Summary of FZ-16

Page 1

1es-f8107-e0 2010 fz 16.

Page 2

Fz 16 assembly manual first edition all rights reserved. Any reproduction or unauthorized use without the written permission of india yamaha motor pvt. Ltd. Is expressly prohibited. Printed in india.

Page 3: Foreword

This assembly manual contains the information required for the correct assembly of this motorcycle prior to delivery to the customer. Since some external parts of the motorcycle have been removed at the yamaha factory for the convenience of packing, assembly by the yamaha dealer is required. It shou...

Page 4: Index

Index 1. Symbols used in the assembly manual …………............................................ 2. Unpackaging ……………………………………………………………………………….. 3. Parts location ………………..…………….............................................................. A. Carton a ……………………………………………………………...……. B. Carton b……………………………...

Page 5

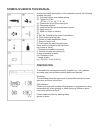

1 symbols used in this manual in order to simplify descriptions in this assembly manual, the following symbols are used: (1): coat with lithium-soap-based grease. (2): tighten to 10 nm. (10 nm = 1.0 m · kg, 7.2 ft · lb) (3): towards the front of the motorcycle (4): clearance required (5): install so...

Page 6: Unpackaging

2 1. Remove all the strips from all the corners & top cover “1”. 2. Remove the front wheel “2” by untagging its cords.“1”. 3. Remove wooden angles “3” 4. Remove side covers “4” 5. Remove front cover “5”. 6 6. Remove the nut “6” in order to remove the front wheel assy. From the packing box.. 2 4 4 3 ...

Page 7

3 8. Untag & remove the loosen parts kept on the vehicle. 9. Remove all the carton boxes “8”. 10. Remove the wooden support bracket “9” from the mounting bracket “10”. 11. Remove mounting bracket by removing the bolt “11” from seat handle.. 10 9 8 8 12. Tighten the bolt”11” at its original position....

Page 8

4 12. Remove carton box “12” from the rear side of the vehicle by untagging its cord. 13. Remove handlebar “13” from both the side of rear wheel of both motorcycle. 14. Remove the carton box “14” placed over frame at the area of rider seat. 12 13 15. Remove the axle nut “15” from the front fork, and...

Page 9

Hardware in carton “b” s. No. Part no. / description qty. Illustration 1. 97027-06020 2 each bolt hex 2. 90154-06061 2 each screw cross recess 3. 90387-068c5 4 each collar 4. 90201-6726 2 each washer plain 5. 21c-f5183-00 2 nos. Coller wheel shaft 6. 95827-08016 2 nos. Bolt flange 7. 36l-h3936-00 2 ...

Page 10

S. No. Part no. / description qty. Illustration 12. 21c-f8100-10 2 each tool kit 6.

Page 11: Part Location

7 1. Carton a 2. Carton b 3. Carton c carton box a content rider seat (2nos, 1 for each vehicle) carton box b content carton box c content 1. Owner’s manual (2nos, 1 for each vehicle) 2. Tool kit (2nos, 1 for each vehicle) 3. Installation hardware. 4. Mirror assy 1 (2nos, 1 for each vehicle) 5. Mirr...

Page 12

8 setup and predilivery check list tip: check the following items again after setup and predelivery service have been completed. A: installation of the parts included in the crate front wheel rearview mirrors front fender seat handlebar b: tightening torque of each part flange bolt (front fender) fr...

Page 13: Setup Procedure

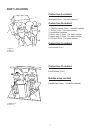

9 setup procedure perform the setup procedures in the order indicated by the numbers. Always follow the order asshown. 1. Front fender 2. Front wheel 3. Handlebar 4. Left handlebar switch 5. Right handlebar switch 6. Cdi unit 7. Seat 8. Rear view mirror 1 2 3 8 6 7 4 5.

Page 14

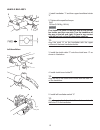

Front fender 1. Seat the front fender assy. “1” between the front fork leg “2” . 2. Install the screw cross recess “3” along with the collar “4”. 3. Install the hex bolt “5” along with the washer “6” from the inner side of fender. 4. Tighten the screws and bolts as per the specification. Screw 3.0 n...

Page 15

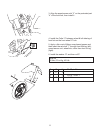

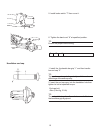

3. Align the speed sensor slot “3” on the protruded part “4” of the front fork, then install it . 4. Install the collar “5” between wheel & left side leg of front fork on the front wheel “6” hub. 5. Apply a thin coat of lithium soap based grease and then insert the axle bolt “7” through front fork l...

Page 16

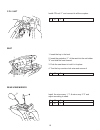

A b 6 handle bar assy. A 1 2 2 3 4 3. Install the clutch cable “3” onto the clutch lever “4” as shown in illustration. 4. Install clutch lever holder”5”. Tip: align the slit of the clutch lever holder with the mark “a” on the handlebar. 5. Install left handlebar switch “6” tip: align the projection ...

Page 17

7. Install the clutch switch “8” by pushing it in. 8. Install the band cord “9”. 9 8 7 6. Install the handle switch screws “7” at specified torque. Screw 7 nm (0.7 kg.M, 5 ft.Lb) 13 9 c 1.

Page 18

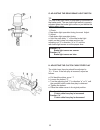

Right handlebar 1. Install brake master cylinder holder “1” and then tighten its bolts at specified torque. Bolt 10nm, 1.0m.Kg, 7 ft.Lb. 3. Install throttle grip “1”, throttle cable “2” and then right handlebar switch “3”. Tip: align the projection “a” on the right handlebar switch with the hole “b”...

Page 19

Handlebar end cap 1. Install the the handle bar grip “1” and then handle bar end cap “2”. Tip: tighten the end cap bolt gradually until it reaches to plastic legs of the end cap assy. 2. Insert the end cap assy into the handlebar hole then tighten its bolt at specified torque. End cap bolt 4nm (0.4m...

Page 20

C.D.I. Unit 1 install cdi unit “1” and connect its all the couplers. 1 c 1 seat 1. Insert the key in the lock. 2. Insert the projection “1” of the seat into the set holder “2” and slide the seat forward. 3. Push the seat down to lock it in its place. 4. Turn the key counter clock wise and remove it ...

Page 21: Cable Routing

Cable routing r r 3 1 4 10 9 6 5 8 g 11 7 6 5 8 7 5 6 11 9 d 9 h i 14 13 1 2 12 f 2 3 2 1 4 a 1 4 3 12 b a c d c b r-r 17.

Page 22

1. Front brake hose 2. Throttle cable 3. Front brake light switch lead 4. Right handlebar switch lead 5. Left handlebar switch lead 6. Clutch switch lead 7. Clutch cable 8. Starter cable 9. Main switch lead 10. Meter lead 11. Lh front turn signal lead 12. Rh front lead 13. Headlight lead 14. Pilot l...

Page 23

13 13 5 2 b b l m c c d d e j s s f 3 1 2 4 b c a 5 d 6 7 8 9 e 10 2 f 11 h g i 14 15 16 n m m e e c b b s 11 14 13 16 15 2 l 2 12 13 14 16 15 j 12 s-s 6 m-m 6 n e-e b-b d-d c-c 3 4 17 17 17 19.

Page 24

1. Clutch cable 2. Overflow pipe 3. Throttle cable 4. Starter cable 5. Carburetor air bend 6. Ac magneto generator lead 7. Wire minus lead 8. Battery breather hose 9. Carburetor drain hose 10. Fuel pipe 11. Horn lead 12. Connector cover 13. Wire harness 14. Sensor unit lead 15. Switch handle (lh) le...

Page 25

A 1 4 2 3 5 6 9 10 8 11 10 3 13 21 22 20 14 15 12 16 17 18 19 a a-a 7 15 a 21.

Page 26

1. Lh handle switch 2. Clutch switch lead 3. Clutch cable 4. Lh handle switch lead 5. Starter cable 6. Main switch lead 7. Rh handle switch lead 8. Brake hose 9. Front stop switch assembly lead 10. Throttle cable 11. Rh handle switch 12. Rear lead (lh) 13. Relay assembly 14. Tail light unit assembly...

Page 27

29 17 16 h-h 16 28 10 k-k 30 25 u-u 31 5 t-t p p 16 a 18 19 b 10 c 21 22 26 e 24 27 23 251 5 6 7 8 f g 9 h i j k 12 11 10 13 l 14 29 15 m n h 31 30 k k k u u u t t t t o 23.

Page 28

1. Throttle cable 2. Sensor unit lead 3. Brake hose 4. Horn lead 5. Ht lead 6. Spark plug cap 7. Starting motor lead 8. Starter relay lead 9. Fuse holder assembly 10. Wire minus lead 11. Carburetor drain hose 12. Battery breather hose 13. Starter relay assembly 14. Stop switch assembly 15. Battery 1...

Page 29

Adjustments and pre deliveryservice perform the pre delivery service in the order indicated by the letters. Always follow the order as shown. A. Checking & charging the battery b. Measuring the tire pressure c. Checking the engine oil level d. Adjusting the engine idle speed e. Adjusting the throttl...

Page 30

Notice a. Checking and charging the battery 1. Charging: the battery must be charged properly before using for the first time. This initial charge will prolong the life of the battery. (a) upper level line (b) lower level line a. Remove all filler caps from the battery and remove the breather hose c...

Page 31

Batteries also generate explosive hydrogen gas, therefore you should always follow these preventive measures: charge batteries in a well-ventilated area. Keep batteries away from fire, sparks, or open flames (e.G., welding equipment, lighted cigarettes, etc.). Batteries. Keep batteries and electroly...

Page 32

Make sure that the battery leads are connected correctly. Reversing leads can seriously damage the electrical system. Notice 1. Measure tire pressure, if found out of specification, maintain the tire pressure. • the tire pressure should only be checked and regulated when the tire temperature equals ...

Page 33

1. Stand the motorcycle on a level surface. Tip: place the motorcycle on a suitable stand. 2. Start the engine, warm it up for several minutes, and then turn it off. 3. Remove dipstick “1”. 4. Check: • engine oil level the engine oil level should be between the minimum level mark (a) and maximum lev...

Page 34

D. Adjusting the engine idling speed tip: prior to adjusting the engine idling speed, the carburetor synchronization should be adjusted properly, the air filter should be clean, and the engine should have adequate compression. 1. Start the engine and let it warm up for several minutes. 2. Install: •...

Page 35

E. Adjusting the throttle cable free play direction “a” throttle cable free play is increased. Direction “b” throttle cable free play is decreased. After adjusting the throttle cable free play, start the engine and turn the handlebar to the right or left to ensure that this does not cause the engine...

Page 36

G. Adjusting the rear brake light switch direction “a” brake light comes on sooner. Direction “b” brake light comes on later. Tip: the rear brake light switch is operated by movement of the brake pedal. The rear brake light switch is properly adjusted when the brake light comes on just before the br...

Page 37

I. Adjusting the drive chain slack a drive chain that is too tight will overload the engine and other vital parts, and one that is too loose can skip and damage the swingarm or cause an accident. Therefore, keep the drive chain slack within the specified limits. Securely support the vehicle so that ...

Page 38

J. Adjusting headlight beam direction “a” headlight beam is lowered. Direction “b” headlight beam is raised. 1. Loosen: • head light mounting bolt “1” from both the end. • head light beam adjustment bolt “2”. 2. Adjust : loosen the headlight adjusting screw and move the headlight in the following ma...

Page 39: Appendices

Service data engine idling speed: spark plug: fuel: valve clearance (cold): maximum load*: tire pressure: standard equipment 1,300 ~ 1,500 r/min type (manufacturer) ngk/cpr8ea-9 gap 0.8 ~0.9 recommended fuel unleaded gasoline only fuel tank capacity total: 12.0 l in 0.08 ~ 0.12 mm ex 0.12 ~ 0.16 mm ...

Page 40: Tightening Torque

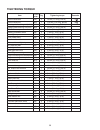

36 tightening torque item thread size qty tightening torque remarks e e crown handle bolt m8 2 16 nm (1.6 m kg, 12ft ib) crown handle nut m22 1 110 nm (11.0 m kg, 80ft ib) . . . . Steering shaft and ring nut (initial) m25 1 33 nm (3.3 m.Kg, 24ft.Ib) steering shaft and ring nut (final) m25 1 22 nm (2...

Page 41

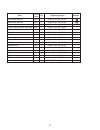

37 item thread size qty tightening torque remarks e e front wheel axle nut m14 1 60 nm (6.0 m.Kg, 43ft.Ib) rear wheel axle nut m14 1 90 nm (9.0 m.Kg, 65ft.Ib) m8 6 43 nm (4.3 m.Kg, 31ft.Ib) tension bar and brake shoe plate m8 1 20 nm (2.0 m.Kg, 14ft.Ib) camshaft and lever cam shaft m6 1 10 nm (1.0 m...

Page 42

India yamaha motor pvt. Ltd..