- DL manuals

- Yamaha

- Motorcycle

- FZ-16

- Service Manual

Yamaha FZ-16 Service Manual

Summary of FZ-16

Page 1

Service manual fz-16 21c-f8197-eo.

Page 2

Fz-16 service manual all rights reserved. Any reproduction or unauthorized use without the written consent of yamaha motor india pvt. Ltd. Is strictly prohibited..

Page 3

Attention this manual has been prepared by iym, mainly for use by dealers and their mechanics qualified. It is not possible to gather in a manual all the knowledge of a mechanic. Any person carrying out maintenance and repairs on yamaha vehicles should basic knowledge of mechanics and techniques nee...

Page 4

How to use this manual this manual is intended as a practical tool, easy to read, a book of reference for the mechanic. Includes explanations of all installation, removal, disassembly, assembly, repair, and testing procedures are set out in individual steps in sequential order. The manual is divided...

Page 5

Symbols the following symbols are used in this manual to facilitate understanding. Note: the following symbols are not relevant to each vehicle. 1 2 3 4 5 6 1. Serviceable with engine mounted 2. Liquid fill 3. Lubricant 4. Special tool 5. Torque 6. Wear limit, tolerance 7. Engine speed 8. Electrical...

Page 6: Table of Contents

Table of contents general information 1 2 3 4 5 6 7 8 specifications inspections newspapers and adjustments chassis engine carb electrical troubleshooting.

Page 7

General information identification of motorcycle .............................................. 1-1 ....... Vehicle identification number .......................................... 1-1 engine serial number ............................................. 1-1 .................... Lcd meter ................

Page 8

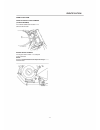

Identification identification vehicle identification number (chassis number) the vehicle identification number "1" is affixed to the chassis. Engine serial number the engine serial number "1" is stamped in the crankcase. Note: designs and specifications are subject to change without notice. 1 1-1.

Page 9

Features multifunction display 1 2 select 1. Multi-function display 2. "select" button (select) the multi-function display is equipped with the following: • a speedometer (which shows the speed offset) • an odometer (which shows the total distance traveled) • an odometer (indicating the distance tra...

Page 10

Important information important information preparing for the removal and disassembly 1. Before you remove and disassemble, clean all dirt, mud, dust and material strangers. Packing, oil seals and o rings 1. When assembling the engine, replace all gaskets, oil seals and o-rings. All surfaces of pack...

Page 11

Important information bearings and oil seals assemble the bearings and oil seals so that the mark of the manufacturer or the numbers are visible. When installing oil seals "1", lubricate the edges of oil seals with a thin layer of grease lithium soap base. In the bearings, apply oil, if requested. P...

Page 12

Inspection of connections inspection of connections check the cables, couplers and connectors stains, oxidation, humidity, etc.. 1. Disconnect: • cable • coupler • connector 2. Check • cable • coupler • connector moisture → dry air-jet oxidation / patches → connect and disconnect several times. Note...

Page 13

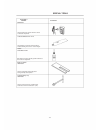

Special tools special tools special tools shown below, are required for assembly and adjustment precise. Use only the appropriate special tools, which will help to prevent damage by the use of inappropriate tools or improvised techniques. Tool name / tool no. Tappet screw holder ysst-706 illustratio...

Page 14

Special tools tool name / tool no. Tool to install the crankshaft spacer. (a) ysst-266 (b) ysst-267 illustration (a) (b) these tools are use to install the crankshaft. Tool to remove the crankshaft. Ysst-265 this tool is used to remove the crankshaft from crankcase fixer clutch hub ysst-733 this too...

Page 15

Special tools tool name / tool no. Adapter valve spring compressor ysst-803 a illustration this tool is used to remove and install valve and the valve spring using ysst 603. Set pump pressure gauges vacuum / pressure this instrument is used to test and verify the vacuum the air induction system. Nut...

Page 16

Special tools tool name / tool no. Multimeter illustration theste instrument is used to check the circuits or electrical components. Yamaha adhesive no. 1215 this adhesive is used in the contact surfaces, while assembling the covers # 1 and # 2 engine. Loctite three bond 1322 this adhesive is used t...

Page 17

Specifications general ................................................ 2-1 ........ Engine specifications ............................................... 2-2 ......... Chassis specifications ............................................... 2-9 ........ Electrical .......................................

Page 18

General general model model dimensions total length overall width overall height l seat height wheelbase ground clearance minimum turning radius weight with gasoline and oil peak load 21c1 1973mm 770mm 1045mm 790mm 1334mm 160mm 2340mm 135.0kg 195.0kg 2-1.

Page 19

Specifications engine specifications engine engine engine type displacement arrangement of cylinder bore x stroke compression ratio compression pressure (at sea level) starting system fuel recommended fuel fuel tank capacity reserve capacity 4 stroke, air cooled sohc 153.0cm 3 a cylinder leaning for...

Page 20

Specifications engine spark plug (s) manufacturer / model distance between electrodes head volume maximum deformation ngk / cpr8ea-9 0.8-0.9mm 13.40-14.00cm ³ 0.03mm camshaft drive system dimensions of camshaft lobes admission to limit admission b limit escape a limit escape b limit chain drive (lef...

Page 21

Specifications engine supply chain model tensioning system rocker / rocker inner diameter of the beam limit outer diameter of the beam limit valves, valve seats, valve guides valve clearance (cold) admission exhaust valve dimensions diameter of the valve head a (admission) diameter of the valve head...

Page 22

Specifications engine limit clearance between the valve stem and guide (escape) limit limit deformation of the valve stem 0.080mm 0.025-0.052mm 0.100mm 0.010mm valve spring free length (admission) limit free length (escape) limit installed length (admission) installed length (escape) elasticity of t...

Page 23

Specifications engine h d deviation direction of deviation diameter hole for the piston pin limit outside diameter of piston pin limit piston rings top ring ring type dimensions (b × t) 0.25 mm admission side 15002-15013 mm 15043 mm 14995-15000 mm 14975 mm barrel 0.80 x 2.30 mm b t distance between ...

Page 24

Specifications engine rod small end bore large end bore crankshaft width a maximum deformation c side clearance of large side d 14090-15028 mm 36000-36009 mm 47.95-48.00 mm 0030 mm 0110-0140 mm balancer method of synchronizing the balanced clutch gear oil-bathed multi-disc inner force, driven by cam...

Page 25

Specifications engine mechanism of change type shifting mechanism thickness of the shift fork decompression device type of device air filter air filter element carburetor type x number identifying mark leading supplier leading supplier of air needle needle seat output supplier jet pilot pilot screw ...

Page 26

Chassis specifications chassis specifications chassis frame type angle advance front wheel wheel type rim size material of rim wheel stroke radial deviation limit of the wheel limit lateral deflection of the wheel rear wheel wheel type rim size material of rim wheel stroke radial deviation limit of ...

Page 27

Chassis specifications front brake disc thickness and outer diameter of the disc thickness limit of the brake disk deviation limit of the brake disk coating thickness of brake pads (inside) limit coating thickness of brake pads (exterior) limit bore master cylinder inner diameter of the cylinder rec...

Page 28

Chassis specifications free length of spring installed length k1 spring tension k1 race spring tilt free play at the end of the rocker (limit axial) drive chain type / manufacturer number of links clearance of the drive chain length limit of 15 links 187.0 mm 178.0 mm 120.0 n / mm 0.0-20.0 mm 2.4 mm...

Page 29

Electrical electrical voltage system voltage ignition system ignition system type of feed ignition timing (b.T.D.C.) coil resistance pulse ignition coil primary coil resistance secondary coil resistance plug cap material resistance magneto ca standard output resistance of the stator coil regulator /...

Page 30

Electrical electrical ignition system type of system starter output power start relay amperage coil resistance horn horn type amount maximum amperage constant gear 0.25 kw 100 a 3.51-4.29 Ù flat 1 pc 1.5 a turn signal relay relay type integrated self-cancellation device sign of the flicker frequency...

Page 31

Torque torque general of torque this table specifies the pairs of tightening threaded fasteners i.S.O. Standard normalized. Torque specifications tightening of the components or assemblies special mentioned in each chapter this manual. To prevent distortion, cross-clamping assemblies with several fa...

Page 32

Torque motor torque motor item head screws (inside) head screws (side chain) plug screw head cover (conduit) cylinder head bolts (exhaust) balancer sprocket nut screw nut screw the decompressor screw small chain guide 2 tensioner bolts cap screws bolts rocker screws oil pump oil drain plug element c...

Page 33

Torque motor item screw the housing 1 and 2 nut kickstarter lead screw gear screw clutch motor start main gear nut the pressure plate bolts 1 screw the push rod 1 clutch nut screw drive sprocket screw cover plate screw cap lever changes cam screw screw the stator screws pulse coil magneto nut neutra...

Page 34

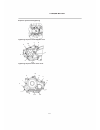

Torque motor sequence cylinder head tightening 5 tightening sequence of the magneto cover 7 5 1.6 8 9 4 3 2.10 tightening sequence of the clutch cover 1.9 8 10 11 7 6 12 13 5 4 3.15 2.14 2-17.

Page 35

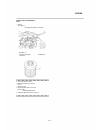

Torque motor crankcase tightening sequence a b 14 1.6 7 8 5 4 3.13 a. Carter left b. Right side crankcase 15 9 2.12 10 11 2-18.

Page 36

Torque torque item screw of the steering column nut of the steering column lower ring nut (mi) upper ring nut (final) front fender main switch / block address support lamppost lever bracket screw handlebar switch screw meter and lamppost license holder bolts screw lamp screw cap lamp front engine mo...

Page 37

Torque size of thread m14 m14 m8 m8 m6 m10 m8 m6 m10 m8 m10 m10 m8 m10 m6 m6 m6 item spindle nut of the front wheel nut rear wheel axle screw crown and hub clutch tension bar and shoe holder plate camshaft and brake lever s of the clamp screw screw the brake disc master cylinder screws brake pedal a...

Page 38

Lubrication points and lubricant types lubrication points and lubricant types point lubrication edge of the oil seals bearings o-rings head screws and washers thrust surface of the large end of the rod piston, piston rings and the inner surface of the cylinder inner surface of the balancer sprocket ...

Page 39

Lubrication points and lubricant types point lubrication crankshaft position sensor / washer assembly lead stator contact surface of carcasses lubricant yamaha adhesive no. 1215 (three bond no.1215r) yamaha adhesive no. 1215 (three bond no.1215r) yamaha adhesive no. 1215 (three bond no.1215r) tensio...

Page 40

Lubrication points and lubricant types point lubrication seal edges of the front wheel (left and right) outer surface of the front wheel axle speed sensor unit seal edges of the rear wheel hub contact surface of the rear wheel hub outer surface of the rear wheel axle rear wheel axle and the threads ...

Page 41

Lubrication points and lubricant types tables and diagrams lubrication system table of engine oil lubrication 5 3 4 2 6 1 7 1. 2. 3. 4. 5. 6. 7. Oil strainer oil pump oil filter element crankshaft camshaft main shaft driven shaft 2-24.

Page 42

Lubrication points and lubricant types lubrication charts 1 2 3 a 4 5 6 7 1. 2. 3. 4. 5. 6. 7. A. Push the clutch lever main shaft drive shaft crankshaft oil filter oil pump oil strainer toward the head 2-25.

Page 43

Lubrication points and lubricant types lubrication charts 1 2 3 4 1. 2. 3. 4. Camshaft crankshaft main shaft driven shaft 2-26.

Page 44

Guiding cables 3 1 4 a 10 june 9 5 3 c f g r r 1 1 12 7 8 6 5 2 1 2 c d 7 5 6 1 1 9 9 8 a 4 4 2 3 13 14 1 12 b r-r b 1 d h i 2-27.

Page 45

Guiding cables 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. A. B. C. D. E. F. G. H. I. Front brake hose throttle cable cable front brake switch cable right handlebar switch switch wire left handlebar clutch switch wire clutch cable starter cable main switch lead meter cable lead right front turn s...

Page 46

Guiding cables 3 17 17 17 13 2 5 4 13 ee b-b d-d c-c 1 a 3 2 4 b c 5 f e 14 15 16 dc d b s l i g h 11 s j e c m m n d 6 7 8 f 2 10 13 14 11 february 12 13 16 15 14 16 e 9 l 2 j 15 s-s 12 n 6 6 m-m 2-29.

Page 47

Guiding cables clutch cable overflow pipe throttle cable starter cable carburetor vent hose ac magneto lead negative lead breather hose from the battery carburetor drain hose fuel line speaker cable connector cover harness cable sensor unit switch wires left handlebar cables right handlebar switch a...

Page 48

Guiding cables 6 9 10 8 5 february 3 4 1 11 7 10 3 20 a 19 18 13 17 16 15 12 a a 21 22 14 15 a-a 2-31.

Page 49

Guiding cables left handlebar switches clutch switch wire clutch cable cable left handlebar switch booster cable main switch lead handlebar switch lead right brake hose cable front brake switch throttle cable handlebar switches right cable left rear turn signal turn signal relay cable from the backl...

Page 50

Guiding cables 25 17 16 10 30 16 28 31 29 5 h-h k-k u-u t-t 30 january 25 31 a 18 19 b 10 c 21 26 22 e 24 27 23 u t u t 5 k 16 m n 15 h p k o 6 8 7 f 9 g i 29 14 l 13 k 12 11 j 10 h 2-33.

Page 51

Guiding cables 1. Throttle cable 2. Cable sensor unit 3. Brake hose 4. Speaker cable 5. Cable high 6. Plug cap 7. Starter cable 8. Starter relay cable 9. Fuse holder 10. Negative lead 11. Carburetor drain hose 12. Breather hose from the battery 13. Start relay 14. Brake switch 15. Battery 16. Harnes...

Page 52

Periodic maintenance and adjustments periodic maintenance .................................................. 3-1 ........................ Periodic maintenance and lubrication intervals ... 3-1 adjusting the valve clearance ........................................ 3-3 engine idle adjustment ............

Page 53

Troubleshooting electrical ................................................ ...................................... 3-22 checking and charging the battery ............................................ 3-22 ...... Fuse inspection ............................................... 3-22 .......................

Page 54

Periodic maintenance periodic maintenance table of lubrication and routine maintenance note: all maintenance must be performed according to the periodic maintenance schedule (which mentioned below) to maintain the best performance of the vehicle. The items marked with an asterisk must be performed b...

Page 55

Periodic maintenance no. Element inspection or operation of maintenance •check the clearance of the bearings and if the steering for roughness •lubricating grease based on lithium soap. •check that all nuts, bolts and screws are properly tightened. •check operation. •lubricate •check operation and l...

Page 56

Engine engine adjusting the clearance valves the following procedure applies to all valves. Note: a. Rotate the crankshaft in the opposite direction of the b. When the piston is at tdc . (pms) of the compression stroke, align the "a" in the magnet with the fixed point "b" of the cover the magnet. Ad...

Page 57

Engine 8. Assembly: pin packing the cylinder head cover new cylinder head cover see the "head" on page 5-5 9. Assembly: hose air induction system . C. Turn the adjustment screw "3" in direction "a" or "b" to obtain the specified valve clearance. 2 1 see "induction system air "on page 6-9 10. Assembl...

Page 58

Engine 3. Check: engine idle if out of specification? Set. Refer to "adjusting the idle engine "on page 3-4. 4. Insert: probe "2" meter co (calibrated) for the exhaust pipe "3", using the appropriate adapter "4" b to 1 direction "a" increases engine idle direction "b" engine idle speed is reduced 8....

Page 59

Engine caution do not alter the settings of the carburetor, if the engine performance is good. If necessary, adjustments should be recorded existing (no. Of turns) screw mixture. To verify the configuration of the screw demezcladelcarburador, sigael co adjustment procedure " ensure the correct insta...

Page 60

Engine checking the spark 1. Disconnect: spark plug cap 2. Remove: plug caution note: before installing the spark plug, clean the surface the spark plug and gasket. 8. Connect: the spark plug cap on inspection time note: before removing the spark plug, clean air compressed dirt that may have accumul...

Page 61

Engine a. Start the engine and let it warm up for few minutes and then leave the engine up in the specified idle engine idle 1300-1500 r / min b. Verify that the stationary pointer "a" in the magneto cover is within the firing interval "b" of the rotor magnet. Improper firing interval → check the ig...

Page 62

Engine compression pressure (with oil applied inside the cylinder) lecturadiagnóstico greater than without oil piston rings are worn or damaged repair piston, valves, packing possibly the cylinder head oil-like defective repair / replace type sae 20w50 (engine oil yamalube-4 times) caution do not le...

Page 63

Engine c. Assemble the new oil filter element and cover of the oil filter element. Cover screw element oil filter 10 nm (1.0 m · kg, 7.2 ft · lb) verification of oil. If it is not engine oil after one minute, turn off the engine to no damage occurs. C. Check the engine oil passages, the oil filter e...

Page 64

Engine d. Tighten the lock nut. E. Slide the rubber cover into position original. Note: if the specified free play of clutch cable, can not be obtained on the side of the handlebar, use the adjusting nut on the motor side. Motor side a. Loosen the locknut "1" b. Turn the adjustment screw "2" in the ...

Page 65

Engine 1 caution: never run the engine without the element of air filter installed. The unfiltered air cause rapid wear of engine parts and may damage it. Note: make sure the air filter element is installed correctly in the filter housing of air. Check carburetor and unon connection filter housing a...

Page 66

Engine check the filter wrench fuel 1. Check: • fuel pipe "1" reemplácelogrietas / damaged 3 1 • fuel filter "1" tainted / damaged fuel wash. Replace the 2 a. Turn fuel valve to "off" b. Remove the filter cup wrench fuel "3". C. Drain the fuel. D. Check the filter of the fuel cock. Clean if dirty re...

Page 67

Chassis chassis adjusting the rear brake drum checking the brake fluid level 1. Place the vehicle on a flat surface. Note: 1. Check: free pedal brake "a" set out of specification free game 15.0-20.0 mm drive your vehicle to the center support make sure the vehicle is vertical 2. Check: brake fluid l...

Page 68

Chassis checking the brake front the procedure applies to all brake pads. 2 1 1. Operate the front brake. 2. Check: front brake pads tread wear indicators "1" almost touch the replace brake disc game brake pads. See "front brake" on page 4-20 1 adjusting the light switch rear brake note: the rear br...

Page 69

Chassis 1. Remove: cover the brake master cylinder "1" g. Loosen the bleed screw. Note: when you release the bleed screw, the pressure will be released and cause the contact of the lever brake with the throttle. 1 h. Tighten the bleed screw and then release the brake lever i. Repeat steps "e" to "h"...

Page 70

Chassis 2. Rotate the rear wheel to find the point with greater tension in the chain. 3. Check: clearance of the transmission chain "a" out of specification adjust. Note: to maintain proper alignment of the wheel, adjust both sides equally. E. Secure the axle nut to the torque wheel specified. Spind...

Page 71

Chassis b. Tighten the lower ring nut "4" key of the nut on the steering column "5". Note: set the torque wrench at a right angle for the nut wrench the steering column. 5 4 spray the lubricant inside the chain between inner and outer plates, rollers and bearings. 5 after waiting for lubrication 15 ...

Page 72

Chassis 5. Assembly: upper yoke refer to "steering column" on page 4-43 verification of the fork front 1. Place the vehicle on a flat surface. Warning warning support the vehicle with safety to there is no risk of falling. 2. Check: inner tubes damage / rasguñosreemplace. Oil seals aceitereemplace l...

Page 73

Chassis inspection of the wheels the following procedure applies to both wheels. 1. Check: wheels. Damage / deformacionesreemplazar. Warning warning do not use tubeless tire on a wheel tires designed only for camera failures and avoid personal injury due to sudden deflation. After extensive testing,...

Page 74

Chassis lubricating the brake lever lubricate the pivot points and moving parts metal-metal of the lever. Recommended lubricant silicone grease pedal lubrication lubricate the pivot points and moving parts metal-metal of the lever. Recommended lubricant based grease lithium soap lubrication sidestan...

Page 75

Electrical system electrical checking and charging the battery see "components electric "on page 7-34 fuse inspection see "components electric "on page 7-34 change the bulb farola the following procedure applies to the light bulb dipped and main beam. 1. Remove: • side cover "1" 4. Remove: • lamp "1...

Page 76

Electrical system 4. Assembly: • lamp bulb secure the lamp bulb again the lamp bulb holder caution: avoid touching the glass bulb of the cembran to keep it free of oil, it otherwise the transparency of glass, the life of bulb and the brightness will be affected negatively. If the lamp bulb is dirty,...

Page 77

Electrical system to replace the rear light 3. Remove: • coupler taillight "1" • screws "2" from inside the mudguard 2 2 1 change indicator light bulb drawing 1. Remove: • screw "1" from the indicator light • lens "2" of light 2. Push the bulb "3" and gently turn counterclockwise. 3 2 1 3-24.

Page 78

Chassis general chassis assembly of the air filter housing front wheel removing the front wheel disassembly of the front wheel checking the front wheel front wheel assembly tera front wheel assembly (disco) rear wheel removing the rear wheel checking the rear wheel checking the rear wheel hub checki...

Page 79

Chassis steering column removing the lower bracket verification of the steering column column mount direction n 4-43 4-45 4-45 4-45 rear shock removing the rear shock checking the rear shock rear shock mounting swing removing the rocker verification of overhead tilt mount chain checking the drive ch...

Page 80

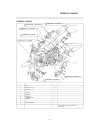

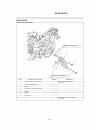

General chassis general chassis 25 nm (2.5 m l l kg, 18 ft l ib) 2 nm (0.2 m l kg, 1ft l ib) 1 t. R. 2 nm (0.2 m t. R. Kg, 1ft l ib) 3 2 4 7 nm (0.7 m t. R. 2 nm (0.2 m l kg, 1ft l ib) t. R. L kg, 5ft l ib) order 1 2 3 4 5 6 7 8 9 t. R. 5 2 nm (0.2 m l kg, 1ft l ib) t. R. 6 9 3 7 8 t. 2 nm (0.2 m l ...

Page 81

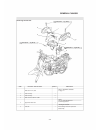

General chassis removing the fuel tank t. 2 nm (0.2 m l kg, 1ft l ib) r. 2 1 3 2 4 nm (0.4 m l kg, 3ft l ib) order 1 2 3 4 5 t. R. 4 4 nm (0.4 m l kg, 3ft l ib) t. R. 5 procedure / parts to remove side cover 1 & 2, seat fuel tank cap fuel tank cap side covers fuel tank lh & rh amount observations re...

Page 82

General chassis removing the lamp and the meter 2 nm (0.2 m l kg, 1ft l ib) kg, 1ft l ib) kg, 1ft l ib) 1 order t. R. 2 nm (0.2 m l t. R. 2 nm (0.2 m 6 2 nm (0.2 m l l 2 1 t. R. 3 4 5 kg, 1ft l ib) t. R. 7 7 nm (0.7 m l kg, 5ft l ib) procedure / parts to remove side covers full streetlight license p...

Page 83

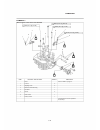

General chassis removing the air filter full 2 nm (0.2 m l 1 kg, 1ft l ib) order t. R. 2 4 3 23 nm (2.3 m l kg, 17 ft l ib) t. R. 5 8 6 procedure / parts to remove seat, side cover 1 & 2 amount 7 t. 7 nm (0.7 m l kg, 5ft l ib) refer to "general chassis "on page 4-1 r. Observations 1 2 3 4 5 6 7 8 fi...

Page 84

General chassis installing the air filter housing 1. Install: bracket air filter binding note; align the projection "a" in the filter housing air slot "b" in the union of air filter. To b 4-5.

Page 85

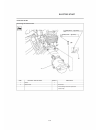

Front wheel front wheel removing the front wheel and brake disc 30 nm (3.0 m l kg, 22 ft l ib) ls (5 6 2 7 order 1 2 3 4 5 6 7 sensor cable clamp speed spindle nut of the front wheel front wheel axle front wheel speed sensor spacer brake disc ( t. R. 3 lt 1 7 nm (0.7 m l kg, 5ft l ib) t. R. Ls 60 nm...

Page 86

Front wheel disassembly of the front wheel 4 3 ls 2 new 1 order procedure / parts to remove oil seal bearing spacer bearing amount observations 1 2 3 4 1 1 1 1 for assembly, reverse the procedure disassembly. 4-7.

Page 87

Front wheel removing the front wheel 1. Place the vehicle on a flat surface. Warning support the vehicle safely to avoid there is a risk of falling. 2. Survey: • front wheel note: place the vehicle on a suitable support, so that the front wheel is lifted. 3. Remove: • front wheel • speed sensor unit...

Page 88

Front wheel front wheel assembly (disco) 1. Ensemble: l brake delantero.Disco screw the front brake disc 30 nm (3.0 m · kg, 22 ft · lb) loctite ® 4. Check: wheel bearings the front wheel rotates irregularly shaped or this loose replace bearings wheel. Of aceitesello damage / wear replace. Note: tigh...

Page 89

Front wheel 5. Assembly: velocidadunidad sensor note: make sure the speed sensor and the wheel hub are installed with the two interlocking projections into the two slots respectively. 6. Assembly: delanterarueda note: make sure the slot "a" enters the tube foreign and fits over the top "b" in the un...

Page 90

Front wheel 4-11.

Page 91

Rear wheel removing the rear wheel and brake bands holder 90 nm (9.0 m kg, 65 ft lb) ls 6 7 . Tr. 10 new 11 3 4 1 13 5 2 12 10 14 8 9 ls order procedure / parts to remove adjusting nut brake rod brake rod spring pin tension bar nut washer rear wheel axle washer chain tensioner spacer spacer rear whe...

Page 92

Rear wheel disassembly of the rear wheel order procedure / parts to remove rear wheel sprocket necklace oil seal bearing rear-wheel hub shock rear drive hub bearing spacer oil seal amount observations 1 2 3 4 5 6 7 8 9 1 1 1 1 1 4 2 1 1 for assembly, reverse the procedure disassembly. 4-13.

Page 93

Rear wheel removing the rear wheel (drum) 1. Place the vehicle on a flat surface. Warning support the vehicle with safety to there is no risk of falling. Note: 3. Measure: radial deviation of the wheel lateral deviation of the wheel refer to "checking front wheel "on page 4-8 checking the rear wheel...

Page 94

Rear wheel note: sprocket assembly of the rear wheel manufacturer's brand out. Tighten self-locking nuts in stages and in a crisscross pattern 5. Tighten: nut wheel axle nut wheel axle 90 nm (8.0 m · kg, 58 ft · lb) 6. Fit: free pedal brake refer to "brake adjustment drum "on page 3-14 t. R. Free pe...

Page 95

Front brake front brake disassembly of the front brake pads order procedure / parts to remove bra brake hose screw the front brake caliper front brake callipers brake pad clip pin pads front brake pads spring brake pads amount observations 1 2 3 4 5 6 7 1 2 1 2 1 2 1 for assembly, reverse the proced...

Page 96

Front brake removing the front brake master cylinder 10 nm (1.0 m kg 7ft ib) . R. 1 2 7 nm (0.7 m kg 5ft ib) 10 order 10 11 . R. 3 4 s 1 1 9 5 7 8 7 6 new . R. 26 nm (2.6 m kg, 19 ft lb) observations procedure / parts to remove brake fluid amount drain. Refer to "bleeding the system hydraulic brake ...

Page 97

Front brake disassemble the front brake master cylinder 2 4 1 5 3 7 6 order procedure / parts to remove smock pushrod spring pin lock full piston spring cylinder body amount observations 1 2 3 4 5 6 7 1 1 1 1 1 1 1 for assembly, reverse the procedure disassembly. 4-18.

Page 98

Front brake introduction warning the disc brake components seldom require disassembly. Therefore, always follow these precautions: never disassemble the brake components, to unless absolutely necessary. If you disconnect any connections in the brake hydraulic, must disarm all the brake system, drain...

Page 99

Front brake note: assemble the new brake pads and spring new brake pads. A. Securely attach a plastic hose transparent "1" bleed screw "2". Place the other end of the hose a container. D. Measuring deformation of the brake disk e. If out of specification, repeat the setting until the deformation of ...

Page 100

Front brake removing the brake caliper front note: b. Disassemble the seals and dust covers the brake caliper before disassembling the brake caliper, drain all the brake fluid brake system. Checking the brake caliper replacement recommended plan brake components brake pads piston seals dust brake ho...

Page 101

Front brake assembly of the brake caliper front warning before assembly, all components internal brake should be lubricated and cleaned with a liquid cleaner or new brake. Never use solvents on the components internal brake, as it will make the seals piston and the dust to dilate and warping. Each t...

Page 102

Front brake max. Min check the master cylinder front brake 1. Check: brake master cylinder "1" damage / scratches / wear replace. Liquid distribution passages brake "2" (body of the brake caliper) blow with compressed air clogged. 7. 7. Check: operation of the brake lever soft or spongy feeling blee...

Page 103

Front brake 3. Fill: deposit brake master cylinder (with the specified amount and recommended brake fluid) liquid preferred dot 3 or dot 4 warning 2 1 2. Ensemble: copper washers "1" new brake hose "2" screw attachment of the brake hose "3" screw connection of the hose brake 26 nm (2.6 m · kg, 19 ft...

Page 104

Front brake see "purging system hydraulic brake "on page 3-15. 4-25.

Page 105

Rear brake rear brake disassembly of the bands brake 3 4 l 10 nm (1.0 m kg, 7ft l ib) ls 2 5 6 s 1 ls new (6) 43 nm (4.3 m l kg, 31 ft l ib) order procedure / parts to remove ls amount observations porta full bands refer to "rear wheel" on page 4-12 1 2 3 4 5 6 brake bands spring full bands lever br...

Page 106

Rear brake rear brake 1. Check: • covering the brake shoe repair crystallized areas. Sand the crystallized areas with sandpaper thick. Note: to after sanding the surface crystallized clean brake bands with a cloth. 2. Measure: coating thickness of the bands brake "to" out of specification replace. C...

Page 107

Rear brake new 1 a s a b c. Align the slot "c" in the handle of the tree brake cam with the slot in the tree brake cam. B new 1 a-a 3 c b-b d. Verify that the bands are correctly positioned. Testing the limits of wear drum brake wheel rear note: 2. Assembly: • spring brake bands "1" new • brake band...

Page 108

Rear brake 3. While pressing the brake pedal to down to the end, push the lever brake camshaft completely the direction of the arrow and check the wear indicator strips does not reach the brake wear indicator of the brake drum. Not enough can still be used. Reach replace the wheel. 4-29.

Page 109

Handle handle removing the handle 10 nm (1.0 m 26 nm (2.6 m • kg 7ft • ib) kg, 19 ft • ib) ls t. R. 1 2 5 ls ls • t. R. 7 16 3 1 10 13 17 8 6 4 9 15 12 14 1 1 ls 2 7 nm (0.7 m • kg, 5ft • ib) t. R. Order procedure / parts to remove amount observations 1 2 3 4 5 6 7 8 9 10 11 12 13 14 rearview mirror...

Page 110

Handle removing the handle 10 nm (1.0 m 26 nm (2.6 m • kg 7ft • ib) kg, 19 ft • ib) ls t. R. 1 2 5 ls ls • t. R. 7 16 3 1 10 13 17 8 6 4 9 15 12 january 14 1 ls 2 7 nm (0.7 m • kg, 5ft • ib) t. R. Order procedure / parts to remove amount observations 15 16 17 support of the clutch handlebar top clam...

Page 111

Handle removing the handlebar 1. I placed the vehicle on a flat surface warning handlebar assembly 1. I placed the vehicle on a flat surface warning support the vehicle safely to avoid there is a risk of falling. Support the vehicle with safety to there is no risk of falling. 2. Remove: • brake ligh...

Page 112

Handle 1 to 4. Assembly: • brake light switch front "1" note: 6. Assembly: • clutch cable note: align the projection "a" in the handlebar switch left with the hole "b" on the handlebars. Lubricate the clutch cable end with a thin layer of grease lithium soap base. To 1 b 5. Assembly: • left handleba...

Page 113

Handle 3 b 1 2 to c 9. Fit: • free play of clutch cable see "setting the game clutch cable free "on page 3-10. Free play of the lever clutch 10.0-15.0 mm 10. Fit: • set throttle cable free see "setting the game throttle cable free "in page 3-6. Cable free play accelerator 3.0-5.0 mm 4-34.

Page 114

Front fork front fork removing the fork legs lead • 25 nm (2.5 m kg , 18 ft • ib) t. R. 3 • 25 nm (2.5 m kg, 18 ft • ib) t. 2 r. 1 4 6 nm (0.6 m • kg, 4ft • ib) t. R. Order procedure / parts to remove amount observations front wheel the following procedure applies to both front fork legs refer to "r...

Page 115

Front fork disassembly of the front fork legs new 1 2 3 12 4 6 new 7 new 13 14 new 5 10 15 11 9 8 order procedure / parts to remove amount observations the following procedure applies to both front fork legs 1 2 3 4 5 6 7 8 9 10 11 12 13 14 screw cap o-ring spacer washer the fork spring smock oil se...

Page 116

Front fork disassembly of the front fork legs new 1 2 3 12 4 new 7 13 new 14 new 6 5 10 15 11 9 8 order procedure / parts to remove amount observations 15 outer tube 1 for assembly, reverse the procedure disassembly. 4-37.

Page 117

Front fork removing the bars front fork the following procedure applies to both front fork bars 1. I placed the vehicle on a flat surface warning 2. Drain: • fork oil note: operate the outer tube several times while leaving the fork oil support the vehicle with safety to there is no risk of falling....

Page 118

Front fork note: while holding the damper rod with the holder of the damper rod "2" and t key in "3", loosen the screw rod shock. 3. Check: • damper rod damage / wear replace. Blow with compressed air blocked all oil passage • plug flow of oil replace damaged. Caution when disassembling and assembli...

Page 119

Front fork recommended oil oil suspension 10w or equivalent seal assembly tool of the front fork oil ysst-875 caution 3. Press: • screw rod of the damper "1" screw rod buffer 28 nm (2.8 m · kg, 20 ft · lb) be sure to join the oil seal with the number upwards. Note: note: while holding the damper rod...

Page 120

Front fork 7. Assembly: • dust "1" new (with the seal assembly tool of front fork oil "2") seal assembly tool of the front fork oil ysst-875 10.Antes measure the level of fork oil, wait ten minutes until the oil has settled and the air bubbles has dispersed. Note: new be sure to purge the fork leg f...

Page 121

Front fork 13. Assembly: • o-ring new (in the screw cap of the front fork) • screw the top of the front fork • clip new black: warning make sure the brake hose, cable clutch, and the cables are guided correctly. • before installing the screw cap of the fork front, lubricate the o-ring grease. • befo...

Page 122

Steering steering disassembly of the steering column 110 nm (11.0m • kg, 80 ft • lb) t. 22 nm (2.2 m • kg, 16 ft • lb) r. 1 t. Ls 13 1 1 14 new 15 12 7 r. 2 3 4 5 6 8 9 10 7 nm (0.7 m • kg, 5ft • lb) 22 nm (2.2 m • kg, 16 ft • lb) 1s 33 nm (3.3 m • kg, 24 ft • lb) t 2nd 22 nm (2.2 m • kg, 16 ft • lb...

Page 123

Steering disassembly of the steering column t. 22 nm (2.2 m • kg 16 ft • lb) r. 1 22 nm (2.2 m • kg 16 ft • lb) ls 13 1 1 14 new 15 12 7 t. R. 2 3 4 5 6 8 9 10 7 nm (0.7 m • kg, 5ft • lb) 22 nm (2.2 m • kg, 16 ft • lb) 1st 33 nm (3.3 m • kg, 24 ft • lb) 2nd 22 nm (2.2 m • kg, 16 ft • lb) order 13 14...

Page 124

Steering disassembly of lower bracket 1. I placed the vehicle on a flat surface warning b. Remove the lower bearing support chisel "2" and the hammer. C. Install the bearing races and a new overall. Caution support the vehicle with safety to there is no risk of falling. 2. • • • • disassembly: upper...

Page 125

Steering • upper ring nut • lockwasher refer to "checking and adjusting the steering column " on page 3-18 3. Assemble: • upper bracket • nut of the steering column 4. Assemble: • front fork bars see section "fork front "on page 4-35 note: temporarily tighten the mounting bolts top and bottom. 5. Pr...

Page 126

Rear shock rear shock removing the rear shock 60 nm (6.0 m • kg, 43 ft • lb) t. R. 1 2 6 1 3 4 5 3 40 nm (4.0 m • kg, 29 ft • lb) amount observations t. R. Order procedure / parts to remove seat, side covers 1 & 2, mud guard refer to "general chassis" on page 4-1 1 2 3 4 5 6 nut / bolt rear upper sh...

Page 127

Rear shock removing the shock rear 1. I placed the vehicle on a flat surface warning support the vehicle with safety to there is no risk of falling. Note: place the vehicle on a suitable support so that the rear wheel is elevated. Verification of shock rear 1. Check: • rear shock rod. Deformation / ...

Page 128

Swing swing removing the rocker 60 nm (6.0 m • kg, 43 ft • lb) 10 nm (1.0 m • kg, 7 ft • lb) t. T. R. R. 1 3 5 4 10 nm (1.0 m • kg, 7 ft • lb) t. 2 r. 30 nm (3.0 m • kg, 22 ft • lb) observations t. R. Order procedure / parts to remove amount rear wheel rear shock rear fender see "shock back "on page...

Page 129

Swing removing the rocker 60 nm (6.0 m • kg, 43 ft • lb) 10 nm (1.0 m • t. R. Kg, 7 ft • lb) t. R. 1 3 5 4 10 nm (1.0 m • kg, 7 ft • lb) t. 2 r. 30 nm (3.0 m • kg, 22 ft • lb) observations t. R. Order procedure / parts to remove amount 11 bearing 2 for assembly, reverse the procedure disassembly. 4-...

Page 130

Swing removing the rocker 1. I placed the vehicle on a flat surface warning warning do not attempt to straighten the axis of the pivot. Support the vehicle with safety to there is no risk of falling. Note: support the vehicle safely to avoid there is a risk of falling. 2. Measure: • swingarm side pl...

Page 131

Swing to a 1 2 1 to b 2. Tilt a. Left b. Right side to 4. • • • assembly: rear shock tension bar rear wheel refer to "shock back "on page 4-47 and" wheel back "on page 4-12. 5. Fit: • backlash of the drive chain see section "clearance chain "on page 3-16. Chain slack transmission: 30-40 mm 4-52.

Page 132

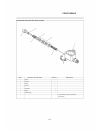

Chain chain removing the transmission chain 4 1 3 2 10 nm (1.0 m • kg, 7 ft • lb) kg, 7 ft • lb) observations t. R. 10 nm (1.0 m • t. R. Order procedure / parts to remove amount rear wheel footrest bracket right bracket left footrest rear fender refer to "rear wheel" on page 4-12 see "tilt" on page ...

Page 133

Chain chain check transmission 1. Measure: • 15 links the drive chain replace out of specification chain. Length limit of 15 links 191.5 mm a. Measure the length "a" between the inner faces of the rollers and the length "b" between faces outside of the rollers in a section 15 links of the chain of t...

Page 134

Chain 6. Check: • gear refer to "rear wheel" in page 4-12 assembly of the chain 1. Lubricate: • drive chain recommended lubricant proper chain lubricant for chains with o-ring 2. Assemble: • drive chain • drive sprocket • retaining the drive sprocket screw retention of the wheel sprocket 10 nm (1.0 ...

Page 135

Engine reassembly motor assembly changes arm assembly head removing the head inspection of the head inspection of distribution and pinion guide to the supply chain inspection of tension distribution chain decompression system inspection head assembly camshaft removing the rocker arms and camshaft ca...

Page 136

Clutch removing the clutch inspection of records of friction checking the clutch plates checking the clutch springs inspection cutterbar checking the pressure plate checking the clutch lever push short and push rod primary drive gear inspection primary driven gear inspection clutch inspection oil pu...

Page 137

Crankshaft removing the crankshaft crankshaft inspection crankshaft assembly transmission checking the shift forks checking the shift drum inspection of transmission fitting the push rods main shaft assembly and drive axle assembly of forks and change drum 5-58 5-59 5-59 5-59 5-61 5-64 5-64 5-64 5-6...

Page 138

Reassembly reassembly removing the silencer 1 2 12 nm (1.2 m • kg, 9 ft • ib) t. Order r. 4 3 15 nm (1.5 m • kg, 11 ft • ib) 20 nm (2.0 m • kg, 14 ft • ib) observations t. R. T. R. Procedure / parts to remove amount 1 2 3 4 air duct air guide silencer gasket, exhaust pipe 2 1 1 1 for assembly, rever...

Page 139

Reassembly disconnect cables and connectors 3 4 8 2 1 6 10 5 10 nm (1.0 m • kg, 7 ft • ib) 7 9 t. 10 nm (1.0 m • kg, 7 ft • ib) observations order t. R. R. Procedure / parts to remove amount caution first, disconnect the negative battery cable and then positive battery. Negative battery cable / wire...

Page 140

Reassembly removing the motor 30 nm (3.4 m • kg, 22 ft • ib) t. R. 3 4 2 5 1 t. 3 55 nm (5.5 m • kg, 40 ft • ib) r. 2 55 nm (5.5 m • kg, 40 ft • ib) amount observations t. R. Order procedure / parts to remove silencer fuel tank refer to "removal motor "on page 5-1 refer to "general chassis "on page ...

Page 141

Reassembly motor assembly 1. Urge: • motor "1" • motor mounting screw (upper side) "2" • motor mounting nut (top rear side) "3" • motor mounting screw (rear bottom side ) "4" • motor mounting nut (front side ) "5" note: arm assembly of changes 1. Install: • arm changes "1" screw the arm of the chang...

Page 142

Head head removing the head 13 nm (1.3 m • kg, 9 ft • ib) t. T. 22 nm (1.0 m • kg, 16 ft • ib) 10 nm (1.0 m • kg, 7 ft • ib) 8 nm (0.8 m • kg, 6 ft • ib) t. T. R. R. R. Order r. T. 5 e 9 nm (0.9 m • kg, 7 ft • ib) t. R. 8 e 6 1 t. 8 nm (0.8 m • kg, 6 ft • ib) 20 nm (2.0 m • kg, 14 ft • ib) ls t. R. ...

Page 143

Head removing the head t. 22 nm (2.2 m 10 nm (1.0 m • • kg, 16 ft • ib) kg 7ft • ib) 8 nm (0.8 m • kg, 6 ft • ib) t. T. R. R. R. 5 e 9 nm (0.9 m • kg, 7 ft • ib) t. R. 8 e t. 8 nm (0.8 m • kg, 6 ft • ib) r. 6 1 t. New 9 20 nm (2.0 m • kg, 14 ft • ib) ls r. New ls 10 7 2 new 11 m e 12 13 14 4 ls 15 1...

Page 144

Head removing the head 1. Align: • the mark "i" in the rotor magnet "a" (with the stationary mark "b" on the cover magneto) 1 2 a. Rotate the crankshaft counterclockwise. B. When the piston is in the neutral upper (pms) in the compression stroke, align the "i" of the timing sprocket "c" with the sta...

Page 145

Head 2. Check: • stock. Damage / scratches → replace. • water jacket of the cylinder head mineral deposits oxide / remove. 3. Measure: • deformation of the cylinder head. Out of specification → rectify the butt. Limit deformation 0.03 mm a. B. 1. 2. ¼ tooth correct contact roller chain camshaft spro...

Page 146

Head inspection system decompression b 2 1. Check: • decompression system a. Check the decompression system with camshaft sprocket and the cam decompression installed on the camshaft. B. Verify that the decompression lever "1" moves smoothly. C. Without operating the decompression lever, verify that...

Page 147

Head c. Align the "i" of the timing sprocket "c" with the stationary mark "d" on the plate retention of the camshaft. D. Install the timing chain on the pinion camshaft and then install the pinion camshaft camshaft. C. Tighten the chain tensioner distribution "3" to the specified torque. Screw the c...

Page 148

Head d c 7. Press: • screw camshaft sprocket screw camshaft sprocket 20 nm (2.0 m · kg, 14 ft · lb) prcauciÓn be sure to tighten the screw on the pinion camshaft to the specified torque avoid the possibility that the screw is loosened and damaging the motor. 8. Measure: • valve clearance out of spec...

Page 149

Camshaft camshaft removing the rocker arms and camshaft t. 22 nm (2.2 m • kg, 16 ft • ib) 10 nm (1.0 m • kg, 7 ft • ib) t. R. 7 nm (0.7 m • kg, 5 ft • ib) r. T. R. 7 2 m 6 3 1 13 nm (1.3 m • kg, 9 ft • ib) t. R. 1 2 m 5 e 4 e m order procedure / parts to remove amount observations head see the "head...

Page 150

Camshaft removing the rocker and camshaft 1. Loosen: • locknut "1" • screw adjustment valve clearance "2" • rocker "3" 2 dimensions of the lobes of camshaft admission to 31342-31442 mm limit 31,342 mm admission b 25166-25266 mm limit 25,136 mm escape a 31110-31210 mm limit 31,080 mm 1 3 2. Remove: •...

Page 151

Camshaft inspection 2. Check: • shaft rocker blue discoloration / wear excessive bite / scratch replace to verify the lubrication system. 3. Measure: • internal diameter of the beam "a" replace out of specification. Inner diameter of the beam 9985-10000 mm limit 10,030 mm clearance between the rocke...

Page 152

Valves and valve springs valves and valve springs removing the valves and valve springs 1 1 2 3 2 3 6 new 7 7 m m new 6 m m 5 4 order procedure / parts to remove amount observations head rocker / camshaft see the "head" on page 5-5 refer to "camshaft" in page 5-12 1 2 3 4 5 6 7 8 valve pin upper spr...

Page 153

Valves and valve springs removing the valves the following procedure applies to all valves and related components. Note: note: identify the position of each part with much care that can be reinstalled in their original place. Before removing the internal parts of the head (for example, valves, valve...

Page 154

Valves and valve springs 2. Delete: • carbon deposits (from the valve face and valve seat) 3. Check: • side valve pitting / wear face grind the valve. • end of the valve stem mushroom or a larger diameter than the replace valve stem and the valve. 4. Measure: • thickness of the valve margin d "a" ou...

Page 155

Valves and valve springs 4. Rectify: • valve face • valve seat note: after replacing the cylinder head or replacing the valve and valve guide must be lapped the valve seat and the face of the valve a. Apply lapping compound secondary "a" to the face of the valve. Caution do not let the lapping compo...

Page 156

Valves and valve springs free length (admission) 39.40 mm limit 37.40 mm free length (escape) 39.40 mm limit 37.40 mm tilt spring compression (admission) 2.5 ° / 1.7 mm tilt spring compression (escape) 2.5 ° / 1.7 mm 2. Measure: • compression force of the spring installed valve "a" out of specificat...

Page 157

Valves and valve springs • stem seal valve "2" new • valve "3" • valve spring "4" • upper spring seat valve "5" (in stock) note: 1 • ensure that each valve is installed in its original position • install the valve with the long end "a" upwards. 5. To secure the valve pin in the valve stem, lightly t...

Page 158

Cylinder and piston cylinder and piston removal of the cylinder and piston 7 e 8 9 6 5 new 4 1 e e 4 new e 2 new 3 3 order procedure / parts to remove amount observations head see the "head" on page 5-5 1 2 3 4 5 6 7 8 9 cylinder cylinder gasket dowel pin piston pin piston pin piston top ring second...

Page 159

Cylinder and piston removing the cylinder and piston 1. Remove: • piston pin "1" • piston pin "2" • piston "3" caution do not use a hammer to remove the bolt from piston note: • before removing the piston pin, cover the crankcase opening with a clean cloth prevent the piston pin from falling into th...

Page 160

Cylinder and piston "c" = maximum of d1-d2 "t" = maximum of d1 or d2 - d5 or d6 maximum "r" = maximum of d1, d3 or d5 - minimum of d2, d 4 or d6 checking the piston rings 1. Measure: • ring side clearance out of specification replace the piston and piston rings, as a whole. Note: b. If out of specif...

Page 161

Cylinder and piston 3. Measure: • distance between centers of rings out of specification replace piston rings. Note: 3. Measure: • inner diameter of the pin piston "a" out of specification replace the piston inner diameter of piston pin 15002-15013 limit 15,043 mm the opening of the oil ring spacer ...

Page 162

Cylinder and piston and 120 ° 120 ° 120 ° to b 90 ° cd 45 º a 45 º 2. Install: • piston "1" • piston pin "2" • piston pins "3" new note: a. B. C. D. E. A. • apply engine oil to the piston pin. • make sure the arrow mark "a" piston pointing towards the exhaust side of the cylinder. • before installin...

Page 163

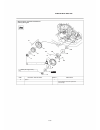

Magneto and starter clutch magneto and starter clutch removing the magneto and starter clutch 1 2 10 nm (1.0 m l kg 7ft ib) l t. R. L lt 9 10 nm (1.0 m l kg 7ft ib) l t. R. 12 8 7 new 19 e 17 14 16 e 3 e 15 13 10 8 ls new 4 6 e new 18 14 nm (1.4 m l t. New kg, 10 ft lb) l 5 new ls order r. E t. 20 1...

Page 164

Magneto and starter clutch removing the magneto and starter clutch 1 2 10 nm (1.0 m l kg 7ft ib) l t. R. L lt 9 10 nm (1.0 m l kg 7ft ib) l t. R. 12 8 7 new 19 e 17 14 16 e 3 e 15 13 10 8 ls newnuevo 4 6 e new 18 14 nm (1.4 m l t. New kg, 10 ft lb) l 5 new ls order r. E t. 20 11 l 70 nm (7.0 m kg, 5...

Page 165

Magneto and starter clutch magnet removal 1. Remove: • magneto rotor nut • washer note: 2 • while holding the rotor magnet using the rotor magnet holder "1", loosen the magneto rotor nut. 1 1 removing the starter clutch 1. Remove: • starter clutch bolts "1" note: • while holding the rotor magnet wit...

Page 166

Magneto and starter clutch 1 2 note: 3 1 2 • while holding the rotor magnet, tighten the starter clutch "1". • mark the end "a" of each screw starter clutch. 3 2 1 3 1 2. Check: • freewheel clutch start • starter clutch sprocket burrs / chips / roughness replace defective parts. 3. Check: • contact ...

Page 167

Magneto and starter clutch note: • while holding the rotor magnet "2", tighten the magneto rotor nut "1". 7 5 1.6 8 1 4 9 3 2.10 2 3. Apply: • sealant (in the crankshaft position sensor / in eyelet for mounting the stator wire) yamaha adhesive no. 1215 tg-1215 ls 4. Install: • cover the magnet magne...

Page 168

Electric start electric start removing the starter motor 2 nm (0.2 m • kg, 1ft • ib) 10 nm (1.0 m t. R. • kg 7ft • ib) t. R. (2) 2 1 order procedure / parts to remove amount observations 1 2 starter starter cable 1 1 disconnect for assembly, reverse the procedure disassembly. 5-31.

Page 169

Electric start disassemble the starter 1 1 2 9 10 3 4 5 6 7 8 1 order procedure / parts to remove amount observations 1 2 3 4 5 6 7 8 9 10 11 starter cover gasket set of carbon brushes support for carbon brushes oil seal pin lock stop washer washer bearing front cover of the starter starter 1 1 1 1 ...

Page 170

Electric start disassembly starter 1. Remove: • starter "1" • engine front cover start / brush holder assembly "2" note: note: to ensure correct operation of the switch should be cut mica. Before disassembling the starter, make alignment marks "a" in the starter cover and front cover starter / brush...

Page 171

Electric start 6. Check: • sprocket teeth damage / wear replace the sprocket. 7. Check: • bearing • oil seal damage / wear replace the cover starter frontal / group brush holder starter assembly 1. Install: • front cover of the starter / brush support assembly "1" • cover starter "2" note: align the...

Page 172

Clutch clutch removing the clutch cover 9 nm (0.9 m • kg 7ft • ib) t. R. 1 8 new 7 new 2 e 5 6 3 ls 4 new ls (4) t. (6) 10 nm (1.0 m • kg 7ft • ib) amount 10 nm (1.0 m • kg 7ft • ib) t. R. R. Order procedure / parts to remove observations motor oil 1 2 3 4 5 6 7 clutch cable oil seal oil filter cove...

Page 173

Clutch removing the clutch 70 nm (7.0 m kg, 51 ft lb) t. R. 11 new 8 nm (0.8 m kg 6ft ib) e order 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 t. R. 3 4 5 1 10 6 12 15 (4) (4) 8 7 e 2 8 7 8 9 7 13 14 e procedure / parts to remove amount observations locknut clutch spring pressure plate short rod clutch thrus...

Page 174

Clutch removing the push lever 1 e 2 3 new e ls 4 new 5 order procedure / parts to remove amount observations clutch 1 2 3 4 5 refer to "clutch" on page 5-35 1 1 1 1 1 push the clutch lever spring clutch push lever pin lock oil seal bearing for assembly, reverse the procedure disassembly. 5-37.

Page 175

Clutch removing the clutch 1. Straighten the lock washer. 2. Loosen: • the nut of the clutch disc carrier "1" note: while holding the clutch disc carrier "2" with the clutch fastener "3", loosen the clutch cutterbar nut. Clutch retainer ysst-733 2 1 a b 3 x a. Friction disc 1 b. B. Friction disc 2 a...

Page 176

Clutch thickness of clutch discs 1.85-2.15 mm limit deformation 0.20 mm 2. Check: • bearing damage / wear replace the bearing and the clutch. Inspection of springs clutch the following procedure applies to all clutch springs. 1. Check: • clutch springs replace damaged clutch springs as a set inspect...

Page 177

Clutch 2. Check: • primary drive gear damage / wear replace gear primary drive and clutch as a whole. Excessive noise during operation replace the primary drive gear and the clutch as a whole. 3. Install: • primary drive gear see "pinion balancer "on page 5-49. Driven gear inspection primary 1. Chec...

Page 178

Clutch 2 1 5. Bend the tab washer along a flat side of the nut. 6. Lubricate: • friction discs • clutch discs (with the recommended lubricant) recommended lubricant engine oil 9. Fit: • free play of the clutch mechanism a. Verify that the projection "a" in the lever clutch "1" is aligned with the ma...

Page 179

Clutch 10. Install: • oil seal "1" • oil seal "2" 1 to 2 b 11. Install: • clutch cover clutch cover screw 10 nm (1.0 m · kg, 7.2 ft · lb) note: tighten the the cover screws clutch in proper tightening sequence as shown. 1.9 8 10 1 1 7 6 12 t. R. 13 5 4 3.15 2.14 13. Fit: • set the clutch cable free ...

Page 180

Oil pump oil pump removing the oil pump 3 4 nm (0.4 m • kg, 3ft • ib) order t. R. 2 1 lt l t t. 4 nm (0.4 m • kg, 3ft • ib) r. 10 nm (1.0 m • kg 7ft • ib) t. 10 nm (1.0 m • kg 7ft • ib) observations clutch primary drive gear / pinion balancer t. R. R. Procedure / parts to remove amount refer to "clu...

Page 181

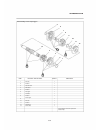

Oil pump disassembly of the oil pump 2 6 5 4 3 e 1 e order procedure / parts to remove amount observations 1 2 3 4 5 6 housing cover of the oil pump pin primary driven gear oil pump internal rotor of the oil pump external rotor oil pump pump housing oil 1 1 1 1 1 1 for assembly, reverse the procedur...

Page 182

Oil pump checking the oil pump 1. Check: • primary drive gear pump oil • primary driven gear pump oil • pump housing oil cracks / damage / wear replace defective parts. 2. Measure: • clearance between the inner rotor and outer rotor "a" • clearance between the outer rotor and the housing oil pump "b...

Page 183

Oil pump 1 2 to 3. Check: • operating the oil pump see "inspection oil pump "on page 5-45. Assembling the oil pump 1. Install: • oil pump screw oil bulges 4 nm (0.4 m · kg, 2.4 ft · lb) caution after tightening the screws, make sure that the oil pump rotates smoothly. T. R. 5-46.

Page 184

Axis of changes axis of changes removing the shift shaft and lever stop 6 ls new 2 e 3 lt 4 5 1 9 nm (0.9 m • kg 7ft • ib) t. R. Order procedure / parts to remove amount observations clutch shift arm refer to "clutch" on page 5-35 1 2 3 4 5 6 axis changes pin lock shift shaft spring lever cap stop l...

Page 185

Axis of changes shaft inspection of changes 1. Check: • axis changes curves / damage / wear replace. • changes shaft spring damage / wear replace. Top lever inspection 1. Check: • lever cap curves / damage replace. Replace harsh roller rotates the top of the lever. • stop lever spring damage / wear ...

Page 186

Pinion balancer pinion balancer removing the sprocket and balancer primary drive gear 6 5 13 4 3 1 60 nm (6.0 m • kg, 43 ft • ib) e 15 10 14 9 12 11 t. R. 8 7 new 2 order procedure / parts to remove 45 nm (4.5 m • kg, 33 ft • ib) observations amount t. R. Clutch refer to "clutch" on page 5-35 1 2 3 ...

Page 187

Pinion balancer removing the sprocket and balancer primary drive gear 6 5 13 4 3 1 60 nm (6.0 m • kg, 43 ft • ib) e 15 10 14 9 12 11 45 nm (4.5 m kg, 33 ft lb) • • t. R. 8 t. Order 15 r. 7 new 2 procedure / parts to remove amount observations spacer 1 for assembly, reverse the procedure disassembly....

Page 188

Pinion balancer pinion balancer driven gear assembly primary balancer 1. Assembly: • pin pin "1" • spring "2" (with the glass top) note: 1. Loosen: • primary drive gear nut "1" note: place a sheet of leather or a leather "a" between the primary drive gear balancer "2" and engranaj and led primary ba...

Page 189

Pinion balancer 2 1 3 b 2 4 to b 3. Bend the tab washer along a flat side of the nut. 3 c 2. Press: • nut primary driven gear balancer "1" • primary drive gear "2" driven gear nut primary balancer 45 nm (4.5 m · kg, 33 ft · lb) primary drive gear 60 nm (6.0 m · kg, 43 ft · lb) note: • place an alumi...

Page 190

Carter carter separation of the crankcase 10 nm (1.0 m • kg, 7 ft • ib) order t. R. 4 5 6 10 nm (1.0 m • kg, 7 ft • ib) t. R. 3 1 5 7 2 10 nm (1.0 m • kg, 7 ft • ib) amount observations t. R. Procedure / parts to remove engine head cylinder and piston clutch bell oil pump axis changes electric start...

Page 191

Carter separation of the crankcase 10 nm (1.0 m • kg, 7 ft • ib) t. Order r. 4 5 6 10 nm (1.0 m • kg, 7 ft • ib) t. R. T. 10 nm (1.0 m • kg, 7 ft • ib) r. 3 1 5 7 2 10 nm (1.0 m • kg, 7 ft • ib) amount observations t. R. Procedure / parts to remove 5 6 7 dowel pin casing left nozzle 2 1 1 for assemb...

Page 192

Carter dismantling of bearings and oil seals 3 e 7 nm (0.7 m • kg, 5 ft • ib) e t. R. 3 2 3 3 3 3 lt 1 3 e ls order procedure / parts to remove amount observations crankshaft / balancer transmission refer to "crankshaft" on page 5-58 refer to "transmission" on page 5-61 1 2 3 oil seal bearing retain...

Page 193

Carter crankcase separation 1. Remove: • crankcase screws note: caution loosen each bolt 1/4 turn back to the stage and in the correct sequence as shown. A tapping on a side of the crankcase with a soft-faced hammer. Hit only in the reinforced portions of the sump, not on the contact surfaces crankc...

Page 194

Carter replace harsh movement. • oil seals damage / wear replace. Bearing retainer assembly 1. Install: • bearing retainer "1" note: 3. Install: • housing right note: rotate the drum segment changes "1" to the position shown in the illustration. In this position, the teeth of the drum segment change...

Page 195

Crankshaft crankshaft removing the crankshaft and the balancer 2 e e ls 1 new ls new order procedure / parts to remove amount observations sump refer to "crankcase" on page 5-53 1 2 balancer crankshaft 1 1 for assembly, reverse the procedure disassembly. 5-58.

Page 196

Crankshaft removing the crankshaft 1. Remove: • crankshaft "1" note: • remove the crankshaft with the tool to remove the crankshaft "2". • make sure the tool to remove the crankshaft is centered on the crankshaft. Caution • to protect the end of the crankshaft, placing a key of suitable size between...

Page 197

Crankshaft 1 caution to avoid scratching the crankshaft and to facilitate procedure, assembly, lubricate the edges of oil seals with soap-based grease lithium and each bearing with engine oil. Note: keep the rod in the top dead (pms) with one hand while turning the nut crankshaft mounting screw with...

Page 198

Transmission transmission removing the transmission, the drum changes and changes the hairpin 7 1 2 4 8 9 e 5 2 6 2 e 3 e order procedure / parts to remove amount observations sump refer to "crankcase" on page 5-53 1 2 3 4 5 6 7 8 9 guide bar claw changes spring shift drum right-shift fork shift for...

Page 199

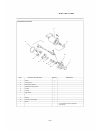

Transmission disassemble the main axis m 7 m 6 5 4 3 2 1 m order procedure / parts to remove amount observations 1 2 3 4 5 6 7 second pinion fifth-pinion third-pinion pin lock toothed washer fourth pinion main shaft / pinion first 1 1 1 1 1 1 1 for assembly, reverse the procedure disassembly. 5-62.

Page 200

Transmission disassembly of the coupling pin 5 6 7 8 9 10 1 1 12 13 4 3 2 1 m m m m order procedure / parts to remove amount observations 1 2 3 4 5 6 7 8 9 10 11 12 13 pin lock washer second gear fifth gear washer first gear necklace washer fourth gear pin lock washer third gear drive shaft 1 1 1 1 ...

Page 201

Transmission inspection of forks changes the following procedure applies to all changes forks. 1. Check: cam pin of the yoke of change "1" clips shift fork "2" curves / damage / stretch marks / wear replace the fork of the changes. L l inspection of change drum 1. Check: s urcos changes in the drum ...

Page 202

Transmission main shaft assy, spindle traction 1. Install: adjust dial "1" pin lock "2" new l l note: l 3. Check: gears of work pool such knowledge within blue discoloration / pitting / wear replace defective gear. Lace gear transmission cracks / damage / rounded edges replace defective parts. L l l...

Page 203

Transmission note: the markings on the shift forks should be facing the right side of engine and be in the following sequence: "r", "c", "l". 2. Check: transmission rough motion l repair note: l l apply engine oil to each gear and bearing. Before assembling the engine crankcase, make sure the transm...

Page 204

Fuel system carb carburetor removal carburetor disassembly carb inspection carburetor assy carburetor assembly measuring and adjusting the fuel ble inspection of the fuel wrench 6-1 6-2 6-4 6-6 6-7 6-7 6-8 air induction system air induction system removing the air induction system inspection system ...

Page 205

Carb carb removing the carburetor order procedure / parts to remove amount observations seat, side covers 1 & 2, hose fuel refer to "general chassis "on page 4-1 1 2 3 4 5 6 7 8 overflow fuel hose fuel line screw clamp connection carburetor screw clamp throttle cable starter cable tps connector carb...

Page 206

Carb disassemble the carburetor order procedure / parts to remove amount observations disassemble the carburetor remove the parts in the order listed 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Diaphragm cover diaphragm spring needle valve piston valve diaphragm ring drain screw float chamber o-ring ...

Page 207

Carb disassemble the carburetor 31 order procedure / parts to remove amount observations 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. Float pin float set needle throttle stop screw washer spring jet pilot o-ring washer spring o-ring filter mesh cover plunger support guide 1 1 1 1 1 1 1 1 ...

Page 208

Carb disassemble the carburetor 7 order procedure / parts to remove amount observations 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. O-ring spring plunger plunger spring washer throttle stop stop washer spring tps o-ring pin lock washer washer 1 1 1 1 1 1 1 1 1 1 1 1 for assembly, reverse the pro...

Page 209

Carb carburetor disassembly 1. Check: • carburetor body "1" • float chamber "2" • accommodation supplier "3" cracks / damage-replace. 4.Verificar: • body of the float chamber "1" dirt - clean. 5.Verificar: • rubber gasket of the chamber float "1" cracks / damage / wear - replace. 2. Check: • fuel pa...

Page 210

Carb 8. Check: • mesh filter "1" damaged / obstructed ---- replace 1 1 2 9. Check: • leading supplier "1" / accommodation supplier "2" / o-ring "3" / main nozzle "4" damage / obstruction - replace 432 1 carburetor assy 10. Check: • jet pilot "1" damage / obstruction - replace 1 11. Check: • mixture ...

Page 211

Carb 2.Install: • mixture screw "1" • mesh filter "2" 4. Install: • float "1" • float pin "2" • screw "3" • gasket float chamber "4" • float chamber "5" 1 3 2 2 1 5 4 5.Instalar: • diaphragm valve "1" 3.Instalar: • needle valve "1" caution do not overtighten any screws, this can damage gaskets and o...

Page 212

Carb 6. Install: • spring iris "1" • cover the diaphragm "2", tighten the screws 2 1 4 2.Ajustar: • fuel level carburetor assembly 1.Connect all wires and cables. Refer to "removal motor "on page 5-2. 2.Ajustar • set throttle cable free refer to "adjusting the game throttle cable free " on page 3-6 ...

Page 213

Air induction system air induction system 5 1 2 3 4 3 2 5 1 4 1 2 3 4 5 hose air induction system (air filter). Vacuum hose of the air induction system. Through the air induction system (to the motor) air filter air induction system. 6-9.

Page 214

Air induction system removing the air induction system 1 3 4 2 order procedure / parts to remove amount observations seat, side cover, side cover 1 & 2 fuel tank refer to "general chassis "on page 4-1 refer to "general chassis "on page 4-2 1 2 3 4 hose air induction system (air filter). Vacuum hose ...

Page 215

Air induction system induction system inspection air air injection the air induction system burning gases unburned exhaust by injecting fresh air (secondary air) at the port of exhaust, reducing the emission of hydrocarbons. When there is negative pressure in the port exhaust valve plates is opened,...

Page 216

Air induction system air shutoff valve is opened replace the air shutoff valve. Air shutoff valve closed the air shutoff valve is ok 1 note: this test should be performed when the pressure is less than - 50 kpa. 6-12.

Page 217

Electrical ignition system circuit diagram troubleshooting electric starting system circuit diagram operating system boot cut troubleshooting charging system circuit diagram troubleshooting lighting system circuit diagram troubleshooting signalling system circuit diagram troubleshooting self diagnos...

Page 218

Gb sbly g b br r w - w (black) ly crk + ig bl w r or or w br b rb 1 8 w w 3 b r sb r w wsb sb ly g 20 7 bl vcc s ig sgnd bl and l sb bl ly 2 bl l and w wsb 6 19 26 30 31 4 15a startoffstart and tc diag vb gnd lw b br rw l wb lg yw stopoffrun l r br mainonoff lightof fpoon ignition system r 21 lw wbb...

Page 219

Ignition system 1. Magneto ca 3. Unit regulator / rectifier 4. Main fuse 5. Battery 6. Main switch 7. Cdi 8. Ignition coil 19. Tps 20. Plug 21. Cable positive + 22. Negative cable - 30. Engine stop switch 7-2.

Page 220

Ignition system troubleshooting the ignition system is not working (no spark or intermittent spark). Note: • before troubleshooting, remove the following parts: 1. Seat 2. Side cover 1 and 2 3. Fuel tank 1. Check the fuse. See the section "checking the fuse" on page 7-34. Ok ↓ 2. Check the battery. ...

Page 221

Ignition system 9. Check the stop switch motor. Refer to the "verification switch "on page 7-30. Ok ↓ 10.Verificar wiring system full power. See section "chart circuit "on page 7-1. Ok ↓ replace the cdi. Ng → the engine stop switch is damaged. Replace the switch right handlebar ng → connect or repai...

Page 222

Gb sbly g b br r w - r ly crk + ig bl w w (black) or or w br b rb 1 8 w w 3 b r sb r w wsb sb ly g 20 7 bl vcc s ig sgnd bl and l sb bl ly 2 bl l and w wsb 6 19 26 30 31 4 15a startoffstart and tc diag vb gnd lw b br rw l wb lg yw stopoffrun l r br mainonoff lightof fpoon r circuit diagram 21 lw wbb...

Page 223

Electric starting system 2. Neutral switch 4. Main fuse 5. Battery 6. Main switch 21. Cable positive + 22. Negative cable - 23. Starter relay 24. Starter 26. Start switch 27. Starter cut relay 28. Clutch switch 30. Engine stop switch 7-6.

Page 224

Electric starting system system operation starting circuit court if the engine cutoff switch is set to "" and the ignition key is positioned "on" (both switches are closed), the starter will operate if one of the following conditions is served: • the transmission is in neutral (the neutral switch is...

Page 225

Electric starting system a. When the transmission is in neutral b. When is clutch lever shot to the handlebars 1. Battery 2. Fuse 3. Main switch 4. Engine stop switch 5. Starter cut relay 6. Clutch switch 7. Neutral switch 8. Start switch 9. Start relay 10. Starter 7-8.

Page 226

Electric starting system troubleshooting the starter will not start. Note: • before troubleshooting, remove the following parts: 1. Seat 2. Side cover 1 and 2 1. Check the fuse. Refer to the "verification fuse "on page 7-34. Ok ↓ 2. Check the battery. See the section "checking and charging battery "...

Page 227

Electric starting system 8. Check the stop switch motor. See the section "verification switches "on page 7-30. Ok ↓ 9. Check the neutral switch. Refer to the "verification switch "on page 7-30. Ok ↓ 10.Verificar clutch switch. Refer to the "verification switch "on page 7-30. Ok ↓ 11.Verificar the st...

Page 228

Gb sbly g b br r w - w (black) ly crk + ig bl w r or or w br b 1 8 w w 3 b r sb r w wsb sb ly g 20 7 sb bl ly 2 gis sgnd bl and w wsb 6 vcc l 26 30 19 bl l and 31 bl 4 15a startoffstart and tc diag vb gnd lw b br rw l wb lg yw stopoffrun l r charging system br mainonoff lightoffpoon r 21 lw wbb rwlw...

Page 229

Charging system 1. Magneto ca 3. Regulator / rectifier 4. Main fuse 5. Battery 21. Cable positive + 22. Negative cable - 7-12.

Page 230

Charging system troubleshooting the battery is not charging. Note: • before troubleshooting, remove the following parts: 1. Seat 2. Left side panel / cap. 1. Check the fuse. Refer to the "verification fuse "on page 7-34 ok ↓ 2. Check the battery. Refer to the "verification and charging the battery "...

Page 231

Gb sbly g b br r w - r ly crk + ig bl w w2 (black) or or r2 w br b 1 8 w2 w2 3 b r sb2 r w wsb sb ly g 37 7 bl vcc gis sgnd bl and l sb2 bl ly 2 bl l and w w2sb 6 19 26 30 31 4 15a startoffstart and tc diag vb gnd lw b br rw l wb lg yw stopoffrun l lighting system br mainonoff lightoffpoon r2 circui...

Page 232

Lighting system 4. Main fuse 5. Battery 6. Main switch 13. Meter 15. Streetlight 18. Taillight 21. Cable positive + 22. Negative cable - light switch 31 34. Light switch.

Page 233

Lighting system troubleshooting any of the following lights failure: lamp, light-beam indicator, backlight, auxiliary light or light meter. Note: • before troubleshooting, remove the following parts: 1. Seat 2. Cap 1 and cap 2 3. Streetlight 4. Fuel tank 1. Check each bulb and the condition each bul...

Page 234

Gb sbly bl b br r w - r ly crk + ig w w (black) or or w br b sb 1 8 w w 3 b sb w wsb 20 7 6 vcc gis sgnd bl and l ly g sb 2 bl l and w wsb 26 30 19 31 bl bl ly 4 15a startoffstart stopoffrun l and yw lg r br main r onoff tc diag vb gnd lw b br rw l wb lightoffpoon r 21 lw br rwlwwbb l (black) rwbr b...

Page 235

Signalling system 2. Neutral switch 4. Main fuse 5. Battery 6. Main switch 7. Cdi 9. Horn 10. Relay turn signal 11. Front brake switch 12. Rear brake switch 13. Meter 16. Headlight turn indicator (lh) 17. Headlight turn indicator (rh) 21. Cable positive + 22. Negative cable - 25. Speed sensor 29. Fu...

Page 236

Signalling system troubleshooting •any failure following lights: turn indicator lights, brake light or indicator lights. •the horn does not sound. •the fuel gauge does not work. Note: •before troubleshooting, remove the following parts: 1. Seat 2. Fuel tank 3. Streetlight 4. Multi-function display 1...

Page 237

Signalling system 3. Check the wiring system signaling. See the section "circuit diagram" on page 7-17. Ok ↓ the system circuit is ok the brake light / rear does not light. Ng → connect or repair wiring system signaling 1. Check the bulb brake light / back and the socket. Refer to the "verification ...

Page 238

Signalling system 3. Check the light switch indicator of rotation. Refer to section "verification switches "on page 7-30. Ok ↓ 4.Verificar relay indicator light of rotation. See the section "checking the relay turn indicator lamp "on page 7-38. Ok ↓ ng → the horn switch is faulty. Replace the left s...

Page 239

Signalling system 2.Check wiring system signaling. See the section "circuit diagram" on page 7-17. Ng → connect or repair wiring system signaling ok ↓ replace the meter. 7-22.

Page 240

Self-diagnosis function self-diagnosis function the vehicle is equipped with an auto-diagnosis. If this function detects a bad operating on the system immediately operates the engine under substitute characteristics and illuminates the warning light engine failure to alert the driver that there has ...

Page 241

Self-diagnosis function fault code table code fault 15 16 item symptom can / can / can not can not boot drive can can can can throttle position sensor throttle position sensor: (open or short) open or short circuit detected. Throttle position sensor throttle position sensor (attached) is attached ve...

Page 242

Self-diagnosis function troubleshooting details this section describes the steps to the fault code number displayed on the meter. Check and service elements or components that are the likely cause of failure. Fault code no. 15 symptom throttle position sensor: open circuit or short circuit detected ...

Page 243

Self-diagnosis function fault code no. 16 the throttle position sensor is attached component: throttle position sensor order 1 item / components and cause verification or maintenance work likely condition sensor assembly • check for loose or pressed. Throttle position. • check that the sensor is ass...

Page 244

Self-diagnosis function symptom: the signals received from the speed sensor is not normal. Component: vehicle speed sensor order 1 2 item / components and cause likely condition sensor assembly speed. Connections • speed sensor coupler • main cable coupler harness. Method reinstatement start the • c...

Page 245

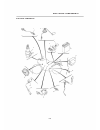

Electrical components electrical components 1 2 3 4 5 10 11 12 6 9 14 13 8 7 7-28.

Page 246

Electrical components 1. Front brake switch 2. Fuel gauge 3. Starter cut relay 4. Cdi 5. Main switch 6. Horn 7. Start relay 8. Neutral switch 9. Rear brake switch 10. Battery 11. Regulator / rectifier 12. Fuse 13. Spark plug cap 14. Ignition coil 7-29.

Page 247

Electrical components switch inspection 1 b r /b b (black) 2 r off on b (red) 3 br gy 4 br r br br br and and 5 sb 12 off po on 11 l / w b 10 br r / w 9 br pass 8 and w /b and g 7 br p 6 br ch /wdg br dg w /br b / w y p ch br r / w l / w w / b b l and g b 7-30

Page 248

Electrical components 1. Clutch switch 2. Main switch 3. Front brake switch 4. Rear brake switch 5. Neutral switch 6. Switch turn signal 7. The horn switch 8. Light switch 9. Light switch step 1 0 . Engine stop switch 11. Start switch 12. Headlight switch 7-31.

Page 249

Electrical components check continuity of each circuit with the multimeter. If the reading of continuity is not correct, check the connections, and if necessary, replace the switch. Caution: never insert the tester probes into the slots of the coupling terminal "a". Insert the probes provided by the...

Page 250

Electrical components verification of bulbs and sockets of bulbs check each bulb and bulb socket damage or wear, proper connections and continuity between the terminals. Damage / desgasterepare or replace bulb, the bulb socket or both. Incorrectaconecte connection correctly. No continuidadrepare or ...

Page 251

Electrical components checking the status of sockets of bulbs the following procedure applies to all sockets for light bulbs. 1. Check: • bulb socket (for continuity) (with multimeter) no continuity replace. Multimeter article note: a. Set the main switch to "off". B. Install a new fuse of the corre...

Page 252

Electrical components internal • drink plenty of water or milk followed by milk of magnesia, beaten eggs or vegetable oil. Get medical attention immediately. 1. Remove: • seat and right side cover refer to "general chassis" on page 4-1. 2. Disconnect: • battery cables (since the battery terminals) c...

Page 253

Electrical components warning do not charge a battery quickly. Caution: do not use a battery charger charging fast, as it forces a high amperage the battery quickly and can cause overheating and damage to the plates battery. If it is impossible to regulate the load current in the battery charger, be...

Page 254

Electrical components 8. Check: • battery terminals sulfation → clean with hot water. Connect loose connection correctly. 9. Lubricate: • battery terminals recommended lubricant dielectric grease charging method with a charging voltage constant a. Measuring open circuit voltage before upload. Note: ...

Page 255

Electrical components starter cut relay 1 b. Turn the main switch to "on". C. Measuring the input voltage signal relay of rotation. Output voltage relay turn signal 12 v dc 2 lb rb rw 3 2. Check: • the output voltage relay turn signal. Replace out of specification. A. Connect the multimeter to the r...

Page 256

Electrical components checking the spark plug hood a. Disconnect the coil connectors ignition of the coil terminals lit. B. Connect the multimeter (Ù × 1) to the coil on, as shown. Multimeter 1.Check: • plug cap resistance replace out of specification. Plug cap resistance ku 5.0 at 20 ° c (68 ° f) a...

Page 257

Electrical components • tester positive probe high voltage cable • tester negative probe land verification of the position sensor crankshaft 1 .. Disconnect: • coupler crankshaft position sensor (from the wiring harness) 2.Check: • reliability of crankshaft position sensor off-specification position...

Page 258

Electrical components a. Connect the positive battery terminal "1" and the starter cable "2" with a jumper cable "3". Warning • the cable used for the bridge should have at least the same capacity of the cable battery, otherwise, the cable bridge will burn. • this check is likely to cause sparks, th...

Page 259