- DL manuals

- Yamaha

- Outboard Motor

- F225A

- Service Manual

Yamaha F225A Service Manual

Summary of F225A

Page 1

Service manual 290435 69j-28197-3d-11 f225a fl225a.

Page 2

Notice this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical conc...

Page 3: Contents

Contents general information 1 gen info specifications 2 spec periodic checks and adjustments 3 chk adj fuel system 4 fuel power unit 5 powr lower unit 6 lowr bracket unit 7 brkt electrical systems 8 elec troubleshooting 9 trbl shtg index – +.

Page 4: General Information

Gen info 69j3d11 general information how to use this manual ................................................................................. 1-1 manual format............................................................................................ 1-1 symbols........................................

Page 5

69j3d11 1 2 3 4 5 6 7 8 9 predelivery checks ...................................................................................... 1-28 checking the fuel system ........................................................................ 1-28 checking the gear oil..........................................

Page 6

Gen info general information 1-1 69j3d11 how to use this manual 1 manual format the format of this manual has been designed to make service procedures clear and easy to under- stand. Use the information below as a guide for effective and quality service. 1 parts are shown and detailed in an exploded...

Page 7

69j3d11 1-2 1 2 3 4 5 6 7 8 9 symbols the symbols below are designed to indicate the content of a chapter. General information specifications periodic checks and adjustments fuel system power unit lower unit bracket unit electrical systems troubleshooting gen info spec chk adj fuel powr lowr brkt el...

Page 8

Gen info general information 1-3 69j3d11 safety while working 1 to prevent an accident or injury and to ensure quality service, follow the safety pro- cedures provided below. Fire prevention gasoline is highly flammable. Keep gasoline and all flammable products away from heat, sparks, and open flame...

Page 9

69j3d11 1-4 1 2 3 4 5 6 7 8 9 6. Keep a supply of clean, lint-free cloths for wiping up spills, etc. Good working practices special tools use the recommended special tools to pro- tect parts from damage. Use the right tool in the right manner—do not improvise. Tightening torques follow the tightenin...

Page 10

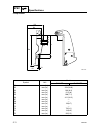

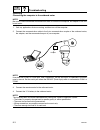

Gen info general information 1-5 69j3d11 identification 1 applicable models this manual covers the following models. Serial number the outboard motor serial number is stamped on a label attached to the port clamp bracket. 1 model name 2 approved model code 3 transom height 4 serial number applicable...

Page 11

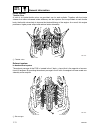

69j3d11 1-6 1 2 3 4 5 6 7 8 9 features and benefits 1 newly developed v6 4-stroke engine the f225 is a newly developed 60-degree v6 4-stroke engine with a very compact and lightweight design. Its size and weight are almost the same as the v6 2-stroke engines that are in current use. This f225 offers...

Page 12

Gen info general information 1-7 69j3d11 crankcase the crankcase is made of cast aluminum, however steel has been cast into the areas for the crank- shaft bearings. By distinguishing the area that requires strength from the area that allows the use of a lighter material, both weight reduction and a ...

Page 13

69j3d11 1-8 1 2 3 4 5 6 7 8 9 piston the piston has been carved out of a forged stock. To prevent the valves from coming in contact with the piston, the piston is provided with a valve recess. If the engine goes out of timing and a valve opens when the piston is at top-dead-center, this recess preve...

Page 14

Gen info general information 1-9 69j3d11 valve train system the valve train consists of a total of four camshafts, with two in each bank. The camshafts are driven with the combination of a belt and chains. The crankshaft turns the belt to drive the exhaust camshafts in both banks. Chains connect the...

Page 15

69j3d11 1-10 1 2 3 4 5 6 7 8 9 tensioner a timing chain tensioner is provided at the mid-span of the timing chain, between both camshafts. The timing chain tensioner uses the force of a spring to maintain its tension. After the engine is started, oil is pumped into the tensioner, and the resulting p...

Page 16

Gen info general information 1-11 69j3d11 intake system throttle valve a total of six intake throttle valves are provided, one for each cylinder. Together with the intake silencer that offers enhanced intake efficiency and the injectors that are provided at each throttle body, the throttle valves he...

Page 17

69j3d11 1-12 1 2 3 4 5 6 7 8 9 exhaust passage during idle to reduce noise when the engine is idling, the exhaust gas passage of the f225 has adopted a lab- yrinth construction. During idling, the exhaust gas passes through the passage on the side of the exhaust guide, and enters the upper case thro...

Page 18

Gen info general information 1-13 69j3d11 fuel system the fuel flows in the following order: fuel filter, low-pressure fuel pump, vapor separator, high-pres- sure fuel pump, and injectors. The excess fuel at the injectors passes through the pressure regula- tor and fuel cooler, and returns to the va...

Page 19

69j3d11 1-14 1 2 3 4 5 6 7 8 9 low-pressure fuel pump the f225 has adopted a newly developed, low-pressure electrical fuel pump, in place of the low- pressure mechanical fuel pump used in the previous electronic fuel injection system. With the adop- tion of the electric pump, the routing of the fuel...

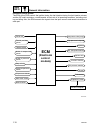

Page 20: Ecm

Gen info general information 1-15 69j3d11 electronic control system the ecm of the f225 controls the ignition timing, the fuel injection timing, the fuel injection volume, and the isc and it maintains a stoichiometric air-fuel ratio in all operating conditions, including start- ing and idling. Also,...

Page 21

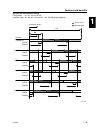

69j3d11 1-16 1 2 3 4 5 6 7 8 9 ignition and fuel injection timing firing order : #1, #2, #3, #4, #5, #6 injection order : #1 and #4 → #2 and #5 → #3 and #6 (group injection) tdc 720 ˚ 180 ˚ 120 ˚ tdc tdc tdc tdc crankshaft angle cylinder cylinder #1 cylinder #2 cylinder #3 cylinder #4 cylinder #5 cy...

Page 22

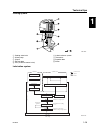

Gen info general information 1-17 69j3d11 ptt (power trim and tilt) unit the ptt unit has been newly developed for the f225. Based on the field-proven 61a type, its ptt fluid passage and internal valve construction have been changed for this application. Although the valves of the 61a type have been...

Page 23

69j3d11 1-18 1 2 3 4 5 6 7 8 9 technical tips 1 fuel injection control the f225 injects fuel simultaneously to the following cylinder pairs: #1 and #4, #2 and #5, and #3 and #6. Optimal injection timing is provided in accordance with the operating conditions of the engine. Starting fuel injection vo...

Page 24

Gen info general information 1-19 69j3d11 over-revolution control if the engine speed exceeds 4,500 r/min, while the shift is in neutral, ignition is stopped. The various stages of ignition cutoff are shown in the table below. Ignition cutoff cylinder in neutral : indicates a misfire at either cylin...

Page 25

69j3d11 1-20 1 2 3 4 5 6 7 8 9 fail-safe function table symptom fail-safe function diagnosis code ignition injection isc engine condition incorrect pulser coil signal engine starting: only the cylinders outputting normal signal ignite at btdc10°, and all cylinders thereafter. All cylinders inject si...

Page 26

Gen info general information 1-21 69j3d11 ptt (power trim and tilt) unit in the newly designed ptt unit, the up-main valve, down-main valve, up-relief valve, and down- relief valve have been concentrated in the gear pump housing in order to improve the serviceability of the engine and ensure reliabl...

Page 27

69j3d11 1-22 1 2 3 4 5 6 7 8 9 trim-up and tilt-up function when the ptt switch is pressed to “up,” the power trim and tilt motor operates the gear pump and fluid pressure is generated. As a result, the fluid pressure pushes the up-shuttle piston upward, enters the trim cylinder and tilt cylinder lo...

Page 28

Gen info general information 1-23 69j3d11 trim ram retraction function when the outboard motor is tilted up and held in place with the tilt stop lever and the ptt switch is pressed to “dn,” the trim ram will be retracted. Although the gear pump attempts to draw oil from the tilt cylinder and trim cy...

Page 29

69j3d11 1-24 1 2 3 4 5 6 7 8 9 trim-down and tilt-down function when the ptt switch is pressed to “dn,” the power trim and tilt motor operates the gear pump and fluid pressure is generated. As a result, the fluid pressure pushes the down-shuttle piston upward, enters the tilt cylinder upper chamber ...

Page 30

Gen info general information 1-25 69j3d11 stationary condition when the ptt switch is not pressed, the gear pump will not pump the fluid, the up-main valve and the down-main valve will remain closed, and the ptt unit in the system remains constant. This will allow the tilt ram and the trim ram to ma...

Page 31

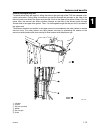

69j3d11 1-26 1 2 3 4 5 6 7 8 9 cooling system 1 cooling water inlet 2 water pump 3 oil pan 4 exhaust pipe 5 pcv (pressure control valve) 6 in-bank exhaust system 7 thermostat 8 propeller boss È water lubrication system : s69j1460 sleeve piston crankshaft pin crankshaft journal retur n route retur n ...

Page 32

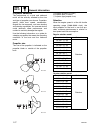

Gen info general information 1-27 69j3d11 propeller selection 1 the performance of a boat and outboard motor will be critically affected by the size and type of propeller you choose. Propellers greatly affect boat speed, acceleration, engine life, fuel economy, and even boating and steering capabili...

Page 33

69j3d11 1-28 1 2 3 4 5 6 7 8 9 predelivery checks 1 to make the delivery process smooth and efficient, the predelivery checks should be completed as explained below. Checking the fuel system 1. Check that the fuel hoses are securely connected and that the fuel tank is full with fuel. Caution: this i...

Page 34

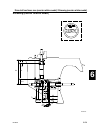

Gen info general information 1-29 69j3d11 checking the outboard motor mounting height 1. Check that the anti-cavitation plate is aligned with the bottom of the boat. If the mounting height is too high, cavitation will occur and propulsion will be reduced. Also, the engine speed will increase abnorma...

Page 35

69j3d11 1-30 1 2 3 4 5 6 7 8 9 checking the steering wheel 1. Check the steering friction for proper adjustment. 2. Check that the steering operates smoothly. 3. Check that there is no interference with wires or hoses when the outboard motor is steered. Checking the gearshift and throttle operation ...

Page 36

Gen info general information 1-31 69j3d11 checking the cooling water pilot hole 1. Check that cooling water is discharged from the cooling water pilot hole. Test run 1. Start the engine, and then check that the gearshift operates smoothly. 2. Check the engine idle speed after the engine has been war...

Page 37: Specifications

69j3d11 spec 1 2 3 4 5 6 7 8 9 specifications general specifications................................................................................... 2-1 maintenance specifications .......................................................................... 2-3 power unit...............................

Page 38

Spec specifications 2-1 69j3d11 general specifications 2 item unit model f225aet fl225aet dimension overall length mm (in) 892 (35.1) overall width mm (in) 634 (25.0) overall height (x) mm (in) 1,805 (71.1) (u) mm (in) 1,932 (76.1) boat transom height (x) mm (in) 635 (25.0) (u) mm (in) 762 (30.0) we...

Page 39

69j3d11 2-2 1 2 3 4 5 6 7 8 9 fuel and oil fuel type regular unleaded gasoline fuel rating pon* ron 86 91 engine oil type 4-stroke motor oil engine oil grade api sae se, sf, sg, or sh 10w-30 or 10w-40 engine oil quantity (with oil filter replacement) l (us qt, lmp qt) 6.0 (6.3, 5.3) (without oil fil...

Page 40

Spec specifications 2-3 69j3d11 maintenance specifications 2 power unit item unit model f225aet fl225aet power unit minimum compression pressure* kpa (kgf/cm 2 , psi) 880 (8.8, 125) lubrication oil pressure kpa (kgf/cm 2 , psi) at 700 r/min 650 (6.5, 924) cylinder heads warpage limit mm (in) 0.1 (0....

Page 41

69j3d11 2-4 1 2 3 4 5 6 7 8 9 oil ring dimension b mm (in) 2.40–2.47 (0.0945–0.0972) dimension t mm (in) 2.3–2.7 (0.091–0.106) end gap mm (in) 0.15–0.60 (0.0059–0.0236) side clearance mm (in) 0.04–0.13 (0.0016–0.0051) camshafts intake (a) mm (in) 45.30–45.40 (1.7835–1.7874) exhaust (a) mm (in) 45.35...

Page 42

Spec specifications 2-5 69j3d11 valve lifters valve lifter outside diameter mm (in) 32.98–33.00 (1.2984–1.2992) valve lifter-to-cylinder head clearance mm (in) 0.02–0.05 (0.0008–0.0020) valve shims valve shim thickness (in 0.020 mm increments) mm (in) 2.320–2.960 (0.0913–0.1165) connecting rods smal...

Page 43

69j3d11 2-6 1 2 3 4 5 6 7 8 9 lower unit oil pump discharge at 97–103 °c (207–217 °f) with 10w-40 engine oil l (us gal, imp gal)/min at 700 r/min 8.8 (2.32, 1.94) pressure kpa (kgf/cm 2 , psi) 138 (1.38, 19.62) relief valve opening pressure kpa (kgf/cm 2 , psi) 529–647 (5.29–6.47, 75.22–92.00) therm...

Page 44

Spec specifications 2-7 69j3d11 electrical item unit model f225aet fl225aet ignition and ignition control system ignition timing (engine idle speed) degree tdc pulser coil output peak voltage (w/r – b, w/b – b, w/g – b) at cranking (unloaded) v 5.3 at cranking (loaded) v 5.3 at 1,500 r/min (loaded) ...

Page 45

69j3d11 2-8 1 2 3 4 5 6 7 8 9 starter motor type sliding gear output kw 1.4 cranking time limit second 30 brushes standard length mm (in) 15.5 (0.61) wear limit mm (in) 9.5 (0.37) commutator standard diameter mm (in) 29.0 (1.14) wear limit mm (in) 28.0 (1.10) mica standard undercut mm (in) 0.5–0.8 (...

Page 46

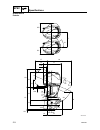

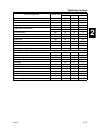

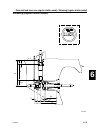

Spec specifications 2-9 69j3d11 dimensions exterior s69j2130 w5 a1 t1 w1 l7 h9 h1 h11 h2 h4 h3 h7 h8 h10 l8 l5 a2 h6 l9 l4 a3 12˚ c3 l2 l1 l10 l6.

Page 47

69j3d11 2-10 1 2 3 4 5 6 7 8 9 symbol unit model f225aet fl225aet l1 mm (in) 651 (25.6) l2 mm (in) 219 (8.6) l3 mm (in) — l4 mm (in) 673 (26.5) l5 (x) mm (in) 59 (2.3) (u) mm (in) 59 (2.3) l6 (x) mm (in) 1,155 (45.5) (u) mm (in) 1,272 (50.1) l7 mm (in) 618 (24.3) l8 mm (in) 230 (9.1) l9 (x) mm (in) ...

Page 48

Spec specifications 2-11 69j3d11 clamp bracket symbol unit model f225aet fl225aet b1 mm (in) 125 (4.9) b2 mm (in) 254 (10.0) b3 mm (in) 163 (6.4) b4 mm (in) 51 (2.0) b5 mm (in) 180 (7.1) b6 mm (in) 411 (16.2) b7 mm (in) — b8 mm (in) — b9 mm (in) 19 (0.7) c2 mm (in) — c3 mm (in) 79 (3.1) d1 mm (in) 1...

Page 49

69j3d11 2-12 1 2 3 4 5 6 7 8 9 tightening torques 2 specified torques part to be tightened thread size tightening torques n·m kgf·m ft·lb fuel system fuel filter holder bolt m6 8 0.8 5.8 fuel filter bracket bolt m6 8 0.8 5.8 intake air temperature sensor — 4 0.4 2.9 low-pressure fuel pump bracket bo...

Page 50

Spec specifications 2-13 69j3d11 timing chain tensioner bolt m6 12 1.2 8.7 spark plug — 25 2.5 18 cylinder head bolt 1st m10 19 1.9 14 2nd 37 3.7 27 3rd 90° 1st m8 14 1.4 10 2nd 28 2.8 20 engine hanger bolt m6 12 1.2 8.7 cooling water cover bolt m6 12 1.2 8.7 starboard cylinder head plug — 23 2.3 17...

Page 51

69j3d11 2-14 1 2 3 4 5 6 7 8 9 upper case mount nut — 72 7.2 52 engine oil drain bolt m14 27 2.7 19 apron stay — 8 0.8 5.8 pressure control valve — 8 0.8 5.8 upper exhaust guide bolt m8 20 2.0 14 m10 42 4.2 30 oil strainer bolt m6 10 1.0 7.2 oil pan bolt m8 20 2.0 14 exhaust manifold bolt m8 20 2.0 ...

Page 52

Spec specifications 2-15 69j3d11 general torques this chart specifies tightening torques for standard fasteners with a standard iso thread pitch. Tightening torque specifications for special components or assemblies are provided in applicable sections of this man- ual. To avoid warpage, tighten mult...

Page 53

69j3d11 chk adj 1 2 3 4 5 6 7 8 9 periodic checks and adjustments special service tools ..................................................................................... 3-1 maintenance interval chart............................................................................ 3-2 top cowling ......

Page 54

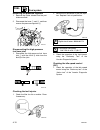

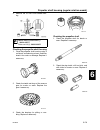

Chk adj periodic checks and adjustments 3-1 69j3d11 special service tools 3 fuel pressure gauge 90890-06786 digital tachometer 90890-06760 timing light 90890-03141 leakage tester 90890-06762.

Page 55

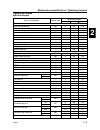

69j3d11 3-2 1 2 3 4 5 6 7 8 9 maintenance interval chart 3 use the following chart as a guideline for general maintenance. Adjust the maintenance intervals according to the operating conditions of the outboard motor. Item remarks initial every refer to page 10 h ours (b reak-in) 50 h ours (3 months ...

Page 56

Chk adj periodic checks and adjustments 3-3 69j3d11 note: (*1) if equipped with a portable fuel tank. (*2) be sure to replace the timing belt every 1,000 hours of operation or every five years. (*3) the engine should be flushed with fresh water after operating in salt, turbid, or muddy water. (*4) d...

Page 57

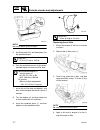

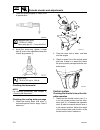

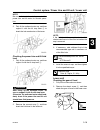

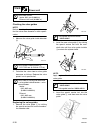

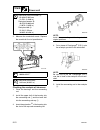

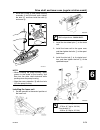

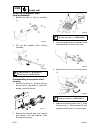

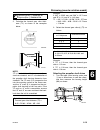

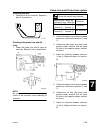

69j3d11 3-4 1 2 3 4 5 6 7 8 9 top cowling 3 checking the top cowling 1. Check the fitting by pushing the cowling with both hands. Adjust if necessary. 2. Loosen the bolts 1. 3. Move the hook 2 up or down slightly to adjust its position. Note: • to loosen the fitting, move the hook in direction a. • ...

Page 58

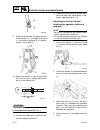

Chk adj periodic checks and adjustments 3-5 69j3d11 measuring the fuel pressure (high- pressure fuel line) 1. Remove the cap 1. 2. Install the fuel pressure gauge onto the pressure check valve. 3. Turn the engine start switch to on, and then measure the fuel pressure. Note: after the engine start sw...

Page 59

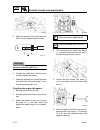

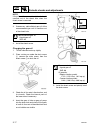

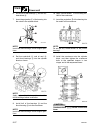

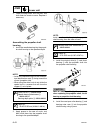

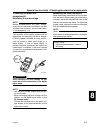

69j3d11 3-6 1 2 3 4 5 6 7 8 9 changing the engine oil using an oil changer 1. Start the engine and warm it up. 2. Remove the engine oil dipstick and oil filler cap 1. 3. Insert the tube of the oil changer 2 into the dipstick guide 3. 4. Operate the oil changer to extract the oil. Note: be sure to cl...

Page 60

Chk adj periodic checks and adjustments 3-7 69j3d11 note: be sure to clean up any oil spills. 5. Install the drain bolt, and then tighten it to the specified torque. 6. Pour the specified amount of the recom- mended engine oil into the oil filler hole. 7. Install the oil filler cap and dipstick, and...

Page 61

69j3d11 3-8 1 2 3 4 5 6 7 8 9 5. Install the oil filter, and then tighten it to the specified torque using a 72.5 mm (2.9 in) oil filter wrench. 6. Pour the specified amount of the recom- mended engine oil into the oil filler hole. 7. Install the oil filler cap and dipstick, and then start the engin...

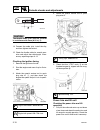

Page 62

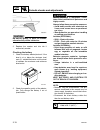

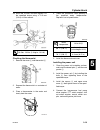

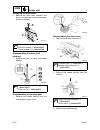

Chk adj periodic checks and adjustments 3-9 69j3d11 5. Check the spark plug gap a. Adjust if out of specification. 6. Install the spark plug, tighten it finger tight b, then to the specified torque with a spark plug wrench c. Checking the thermostat note: for checking procedures, see chapter 5, “che...

Page 63

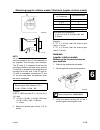

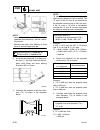

69j3d11 3-10 1 2 3 4 5 6 7 8 9 adjusting the throttle link and throttle cable operation (with a stop bolt) note: • be sure to synchronize the throttle valves before adjusting the throttle link. • for synchronizing procedures, see chapter 4, “synchronizing the throttle valve.” 1. Loosen the locknut 1...

Page 64

Chk adj periodic checks and adjustments 3-11 69j3d11 9. Place the throttle cam 0 against the fully closed stopper f, and check that there is a minimum clearance g of approxi- mately 1.0 mm (0.04 in). 10. Adjust the position of the throttle cable joint until its hole is aligned with the set pin h on ...

Page 65

69j3d11 3-12 1 2 3 4 5 6 7 8 9 5. Check that the alignment mark a is between the alignment marks b. If not, repeat steps 2–4. 6. Place the throttle cam 7 against the fully closed stopper c, and check that there is a minimum clearance d of approxi- mately 1.0 mm (0.04 in). 7. Adjust the position of t...

Page 66

Chk adj periodic checks and adjustments 3-13 69j3d11 5. Adjust the position of the shift cable joint until its hole is aligned with the set pin. Caution: the shift cable joint must be screwed in a minimum of 8.0 mm (0.31 in) c. 6. Connect the cable joint, install the clip, and then tighten the lockn...

Page 67

69j3d11 3-14 1 2 3 4 5 6 7 8 9 note: • to increase the idle speed, turn the throttle stop screw in direction a. • to decrease the idle speed, turn the throttle stop screw in direction b. 7. Tighten the port throttle stop screw 5 until it contacts the throttle body lever 6. 8. Loosen the locknut 8, r...

Page 68

Chk adj periodic checks and adjustments 3-15 69j3d11 caution: the throttle cable joint must be screwed in a minimum of 8.0 mm (0.31 in) h. 14. Connect the cable joint, install the clip, and then tighten the locknut. 15. Check the throttle cable for smooth oper- ation and adjust the cable length, if ...

Page 69

69j3d11 3-16 1 2 3 4 5 6 7 8 9 note: be sure to listen to the winding sound of the power trim and tilt motor for smooth opera- tion. 2. Fully tilt the outboard motor up, and then support it with the tilt stop lever 1 to check the lock mechanism of the lever. Checking the power trim and tilt fluid le...

Page 70

Chk adj periodic checks and adjustments 3-17 69j3d11 note: if the oil is at the correct level, the oil should overflow out of the check hole when the check screw is removed. 3. If necessary, add sufficient gear oil of the recommended type until it overflows out of the check hole. 4. Install the chec...

Page 71

69j3d11 3-18 1 2 3 4 5 6 7 8 9 checking the lower unit (for air leakage) 1. Remove the check screw 1, and then install the special service tool. 2. Apply the specified pressure to check whether the lower unit can hold it for at least 10 seconds. Caution: do not over pressurize the lower unit, oth- e...

Page 72

Chk adj periodic checks and adjustments 3-19 69j3d11 caution: do not oil, grease, or paint the anodes, otherwise they will be ineffective. 2. Replace the anodes and trim tab if excessively eroded. Checking the battery 1. Check the battery electrolyte level. If the level is at or below the minimum le...

Page 73

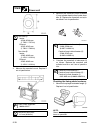

69j3d11 3-20 1 2 3 4 5 6 7 8 9 lubrication 1. Apply water resistant grease to the areas shown. General.

Page 74

Chk adj periodic checks and adjustments 3-21 69j3d11 note: apply grease to the grease nipple until it flows from the bushings a. 2. Apply corrosion resistant grease to the areas shown..

Page 75: Fuel System

69j3d11 fuel 1 2 3 4 5 6 7 8 9 fuel system special service tools ..................................................................................... 4-1 hose routing ................................................................................................... 4-2 fuel and blowby hoses..........

Page 76

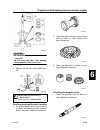

Fuel fuel system 4-1 69j3d11 special service tools 4 vacuum/pressure pump gauge set 90890-06756 digital circuit tester 90890-03174 test harness (3 pins) 90890-06793 vacuum gauge 90890-03159.

Page 77

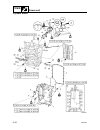

69j3d11 4-2 1 2 3 4 5 6 7 8 9 hose routing 4 fuel and blowby hoses 1 blowby hose 2 fuel hose (fuel joint-to-fuel filter) 3 fuel hose (fuel filter-to-fuel pump) 4 fuel hose (fuel pump-to-vapor separator) 5 fuel hose (vapor separator-to-fuel pump) 6 high-pressure fuel hose (vapor separator-to-starboar...

Page 78

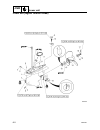

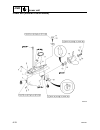

Fuel fuel system 4-3 69j3d11 intake silencer, fuel filter, and fuel pump 4.

Page 79

69j3d11 4-4 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 cover 1 2 bolt 3 m6 × 28 mm 3 bolt 1 m6 × 16 mm 4 washer 1 5 holder 1 6 bolt 1 m6 × 14 mm 7 bracket 1 8 bolt 2 m6 × 19 mm 9 cap 1 10 fuel hose 8 11 fuel joint 1 12 o-ring 1 not reusable 13 fuel filter element 1 14 spring 1 15 o-ring 1 not re...

Page 80

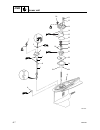

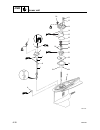

Fuel fuel system 4-5 69j3d11 vapor separator 4.

Page 81

69j3d11 4-6 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 float chamber 1 2 cover 1 3 high-pressure fuel pump 1 4 float 1 5 water hose 1 6 fuel hose 3 7 joint 1 8 fuel cooler 1 9 washer 2 10 nut 2 11 water hose 1 12 bracket 1 13 bolt 3 m8 × 16 mm 14 collar 6 15 bushing 4 16 bolt 4 m8 × 16 mm 17 col...

Page 82

Fuel fuel system 4-7 69j3d11 removing the hose clamps 1. Remove the hose clamps by cutting the joint. Caution: if the hose clamps are removed without cutting the joint first, the fuel hose will be damaged. Installing the hose clamps 1. Crimp the hose clamps properly to securely fasten them. Warning ...

Page 83

69j3d11 4-8 1 2 3 4 5 6 7 8 9 warning always reduce the fuel pressure in the high-pressure fuel line before servicing the line or the vapor separator. If the fuel pressure is not released, pressurized fuel may spray out. 3. Remove the cap 3, and then press in the valve b using a thin screwdriver 2. ...

Page 84

Fuel fuel system 4-9 69j3d11 intake manifold and high-pressure fuel line 4.

Page 85

69j3d11 4-10 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 hose 1 2 high-pressure fuel hose 4 3 clamp 7 4 joint 2 5 joint 2 6 screw 2 7 washer 4 8 throttle position sensor 1 9 screw 2 10 bracket 1 11 bracket 1 12 screw 2 m5 × 15 mm 13 bracket 1 14 joint 1 15 o-ring 1 not reusable 16 metal gasket 2 ...

Page 86

Fuel fuel system 4-11 69j3d11.

Page 87

69j3d11 4-12 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 starboard intake manifold 1 2 throttle body #1 1 3 throttle body #3 1 4 throttle body #5 1 5 starboard fuel rail 1 6 port intake manifold 1 7 throttle body #2 1 8 throttle body #4 1 9 throttle body #6 1 10 port fuel rail 1 11 pressure regul...

Page 88

Fuel fuel system 4-13 69j3d11 throttle control 4.

Page 89

69j3d11 4-14 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 bracket 1 2 joint 1 3 magnet control lever 1 4 pin 4 5 shaft 1 6 bracket 1 7 bolt 2 m6 × 20 mm 8 washer 2 9 bushing 5 10 gear 2 11 throttle control lever 1 12 circlip 1 13 bolt 1 14 wave washer 1 15 washer 1 16 throttle cam 1 17 spring 1 18...

Page 90

Fuel fuel system 4-15 69j3d11 removing the pressure regulator 1. Remove the intake silencer and the port intake manifold. 2. Disconnect the hose 1 and 2, and then remove the pressure regulator 3. Disconnecting the high-pressure fuel hose joint 1. Disconnect the high-pressure fuel hose joint 1 with t...

Page 91

69j3d11 4-16 1 2 3 4 5 6 7 8 9 synchronizing the throttle valve 1. Loosen the bank synchronizing screw 1. 2. Remove the port link rod 2 and star- board link rod 3. 3. Loosen the starboard throttle stop screw 4 until it separates from the throttle body lever 5. 4. Loosen the synchronizing screw 6 of ...

Page 92

Fuel fuel system 4-17 69j3d11 10. Turn the engine start switch to on. 11. Measure the throttle position sensor out- put voltage. Adjust the throttle position sensor b position if out of specification. 12. Tighten the synchronizing screw 6 of cylinder #3 and stop tightening it when the throttle posit...

Page 93

69j3d11 4-18 1 2 3 4 5 6 7 8 9 15. Tighten the synchronizing screw 0 of cylinder #4, and stop tightening when the throttle plate starts to move. Similarly, tighten and adjust the synchronizing screw a of cylinder #6. 16. Tighten the port throttle stop screw 8 until it contacts the throttle body leve...

Page 94

Fuel fuel system 4-19 69j3d11 19. Measure the vacuum of cylinders #1, #3, and #5. Repeat step 12 if out of specifi- cation. 20. Measure the vacuum of cylinders #2, #4, and #6. Repeat step 12 if out of specifi- cation. 21. Check the average vacuum difference between the port and starboard banks. Adju...

Page 95

69j3d11 4-20 1 2 3 4 5 6 7 8 9 25. Check that there is no clearance a between the port and starboard throttle stop screws 4 and 8, and the throttle body levers 5 and 9. If there is any clearance, repeat step 24. 26. Start the engine, and when the engine speed is at idle, check the average vac- uum d...

Page 96: Power Unit

Powr 69j3d11 power unit special service tools ..................................................................................... 5-1 power unit....................................................................................................... 5-3 checking the compression pressure ...............

Page 97

69j3d11 1 2 3 4 5 6 7 8 9 cylinder block .............................................................................................. 5-43 disassembling the cylinder block ............................................................ 5-47 checking the piston diameter ..................................

Page 98

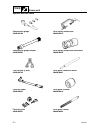

Powr power unit 5-1 69j3d11 special service tools 5 compression gauge 90890-03160 compression gauge adaptor 90890-06563 test harness (3 pins) 90890-06769 flywheel holder 90890-06522 flywheel puller 90890-06521 valve spring compressor 90890-04019 valve spring compressor attachment 90890-06320 valve g...

Page 99

69j3d11 5-2 1 2 3 4 5 6 7 8 9 valve seat cutter holder 90890-06316 valve seat cutter 90890-06324, 90890-06325, 90890-06327 crank stand alignment 90890-03107 piston ring compressor 90890-05158 special service tools.

Page 100

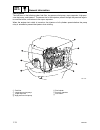

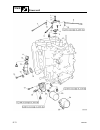

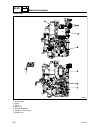

Powr power unit 5-3 69j3d11 power unit 5.

Page 101

69j3d11 5-4 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 power unit 1 2 screw 4 3 cover 1 4 dipstick 1 5 bolt 1 m6 × 20 mm 6 dipstick guide 1 7 o-ring 1 not reusable 8 plastic tie 2 not reusable 9 fuel hose 1 10 bolt 2 m6 × 10 mm 11 ptt motor lead 2 sky blue, light green 12 gasket 1 not reusable 1...

Page 102

Powr power unit 5-5 69j3d11.

Page 103

69j3d11 5-6 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 nut 1 2 washer 1 3 flywheel magnet 1 4 screw 4 m6 × 30 mm 5 stator coil 1 6 bolt 4 m6 × 35 mm 7 blowby hose guide 1 8 blowby hose 1 9 blowby hose 1 10 stator coil bracket 1 11 collar 2 12 woodruff key 1 13 plastic tie 5 not reusable 14 wirin...

Page 104

Powr power unit 5-7 69j3d11.

Page 105

69j3d11 5-8 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 wiring harness 1 2 rectifier regulator coupler 1 3 bolt 1 m6 × 20 mm 4 ground lead 3 5 bolt 1 m6 × 16 mm 6 bracket 1 7 bolt 4 m6 × 16 mm 8 ecm 1 9 bolt 2 m6 × 25 mm 10 power trim and tilt relay 1 11 cap 2 12 nut 4 13 washer 2 14 cap 1 15 spr...

Page 106

Powr power unit 5-9 69j3d11 no. Part name q’ty remarks 1 starter motor 1 2 nut 1 3 spring washer 1 4 battery cable 1 from terminal and power trim and tilt relay 5 bolt 3 m8 × 45 mm 6 bolt 1 m6 × 20 mm 7 ground lead 1 8 bolt 2 m6 × 35 mm 9 rectifier regulator 1 10 gasket 1 not reusable 11 cover 1 12 ...

Page 107

69j3d11 5-10 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 ignition coil 3 2 bolt 6 m6 × 20 mm 3 bolt 6 m6 × 20 mm 4 bracket 1 5 clamp 3 6 clamp 3 7 screw 3 m6 × 20 mm 8 plate 1 9 gasket 1 10 grommet 1 11 idle speed control hose 1 power unit.

Page 108

Powr power unit 5-11 69j3d11.

Page 109

69j3d11 5-12 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 bolt 1 m6 × 30 mm 2 washer 1 3 link rod arm 1 4 plug 1 5 o-ring 1 not reusable 6 bolt 2 m6 × 20 mm 7 link rod 1 long 8 link rod 1 short 9 link rod 1 10 nut 3 11 oil filler cap 1 12 o-ring 1 not reusable 13 oil filler neck 1 14 bolt 2 m6 × 4...

Page 110

Powr power unit 5-13 69j3d11 no. Part name q’ty remarks 1 timing belt 1 2 bolt 4 m5 × 45 mm 3 drive sprocket 1 4 plate 1 5 woodruff key 1 6 timing belt tensioner 1 7 bolt 2 m10 × 35 mm 8 driven sprocket 2 9 dowel pin 2 10 bolt 28 m6 × 30 mm 11 port cylinder head cover 1 12 gasket 1 not reusable 13 s...

Page 111

69j3d11 5-14 1 2 3 4 5 6 7 8 9 checking the compression pressure 1. Start the engine, warm it up for 5 min- utes, and then turn it off. 2. Remove the clip from the engine shut-off switch on the remote control box. 3. Remove the ignition coil cover and all spark plugs, and then install the special se...

Page 112

Powr power unit 5-15 69j3d11 5. Check the oil pressure. Check the oil pump, oil leakage, and oil strainer if out of specification. Checking the oil pressure sensor 1. Connect the test harness (3 pins) to the oil pressure sensor. 2. Start the engine and warm it up for 5 min- utes. 3. Measure the oil ...

Page 113

69j3d11 5-16 1 2 3 4 5 6 7 8 9 note: do not turn the flywheel magnet counter- clockwise. 4. Check the intake and exhaust valve clearance for cylinder #4. 5. Turn the flywheel magnet an additional 120° clockwise and align the “2tdc” mark g on the flywheel magnet with the pointer b. 6. Check the intak...

Page 114

Powr power unit 5-17 69j3d11 10. Turn the flywheel magnet an additional 120° clockwise and align the “1tdc” mark on the flywheel magnet with the pointer, and check that the “i” marks on the driven sprockets are aligned with the alignment marks on the cylinder head. 11. Remove the flywheel magnet. Ca...

Page 115

69j3d11 5-18 1 2 3 4 5 6 7 8 9 15. Remove the driven sprockets. Note: hold the camshaft with a wrench, and be careful not to damage the driven sprocket. 16. Remove the timing chain tensioners b, then the camshaft caps in the order shown in the illustration. 17. Remove the camshafts and timing chains...

Page 116

Powr power unit 5-19 69j3d11 23. Install the camshaft caps, and then tighten them to the specified torque in the order shown in the illustration. 24. Install the timing chain tensioners b, and then tighten the bolts to the specified torque in the sequence shown. Note: • install the camshaft caps in ...

Page 117

69j3d11 5-20 1 2 3 4 5 6 7 8 9 28. Install the woodruff key. 29. Install the flywheel magnet. Caution: apply force in the direction of the arrows shown, to prevent the flywheel holder from slipping off easily. Note: apply engine oil to the flywheel magnet nut before installation. 30. Turn the flywhe...

Page 118

Powr power unit 5-21 69j3d11 35. Install the ignition coil cover, wiring har- ness guide, and flywheel magnet cover. Replacing the timing belt 1. Remove the flywheel magnet cover, igni- tion coil cover, and intake silencer. 2. Turn the flywheel magnet clockwise and align the “1tdc” mark a on the fly...

Page 119

69j3d11 5-22 1 2 3 4 5 6 7 8 9 5. Disconnect the stator coil couplers 3 and pulser coil coupler 4, and remove the blowby hose 5 and stator coil bracket 6. 6. Remove the wiring harness guide bolts. Note: move the wiring harness guide 7 to a posi- tion that will make servicing easy. 7. Using a hexagon...

Page 120

Powr power unit 5-23 69j3d11 caution: • do not twist, turn inside out, or bend the timing belt beyond the maximum limit of 25 mm (1.0 in) j, otherwise it may be damaged. • do not get oil or grease on the timing belt. 11. Turn the drive sprocket clockwise two turns, and then check that all alignment ...

Page 121

69j3d11 5-24 1 2 3 4 5 6 7 8 9 3. Remove the dipstick guide 5, and dis- connect the fuel hose 6, ptt motor leads 7, and flushing device hose (flush- ing device model) 8. 4. Disconnect the low-pressure fuel pump driver coupler, ptt switch coupler, shift cut switch coupler, neutral switch cou- pler, a...

Page 122

Powr power unit 5-25 69j3d11 caution: • apply force in the direction of the arrows shown, to prevent the flywheel holder from slipping off easily. • to prevent damage to the engine or tools, screw in the flywheel puller set bolts evenly and completely so that the flywheel puller plate is parallel to...

Page 123

69j3d11 5-26 1 2 3 4 5 6 7 8 9 2. Using a hexagon wrench, turn the timing belt tensioner 1 clockwise to push the timing belt, increase strength gradually, and then insert a ø5.0 mm (0.2 in) pin 2 into the hole g. 3. Remove the timing belt 3 from the driven sprocket side. 4. Remove the pin and timing...

Page 124

Powr power unit 5-27 69j3d11 installing the sprockets and timing belt 1. Install the driven sprockets 1, and then tighten the bolts to the specified torque. 2. Check that “i” marks a and b on the driven sprockets are aligned with marks c and d. Align if necessary. 3. Install the new gaskets, cylinde...

Page 125

69j3d11 5-28 1 2 3 4 5 6 7 8 9 7. Install the timing belt 6 from the drive sprocket side with its part number in the upright position, turn the belt a half turn counterclockwise to align it, and then remove the pin 5. 8. Turn the drive sprocket clockwise two turns, and then check that the alignment ...

Page 126

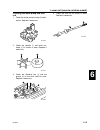

Powr power unit 5-29 69j3d11 cylinder head 5.

Page 127

69j3d11 5-30 1 2 3 4 5 6 7 8 9 È tightening sequence no. Part name q’ty remarks 1 timing chain tensioner 1 2 bolt 4 m6 × 25 mm 3 timing chain tensioner 1 4 bolt 32 m7 × 37 mm 5 bolt 4 m7 × 48 mm 6 camshaft cap 16 7 camshaft cap 2 8 timing chain 2 9 oil seal 2 not reusable 10 camshaft 3 1 11 camshaft...

Page 128

Powr power unit 5-31 69j3d11.

Page 129

69j3d11 5-32 1 2 3 4 5 6 7 8 9 È tightening sequence no. Part name q’ty remarks 1 spark plug 6 2 bolt 16 m10 × 120 mm 3 bolt 4 m8 × 55 mm 4 bolt 2 m8 × 90 mm 5 port cylinder head 1 6 bolt 4 m6 × 20 mm 7 engine hanger 2 8 bolt 2 m6 × 12 mm 9 ground lead 1 10 gasket 1 not reusable 11 starboard cylinde...

Page 130

Powr power unit 5-33 69j3d11 removing the cylinder head 1. Remove the exhaust cover bolts in the sequence shown. 2. Remove the timing chain tensioner 1 and camshaft caps in the sequence shown. 3. Remove the camshafts and timing chains, and disconnect the ground lead. 4. Remove the cylinder head bolt...

Page 131

69j3d11 5-34 1 2 3 4 5 6 7 8 9 checking the valve springs 1. Measure the valve spring free length a. Replace if out of specification. 2. Measure the valve spring tilt b. Replace if out of specification. Checking the valves 1. Check the valve face for pitting or wear. Replace if necessary. 2. Measure...

Page 132

Powr power unit 5-35 69j3d11 checking the valve guides note: before checking the valve guide make sure that the valve stem diameter is within specifi- cation. 1. Measure the valve guide inside diameter a. 2. Calculate the valve stem-to-valve guide clearance as follows. Replace the valve guide if out...

Page 133

69j3d11 5-36 1 2 3 4 5 6 7 8 9 note: • turn the valve guide reamer clockwise to ream the valve guide. • do not turn the reamer counterclockwise when removing the reamer. 4. Measure the valve guide inside diameter. Replace the valve guide if out of specifi- cation. Checking the valve seat 1. Eliminat...

Page 134

Powr power unit 5-37 69j3d11 2. Cut the surface of the valve seat with a 45° cutter by turning the cutter clockwise until the valve seat face has become smooth. A slag or rough surface caution: do not over cut the valve seat. Be sure to turn the cutter evenly downward at a pres- sure of 40–50 n (4–5...

Page 135

69j3d11 5-38 1 2 3 4 5 6 7 8 9 b previous contact width 7. If the valve seat contact area is too nar- row and situated near the top edge of the valve face, use a 30° cutter to cut the top edge of the valve seat. If necessary, use a 45° cutter to center the area and set its width. B previous contact ...

Page 136

Powr power unit 5-39 69j3d11 3. Measure the camshaft runout. Replace if out of specification. 4. Measure the camshaft journal diameter c and cylinder head journal inside diam- eter d. Replace the camshaft and cylin- der head if out of specification. 5. Calculate the camshaft oil clearance e as follo...

Page 137

69j3d11 5-40 1 2 3 4 5 6 7 8 9 checking the timing chain 1. Check the timing chain for damage or wear. Replace if necessary. Checking the cylinder head 1. Eliminate carbon deposits from the com- bustion chambers and check for deterio- ration. 2. Check the cylinder head warpage using a straightedge 1...

Page 138

Powr power unit 5-41 69j3d11 4. Lightly tap the valve spring retainer with a plastic hammer to set the valve cotter securely. Note: apply engine oil to the valve shims and valve lifters before installation. Installing the cylinder head 1. Install the new gaskets and cylinder heads, and then tighten ...

Page 139

69j3d11 5-42 1 2 3 4 5 6 7 8 9 4. Install the camshaft caps, and then tighten the bolts to the specified torques in two stages and in the sequence shown. 5. Install the timing chain tensioners 1, and then tighten the bolts to the specified torque in the sequence shown. Note: • install the camshaft c...

Page 140

Powr power unit 5-43 69j3d11 cylinder block 5.

Page 141

69j3d11 5-44 1 2 3 4 5 6 7 8 9 È tightening sequence no. Part name q’ty remarks 1 crankcase cover 1 2 bolt 17 m8 × 45 mm 3 bolt 2 m6 × 20 mm 4 engine hanger 1 5 plate 1 6 screw 14 m4 × 8 mm 7 gasket 1 not reusable 8 nut 6 9 baffle plate 1 10 dowel pin 2 11 bolt 12 not reusable 12 connecting rod cap ...

Page 142

Powr power unit 5-45 69j3d11.

Page 143

69j3d11 5-46 1 2 3 4 5 6 7 8 9 È tightening sequence no. Part name q’ty remarks 1 crankshaft 1 2 cylinder block 1 3 crankcase 1 4 oil seal 1 not reusable 5 thrust bearing 2 6 thrust bearing 1 7 main bearing 4 8 main bearing 4 9 stud bolt 6 m8 × 95 mm 10 bolt 8 m10 × 105 mm 11 bolt 2 m8 × 95 mm 12 bo...

Page 144

Powr power unit 5-47 69j3d11 disassembling the cylinder block 1. Remove the cooling water passage cover bolts in the sequence shown. 2. Remove the crankcase cover bolts in the sequence shown. Note: do not remove the ignition timing pointer from the crankcase cover. 3. Remove the baffle plate. 4. Rem...

Page 145

69j3d11 5-48 1 2 3 4 5 6 7 8 9 checking the cylinder bore 1. Measure the cylinder bore (d 1 –d 6 ) at measuring points a, b, and c, and in direction d (d 1 , d 3 , d 5 ), which is parallel to the crankshaft, and direction e (d 2 , d 4 , d 6 ), which is at a right angle to the crankshaft. A 20 mm (0....

Page 146

Powr power unit 5-49 69j3d11 checking the piston ring grooves 1. Measure the piston ring grooves. Replace the piston if out of specification. Checking the piston ring side clearance 1. Measure the piston ring side clearance. Replace the piston and piston rings as a set if out of specification. Check...

Page 147

69j3d11 5-50 1 2 3 4 5 6 7 8 9 checking the piston pin 1. Measure the piston pin diameter. Replace if out of specification. Checking the connecting rod small end inside diameter 1. Measure the connecting rod small end inside diameter a. Replace the connect- ing rod if out of specification. Checking ...

Page 148

Powr power unit 5-51 69j3d11 2. Measure the crankshaft runout. Replace the crankshaft if out of specification. Checking the crankpin oil clearance 1. Clean the bearings and the connecting rod. 2. Install the upper half of the bearing into the connecting rod 1 and the lower half into the connecting r...

Page 149

69j3d11 5-52 1 2 3 4 5 6 7 8 9 note: align the marks b on the connecting rod cap and connecting rod, which you made during disassembly. 6. Tighten the connecting rod bolts to the specified torques in three stages. Note: • reuse the removed connecting rod bolts when checking the oil clearance. • do n...

Page 150

Powr power unit 5-53 69j3d11 3. Select the suitable color b for the con- necting rod bearing from the table. Checking the crankshaft main journal oil clearance 1. Clean the bearings, main journals, and bearing portions of the crankcase and cylinder block. 2. Place the cylinder block upside down on a...

Page 151

69j3d11 5-54 1 2 3 4 5 6 7 8 9 9. Tighten the crankcase bolts to the speci- fied torques in two stages and in the sequence shown. Note: • crankcase bolts 1–f can be reused five times. • do not move the crankshaft until the main journal oil clearance measurement has been completed. • tighten crankcas...

Page 152

Powr power unit 5-55 69j3d11 3. Select the suitable main bearing number c from the table. Note: • example: if the crankshaft journal mark a is “81” and the cylinder block mark b is “04,” then the main bearing number c is “1.” • main bearing #3 is a thrust bearing. Disassembling the oil pump 1. Remov...

Page 153

69j3d11 5-56 1 2 3 4 5 6 7 8 9 note: install the oil seals using a general pipe of the proper size. Assembling the piston and cylinder block 1. Assemble the piston 1, connecting rod 2, piston pin 3, and new piston pin clips 4. Note: • face the mark a on the connecting rod in the same direction as th...

Page 154

Powr power unit 5-57 69j3d11 6. Install half of the bearings 9 into the cyl- inder block 0. 7. Insert the projection f of the bearing into the notch in the cylinder block. Note: install the main bearings in their original posi- tions. 8. Set the crankshaft a, and oil seal b, and thrust bearings c in...

Page 155

69j3d11 5-58 1 2 3 4 5 6 7 8 9 note: • the oil seals must be installed before tight- ening the crankcase bolts. • apply engine oil to the crankcase bolts before installation. • tighten crankcase bolts 1–f to the speci- fied torques in two stages first, and then tighten crankcase bolts g–s to the spe...

Page 156

Powr power unit 5-59 69j3d11 caution: before installing the oil pump, be sure to fill it with engine oil through the oil pas- sage k. 16. Install the baffle plate g to the specified torque. 17. Install the new gasket and crankcase cover, and then tighten the bolts to the specified torque in two stag...

Page 157

69j3d11 5-60 1 2 3 4 5 6 7 8 9 20. Install the oil filter, and then tighten it to the specified torque using a 72.5 mm (2.9 in) oil filter wrench. Checking the thermostat 1. Remove the cover 1 and thermostat 2. 2. Suspend the thermostat in a container of water. 3. Place a thermometer in the water an...

Page 158

Powr power unit 5-61 69j3d11 5. Install the dipstick guide 7, and connect the fuel hose 8, ptt motor leads 9, and flushing device hose (flushing device model) 0. 6. Connect the shift cable a and throttle cable b, and then adjust their lengths. For adjustment procedures, see chapter 3, “checking the ...

Page 159

69j3d11 5-62 1 2 3 4 5 6 7 8 9 7. Install the holders c and retaining plate d. 8. Install the stator coil bracket and stator coil. 9. Install the woodruff key. 10. Install the flywheel magnet. Caution: apply force in the direction of the arrows shown, to prevent the flywheel holder from slipping off...

Page 160: Lower Unit

Lowr 69j3d11 lower unit special service tools ..................................................................................... 6-1 lower unit (regular rotation model) ............................................................. 6-5 removing the lower unit .........................................

Page 161

69j3d11 1 2 3 4 5 6 7 8 9 propeller shaft housing (counter rotation model) .................................... 6-39 removing the propeller shaft housing assembly..................................... 6-41 disassembling the propeller shaft housing.............................................. 6-41 ch...

Page 162

Lowr lower unit 6-1 69j3d11 special service tools 6 bearing housing puller claw l 90890-06502 stopper guide plate 90890-06501 center bolt 90890-06504 bearing separator 90890-06534 stopper guide stand 90890-06538 bearing puller 90890-06535 bearing puller claw 1 90890-06536 slide hammer 90890-06531 be...

Page 163

69j3d11 6-2 1 2 3 4 5 6 7 8 9 needle bearing attachment 90890-06610, 90890-06653, 90890-06654 driver rod l3 90890-06652 driver rod ss 90890-06604 bearing depth plate 90890-06603 bearing inner race attachment 90890-06640, 90890-06659 ball bearing attachment 90890-06636, 90890-06656, 90890-06657 drive...

Page 164

Lowr lower unit 6-3 69j3d11 socket adapter 3 90890-06508 driver rod ll 90890-06605 pinion height gauge 90890-06702 fixing plate 90890-06711 digital caliper 90890-06704 shimming plate 90890-06701 shift rod push arm 90890-06052 backlash indicator 90890-06706 magnet base plate 90890-07003 dial gauge se...

Page 165

69j3d11 6-4 1 2 3 4 5 6 7 8 9 magnet base 90890-06705 puller head 90890-06514 ring nut wrench 90890-06578 flywheel puller 90890-06521 special service tools.

Page 166

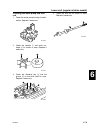

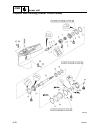

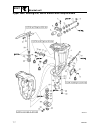

Lowr lower unit 6-5 69j3d11 lower unit (regular rotation model) 6.

Page 167

69j3d11 6-6 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 lower unit 1 2 plate 1 3 rubber seal 1 4 check screw 1 5 gasket 2 not reusable 6 dowel pin 2 7 bolt 7 m10 × 45 mm 8 drain screw 1 9 grommet 1 10 bolt 1 m10 × 44 mm 11 bolt 1 m10 × 70 mm 12 spacer 1 13 washer 1 14 propeller 1 15 washer 1 16 w...

Page 168

Lowr lower unit 6-7 69j3d11 s69j6010 a a a a 11 12 13 14 15 16 17 18 20 19 21 22 23 24 24 9 10 1 4 5 6 lt 572 aa a a a a 8 3 2 7 lt 572.

Page 169

69j3d11 6-8 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 shift rod 1 2 oil seal 1 not reusable 3 oil seal housing 1 4 o-ring 1 not reusable 3.1 × 70.6 mm 5 spring 1 6 circlip 1 7 bolt 3 m6 × 20 mm 8 seal 1 9 woodruff key 1 10 bolt 4 m8 × 45 mm 11 cover 1 12 seal 1 13 water pump housing 1 14 o-ring...

Page 170

Lowr lower unit 6-9 69j3d11 removing the lower unit 1. Drain the gear oil. For draining proce- dures, see chapter 3, “changing the gear oil.” 2. Set the gearshift to the neutral position, and place a block of wood between the anti-cavitation plate and propeller to keep the propeller from turning, an...

Page 171

69j3d11 6-10 1 2 3 4 5 6 7 8 9 checking the water pump and shift rod 1. Check the water pump housing for defor- mation. Replace if necessary. 2. Check the impeller 1 and insert car- tridge 2 for cracks or wear. Replace if necessary. 3. Check the woodruff key 3 and the groove a on the drive shaft for...

Page 172

Lowr lower unit 6-11 69j3d11 propeller shaft housing (regular rotation model) 6.

Page 173

69j3d11 6-12 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 shift rod joint 1 2 ball 2 3 slider 1 4 shift plunger 1 5 dog clutch 1 6 cross pin 1 7 spring 1 8 propeller shaft 1 9 washer 1 10 reverse gear 1 11 reverse gear shim — as required 12 ball bearing 1 not reusable 13 o-ring 1 not reusable 3.1 ...

Page 174

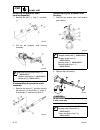

Lowr lower unit 6-13 69j3d11 removing the propeller shaft housing assembly 1. Remove the bolts 1, ring 2, and bolts 3. 2. Pull out the propeller shaft housing assembly. Disassembling the propeller shaft assembly 1. Remove the spring 1, and then remove the cross pin 2, dog clutch 3, slider 4, shift p...

Page 175

69j3d11 6-14 1 2 3 4 5 6 7 8 9 3. Remove the oil seals and needle bear- ing. Checking the propeller shaft housing 1. Clean the propeller shaft housing using a soft brush and cleaning solvent, and then check it for cracks or damage. Replace if necessary. 2. Check the teeth and dogs of the reverse gea...

Page 176

Lowr lower unit 6-15 69j3d11 assembling the propeller shaft assembly 1. Install the dog clutch 1 as shown. Note: install the dog clutch 1 with the “f” mark a facing toward the shift plunger. Assembling the propeller shaft housing 1. Install the needle bearing into the propel- ler shaft housing to th...

Page 177

69j3d11 6-16 1 2 3 4 5 6 7 8 9 4. Install the reverse gear 7 and original shim(s) 8 to the propeller shaft housing using a press. Caution: add or remove shim(s), if necessary, when replacing the reverse gear or ball bearing. Bearing outer race attachment 9: 90890-06622 É propeller shaft housing (reg...

Page 178

Lowr lower unit 6-17 69j3d11 drive shaft and lower case (regular rotation model) 6.

Page 179

69j3d11 6-18 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 drive shaft 1 2 cover 1 3 oil seal 2 not reusable 4 bolt 4 m8 × 25 mm 5 drive shaft housing 1 6 needle bearing 1 7 o-ring 1 not reusable 3 × 60.5 mm 8 pinion shim — as required 9 thrust bearing 1 10 lower case 1 11 needle bearing outer case...

Page 180

Lowr lower unit 6-19 69j3d11 removing the drive shaft 1. Remove the drive shaft, drive shaft hous- ing, and pinion, and then pull out the for- ward gear. Disassembling the drive shaft housing 1. Remove the cover, oil seals, and needle bearing. Disassembling the forward gear 1. Remove the taper rolle...

Page 181

69j3d11 6-20 1 2 3 4 5 6 7 8 9 checking the pinion and forward gear 1. Check the teeth of the pinion, and the teeth and dogs of the forward gear for cracks or wear. Replace if necessary. Checking the bearings 1. Check the bearings for pitting or rum- bling. Replace if necessary. Checking the drive s...

Page 182

Lowr lower unit 6-21 69j3d11 2. Install the needle bearing outer case into the lower case. Note: apply engine oil to the needle bearing outer case before installation. 3. Install the needle bearing into the needle bearing outer case. Note: apply engine oil or grease to the needle bearing, and then i...

Page 183

69j3d11 6-22 1 2 3 4 5 6 7 8 9 2. Install the drive shaft housing 1, thrust bearing 2, and original shim(s) 3 to the drive shaft 4. Caution: add or remove shim(s), if necessary, when replacing the drive shaft housing or drive shaft. 3. Install the drive shaft and drive shaft housing to the lower cas...

Page 184

Lowr lower unit 6-23 69j3d11 2. Install the new gasket 2, outer plate car- tridge 3, and dowel pins 4. 3. Install the woodruff key into the drive shaft. 4. Align the groove on the impeller 5 with the woodruff key 6, and then install it to the drive shaft. 5. Install the washers 7, wave washer 8, spa...

Page 185

69j3d11 6-24 1 2 3 4 5 6 7 8 9 7. Install the o-ring d and pump housing assembly e into the lower case, tighten the bolts f, and then install the seal g and cover h. Note: • when installing the pump housing, apply grease to the inside of the housing, and then turn the drive shaft clockwise while pus...

Page 186

Lowr lower unit 6-25 69j3d11 5. Install the propeller and propeller nut, and then tighten the nut finger tight. Place a block of wood between the anti- cavitation plate and propeller to keep the propeller from turning, and then tighten the nut to the specified torque. Warning do not hold the propell...

Page 187

69j3d11 6-26 1 2 3 4 5 6 7 8 9 shimming (regular rotation model) 6 a b f r p s69j6550 b4 t3 b3 65.0 t1 b1 39.4 41.0 t2 b2 b5 a1 a2 a3 drive shaft and lower case (regular rotation model) / shimming (regular rotation model).

Page 188

Lowr lower unit 6-27 69j3d11 shimming note: • shimming is not required when assembling the original lower case and inner parts. • shimming is required when assembling the original inner parts and a new lower case. • shimming is required when replacing the inner part(s). Selecting the pinion shims 1....

Page 189

69j3d11 6-28 1 2 3 4 5 6 7 8 9 5. Calculate the pinion shim thickness (t3) as shown in the examples below. Note: “p” is the deviation of the lower case dimen- sion from standard. The “p” mark a is stamped on the trim tab mounting surface of the lower case in 0.01 mm units. If the “p” mark is unreada...

Page 190

Lowr lower unit 6-29 69j3d11 2. Calculate the forward gear shim thickness (t1) as shown in the examples below. Note: “f” is the deviation of the lower case dimen- sion from standard. The “f” mark a is stamped on the trim tab mounting surface of the lower case in 0.01 mm units. If the “f” mark is unr...

Page 191

69j3d11 6-30 1 2 3 4 5 6 7 8 9 note: “r” is the deviation of the lower case dimen- sion from standard, and “a” is the deviation of the propeller shaft housing from standard. The “r” mark a is stamped on the trim tab mounting surface of the lower case, and the “a” mark b is stamped on the propeller s...

Page 192

Lowr lower unit 6-31 69j3d11 note: tighten the universal puller or center bolt while turning the drive shaft until the drive shaft can no longer be turned. 4. Install the backlash indicator onto the drive shaft (22.4 mm [0.88 in] in diame- ter), then the dial gauge onto the lower unit. 5. Set the lo...

Page 193

69j3d11 6-32 1 2 3 4 5 6 7 8 9 note: tighten the propeller nut b while turning the drive shaft until the drive shaft can no longer be turned. 10. Slowly turn the drive shaft clockwise and counterclockwise and measure the back- lash when the drive shaft stops in each direction. 11. Add or remove shim...

Page 194

Lowr lower unit 6-33 69j3d11 lower unit (counter rotation model) 6.

Page 195

69j3d11 6-34 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 lower unit 1 2 plate 1 3 rubber seal 1 4 check screw 1 5 gasket 2 not reusable 6 dowel pin 2 7 bolt 7 m10 × 45 mm 8 drain screw 1 9 grommet 1 10 bolt 1 m10 × 44 mm 11 bolt 1 m10 × 70 mm 12 spacer 1 13 washer 1 14 propeller 1 15 washer 1 16 ...

Page 196

Lowr lower unit 6-35 69j3d11 s69j6350 a a a a 11 12 13 14 15 16 17 18 20 19 21 22 23 24 24 9 10 1 4 5 6 lt 572 aa a a a a 8 3 2 7 lt 572.

Page 197

69j3d11 6-36 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 shift rod 1 2 oil seal 1 not reusable 3 oil seal housing 1 4 o-ring 1 not reusable 3.1 × 70.6 mm 5 spring 1 6 circlip 1 7 bolt 3 m6 × 20 mm 8 seal 1 9 woodruff key 1 10 bolt 4 m8 × 45 mm 11 cover 1 12 seal 1 13 water pump housing 1 14 o-rin...

Page 198

Lowr lower unit 6-37 69j3d11 removing the lower unit 1. Drain the gear oil. For draining proce- dures, see chapter 3, “changing the gear oil.” 2. Set the gearshift to the neutral position, and place a block of wood between the anti-cavitation plate and propeller to keep the propeller from turning, a...

Page 199

69j3d11 6-38 1 2 3 4 5 6 7 8 9 checking the water pump and shift rod 1. Check the water pump housing for defor- mation. Replace if necessary. 2. Check the impeller 1 and insert car- tridge 2 for cracks or wear. Replace if necessary. 3. Check the woodruff key 3 and the groove a on the drive shaft for...

Page 200

Lowr lower unit 6-39 69j3d11 propeller shaft housing (counter rotation model) 6.

Page 201

69j3d11 6-40 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 shift rod joint 1 2 ball 2 3 slider 1 4 shift plunger 1 5 dog clutch 1 6 cross pin 1 7 spring 1 8 forward gear 1 9 forward gear shim — as required 10 ring nut 1 11 claw washer 1 12 bearing outer race 1 not reusable 13 taper roller bearing 1...

Page 202

Lowr lower unit 6-41 69j3d11 removing the propeller shaft housing assembly 1. Remove the bolts 1, ring 2, and bolts 3. 2. Pull out the propeller shaft housing assembly. Disassembling the propeller shaft housing 1. Remove the spring 1, and then remove the cross pin 2, dog clutch 3, slider shift plung...

Page 203

69j3d11 6-42 1 2 3 4 5 6 7 8 9 caution: • do not press the propeller shaft threads a directly. • do not reuse the taper roller bearing, always replace it with a new one. 6. Remove the oil seals and needle bear- ing. Checking the propeller shaft housing 1. Clean the propeller shaft housing using a so...

Page 204

Lowr lower unit 6-43 69j3d11 2. Check the dog clutch, shift rod joint, and shift slider for cracks or wear. Replace if necessary. Assembling the propeller shaft housing 1. Install the needle bearing into the propel- ler shaft housing to the specified depth. Note: • install the needle bearing with th...

Page 205

69j3d11 6-44 1 2 3 4 5 6 7 8 9 5. Install the propeller shaft assembly in the reverse direction into the lower case. 6. Install the ring nut 0 and claw washer a, and then tighten the ring nut to the specified torque. 7. Install the forward gear b, original shim(s) c, and dog clutch d using a press. ...

Page 206

Lowr lower unit 6-45 69j3d11 drive shaft and lower case (counter rotation model) 6.

Page 207

69j3d11 6-46 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 drive shaft 1 2 cover 1 3 oil seal 2 not reusable 4 bolt 4 m8 × 25 mm 5 drive shaft housing 1 6 needle bearing 1 7 o-ring 1 not reusable 3 × 60.5 mm 8 pinion shim — as required 9 thrust bearing 1 10 lower case 1 11 needle bearing case 1 12 ...

Page 208

Lowr lower unit 6-47 69j3d11 removing the drive shaft 1. Remove the drive shaft assembly and pinion, and then pull out the reverse gear and thrust bearing. Disassembling the drive shaft housing 1. Remove the cover, oil seals, and needle bearing. Disassembling the reverse gear 1. Remove the needle be...

Page 209

69j3d11 6-48 1 2 3 4 5 6 7 8 9 checking the pinion and reverse gear 1. Check the teeth of the pinion, and the teeth and dogs of the reverse gear for cracks or wear. Replace if necessary. Checking the bearings 1. Check the bearings for pitting or rum- bling. Replace if necessary. Checking the drive s...

Page 210

Lowr lower unit 6-49 69j3d11 caution: add or remove shim(s), if necessary, when replacing the forward gear or lower case. 3. Install the needle bearing outer case into the lower case. Note: apply engine oil to the needle bearing outer case before installation. 4. Install the needle bearing into the ...

Page 211

69j3d11 6-50 1 2 3 4 5 6 7 8 9 2. Apply grease to the new oil seals, and then install them into the drive shaft housing to the specified depth. Note: install an oil seal halfway into the drive shaft housing, then the other oil seal. Installing the drive shaft 1. Install the forward gear to the lower...

Page 212

Lowr lower unit 6-51 69j3d11 2. Install the bolts 1, ring 2, and bolts 3, and then tighten the bolts 1 to the speci- fied torque. Installing the water pump and shift rod 1. Install the shift rod assembly 1. 2. Install the new gasket 2, outer plate car- tridge 3, and dowel pins 4. 3. Install the wood...

Page 213

69j3d11 6-52 1 2 3 4 5 6 7 8 9 5. Install the washers 7, wave washer 8, spacer 9, and collar 0 to the drive shaft. Note: • the collar and spacer should fit together firmly. • while pulling the drive shaft up, install the collar with an appropriate tool a that fits over the drive shaft as shown. 6. I...

Page 214

Lowr lower unit 6-53 69j3d11 2. Install the two dowel pins 1 to the lower unit. 3. Install the lower unit to the upper case, and then tighten the bolts 2 to the speci- fied torque. 4. Install the trim tab 3 to its original posi- tion, and then tighten the bolt 4 to the specified torque. 5. Install t...

Page 215

69j3d11 6-54 1 2 3 4 5 6 7 8 9 shimming (counter rotation model) 6 a b f r p s69j6670 b4 t3 b3 65.0 a3 t1 b1 38.4 a1 t2 b8 b5 a5 a4 a2 t´4 b7 b6 47.5 drive shaft and lower case (counter rotation model) / shimming (counter rotation model).

Page 216

Lowr lower unit 6-55 69j3d11 shimming note: • shimming is not required when assembling the original lower case and inner parts. • shimming is required when assembling the original inner parts and a new lower case. • shimming is required when replacing the inner part(s). Selecting the pinion shims 1....

Page 217

69j3d11 6-56 1 2 3 4 5 6 7 8 9 5. Calculate the pinion shim thickness (t3) as shown in the examples below. Note: “p” is the deviation of the lower case dimen- sion from standard. The “p” mark a is stamped on the trim tab mounting surface of the lower case in 0.01 mm units. If the “p” mark is unreada...

Page 218

Lowr lower unit 6-57 69j3d11 2. Calculate the reverse gear shim thickness (t1) as shown in the examples below. Note: “f” is the deviation of the lower case dimen- sion from standard. The “f” mark a is stamped on the trim tab mounting surface of the lower case in 0.01 mm units. If the “f” mark is unr...

Page 219

69j3d11 6-58 1 2 3 4 5 6 7 8 9 2. Calculate the forward gear shim thick- ness (t2) as shown in the examples below. Note: “r” is the deviation of the lower case dimen- sion from standard, and “a” is the deviation of the propeller shaft housing dimension from standard. The “r” mark a is stamped on the...

Page 220

Lowr lower unit 6-59 69j3d11 note: • select the shim thickness (t’4) by using the specified measurement(s) and the calcula- tion formula. • measure the taper roller bearing at three points to find the height average. 2. Install the thrust bearing 4 to the propel- ler shaft 5, and then measure the pr...

Page 221

69j3d11 6-60 1 2 3 4 5 6 7 8 9 6. If the “a” mark or “b” mark is unreadable, measure the propeller shaft free play as shown. 7. Install the shim(s) 6, thrust bearing 4, propeller shaft 5, taper roller bearing 7, and claw washer 8, and then tighten the ring nut 9 to the specified torque. 8. Measure t...

Page 222

Lowr lower unit 6-61 69j3d11 5. Set the lower unit upside down. Note: install the dial gauge so that the plunger a contacts the mark b on the backlash indica- tor. 6. Slowly turn the drive shaft clockwise and counterclockwise and measure the back- lash when the drive shaft stops in each direction. 7...

Page 223

69j3d11 6-62 1 2 3 4 5 6 7 8 9 13. Turn the shift rod to the reverse position c with the shift rod push arm. 14. Slowly turn the drive shaft clockwise and counterclockwise and measure the back- lash when the drive shaft stops in each direction. Note: when measuring the reverse gear backlash, turn th...

Page 224: Bracket Unit

Brkt 69j3d11 bracket unit special service tools ..................................................................................... 7-1 bottom cowling .............................................................................................. 7-3 upper case, steering arm, swivel bracket and cla...

Page 225

69j3d11 1 2 3 4 5 6 7 8 9 power trim and tilt electrical system.......................................................... 7-43 checking the fuse.................................................................................... 7-44 checking the power trim and tilt relay ..............................

Page 226

Brkt bracket unit 7-1 69j3d11 special service tools 7 ptt oil pressure gauge assembly 90890-06580 ptt oil pressure gauge adapter 90890-06581 cylinder-end screw wrench 90890-06544 ptt piston vice attachment 90890-06572 tilt rod wrench 90890-06569.

Page 227: — Memo —

69j3d11 7-2 1 2 3 4 5 6 7 8 9 — memo — special service tools.

Page 228

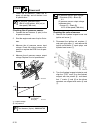

Brkt bracket unit 7-3 69j3d11 bottom cowling 7.

Page 229

69j3d11 7-4 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 bracket 1 2 shift cut switch 1 3 bracket 1 4 neutral switch 1 5 screw 2 m4 × 16 mm 6 plate 1 7 spring 1 8 bushing 2 9 grease nipple 1 10 bolt 1 11 bolt 1 m6 × 35 mm 12 clamp 1 13 bolt 1 m6 × 35 mm 14 screw 2 m4 × 16 mm 15 plate 1 16 clip 2 1...

Page 230

Brkt bracket unit 7-5 69j3d11.

Page 231

69j3d11 7-6 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 bottom cowling 1 2 rubber seal 1 3 cowling lock lever 2 4 bushing 6 5 plate 2 6 bolt 6 m6 × 30 mm 7 wave washer 3 8 lever 2 9 washer 3 10 bolt 3 m6 × 20 mm 11 spring 3 12 hook 3 13 bolt 3 m6 × 20 mm 14 bracket 1 15 bolt 2 m6 × 25 mm 16 plate...

Page 232

Brkt bracket unit 7-7 69j3d11 upper case, steering arm, swivel bracket and clamp brackets 7.

Page 233

69j3d11 7-8 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 upper case assembly 1 2 damper 2 3 bolt 2 m14 × 190 mm 4 washer 6 5 upper mount 2 6 bracket 1 7 bolt 3 m10 × 40 mm 8 bolt 4 m10 × 40 mm 9 mount housing 2 10 bolt 2 m14 × 205 mm 11 washer 2 12 rubber washer 2 13 lower mount 2 14 washer 2 15 d...

Page 234

Brkt bracket unit 7-9 69j3d11.

Page 235

69j3d11 7-10 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 upper exhaust guide 1 2 bolt 2 m8 × 35 mm 3 pressure control valve 1 4 bolt 1 m6 × 20 mm 5 plate 1 6 collar 1 7 bolt 7 m10 × 45 mm 8 gasket 1 not reusable 9 dowel pin 2 10 lower exhaust guide 1 11 gasket 1 not reusable 12 oil strainer 1 13 ...

Page 236

Brkt bracket unit 7-11 69j3d11.

Page 237

69j3d11 7-12 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 through tube 1 2 port clamp bracket 1 3 bolt 8 m10 × 45 mm 4 ground lead 3 5 screw 1 6 washer 2 7 bushing 10 8 friction plate 2 9 screw 4 m6 × 10 mm 10 screw 2 m6 × 15 mm 11 trim sensor 1 12 grease nipple 6 13 screw 1 m6 × 12 mm 14 clamp 2 ...

Page 238

Brkt bracket unit 7-13 69j3d11 draining the engine oil 1. Place a drain pan under the drain hole, and then remove the drain bolt 1 and let the oil drain completely. 2. Remove the cover 2 and damper 3. 3. Remove the upper and lower mounting nut, and then remove the upper case. 4. Remove the muffler a...

Page 239

69j3d11 7-14 1 2 3 4 5 6 7 8 9 2. Install the oil strainer 4 and bolts, and then tighten the bolts to the specified torque. 3. Install the oil pan 5, and then tighten the bolts finger tight. 4. Install the exhaust manifold 6 and bolts, and then tighten the bolts finger tight. 5. Tighten the exhaust ...

Page 240

Brkt bracket unit 7-15 69j3d11 11. Install the upper mounts g and bolts into the upper case. 12. Install the bracket h and bolts. 13. Install the lower mounts i and mount housings j. Removing the steering arm 1. Remove the circlip 1. 2. Remove the steering yoke 2 by striking it with a plastic hammer...

Page 241

69j3d11 7-16 1 2 3 4 5 6 7 8 9 installing the steering arm 1. Install the washer 1 and bushing 2 onto the steering arm 3. 2. Place the swivel bracket 4 in an upright position, and then install the steering arm onto the swivel bracket. 3. Install the bushing 5, o-ring 6, bushing 7, and washer 8 onto ...

Page 242

Brkt bracket unit 7-17 69j3d11 installing the upper case 1. Install the upper and lower mounting bolts into the swivel bracket 1 simulta- neously. 2. Install the upper mounting nut 2 and lower mounting nut 3, and then tighten them to the specified torques. Removing the power trim and tilt unit 1. Fu...

Page 243

69j3d11 7-18 1 2 3 4 5 6 7 8 9 removing the clamp brackets 1. Remove the self-locking nut 1 and ground lead 2, then clamp brackets 3 and 4. 2. Remove the trim sensor 5. Installing the clamp brackets 1. Install the trim sensor 1 onto the port clamp bracket. Note: adjust the trim sensor after installi...

Page 244

Brkt bracket unit 7-19 69j3d11 3. Install the tilt ram upper end into the swivel bracket with the shaft 4 and cir- clip 5. 4. Tighten the self-locking nut 6 to the specified torque. 5. Remove the anode 7. 6. Inject grease into all grease nipples until grease comes out from the bushings a. Adjusting ...

Page 245

69j3d11 7-20 1 2 3 4 5 6 7 8 9 7. Fully tilt the outboard motor up, and then support it with the tilt stop lever. Warning after tilting up the outboard motor, be sure to support it with the tilt stop lever. Otherwise, the outboard motor could sud- denly lower if the power trim and tilt unit should l...

Page 246

Brkt bracket unit 7-21 69j3d11 power trim and tilt unit 7.

Page 247

69j3d11 7-22 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 cylinder block 1 2 reservoir 1 3 bolt 3 m8 × 20 mm 4 o-ring 1 not reusable 1.9 × 12.6 mm 5 reservoir cap 1 m12 × 10 mm 6 o-ring 1 not reusable 7 sheet 1 8 filter 1 9 spacer 1 10 bolt 3 m8 × 20 mm 11 o-ring 1 not reusable 2.4 × 22.6 mm 12 jo...

Page 248

Brkt bracket unit 7-23 69j3d11.

Page 249

69j3d11 7-24 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 circlip 2 2 dust seal 2 not reusable 3 trim cylinder end screw 2 4 o-ring 2 not reusable 5 trim ram 2 6 trim piston 2 7 washer 2 8 bolt 2 m8 × 20 mm 9 backup ring 2 10 o-ring 2 not reusable 11 spring 2 12 adapter 2 13 circlip 2 14 tilt ram ...

Page 250

Brkt bracket unit 7-25 69j3d11.

Page 251

69j3d11 7-26 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 gear housing 1 1 2 bolt 3 m5 × 40 mm 3 plate 1 4 filter 1 5 valve lock screw 2 6 down-relief spring 1 7 valve support pin 1 8 relief valve seal 1 9 up-relief spring 1 10 valve support pin 1 11 o-ring 1 not reusable 1.8 × 11.35 mm 12 ball 1 ...

Page 252

Brkt bracket unit 7-27 69j3d11 disassembling the power trim and tilt motor 1. Remove the ptt motor screws 1, then the yoke 2. Caution: do not allow grease or oil to contact the commutator. Note: place a clean cloth over the end of the arma- ture shaft and carefully pull the armature from the yoke wi...

Page 253

69j3d11 7-28 1 2 3 4 5 6 7 8 9 5. Check the circuit breaker for continuity. Replace the brush holder if there is no continuity. 6. Measure the brush length. Replace if out of specification. 7. Check the base for corrosion or damage. Replace if necessary. 8. Check the bearing for damage or wear. Repl...

Page 254

Brkt bracket unit 7-29 69j3d11 6. Install the wave washer a and washer b into the yoke c. 7. Install the new o-ring and yoke c to the motor base. Note: place a clean cloth over the end of the arma- ture shaft and carefully push the armature from the yoke with a pair of pliers as shown. Checking the ...

Page 255

69j3d11 7-30 1 2 3 4 5 6 7 8 9 6. Reverse the ptt motor leads between the battery terminals to fully extend the trim and tilt rams. 7. Remove the ptt oil pressure gauge adapter set 2. 8. Install the pipe joints 1, and then tight- ening them to the specified torque. 9. Connect the ptt motor leads to ...

Page 256

Brkt bracket unit 7-31 69j3d11 14. Remove the ptt oil pressure gauge adapter set 2. 15. Install the pipe joints 3, and then tight- ening them to the specified torque. 16. After measuring the hydraulic pressure, connect the ptt motor leads to the bat- tery terminals to fully extend the trim and tilt ...

Page 257

69j3d11 7-32 1 2 3 4 5 6 7 8 9 3. Remove the bracket 5, then the balls 6. 4. Remove the gear housing 2 7, then the shuttle pistons 8. 5. Remove the drive gear 9, balls 0, and dowel pins a. Disassembling the tilt cylinder and trim cylinders 1. Hold the tilt cylinder 1 in a vise using aluminum plates ...

Page 258

Brkt bracket unit 7-33 69j3d11 warning never look into the tilt cylinder opening because the free piston and power trim and tilt fluid may be expelled out force- fully. 5. Hold the tilt piston in a vise using the special service tool 4 on both sides. 6. Remove the tilt ram. 7. Hold the cylinder bloc...

Page 259

69j3d11 7-34 1 2 3 4 5 6 7 8 9 checking the reservoir 1. Check the reservoir for cracks or corro- sion. Replace if necessary. Checking the tilt cylinder and trim cylinder 1. Check the power trim and tilt unit for cracks or corrosion. Replace if neces- sary. 2. Check the inner walls of the cylinder b...

Page 260

Brkt bracket unit 7-35 69j3d11 2. Check the up-relief valve and down-relief valve for dirt or residue. Clean if neces- sary. 3. Check the main valves for dirt or residue. Clean if necessary. 4. Check the absorber valves for dirt or res- idue. Clean if necessary. Checking the filters 1. Check gear pu...

Page 261

69j3d11 7-36 1 2 3 4 5 6 7 8 9 3. Install the balls 7, manual release spring 8, and bracket 9 by installing the bolts 0, then tightening them to the specified torque. 4. Install the relief valve seal a and ball b into the gear housing 1 5. 5. Install the filters c and gear pump d by installing the b...

Page 262

Brkt bracket unit 7-37 69j3d11 2. Install the tilt cylinder end screw 6, spring 7, adapter 8, and tilt piston 9 to the tilt ram 5. 3. Hold the tilt piston in a vise using the special service tool a on both sides. 4. Tighten the tilt ram 0 to the specified torque. 5. Install the new o-ring c and back...

Page 263

69j3d11 7-38 1 2 3 4 5 6 7 8 9 4. Install the new o-ring 3, backup ring 4, spring 5, adapter 6, and circlip 7 to the trim piston 1. 5. Install the new oil seal 8, circlip 9, and new o-ring 0 into the trim cylinder end screw a. 6. Install the trim cylinder end screw a into the trim ram 2. Installing ...

Page 264

Brkt bracket unit 7-39 69j3d11 3. Install the trim piston assembly into the trim cylinder, and then tighten the trim cylinder end screw 2 to the specified torque. Warning do not push the trim rams down while installing them into the trim cylinders. Otherwise, the power trim and tilt fluid may spurt ...

Page 265

69j3d11 7-40 1 2 3 4 5 6 7 8 9 note: align the armature shaft with the recess in the joint. Installing the reservoir 1. Install the spacer 1, filter 2 and sheet 3 to the cylinder block. 2. Install the new o-ring 4 and reservoir 5, and then tighten the bolts 6 to the specified torque. 3. Install the ...

Page 266

Brkt bracket unit 7-41 69j3d11 warning to prevent the power trim and tilt fluid from spurting out due to internal pres- sure, the tilt ram should be kept at full length. Note: place the tilt cylinder end screw at the bottom of the tilt ram and install the tilt piston assem- bly into the tilt cylinde...

Page 267

69j3d11 7-42 1 2 3 4 5 6 7 8 9 note: • repeat this procedure so that the rams go up and down four to five times (be sure to wait a few seconds before switching the leads). • the sound of the power trim and tilt motor will change when the rams are fully extended. • if the rams do not move up and down...

Page 268

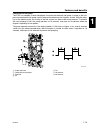

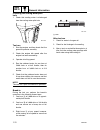

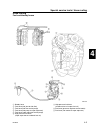

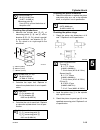

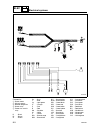

Brkt bracket unit 7-43 69j3d11 power trim and tilt electrical system 7 1 fuse (30 a) 2 fuse (20 a) 3 power trim and tilt relay 4 power trim and tilt motor 5 10-pin coupler 6 battery 7 power trim and tilt switch 8 trim sensor b : black gy : gray lg : light green p : pink r : red sb : sky blue s69j752...

Page 269

69j3d11 7-44 1 2 3 4 5 6 7 8 9 checking the fuse 1. Check the fuse for continuity. Replace if there is no continuity. Checking the power trim and tilt relay 1. Check the power trim and tilt relay for continuity. Replace if out of specification. Note: be sure to set the measurement range a shown in t...

Page 270

Brkt bracket unit 7-45 69j3d11 checking the power trim and tilt switch 1. Check the power trim and tilt switch for continuity. Replace if out of specification. Checking the trim sensor 1. Measure the trim sensor resistance. Replace if out of specification. Note: turn the lever 1 and measure the resi...

Page 271: Electrical Systems

69j3d11 elec – + 1 2 3 4 5 6 7 8 9 electrical systems special service tools ..................................................................................... 8-1 checking the electrical components............................................................ 8-2 measuring the peak voltage ...........

Page 272

Elec electrical systems – + 8-1 69j3d11 special service tools 8 ignition tester 90890-06754 digital circuit tester 90890-03174 peak voltage adaptor 90890-03172 test harness (2 pins) 90890-06792 test harness (4 pins) 90890-06771 test harness (3 pins) 90890-06793 test harness (3 pins) 90890-06770 test...

Page 273

69j3d11 8-2 1 2 3 4 5 6 7 8 9 checking the electrical components 8 measuring the peak voltage note: before troubleshooting the peak voltage, check that all electrical connections are tight and free from corrosion, and that the battery is fully charged to 12 v. The condition of the ignition system ca...

Page 274