00920 gaso...

Page 78: Maintenance

Maintenance 72 them ineffective. Tip: inspect ground leads attached to external anodes on equipped models. Consult a yamaha dealer for inspection and replace- ment of internal anodes attached to the pow- er unit. Emu29322 checking battery (for electric start models) warning ewm01900 battery electrol...

Page 79: Maintenance

Maintenance 73 ing, consult your yamaha dealer. 3. Check the battery connections. They should be clean, secure, and covered by an insulating cover. Warning! Bad connections can produce shorting or arcing and cause an explosion. [ewm01910] emu29333 connecting the battery warning ewm00570 mount the ba...

Page 80: Trouble Recovery

74 trouble recovery emu29427 troubleshooting a problem in the fuel, compression, or igni- tion systems can cause poor starting, loss of power, or other problems. This section de- scribes basic checks and possible remedies, and covers all yamaha outboard motors. Therefore some items may not apply to ...

Page 81: Trouble Recovery

Trouble recovery 75 q. Is fuel system obstructed? A. Check for pinched or kinked fuel line or other obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have servic...

Page 82: Trouble Recovery

Trouble recovery 76 q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine power loss. Q. Is propeller damaged? ...

Page 83: Trouble Recovery

Trouble recovery 77 q. Is fuel joint connection incorrect? A. Connect correctly. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding...

Page 84: Trouble Recovery

Trouble recovery 78 flow. This could cause electric system damage and a fire hazard. Consult your yamaha dealer if the new fuse immediately blows again. Emu29512 power trim and tilt will not operate if the engine cannot be tilted up or down with the power trim and tilt because of a dis- charged batt...

Page 85: Trouble Recovery

Trouble recovery 79 only as instructed. Do not touch the fly- wheel or other moving parts when the engine is running. Do not install the starter mechanism or top cowling after the engine is running. ● do not touch the ignition coil, spark plug wire, spark plug cap, or other elec- trical components w...

Page 86: Trouble Recovery

Trouble recovery 80 5. Insert the knotted end of the emergency starter rope into the notch in the flywheel rotor and wind the rope around the fly- wheel several turns clockwise. 6. Pull the rope slowly until resistance is felt. 7. Give a strong pull straight out to crank and start the engine. Repeat...

Page 88

Yamaha motor co., ltd. Printed on recycled paper printed in japan april 2008–0.1 × 1 !.