- DL manuals

- Yamaha

- Motorcycle

- FZS6W

- Service Manual

Yamaha FZS6W Service Manual

Summary of FZS6W

Page 1

Fzs6w 4s8-28197-10 service manual lit-11616-20-60 fzs6wc.

Page 2

Eas20050 fzs6w/fzs6wc service manual ©2006 by yamaha motor corporation, u.S.A. First edition, octover 2006 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor corporation, u.S.A. Is expressly prohibited. Printed inu.S.A. P/n lit-11616-20-60

Page 3

Eas20070 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha deal- ers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on yama...

Page 4

Eas20090 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. • the manual is di...

Page 5

Eas20100 symbols the following symbols are used in this manual for easier understanding. Note: the following symbols are not relevant to every vehicle. 1. Serviceable with engine mounted 2. Filling fluid 3. Lubricant 4. Special tool 5. Tightening torque 6. Wear limit, clearance 7. Engine speed 8. El...

Page 7: Table of Contents

1 2 3 4 5 6 7 8 9 eas20110 table of contents general information specifications periodic checks and adjustments chassis engine cooling system fuel system electrical system troubleshooting.

Page 9: General Information

1 general information identification ..........................................................................................1-1 vehicle identification number...................................................1-1 model label ............................................................................

Page 10: Identification

Identification 1-1 eas20130 identification eas20140 vehicle identification number the vehicle identification number “1” is stamped into the right side of the steering head pipe. Eas20150 model label the model label “1” is affixed to the frame. This information will be needed to order spare parts..

Page 11: Features

Features 1-2 eas20170 features eas4s81003 outline of fi system the main function of a fuel supply system is to provide fuel to the combustion chamber at the opti- mum air-fuel ratio in accordance with the engine operating conditions and the atmospheric tempera- ture. In the conventional carburetor s...

Page 12: Features

Features 1-3 eas4s81004 fi system the fuel pump delivers fuel to the injector via the fuel filter. The pressure regulator maintains the fuel pressure that is applied to the injector at only 250 kpa (2.5 kg/cm 2 ). Accordingly, when the energiz- ing signal from the ecu energizes the injector, the fue...

Page 13: Features

Features 1-4 eas4s81005 instrument functions warning ewa4s81002 be sure to stop the vehicle before making any setting changes to the multi-function meter unit. The multi-function meter unit is equipped with the following: • a speedometer (which shows the riding speed) • a tachometer (which shows eng...

Page 14: Features

Features 1-5 odometer and tripmeter modes push the “select” button to switch the dis- play between the odometer mode “odo” and the tripmeter modes “trip a” and “trip b” in the following order: “trip a” → “trip b” → “odo” → “trip a” when the fuel amount in the fuel tank decreases to 3.4 l (0.90 us ga...

Page 15: Features

Features 1-6 note: • even if the air intake temperature is set to be displayed, the coolant temperature warning light comes on when the engine overheats. • when the key is turned to “on”, the coolant temperature is automatically displayed, even if the air intake temperature was displayed prior to tu...

Page 16: Important Information

Important information 1-7 eas20180 important information eas20190 preparation for removal and disas- sembly 1. Before removal and disassembly, remove all dirt, mud, dust and foreign material. 2. Use only the proper tools and cleaning equipment. Refer to "special tools" on page 1-10. 3. When disassem...

Page 17: Important Information

Important information 1-8 eas20230 bearings and oil seals install bearings and oil seals so that the manu- facturer’s marks or numbers are visible. When installing oil seals “1”, lubricate the oil seal lips with a light coat of lithium-soap-based grease. Oil bearings liberally when installing, if ap...

Page 18: Checking The Connections

Checking the connections 1-9 eas20250 checking the connections check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: • lead • coupler • connector 2. Check: • lead • coupler • connector moisture → dry with an air blower. Rust/stains → connect and disconnect several...

Page 19: Special Tools

Special tools 1-10 eas20260 special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropri- ate tools or improvised techniques. Special tools, part numbers...

Page 20: Special Tools

Special tools 1-11 steering nut wrench 90890-01403 spanner wrench yu-33975 3-26, 4-53 damper rod holder 90890-01294 damping rod holder set ym-01300 4-45, 4-47 t-handle 90890-01326 ym-01326 4-45, 4-47 oil filter wrench 90890-01426 yu-38411 3-13 fork seal driver weight 90890-01367 replacement hammer y...

Page 21: Special Tools

Special tools 1-12 pocket tester 90890-03112 analog pocket tester yu-03112-c 1-9, 5-38, 8-65, 8-66, 8-67, 8-71, 8-72, 8-73, 8-74, 8-75, 8-76, 8-77, 8-78, 8-79, 8-80, 8-81, 8-82 pressure gauge 90890-03153 yu-03153 3-14, 7-6 oil pressure adapter h 90890-03139 3-14 fuel pressure adapter 90890-03176 ym-...

Page 22: Special Tools

Special tools 1-13 universal clutch holder 90890-04086 ym-91042 5-49, 5-51 valve lapper 90890-04101 valve lapping tool ym-a8998 3-5 valve guide remover (ø4) 90890-04111 valve guide remover (4.0 mm) ym-04111 5-23 valve guide installer (ø4) 90890-04112 valve guide installer (4.0 mm) ym-04112 5-23 valv...

Page 23: Specifications

2 specifications general specifications ......................................................................2-1 engine specifications..........................................................................2-2 chassis specifications....................................................................

Page 24: General Specifications

General specifications 2-1 eas20280 general specifications model model 4s82 (u.S.A.) 4s83 (california) dimensions overall length 2095 mm (82.5 in) overall width 750 mm (29.5 in) overall height 1210 mm (47.6 in) seat height 795 mm (31.3 in) wheelbase 1440 mm (56.7 in) ground clearance 145 mm (5.71 in...

Page 25: Engine Specifications

Engine specifications 2-2 eas20290 engine specifications engine engine type liquid cooled 4-stroke, dohc displacement 600.0 cm³ cylinder arrangement forward-inclined parallel 4-cylinder bore × stroke 65.5 × 44.5 mm (2.58 × 1.75 in) compression ratio 12.20 :1 standard compression pressure (at sea lev...

Page 26: Engine Specifications

Engine specifications 2-3 water pump water pump type single suction centrifugal pump reduction ratio 86/44 × 31/31 (1.955) max. Impeller shaft tilt 0.15 mm (0.006 in) spark plug (s) manufacturer/model ngk/cr9ek spark plug gap 0.6–0.7 mm (0.024–0.028 in) cylinder head volume 10.33–10.93 cm³ (0.63–0.6...

Page 27: Engine Specifications

Engine specifications 2-4 valve dimensions valve head diameter a (intake) 24.90–25.10 mm (0.9803–0.9882 in) valve head diameter a (exhaust) 21.90–22.10 mm (0.8622–0.8701 in) valve face width b (intake) 1.140–1.980 mm (0.0449–0.0780 in) valve face width b (exhaust) 1.140–1.980 mm (0.0449–0.0780 in) v...

Page 28: Engine Specifications

Engine specifications 2-5 limit 1.6 mm (0.06 in) valve spring inner spring free length (intake) 37.04 mm (1.46 in) limit 35.20 mm (1.39 in) free length (exhaust) 41.79 mm (1.65 in) limit 39.70 mm (1.56 in) installed length (intake) 30.02 mm (1.18 in) installed length (exhaust) 36.12 mm (1.42 in) spr...

Page 29: Engine Specifications

Engine specifications 2-6 offset 0.50 mm (0.0197 in) offset direction intake side piston pin bore inside diameter 16.002–16.013 mm (0.6300–0.6304 in) limit 16.043 mm (0.6316 in) piston pin outside diameter 15.991–16.000 mm (0.6296–0.6299 in) limit 15.971 mm (0.6288 in) piston-pin-to-piston-pin-bore ...

Page 30: Engine Specifications

Engine specifications 2-7 crankshaft width a 51.850–52.550 mm (2.04–2.06 in) width b 268.80–270.00 mm (10.58–10.63 in) runout limit c 0.030 mm (0.0012 in) big end side clearance d 0.160–0.262 mm (0.0063–0.0103 in) big end radial clearance 0.028–0.052 mm (0.0011–0.0020 in) small end free play 0.32–0....

Page 31: Engine Specifications

Engine specifications 2-8 shifting mechanism shift mechanism type shift drum shift fork guide bar bending limit 0.050 mm (0.0020 in) shift fork thickness 5.76–5.89 mm (0.2268–0.2319 in) air filter air filter element oil-coated paper element fuel pump pump type electrical model/manufacturer 5vx/denso...

Page 32: Chassis Specifications

Chassis specifications 2-9 eas20300 chassis specifications chassis frame type diamond caster angle 25.00 ° trail 97.5 mm (3.84 in) front wheel wheel type cast wheel rim size 17m/c x mt3.50 rim material aluminum wheel travel 130.0 mm (5.12 in) radial wheel runout limit 1.0 mm (0.04 in) lateral wheel ...

Page 33: Chassis Specifications

Chassis specifications 2-10 front disc brake disc outside diameter × thickness 298.0 × 5.0 mm (11.73 × 0.20 in) brake disc thickness limit 4.5 mm (0.18 in) brake disc deflection limit 0.10 mm (0.0039 in) brake pad lining thickness (inner) 4.5 mm (0.18 in) limit 0.5 mm (0.02 in) brake pad lining thic...

Page 34: Chassis Specifications

Chassis specifications 2-11 rear suspension type swingarm (monocross) spring/shock absorber type coil spring/gas-oil damper rear shock absorber assembly travel 50.0 mm (1.97 in) spring free length 185.0 mm (7.28 in) installed length 172.0 mm (6.77 in) spring rate k1 127.40 n/mm (727.45 lb/in) (12.99...

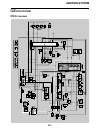

Page 35: Electrical Specifications

Electrical specifications 2-12 eas20310 electrical specifications voltage system voltage 12 v ignition system ignition system transistorized coil ignition (digital) ignition system type dc. Tci advancer type digital ignition timing (b.T.D.C.) 5.0 °/1300 r/min engine control unit model/manufacturer f...

Page 36: Electrical Specifications

Electrical specifications 2-13 indicator light neutral indicator light led turn signal indicator light led oil level warning light led high beam indicator light led coolant temperature warning light led engine trouble warning light led electric starting system system type constant mesh starter motor...

Page 37: Electrical Specifications

Electrical specifications 2-14 fuel injection system relay model/manufacturer g8r-30y-r/omron resistance 162–198 Ω thermo unit model/manufacturer 8cc/mitsubishi resistance at 80 °c 290.0–354.0 Ω fuses main fuse 30.0 a headlight fuse 20.0 a taillight fuse 10.0 a signaling system fuse 10.0 a ignition ...

Page 38: Tightening Torques

Tightening torques 2-15 eas20320 tightening torques eas20330 general tightening torque specifi- cations this chart specifies tightening torques for stan- dard fasteners with a standard iso thread pitch. Tightening torque specifications for spe- cial components or assemblies are provided for each cha...

Page 39: Tightening Torques

Tightening torques 2-16 eas20340 engine tightening torques item thread size q’ty tightening torque remarks spark plugs m10 4 18 nm (1.8 m·kg, 13 ft·lb) cylinder head bolt m10 10 see note cylinder head bolt m6 2 12 nm (1.2 m·kg, 8.7 ft·lb) camshaft caps bolt m6 20 10 nm (1.0 m·kg, 7.2 ft·lb) cylinder...

Page 40: Tightening Torques

Tightening torques 2-17 catalyst pipe and catalyst pipe stay bolt m8 1 20 nm (2.0 m·kg, 14 ft·lb) muffler joint bolt m8 1 20 nm (2.0 m·kg, 14 ft·lb) see note catalyst joint bolt m8 1 20 nm (2.0 m·kg, 14 ft·lb) see note exhaust pipe stay bolt m8 2 20 nm (2.0 m·kg, 14 ft·lb) catalyst pipe stay bolt m8...

Page 41: Tightening Torques

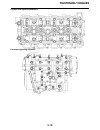

Tightening torques 2-18 note: • cylinder head bolt 1. First, tighten the bolts to approximately 19 nm (1.9 m·kg, 14 ft·lb) with a torque wrench follow- ing the tightening order. 2. Retighten the bolts 50 nm (5.0 m·kg, 36 ft·lb) with a torque wrench. • crankcase bolt (main journal) 1. First, tighten ...

Page 42: Tightening Torques

Tightening torques 2-19 cylinder head tightening sequence. Crankcase tightening sequence..

Page 43: Tightening Torques

Tightening torques 2-20 eas20350 chassis tightening torques item thread size q’ty tightening torque remarks upper bracket pinch bolt m8 2 30 nm (3.0 m·kg, 22 ft·lb) steering stem nut m22 1 110 nm (11 m·kg, 80 ft·lb) upper bracket and upper handle- bar holder m8 4 23 nm (2.3 m·kg, 17 ft·lb) lower bra...

Page 44: Tightening Torques

Tightening torques 2-21 note: • lower ring nut 1. First, tighten the ring nut to approximately 52 nm (5.2 m·kg, 38 ft·lb) with a torque wrench, then loosen the ring nut completely. 2. Retighten the lower ring nut to specification. • engine mount bolts and engine mount self locking nut refer to "inst...

Page 45

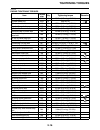

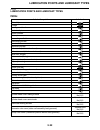

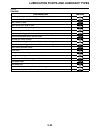

Lubrication points and lubricant types 2-22 eas20360 lubrication points and lubricant types eas20370 engine lubrication point lubricant oil seal lips o-rings bearings and bushes crankshaft pins piston surfaces piston pins connecting rod bolts crankshaft journals camshaft lobes camshaft journals valv...

Page 46

Lubrication points and lubricant types 2-23 eas20380 chassis lubrication point lubricant steering bearings and bearing races (upper and lower) front wheel oil seal (right and left) rear wheel oil seal rear wheel drive hub oil seal rear wheel drive hub mating surface rear brake pedal shaft sidestand ...

Page 47

Lubrication points and lubricant types 2-24.

Page 48

Lubrication system chart and diagrams 2-25 eas20390 lubrication system chart and diagrams eas20400 engine oil lubrication chart.

Page 49

Lubrication system chart and diagrams 2-26 1. Oil strainer 2. Oil pump 3. Relief valve 4. Oil filter 5. Oil cooler 6. Main axle 7. Mission cooler 8. Drive axle 9. Main gallery 10.Piston cooler 11.Intake camshaft 12.Exhaust camshaft.

Page 50

Lubrication system chart and diagrams 2-27 eas20410 lubrication diagrams.

Page 51

Lubrication system chart and diagrams 2-28 1. Oil level switch 2. Oil cooler 3. Relief valve.

Page 52

Lubrication system chart and diagrams 2-29.

Page 53

Lubrication system chart and diagrams 2-30 1. Oil pump 2. Exhaust camshaft 3. Intake camshaft 4. Oil strainer.

Page 54

Lubrication system chart and diagrams 2-31.

Page 55

Lubrication system chart and diagrams 2-32 1. Oil cooler 2. Oil strainer 3. Oil level switch 4. Oil pump.

Page 56

Lubrication system chart and diagrams 2-33.

Page 57

Lubrication system chart and diagrams 2-34 1. Main axle 2. Oil pump 3. Relief valve.

Page 58

Lubrication system chart and diagrams 2-35.

Page 59

Lubrication system chart and diagrams 2-36 1. Cylinder head 2. Intake camshaft 3. Exhaust camshaft 4. Crankshaft.

Page 60

Lubrication system chart and diagrams 2-37.

Page 61

Lubrication system chart and diagrams 2-38 1. Main axle 2. Drive axle.

Page 62: Cooling System Diagrams

Cooling system diagrams 2-39 eas20420 cooling system diagrams.

Page 63: Cooling System Diagrams

Cooling system diagrams 2-40 1. Radiator 2. Oil cooler.

Page 64: Cooling System Diagrams

Cooling system diagrams 2-41.

Page 65: Cooling System Diagrams

Cooling system diagrams 2-42 1. Water pump 2. Oil cooler 3. Radiator.

Page 66: Cooling System Diagrams

Cooling system diagrams 2-43.

Page 67: Cooling System Diagrams

Cooling system diagrams 2-44 1. Oil cooler 2. Water pump.

Page 68: Cooling System Diagrams

Cooling system diagrams 2-45.

Page 69: Cooling System Diagrams

Cooling system diagrams 2-46 1. Radiator 2. Thermostat.

Page 70: Cable Routing

Cable routing 2-47 eas20430 cable routing.

Page 71: Cable Routing

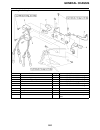

Cable routing 2-48 1. Left handlebar switch lead 2. Main switch lead 3. Clutch cable 4. Throttle cables 5. Right handlebar switch lead a. Clamp the right and left handlebar switch leads and handlebars. Point the tip of the clamp downward in front of the handlebar. B. 70–90 mm (2.76–3.54 in) c. Clamp...

Page 72: Cable Routing

Cable routing 2-49.

Page 73: Cable Routing

Cable routing 2-50 1. Rear brake light switch lead 2. Neutral switch lead 3. Fuel tank breather hose 4. Crankshaft position sensor lead 5. Right handlebar switch lead 6. O 2 sensor lead 7. Bracket 8. Fuel tank drain hose 9. Rear brake reservoir hose a. Pass the fuel tank breather hose, fuel tank dra...

Page 74: Cable Routing

Cable routing 2-51.

Page 75: Cable Routing

Cable routing 2-52 1. Main switch lead 2. Stay assembly 3. Left handlebar switch lead 4. Clutch cable 5. Throttle cables 6. Battery negative lead coupler 7. Starter relay lead 8. Battery negative lead 9. Fuel tank drain hose 10.Rectifier/regulator 11.Turn signal relay 12.Radiator fan motor relay 13....

Page 76: Cable Routing

Cable routing 2-53.

Page 77: Cable Routing

Cable routing 2-54 1. Right handlebar switch lead 2. Throttle cables 3. Battery positive lead 4. Battery cover 5. Connector cover 6. Fuel tank breather hose 7. Lean angle sensor 8. Fuse box 9. Rear right turn signal light lead 10.License plate light lead 11.Rear left turn signal light lead 12.Seat l...

Page 78: Cable Routing

Cable routing 2-55.

Page 79: Cable Routing

Cable routing 2-56 1. Fuel pump assembly 2. Fuel tank breather hose 3. Fuel tank drain hose 4. Fuel hose 5. Clip 6. Clamp 7. Fuel tank protector 8. Charge hose (fzs6wc) 9. Roll over valve (fzs6wc) a. Air opening. B. Install the o-ring with its lip pointed upward. C. Fuel tank breather hose has a whi...

Page 80: Cable Routing

Cable routing 2-57 fzs6wc.

Page 81: Cable Routing

Cable routing 2-58 1. Clip 2. Roll over valve assembly 3. Canister hose 4. Balance hose 5. Clamp 6. Canister assembly 7. Upper bracket 8. Hose 9. Canister bracket 10.Fuel tank drain hose 11.Roll over valve hose a. Front side b. Point the paint marking upward. C. Pass the canister hose outside, pass ...

Page 82: Cable Routing

Cable routing 2-59.

Page 83

3 periodic checks and adjustments periodic maintenance .........................................................................3-1 introduction ....................................................................................3-1 engine................................................................

Page 84

Electrical system.............................................................................. 3-32 replacing the headlight bulbs............................................... 3-32 adjusting the headlight beams .............................................. 3-32.

Page 86: Periodic Maintenance

Periodic maintenance 3-1 eas20450 periodic maintenance eas20460 introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a longer service life and redu...

Page 87: Periodic Maintenance

Periodic maintenance 3-2 4 * rear brake • check operation, fluid level, and for fluid leakage. • replace brake pads if neces- sary. √ √ √ √ √ √ 5 * brake hoses • check for cracks or damage. √ √ √ √ √ • replace. Every 4 years 6 * wheels • check runout and for damage. • replace if necessary. √ √ √ √ √...

Page 88: Periodic Maintenance

Periodic maintenance 3-3 * since these items require special tools, data and technical skills, have a yamaha dealer perform the service. Note: from 24000 mi (37000 km) or 36 months, repeat the maintenance intervals starting from 8000 mi (13000 km) or 12 months. Note: • air filter • this model’s air ...

Page 89: Engine

Engine 3-4 eas20470 engine eas20490 adjusting the valve clearance the following procedure applies to all of the valves. Note: • valve clearance adjustment should be made on a cold engine, at room temperature. • when the valve clearance is to be measured or adjusted, the piston must be at top dead ce...

Page 90: Engine

Engine 3-5 d. To measure the valve clearances of the other cylinders, starting with cylinder #1 at tdc, turn the crankshaft counterclockwise as specified in the following table. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 5. Remove: • camshafts note: • refer to "camshafts" on page 5-8. • when removing the timing...

Page 91: Engine

Engine 3-6 • since valve pads of various sizes are origi- nally installed, the valve pad number must be rounded in order to reach the closest equiva- lent to the original. C. Round off the original valve pad number according to the following table. Example: original valve pad number = 148 (thickness...

Page 92: Engine

Engine 3-7 • air filter case refer to "general chassis" on page 4- 1. 3. Install: • vacuum gauge “1” (onto the synchronizing hose “2”) 4. Install: • air filter case refer to "general chassis" on page 4- 1. • fuel tank refer to "fuel tank" on page 7-1. 5. Start the engine and let it warm up for sev- ...

Page 93: Engine

Engine 3-8 11. Install: • fuel tank refer to "fuel tank" on page 7-1. • seat refer to "general chassis" on page 4- 1. Eas20610 adjusting the engine idling speed note: prior to adjusting the engine idling speed, the throttle bodies synchronization should be adjusted properly, the air filter element s...

Page 94: Engine

Engine 3-9 b. Turn the adjusting nut “3” in direction “a” or “b” to take up any slack on the decelerator cable. C. Tighten the locknuts note: if the specified throttle cable free play cannot be obtained on the throttle body side of the cable, use the adjusting nut on the handlebar side. ▲▲▲▲▲▲▲▲▲▲▲▲...

Page 95: Engine

Engine 3-10 caution: eca13320 before removing the spark plugs, blow away any dirt accumulated in the spark plug wells with compressed air to prevent it from falling into the cylinders. 4. Check: • spark plug type incorrect → change. 5. Check: • electrode “1” damage/wear → replace the spark plug. • i...

Page 96: Engine

Engine 3-11 • battery refer to "general chassis" on page 4- 1 and "checking and charging the battery" on page 8-68. • battery box • battery box bracket refer to "general chassis" on page 4- 1. • heat protector plate • cover • ignition coils 4. Disconnect: • spark plug caps 5. Remove: • spark plugs c...

Page 97: Engine

Engine 3-12 • heat protector plate • battery box bracket • battery box refer to "general chassis" on page 4- 1. • battery refer to "general chassis" on page 4- 1 and "checking and charging the battery" on page 8-68. • air filter case refer to "general chassis" on page 4- 1. • fuel tank refer to "fue...

Page 98: Engine

Engine 3-13 4. Drain: • engine oil (completely from the crankcase) 5. If the oil filter cartridge is also to be replaced, perform the following procedure. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Remove the oil filter cartridge “1” with an oil filter wrench “2”. B. Lubricate the o-ring “3” of the new oil f...

Page 99: Engine

Engine 3-14 caution: eca13410 when the engine is cold, the engine oil will have a higher viscosity, causing the engine oil pressure to increase. Therefore, be sure to measure the engine oil pressure after warming up the engine. 3. Remove: • oil gallery bolt “1” warning ewa12980 the engine, muffler a...

Page 100: Engine

Engine 3-15 2. Adjust: • clutch cable free play ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ handlebar side a. Turn the adjusting bolt “1” in direction “a” or “b” until the specified clutch cable free play is obtained. Note: if the specified clutch cable free play cannot be obtained on the handlebar side of the c...

Page 101: Engine

Engine 3-16 caution: eca4s81008 never operate the engine without the air fil- ter element installed. Unfiltered air will cause rapid wear of engine parts and may damage the engine. Operating the engine without the air filter element will also affect throttle bodies synchronization, leading to poor e...

Page 102: Engine

Engine 3-17 caution: eca13450 make sure the crankcase breather hose is routed correctly. 3. Install: • fuel tank refer to "fuel tank" on page 7-1. • seat refer to "general chassis" on page 4- 1. Eas21080 checking the exhaust system the following procedure applies to all of the exhaust pipes and gask...

Page 103: Engine

Engine 3-18 caution: eca13470 • adding water instead of coolant lowers the antifreeze content of the coolant. If water is used instead of coolant check, and if necessary, correct the antifreeze concentration of the coolant. • use only distilled water. However, if dis- tilled water is not available, ...

Page 104: Engine

Engine 3-19 3. Remove: • radiator cap lock bolt “1” • radiator cap “2” warning ewa13030 a hot radiator is under pressure. Therefore, do not remove the radiator cap when the engine is hot. Scalding hot fluid and steam may be blown out, which could cause seri- ous injury. When the engine has cooled, o...

Page 105: Engine

Engine 3-20 caution: eca13480 • adding water instead of coolant lowers the antifreeze content of the coolant. If water is used instead of coolant check, and if necessary, correct the antifreeze concentration of the coolant. • use only distilled water. However, if dis- tilled water is not available, ...

Page 106: Chassis

Chassis 3-21 eas21140 chassis eas21160 adjusting the front disc brake 1. Adjust: • brake lever position (distance “a” from the throttle grip to the brake lever) note: • while pushing the brake lever forward, turn the adjusting dial “1” until the brake lever is in the desired position. • be sure to a...

Page 107: Chassis

Chassis 3-22 warning ewa4s81005 a soft or spongy feeling in the brake pedal can indicate the presence of air in the brake system. Before the vehicle is operated, the air must be removed by bleeding the brake system. Air in the brake system will consid- erably reduce braking performance. Caution: eca...

Page 108: Chassis

Chassis 3-23 eas21260 checking the rear brake pads the following procedure applies to all of the brake pads. 1. Operate the brake. 2. Check: • rear brake pad wear indicators “b” almost touch the brake disc → replace the brake pads as a set. Refer to "rear brake" on page 4-27. Eas21280 checking the f...

Page 109: Chassis

Chassis 3-24 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas21340 bleeding the hydraulic brake sys- tem warning ewa13100 bleed the hydraulic brake system when- ever: • the system is disassembled. • a brake hose is loosened, disconnected or replaced. • the brake fluid level is very low. • brake operation is fault...

Page 110: Chassis

Chassis 3-25 warning ewa13110 after bleeding the hydraulic brake system, check the brake operation. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas21370 adjusting the shift pedal 1. Check: • shift pedal position align the center of shift pedal “1” and cen- ter of footrest bracket bolt “2” in a straight line. Inc...

Page 111: Chassis

Chassis 3-26 note: to maintain the proper wheel alignment, adjust both sides evenly. D. Tighten both locknuts to specification. E. Tighten the wheel axle nut to specification. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas21440 lubricating the drive chain the drive chain consists of many interacting parts. If t...

Page 112: Chassis

Chassis 3-27 c. Loosen the lower ring nut “4” completely and then tighten it to specification with a steering nut wrench. Warning ewa13140 do not overtighten the lower ring nut. D. Check the steering head for looseness or binding by turning the front fork all the way in both directions. If any bindi...

Page 113: Chassis

Chassis 3-28 eas21530 checking the front fork 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. 2. Check: • inner tube “1” damage/scratches → replace. • oil seal “2” oil leakage → replace. 3. Hold the vehicle upright...

Page 114: Chassis

Chassis 3-29 warning ewa13180 • the tire pressure should only be checked and regulated when the tire temperature equals the ambient air temperature. • the tire pressure and the suspension must be adjusted according to the total weight (including cargo, rider, passenger and accessories) and the antic...

Page 115: Chassis

Chassis 3-30 warning ewa14080 • do not use a tubeless tire on a wheel designed only for tube tires to avoid tire failure and personal injury from sudden deflation. • when using a tube tire, be sure to install the correct tube. • always replace a new tube tire and a new tube as a set. • to avoid pinc...

Page 116: Chassis

Chassis 3-31 eas21670 checking the wheels the following procedure applies to both of the wheels. 1. Check: • wheel damage/out-of-round → replace. Warning ewa13260 never attempt to make any repairs to the wheel. Note: after a tire or wheel has been changed or replaced, always balance the wheel. Eas21...

Page 117: Electrical System

Electrical system 3-32 eas21750 electrical system eas21790 replacing the headlight bulbs the following procedure applies to both of the headlight bulbs. 1. Disconnect: • headlight coupler “1” 2. Remove: • headlight bulb cover “2” 3. Remove: • headlight bulb holder “1” 4. Remove: • headlight bulb “2”...

Page 118: Electrical System

Electrical system 3-33.

Page 119: Chassis

4 chassis general chassis....................................................................................4-1 front wheel ............................................................................................4-5 removing the front wheel .........................................................

Page 120

Installing the handlebar .......................................................... 4-40 front fork ............................................................................................. 4-43 removing the front fork legs ............................................... 4-45 disassembling the f...

Page 122: General Chassis

General chassis 4-1 eas21830 general chassis removing the seat order job/parts to remove q’ty remarks 1 seat 1 for installation, reverse the removal proce- dure..

Page 123: General Chassis

General chassis 4-2 removing the cowlings order job/parts to remove q’ty remarks seat refer to "general chassis" on page 4-1. 1 left front cowling inner panel (with cowling) 1 2 right front cowling inner panel (with cowling) 1 3 front turn signal light coupler 2 disconnect. 4 front cowling 1 5 front...

Page 124: General Chassis

General chassis 4-3 removing the air filter case and battery order job/parts to remove q’ty remarks seat refer to "general chassis" on page 4-1. Left front cowling inner panel refer to "general chassis" on page 4-1. Right front cowling inner panel refer to "general chassis" on page 4-1. Fuel tank re...

Page 125: General Chassis

General chassis 4-4 removing the battery box order job/parts to remove q’ty remarks seat refer to "general chassis" on page 4-1. Left front cowling inner panel refer to "general chassis" on page 4-1. Right front cowling inner panel refer to "general chassis" on page 4-1. Fuel tank refer to "fuel tan...

Page 126: Front Wheel

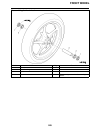

Front wheel 4-5 eas21880 front wheel removing the front wheel and brake discs order job/parts to remove q’ty remarks 1 brake hose holder 1 2 reflector stay 2 3 reflector 2 4 front brake caliper 2 5 front wheel axle pinch bolt 1 loosen. 6 front wheel axle 1 7 collar 2 8 front wheel 1 9 front brake di...

Page 127: Front Wheel

Front wheel 4-6 disassembling the front wheel order job/parts to remove q’ty remarks 1 oil seal 2 2 wheel bearing 2 3 spacer 1 for assembly, reverse the disassembly pro- cedure..

Page 128: Front Wheel

Front wheel 4-7 eas21900 removing the front wheel 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Note: place the vehicle on a suitable stand so that the front wheel is elevated. 2. Remove: • left brake caliper • r...

Page 129: Front Wheel

Front wheel 4-8 c. Remove the wheel bearings “3” with a gen- eral bearing puller. D. Install the new wheel bearings and oil seals in the reverse order of disassembly. Caution: eca14130 do not contact the wheel bearing inner race “4” or balls “5”. Contact should be made only with the outer race “6”. ...

Page 130: Front Wheel

Front wheel 4-9 note: start with the lightest weight. B. Turn the front wheel 90 ° so that the heavy spot is positioned as shown. C. If the heavy spot does not stay in that posi- tion, install a heavier weight. D. Repeat steps (b) and (c) until the front wheel is balanced. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲...

Page 131: Rear Wheel

Rear wheel 4-10 eas22030 rear wheel removing the rear wheel order job/parts to remove q’ty remarks 1 rear brake caliper 1 2 locknut 2 loosen. 3 adjusting nut 2 loosen. 4 rear wheel axle nut 1 5 washer 1 6 rear wheel axle 1 7 washer 1 8 drive chain puller 2 9 rear wheel 1 10 rear brake caliper bracke...

Page 132: Rear Wheel

Rear wheel 4-11 removing the rear brake disc and rear wheel sprocket order job/parts to remove q’ty remarks 1 rear brake disc 1 2 rear wheel sprocket 1 3 collar 2 4 oil seal 2 5 bearing 2 6 rear wheel drive hub 1 7 rear wheel drive hub damper 6 8 rear wheel 1 for installation, reverse the removal pr...

Page 133: Rear Wheel

Rear wheel 4-12 disassembling the rear wheel order job/parts to remove q’ty remarks 1 collar 1 2 bearing 1 3 spacer 1 4 oil seal 1 5 circlip 1 6 bearing 1 for assembly, reverse the disassembly pro- cedure..

Page 134: Rear Wheel

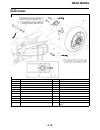

Rear wheel 4-13 eas22040 removing the rear wheel 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Note: place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: • brake caliper “1” note: ...

Page 135: Rear Wheel

Rear wheel 4-14 eas22120 checking and replacing the rear wheel sprocket 1. Check: • rear wheel sprocket more than 1/4 tooth “a” wear → replace the rear wheel sprocket. Bent teeth → replace the rear wheel sprocket. 2. Replace: • rear wheel sprocket ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Remove the self-lo...

Page 136: Front Brake

Front brake 4-15 eas22210 front brake removing the front brake pads order job/parts to remove q’ty remarks 1 brake hose holder 1 2 reflector stay 1 3 reflector 1 4 front brake caliper 1 5 brake pad clip 2 6 brake pad pin 1 7 brake pad spring 1 8 brake pad 2 9 bleed screw 1 for installation, reverse ...

Page 137: Front Brake

Front brake 4-16 removing the front brake master cylinder order job/parts to remove q’ty remarks brake fluid drain. Refer to "bleeding the hydraulic brake system" on page 3-24. 1 brake master cylinder reservoir cap 1 2 brake master cylinder reservoir diaphragm holder 1 3 brake master cylinder reserv...

Page 138: Front Brake

Front brake 4-17 disassembling the front brake master cylinder order job/parts to remove q’ty remarks 1 dust boot 1 2 circlip 1 3 master cylinder kit 1 4 spring 1 5 master cylinder 1 6 push rod 1 for assembly, reverse the disassembly pro- cedure..

Page 139: Front Brake

Front brake 4-18 removing the front brake calipers order job/parts to remove q’ty remarks brake fluid drain. Refer to "bleeding the hydraulic brake system" on page 3-24. 1 union bolt 2 2 copper washer 5 3 brake hose 2 4 reflector stay 1 5 reflector 1 6 brake caliper 1 for installation, reverse the r...

Page 140: Front Brake

Front brake 4-19 disassembling the front brake calipers order job/parts to remove q’ty remarks 1 brake pad clip 2 2 brake pad pin 1 3 brake pad spring 1 4 brake pad 2 5 brake caliper piston 4 6 brake caliper piston seal 8 7 bleed screw 1 for assembly, reverse the disassembly pro- cedure..

Page 141: Front Brake

Front brake 4-20 eas22220 introduction warning ewa14100 disc brake components rarely require dis- assembly. Therefore, always follow these preventive measures: • never disassemble brake components unless absolutely necessary. • if any connection on the hydraulic brake system is disconnected, the ent...

Page 142: Front Brake

Front brake 4-21 d. Measure the brake disc deflection. E. If out of specification, repeat the adjust- ment steps until the brake disc deflection is within specification. F. If the brake disc deflection cannot be brought within specification, replace the brake disc. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas...

Page 143: Front Brake

Front brake 4-22 below the minimum level mark “c” → add the recommended brake fluid to the proper level. Refer to "checking the brake fluid level" on page 3-22. 5. Check: • brake lever operation soft or spongy feeling → bleed the brake system. Refer to "bleeding the hydraulic brake system" on page 3...

Page 144: Front Brake

Front brake 4-23 1. Check: • brake caliper pistons “1” rust/scratches/wear → replace the brake caliper pistons. • brake caliper cylinders “2” scratches/wear → replace the brake cali- per assembly. • brake caliper body “3” cracks/damage → replace the brake cali- per assembly. • brake fluid delivery p...

Page 145: Front Brake

Front brake 4-24 warning ewa13090 • use only the designated brake fluid. Other brake fluids may cause the rubber seals to deteriorate, causing leakage and poor brake performance. • refill with the same type of brake fluid that is already in the system. Mixing brake fluids may result in a harmful che...

Page 146: Front Brake

Front brake 4-25 2. Check: • brake master cylinder kit “1” damage/scratches/wear → replace. 3. Check: • brake master cylinder reservoir “1” cracks/damage → replace. • brake master cylinder reservoir diaphragm “2” damage/wear → replace. 4. Check: • brake hoses cracks/damage/wear → replace. Eas22520 a...

Page 147: Front Brake

Front brake 4-26 caution: eca4s81013 when installing the brake hose onto the brake master cylinder, make sure that the brake pipe touches the projection “b” on the brake master cylinder. Note: • while holding the brake hose, tighten the union bolt as shown. • turn the handlebar to the left and right...

Page 148: Rear Brake

Rear brake 4-27 eas22550 rear brake removing the rear brake pads order job/parts to remove q’ty remarks 1 screw plug 1 2 brake pad pin 1 3 rear brake caliper 1 4 brake pad shim 4 5 brake pad 2 6 brake screw 1 7 brake pad spring 1 for installation, reverse the removal proce- dure..

Page 149: Rear Brake

Rear brake 4-28 removing the rear brake master cylinder order job/parts to remove q’ty remarks brake fluid drain. Refer to "bleeding the hydraulic brake system" on page 3-24. 1 brake fluid reservoir cap 1 2 rear brake fluid reservoir diaphragm holder 1 3 rear brake fluid reservoir diaphragm 1 4 brak...

Page 150: Rear Brake

Rear brake 4-29 disassembling the rear brake master cylinder order job/parts to remove q’ty remarks 1 dust boot 1 2 circlip 1 3 brake master cylinder kit 1 4 spring 1 5 brake master cylinder body 1 for installation, reverse the removal proce- dure..

Page 151: Rear Brake

Rear brake 4-30 removing the rear brake caliper order job/parts to remove q’ty remarks brake fluid drain. Refer to "bleeding the hydraulic brake system" on page 3-24. 1 union bolt 1 2 copper washer 2 3 brake hose 1 4 rear brake caliper 1 for installation, reverse the removal proce- dure..

Page 152: Rear Brake

Rear brake 4-31 disassembling the rear brake caliper order job/parts to remove q’ty remarks 1 screw plug 1 2 brake pad pin 1 3 brake pad 2 4 brake pad shim 4 5 brake pad spring 1 6 brake caliper piston 1 7 brake caliper piston seal 2 8 bleed screw 1 for assembly, reverse the disassembly pro- cedure..

Page 153: Rear Brake

Rear brake 4-32 eas22560 introduction warning ewa14100 disc brake components rarely require dis- assembly. Therefore, always follow these preventive measures: • never disassemble brake components unless absolutely necessary. • if any connection on the hydraulic brake system is disconnected, the enti...

Page 154: Rear Brake

Rear brake 4-33 b. Loosen the bleed screw and push the brake caliper pistons into the brake caliper with your finger. C. Tighten the bleed screw. D. Install a new brake pad shim “3” onto each new brake pad “4”. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Install: • brake caliper • brake pad pin • screw plug 4...

Page 155: Rear Brake

Rear brake 4-34 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Blow compressed air into the brake hose joint opening “a” to force out the piston from the brake caliper. Warning ewa13550 • cover the brake caliper piston with a rag. Be careful not to get injured when the pis- ton is expelled from the brake caliper...

Page 156: Rear Brake

Rear brake 4-35 1. Install: • brake caliper seals • brake caliper piston eas22670 installing the rear brake caliper 1. Install: • brake caliper “1” (temporarily) • copper washers • brake hose “2” • union bolt “3” warning ewa13530 proper brake hose routing is essential to insure safe vehicle operatio...

Page 157: Rear Brake

Rear brake 4-36 7. Check: • brake pedal operation soft or spongy feeling → bleed the brake system. Refer to "bleeding the hydraulic brake system" on page 3-24. Eas22700 removing the rear brake master cylinder 1. Remove: • union bolt “1” • copper washers “2” • brake hose “3” note: to collect any rema...

Page 158: Rear Brake

Rear brake 4-37 eas22730 assembling the rear brake master cylinder warning ewa13520 • before installation, all internal brake com- ponents should be cleaned and lubricated with clean or new brake fluid. • never use solvents on internal brake components. 1. Install: • master cylinder kit • circlip ea...

Page 159: Rear Brake

Rear brake 4-38 6. Adjust: • rear brake light operation timing refer to "adjusting the rear brake light switch" on page 3-23. Brake pedal position 25.8 mm (1.02 in).

Page 160: Handlebar

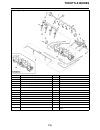

Handlebar 4-39 eas22840 handlebar removing the handlebar order job/parts to remove q’ty remarks 1 grip end 2 2 handlebar grip 1 3 clutch switch connector 1 disconnect. 4 left handlebar switch 1 5 clutch cable 1 6 clutch lever 1 7 right handlebar switch 1 8 throttle grip 1 9 throttle cable 2 10 front...

Page 161: Handlebar

Handlebar 4-40 eas22860 removing the handlebars 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. 2. Remove: • handlebar grip “1” note: blow compressed air between the left handle- bar and the handlebar grip, and gra...

Page 162: Handlebar

Handlebar 4-41 2. Install: • handlebar “1” • upper handlebar holders “2” • upper handlebar holder caps “3” (stan- dard) caution: eca14250 • first, tighten the bolts on the front side of the handlebar holder, and then on the rear side. • turn the handlebar all the way to the left and right. If there ...

Page 163: Handlebar

Handlebar 4-42 note: align the projection “a” on the left handlebar switch with the hole “b” on the handlebar. 7. Install: • handlebar grip • grip end ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Apply a thin coat of rubber adhesive onto the left end of the handlebar. B. Slide the handlebar grip over the left ...

Page 164: Front Fork

Front fork 4-43 eas22950 front fork removing the front fork legs order job/parts to remove q’ty remarks front wheel refer to "front wheel" on page 4-5. Front brake calipers refer to "front brake" on page 4-15. 1 front fender 1 2 cap bolt 1 loosen. 3 upper bracket pinch bolt 1 loosen. 4 under bracket...

Page 165: Front Fork

Front fork 4-44 disassembling the front fork legs order job/parts to remove q’ty remarks 1 cap bolt 1 2 o-ring 1 3 spacer 1 4 washer 1 5 front fork spring 1 6 dust seal 1 7 oil seal clip 1 8 damper rod assembly bolt 1 9 copper washer 1 10 damper rod assembly 1 11 oil seal 1 12 washer 1 13 inner tube...

Page 166: Front Fork

Front fork 4-45 eas22970 removing the front fork legs the following procedure applies to both of the front fork legs. 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Note: place the vehicle on a suitable stand so t...

Page 167: Front Fork

Front fork 4-46 caution: eca14190 • excessive force will damage the oil seal and bushing. A damaged oil seal or bush- ing must be replaced. • avoid bottoming the inner tube into the outer tube during the above procedure, as the oil flow stopper will be damaged. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas2301...

Page 168: Front Fork

Front fork 4-47 eas23020 assembling the front fork legs the following procedure applies to both of the front fork legs. Warning ewa13660 • make sure the oil levels in both front fork legs are equal. • uneven oil levels can result in poor han- dling and a loss of stability. Note: • when assembling th...

Page 169: Front Fork

Front fork 4-48 5. Install: • washer • oil seal “1” (with the fork seal driver and adapter) caution: eca14220 make sure the numbered side of the oil seal faces up. Note: • before installing the oil seal, lubricate its lips with lithium soap base grease. • lubricate the outer surface of the inner tub...

Page 170: Front Fork

Front fork 4-49 9. Measure: • front fork leg oil level “a” out of specification → correct. Note: • while filling the front fork leg, keep it upright. • after filling, slowly pump the front fork leg up and down to distribute the fork oil. 10. Install: • spring “1” • spring seat “2” • spacer “3” • cap...

Page 171: Front Fork

Front fork 4-50

Page 172: Steering Head

Steering head 4-51 eas23090 steering head removing the lower bracket order job/parts to remove q’ty remarks front wheel refer to "front wheel" on page 4-5. Front fender refer to "front fork" on page 4-43. Front fork refer to "front fork" on page 4-43. Handlebar refer to "handlebar" on page 4-39. Fro...

Page 173: Steering Head

Steering head 4-52 13 upper bearing 1 14 lower bearing 1 15 dust seal 1 16 bearing outer race 2 for installation, reverse the removal proce- dure. Removing the lower bracket order job/parts to remove q’ty remarks.

Page 174: Steering Head

Steering head 4-53 eas23110 removing the lower bracket 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. 2. Remove: • steering stem nut • washer • upper ring nut • lock washer • rubber washer • lower ring nut “1” (wi...

Page 175: Steering Head

Steering head 4-54 4. Check: • upper bracket • lower bracket (along with the steering stem) bends/cracks/damage → replace. Eas23140 installing the steering head 1. Lubricate: • upper bearing • lower bearing • bearing races 2. Install: • lower bracket • lower ring nut “1” • rubber washer “2” • upper ...

Page 176: Rear Shock Absorber Assembly

Rear shock absorber assembly 4-55 eas23160 rear shock absorber assembly removing the rear shock absorber assembly order job/parts to remove q’ty remarks seat refer to "general chassis" on page 4-1. Side cover refer to "general chassis" on page 4-1. Rear brake caliper refer to "rear brake" on page 4-...

Page 177: Rear Shock Absorber Assembly

Rear shock absorber assembly 4-56 eas23180 handling the rear shock absorber warning ewa13740 this rear shock absorber contains highly compressed nitrogen gas. Before handling the rear shock absorber, read and make sure you understand the following informa- tion. The manufacturer cannot be held respo...

Page 178: Rear Shock Absorber Assembly

Rear shock absorber assembly 4-57 • bushings damage/wear → replace. • dust seals damage/wear → replace. • bolts bends/damage/wear → replace. Eas23300 installing the rear shock absorber assembly 1. Lubricate: • collar • bearings • oil seals 2. Install: • rear shock absorber assembly note: when instal...

Page 179: Swingarm

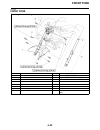

Swingarm 4-58 eas23330 swingarm removing the swingarm order job/parts to remove q’ty remarks muffler assembly refer to "engine removal" on page 5-1. Catalyst assembly refer to "engine removal" on page 5-1. Exhaust pipe assembly refer to "engine removal" on page 5-1. Rear brake caliper refer to "rear...

Page 180: Swingarm

Swingarm 4-59 for installation, reverse the removal proce- dure. Removing the swingarm order job/parts to remove q’ty remarks.

Page 181: Swingarm

Swingarm 4-60 eas23340 removing the swingarm 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Note: place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Measure: • swingarm side play • swinga...

Page 182: Swingarm

Swingarm 4-61 eas23380 installing the swingarm 1. Lubricate: • bearings • spacers • dust covers • pivot shaft “1” 2. Install: • swingarm • pivot shaft nut “2” 3. Install: • rear shock absorber assembly refer to "installing the rear shock absorber assembly" on page 4-57. • rear wheel refer to "instal...

Page 183: Chain Drive

Chain drive 4-62 eas23400 chain drive removing the drive chain order job/parts to remove q’ty remarks drive sprocket cover refer to "engine removal" on page 5-1. Swingarm refer to "removing the swingarm" on page 4-60. 1 rear fender 1 2 drive chain 1 3 chain protector 1 for installation, reverse the ...

Page 184: Chain Drive

Chain drive 4-63 eas23410 removing the drive chain 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Note: place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: • drive chain (with the ...

Page 185: Chain Drive

Chain drive 4-64 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 4. Check: • o-rings “1” damage → replace the drive chain. • drive chain rollers “2” damage/wear → replace the drive chain. • drive chain side plates “3” damage/wear → replace the drive chain. Cracks → replace the drive chain and make sure the battery b...

Page 186: Chain Drive

Chain drive 4-65.

Page 187: Engine

5 engine engine removal ......................................................................................5-1 installing the engine ....................................................................5-6 camshafts......................................................................................

Page 188

Checking the oil nozzles .......................................................... 5-44 assembling the oil pump ............................................................ 5-44 installing the oil pump ............................................................... 5-45 installing the oil strainer ...

Page 190: Engine Removal

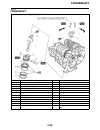

Engine removal 5-1 eas23710 engine removal removing the drive sprocket order job/parts to remove q’ty remarks drive chain loosen refer to "adjusting the shift pedal" on page 3-25. 1 locknut 1 2 shift rod 1 3 shift arm 1 4 drive sprocket cover 1 5 drive sprocket nut 1 6 lock washer 1 7 drive sprocket...

Page 191: Engine Removal

Engine removal 5-2 removing the exhaust pipe order job/parts to remove q’ty remarks 1 exhaust pipe assembly 1 2 exhaust pipe gasket 4 3 catalytic converter pipe 1 4 muffler cover 1 5 muffler 1 for installation, reverse the removal proce- dure..

Page 192: Engine Removal

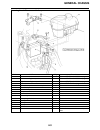

Engine removal 5-3 disconnecting the leads and hoses order job/parts to remove q’ty remarks seat refer to "general chassis" on page 4-1. Right front cowling inner panel refer to "general chassis" on page 4-1. Left front cowling inner panel refer to "general chassis" on page 4-1. Fuel tank refer to "...

Page 193: Engine Removal

Engine removal 5-4 5 starter motor lead 1 disconnect. 6 stator coil assembly coupler 1 disconnect. 7 oil level switch connector 1 disconnect. 8 neutral switch coupler 1 disconnect. 9 speed sensor coupler 1 disconnect. For assembly, reverse the removal proce- dure. Disconnecting the leads and hoses o...

Page 194: Engine Removal

Engine removal 5-5 removing the engine order job/parts to remove q’ty remarks 1 right front engine mounting bolt 1 2 left front engine mounting bolt 2 3 self-locking nut 2 4 rear engine mounting bolt 2 5 engine 1 for installation, reverse the removal proce- dure..

Page 195: Engine Removal

Engine removal 5-6 eas23720 installing the engine 1. Install: • rear engine mounting bolts “1” note: lubricate the rear engine mounting bolt threads with engine oil. 2. Install: • right front engine mounting bolt “2” • left front engine mounting bolts “3” note: do not fully tighten the bolts. 3. Tig...

Page 196: Engine Removal

Engine removal 5-7 note: • before installing, make sure to align the punch mark “a” of the shift shaft with the punch mark “b” of the shift arm. • align the bottom edge of the shift pedal with the mark on the frame-to-swingarm bracket..

Page 197: Camshafts

Camshafts 5-8 eas23760 camshafts removing the cylinder head cover order job/parts to remove q’ty remarks battery refer to "general chassis" on page 4-1. Air filter case refer to "general chassis" on page 4-1. Battery box refer to "fuel tank" on page 7-1. Battery box bracket refer to "general chassis...

Page 198: Camshafts

Camshafts 5-9 removing the camshafts order job/parts to remove q’ty remarks pickup rotor cover refer to "pickup rotor" on page 5-33. 1 camshaft sprocket bolt 4 2 timing chain tensioner 1 3 timing chain tensioner gasket 1 4 timing chain guide (exhaust side) 1 5 intake camshaft cap 3 6 dowel pin 6 7 e...

Page 199: Camshafts

Camshafts 5-10 eas23810 removing the camshafts 1. Remove: • pickup rotor cover refer to "pickup rotor" on page 5-33. 2. Align: • “t” mark “a” on the pickup rotor (with the crankcase mating surface “b”) ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Turn the crankshaft clockwise. B. When piston #1 is at tdc on th...

Page 200: Camshafts

Camshafts 5-11 8. Remove: • camshaft sprockets eas23850 checking the camshafts 1. Check: • camshaft lobes blue discoloration/pitting/scratches → replace the camshaft. 2. Measure: • camshaft lobe dimensions “a” and “b” out of specification → replace the cam- shaft. 3. Measure: • camshaft runout out o...

Page 201: Camshafts

Camshafts 5-12 note: • tighten the camshaft cap bolts in stages and in a crisscross pattern, working from the inner caps out. • do not turn the camshaft when measuring the camshaft journal-to-camshaft cap clear- ance with the plastigauge®. D. Remove the camshaft caps and then mea- sure the width of ...

Page 202: Camshafts

Camshafts 5-13 • timing chain guide (top side) “3” damage/wear → replace the defective part(s). Eas23970 checking the timing chain ten- sioner 1. Check: • timing chain tensioner cracks/damage → replace. 2. Check: • one-way cam rough movement → replace the timing chain tensioner assembly. ▼▼▼▼▼▼▼▼▼▼▼...

Page 203: Camshafts

Camshafts 5-14 3. Install: • dowel pins • intake camshaft caps • exhaust camshaft caps note: • make sure each camshaft cap is installed in its original place. Refer to the identification marks as follows: “i1”, “i2”: intake side camshaft cap mark “e1”, “e2”: exhaust side camshaft cap mark • make sur...

Page 204: Camshafts

Camshafts 5-15 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 7. Turn: • crankshaft (several full turns clockwise) 8. Check: • “t” mark “a” make sure the “t” mark on the pickup rotor is aligned with the crankcase mating sure face “b”. • camshaft sprocket match mark “c” make sure the match marks on the cam- shaft sp...

Page 205: Cylinder Head

Cylinder head 5-16 eas24100 cylinder head removing the cylinder head order job/parts to remove q’ty remarks intake camshaft refer to "camshafts" on page 5-8. Exhaust camshaft refer to "camshafts" on page 5-8. 1 cylinder head 1 2 cylinder head gasket 1 3 dowel pin 2 for installation, reverse the remo...

Page 206: Cylinder Head

Cylinder head 5-17 eas24120 removing the cylinder head 1. Remove: • cylinder head bolts note: • loosen the bolts in the proper sequence as shown. • loosen each bolts 1/2 of a turn at a time. After all of the bolts are fully loosened, remove them. Eas24160 checking the cylinder head 1. Eliminate: • c...

Page 207: Cylinder Head

Cylinder head 5-18 note: pass the timing chain through the timing chain cavity. 3. Tighten: • cylinder head bolts “1” – “10” • cylinder head bolts “11” “12” note: • lubricate the cylinder head bolts with engine oil. • tighten the cylinder head bolts in the proper tightening sequence as shown and tor...

Page 208: Valves and Valve Springs

Valves and valve springs 5-19 eas24270 valves and valve springs removing the valves and valve springs order job/parts to remove q’ty remarks cylinder head refer to "cylinder head" on page 5-16. 1 intake valve lifter 8 2 intake valve pad 8 3 intake valve cotter 16 4 intake valve upper spring seat 8 5...

Page 209: Valves and Valve Springs

Valves and valve springs 5-20 for installation, reverse the removal proce- dure. Removing the valves and valve springs order job/parts to remove q’ty remarks.

Page 210: Valves and Valve Springs

Valves and valve springs 5-21 eas24280 removing the valves the following procedure applies to all of the valves and related components. Note: before removing the internal parts of the cylin- der head (e.G., valves, valve springs, valve seats), make sure the valves properly seal. 1. Remove: • valve l...

Page 211: Valves and Valve Springs

Valves and valve springs 5-22 eas24290 checking the valves and valve guides the following procedure applies to all of the valves and valve guides. 1. Measure: • valve-stem-to-valve-guide clearance out of specification → replace the valve guide. 2. Replace: • valve guide note: to ease valve guide rem...

Page 212: Valves and Valve Springs

Valves and valve springs 5-23 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Eliminate: • carbon deposits (from the valve face and valve seat) 4. Check: • valve face pitting/wear → grind the valve face. • valve stem end mushroom shape or diameter larger than the body of the valve stem → replace the valve. 5. Mea...

Page 213: Valves and Valve Springs

Valves and valve springs 5-24 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Apply mechanic’s blueing dye (dykem) “b” onto the valve face. B. Install the valve into the cylinder head. C. Press the valve through the valve guide and onto the valve seat to make a clear impression. D. Measure the valve seat width. N...

Page 214: Valves and Valve Springs

Valves and valve springs 5-25 h. Install the valve into the cylinder head. I. Press the valve through the valve guide and onto the valve seat to make a clear impression. J. Measure the valve seat width “c” again. If the valve seat width is out of specification, reface and lap the valve seat. ▲▲▲▲▲▲▲...

Page 215: Valves and Valve Springs

Valves and valve springs 5-26 3. Measure: • valve spring tilt “a” out of specification → replace the valve spring. Eas24320 checking the valve lifters the following procedure applies to all of the valve lifters. 1. Check: • valve lifter damage/scratches → replace the valve lifters and cylinder head....

Page 216: Valves and Valve Springs

Valves and valve springs 5-27 4. Install: • valve cotters “1” note: install the valve cotters by compressing the valve spring with the valve spring compressor “2” and the valve spring compressor attach- ment “3”. 5. To secure the valve cotters onto the valve stem, lightly tap the valve tip with a so...

Page 217: Generator and Starter Clutch

Generator and starter clutch 5-28 eas4s81014 generator and starter clutch removing the generator and starter clutch order job/parts to remove q’ty remarks seat refer to "general chassis" on page 4-1. Fuel tank refer to "fuel tank" on page 7-1. Coolant drain refer to "changing the coolant" on page 3-...

Page 218: Generator and Starter Clutch

Generator and starter clutch 5-29 11 idler gear shaft 1 12 idler gear 1 13 starter clutch drive gear 1 for installation, reverse the removal proce- dure. Removing the generator and starter clutch order job/parts to remove q’ty remarks.

Page 219: Generator and Starter Clutch

Generator and starter clutch 5-30 eas24490 removing the generator 1. Remove: • seat refer to "general chassis" on page 4- 1. • fuel tank refer to "fuel tank" on page 7-1. 2. Drain: • coolant refer to "changing the coolant" on page 3-18. • engine oil refer to "changing the engine oil" on page 3-12. 3...

Page 220: Generator and Starter Clutch

Generator and starter clutch 5-31 eas24570 checking the starter clutch 1. Check: • starter clutch rollers “1” damage/wear → replace. 2. Check: • starter clutch idle gear “1” • starter clutch drive gear “2” burrs/chips/roughness/wear → replace the defective part(s). 3. Check: • starter clutch gear’s ...

Page 221: Generator and Starter Clutch

Generator and starter clutch 5-32 eas24500 installing the generator 1. Install: • generator rotor • washer • generator rotor bolt note: • clean the tapered portion of the crankshaft and the generator rotor hub. • replace the washer with a new one. 2. Tighten: • generator rotor bolt “1” note: • while...

Page 222: Pickup Rotor

Pickup rotor 5-33 eas4s81015 pickup rotor removing the pickup rotor order job/parts to remove q’ty remarks seat refer to "general chassis" on page 4-1. Right front cowling inner panel refer to "general chassis" on page 4-1. Left front cowling inner panel refer to "general chassis" on page 4-1. Fuel ...

Page 223: Pickup Rotor

Pickup rotor 5-34 eas4s81041 removing the pickup rotor 1. Remove: • pickup rotor cover “1” note: loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. 2. Remove: • pickup rotor bolt “1” • washer “2” • pickup rotor “3”...

Page 224: Pickup Rotor

Pickup rotor 5-35 3. Apply: • sealant (onto the crankshaft position sensor lead grommet) 4. Install: • pickup rotor cover gasket • pickup rotor cover note: • when installing the pickup rotor cover, align the timing chain guide (intake side) pin “1” with the hole “2” in the pickup rotor cover. • tigh...

Page 225: Electric Starter

Electric starter 5-36 eas24780 electric starter removing the starter motor order job/parts to remove q’ty remarks seat refer to "general chassis" on page 4-1. Right front cowling inner panel refer to "general chassis" on page 4-1. Left front cowling inner panel refer to "general chassis" on page 4-1...

Page 226: Electric Starter

Electric starter 5-37 disassembling the starter motor order job/parts to remove q’ty remarks 1 o-ring 1 2 starter motor front cover 1 3 lock washer 1 4 oil seal 1 5 bearing 1 6 washer set 1 7 starter motor rear cover 1 8 washer set 1 9 o-ring 2 10 brush holder 1 11 armature assembly 1 12 starter mot...

Page 227: Electric Starter

Electric starter 5-38 eas24790 checking the starter motor 1. Check: • commutator dirt → clean with 600 grit sandpaper. 2. Measure: • commutator diameter “a” out of specification → replace the starter motor. 3. Measure: • mica undercut “a” out of specification → scrape the mica to the proper measurem...

Page 228: Electric Starter

Electric starter 5-39 7. Check: • gear teeth damage/wear → replace the gear. 8. Check: • bearing • oil seal damage/wear → replace the defective part(s). Eas24800 assembling the starter motor 1. Install: • brush seat “1” 2. Install: • armature “2” • o-ring “3” note: align the tab “a” on the brush sea...

Page 229: Oil Pump

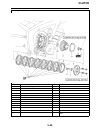

Oil pump 5-40 eas24920 oil pump removing the oil pan and oil pump order job/parts to remove q’ty remarks engine oil drain. Refer to "changing the engine oil" on page 3-12. Coolant drain. Refer to "changing the coolant" on page 3-18. Exhaust pipe assembly refer to "engine removal" on page 5-1. Water ...

Page 230: Oil Pump

Oil pump 5-41 13 relief valve assembly 1 for installation, reverse the removal proce- dure. Removing the oil pan and oil pump order job/parts to remove q’ty remarks.

Page 231: Oil Pump

Oil pump 5-42 disassembling the oil pump order job/parts to remove q’ty remarks 1 oil pump cover 1 2 pin 2 3 oil pump inner rotor 1 4 oil pump outer rotor 1 5 pin 1 6 washer 1 7 oil pump rotor housing 1 8 oil pump driven sprocket 1 for assembly, reverse the removal proce- dure..

Page 232: Oil Pump

Oil pump 5-43 eas24930 removing the oil pan 1. Remove: • oil level switch “1” • oil pan “2” • oil pan gasket • dowel pins note: loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. Eas24960 checking the oil pump 1. C...

Page 233: Oil Pump

Oil pump 5-44 eas24980 checking the oil delivery pipes 1. Check: • oil delivery pipe “1” • oil pipe “2” damage → replace. Obstruction → wash and blow out with compressed air. Eas24990 checking the oil strainer 1. Check: • oil strainer “1” damage → replace. Contaminants → clean with solvent. Eas4s810...

Page 234: Oil Pump

Oil pump 5-45 3. Check: • oil pump operation refer to "checking the oil pump" on page 5-43. Eas25030 installing the oil pump 1. Install: • oil pump drive chain • gear cover • oil pump • oil pump bolts caution: eca4s81018 after tightening the bolts, make sure the oil pump turns smoothly. Eas25040 ins...

Page 235: Clutch

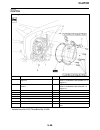

Clutch 5-46 eas25060 clutch * yamaha bond no.1215 (three bond no.1215®) removing the clutch cover order job/parts to remove q’ty remarks engine oil drain refer to "changing the engine oil" on page 3-12. Coolant drain refer to "changing the coolant" on page 3-18. 1 coolant hose 1 2 clutch cable 1 3 c...

Page 236: Clutch

Clutch 5-47 removing the pull lever shaft order job/parts to remove q’ty remarks 1 circlip 2 2 washer 1 3 pull lever 1 4 pull lever spring 1 5 washer 1 6 oil seal 1 7 bearing 2 8 pull lever shaft 1 9 washer 1 for installation, reverse the removal proce- dure..

Page 237: Clutch

Clutch 5-48 removing the clutch order job/parts to remove q’ty remarks 1 compression spring 6 2 pressure plate 1 3 pull rod 1 4 bearing 1 5 friction plate 1 6 6 clutch plate 1 7 7 friction plate 2 2 8 clutch plate 2 1 9 clutch boss nut 1 10 lock washer 1 11 clutch boss 1 12 thrust plate 1 for assemb...

Page 238: Clutch

Clutch 5-49 eas25070 removing the clutch 1. Remove: • clutch cable holder “1” • clutch cover “2” • gasket note: loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. 2. Remove: • compression spring bolts “1” • compres...

Page 239: Clutch

Clutch 5-50 eas25110 checking the clutch plates the following procedure applies to all of the clutch plates. 1. Check: • clutch plate damage → replace the clutch plates as a set. 2. Measure: • clutch plate warpage (with a surface plate and thickness gauge “1”) out of specification → replace the clut...

Page 240: Clutch

Clutch 5-51 note: pitting on the clutch boss splines will cause erratic clutch operation. Eas25170 checking the pressure plate 1. Check: • pressure plate “1” cracks/damage → replace. • bearing “2” damage/wear → replace. Eas25220 checking the pull lever shaft and pull rod 1. Check: • pull lever shaft...

Page 241: Clutch

Clutch 5-52 5. Install: • friction plates • clutch plates note: first, install a friction plate and then alternate between a clutch plate and a friction plate. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a install the clutch plate and friction plate as shown in the illustration. Clutch plate “1”: t=2.3 mm (0.09 ...

Page 242: Shift Shaft

Shift shaft 5-53 eas25410 shift shaft removing the shift shaft and stopper lever order job/parts to remove q’ty remarks drive sprocket cover refer to "engine removal" on page 5-1. 1 shift shaft cover 1 2 shift shaft cover gasket 1 3 dowel pin 2 4 oil seal 1 5 shift shaft 1 6 shift shaft spring 1 7 c...

Page 243: Shift Shaft

Shift shaft 5-54 eas25420 checking the shift shaft 1. Check: • shift shaft “1” bends/damage/wear → replace. • shift shaft spring “2” damage/wear → replace. Eas25430 checking the stopper lever 1. Check: • stopper lever “1” bends/damage → replace. Roller turns roughly → replace the stopper lever. Eas2...

Page 244: Crankcase

Crankcase 5-55 eas25540 crankcase separating the crankcase order job/parts to remove q’ty remarks engine refer to "engine removal" on page 5-1. Cylinder head refer to "cylinder head" on page 5-16. Generator refer to "generator and starter clutch" on page 5-28. Starter clutch refer to "generator and ...

Page 245: Crankcase

Crankcase 5-56 8 plate 1 for installation, reverse the removal proce- dure. Separating the crankcase order job/parts to remove q’ty remarks.

Page 246: Crankcase

Crankcase 5-57 eas25550 disassembling the crankcase 1. Place the engine upside down. 2. Remove: • crankcase bolts note: • loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. • loosen the bolts in decreasing numerica...

Page 247: Crankcase

Crankcase 5-58 eas25660 assembling the crankcase 1. Lubricate: • crankshaft journal bearings (with the recommended lubricant) 2. Apply: • sealant (onto the crankcase mating surfaces) note: do not allow any sealant to come into contact with the oil gallery or crankshaft journal bear- ings. Do not app...

Page 248: Crankcase

Crankcase 5-59.

Page 249: Crankshaft

Crankshaft 5-60 eas25950 crankshaft removing the connecting rods and pistons order job/parts to remove q’ty remarks lower crankcase refer to "crankcase" on page 5-55. 1 connecting rod cap 4 2 big end lower bearing 4 3 big end upper bearing 4 4 piston pin clip 8 5 piston pin 4 6 piston 4 7 connecting...

Page 250: Crankshaft

Crankshaft 5-61 removing the crankshaft order job/parts to remove q’ty remarks crankcase separate. Refer to "crankcase" on page 5-55. Connecting rods caps refer to "crankshaft" on page 5-60. 1 crankshaft 1 2 crankshaft journal lower bearing 5 3 crankshaft journal upper bearing 5 for installation, re...

Page 251: Crankshaft

Crankshaft 5-62 eas26030 removing the connecting rods and pistons the following procedure applies to all of the connecting rods and pistons. 1. Remove: • connecting rod cap “1” • big end bearings note: identify the position of each bigend bearing so that it can be reinstalled in its original place. ...

Page 252: Crankshaft

Crankshaft 5-63 eas24390 checking the cylinder and piston 1. Check: • piston wall • cylinder wall vertical scratches → replace the cylinder, and replace the piston and piston rings as a set. 2. Measure: • piston-to-cylinder clearance ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Measure cylinder bore “c” with t...

Page 253: Crankshaft

Crankshaft 5-64 2. Install: • piston ring (into the cylinder) note: level the piston ring into the cylinder with the piston crown. 3. Measure: • piston ring end gap out of specification → replace the piston ring. Note: the oil ring expander spacer’s end gap cannot be measured. If the oil ring rail’s...

Page 254: Crankshaft

Crankshaft 5-65 4. Calculate: • piston-pin-to-piston-pin-bore clearance out of specification → replace the piston pin and piston as a set. Eas4s81037 checking the big end bearings 1. Measure: • crankshaft-pin-to-big-end-bearing clear- ance out of specification → replace the big end bearings. ▼▼▼▼▼▼▼...

Page 255: Crankshaft

Crankshaft 5-66 e. Tighten the connecting rod bolts. Note: install by carrying out the following procedures in order to assemble in the most suitable con- dition. • connecting rod bolts f. Replace the connecting rod bolts with new ones. G. Clean the connecting rod bolts. H. After installing the big ...

Page 256: Crankshaft

Crankshaft 5-67 p. After the installation, check that the section show “a” is flush with each other by touch- ing the surface. • side machined face “a” warning ewa4s81014 • when the bolt is tightened more than the specified angle, do not loosen the bolt and then retighten it. Replace the bolt with a...

Page 257: Crankshaft

Crankshaft 5-68 eas26190 installing the connecting rod and piston the following procedure applies to all of the connecting rods and pistons. 1. Install: • top ring “1” • 2nd ring “2” • upper oil ring rail “3” • oil ring expander “4” • lower oil ring rail “5” note: be sure to install the piston rings...

Page 258: Crankshaft

Crankshaft 5-69 6. Install: • big end bearings • connecting rod cap (onto the connecting rod) note: • align the projections on the big end bearings with the notches in the connecting rods and connecting rod caps. • make sure that the characters “a” on both the connecting rod and connecting rod cap a...

Page 259: Crankshaft

Crankshaft 5-70 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ caution: eca14980 tighten the connecting rod bolts using the plastic-region tightening angle method. A. Clean the connecting rod bolts. B. Tighten the connecting rod bolts. C. Put a mark “1” on the corner of the con- necting rod bolt “2” and the connect...

Page 260: Crankshaft

Crankshaft 5-71 caution: eca4s81028 do not interchange the crankshaft journal bearings. To obtain the correct crankshaft- journal- to-crankshaft-journal-bearing clearance and prevent engine damage, the crankshaft journal bearings must be installed in their original positions. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼...

Page 261: Crankshaft

Crankshaft 5-72 g. Remove the lower crankcase and the crankshaft journal lower bearings. H. Measure the compressed plastigauge® width “c” on each crankshaft journal. If the crankshaft-journal-to-crankshaft-jour- nal-bearing clearance is out of specifica- tion, select replacement crankshaft journal b...

Page 262: Crankshaft

Crankshaft 5-73 • be sure to install each crankshaft journal upper bearing in its original place. 2. Install: • crankshaft 3. Install: • lower crankcase refer to "crankcase" on page 5-55..

Page 263: Transmission

Transmission 5-74 eas26240 transmission removing the transmission, shift drum assembly, and shift forks order job/parts to remove q’ty remarks lower crankcase 1 refer to "crankcase" on page 5-55. 1 drive axle assembly 1 2 circlip 1 3 oil seal 1 4 bearing 1 5 shift drum retainer 1 6 shift fork guide ...

Page 264: Transmission

Transmission 5-75 disassembling the main axle assembly order job/parts to remove q’ty remarks 1 bearing 1 2 2nd pinion gear 1 3 toothed lock washer 1 4 toothed lock washer retainer 1 5 6th pinion gear 1 6 collar 1 7 washer 1 8 circlip 1 9 3rd pinion gear 1 10 circlip 1 11 washer 1 12 5th pinion gear...

Page 265: Transmission

Transmission 5-76 disassembling the drive axle assembly order job/parts to remove q’ty remarks 1 washer 1 2 1st wheel gear 1 3 collar 1 4 5th wheel gear 1 5 circlip 1 6 washer 1 7 collar 1 8 3rd wheel gear 1 9 toothed lock washer 1 10 toothed lock washer retainer 1 11 4th wheel gear 1 12 collar 1 13...

Page 266: Transmission

Transmission 5-77 for installation, reverse the removal proce- dure. Disassembling the drive axle assembly order job/parts to remove q’ty remarks.

Page 267: Transmission

Transmission 5-78 eas26250 removing the transmission 1. Remove: • main axle assembly “1” (with the torx® wrench) ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Insert two bolts “2” of the proper size, as shown in the illustration, into the main axle assembly bearing housing. B. Tighten the bolts until they conta...

Page 268: Transmission

Transmission 5-79 • shift drum bearing “2” damage/pitting → replace the shift drum assembly. Eas26300 checking the transmission 1. Measure: • main axle runout (with a centering device and dial gauge “1”) out of specification → replace the main axle. 2. Measure: • drive axle runout (with a centering ...

Page 269: Transmission

Transmission 5-80 • install shift fork-c into the groove in the 3rd and 4th pinion gear on the main axle. 3. Install: • shift fork-r “1” • shift fork-l “2” • drive axle “3” • shift fork guide bar • shift drum retainer note: • install shift fork-l into the groove in the 6th wheel gear and shift fork-...

Page 270: Transmission

Transmission 5-81.

Page 271: Cooling System

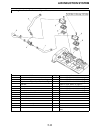

6 cooling system radiator ....................................................................................................6-1 checking the radiator..................................................................6-3 installing the radiator ..........................................................

Page 272: Radiator

Radiator 6-1 eas26380 radiator removing the radiator order job/parts to remove q’ty remarks seat refer to "general chassis" on page 4-1. Left front cowling inner panel refer to "general chassis" on page 4-1. Right front cowling inner panel refer to "general chassis" on page 4-1. Fuel tank refer to "...

Page 273: Radiator

Radiator 6-2 13 coolant reservoir drain hose 1 for installation, reverse the removal proce- dure. Removing the radiator order job/parts to remove q’ty remarks.

Page 274: Radiator

Radiator 6-3 eas26390 checking the radiator 1. Check: • radiator fins obstruction → clean. Apply compressed air to the rear of the radiator. Damage → repair or replace. Note: straighten any flattened fins with a thin, flat- head screwdriver. 2. Check: • radiator hoses • radiator pipes cracks/damage ...

Page 275: Oil Cooler

Oil cooler 6-4 eas26410 oil cooler removing the oil cooler order job/parts to remove q’ty remarks radiator assembly refer to "radiator" on page 6-1. Coolant reservoir refer to "radiator" on page 6-1. Engine oil drain. Refer to "changing the engine oil" on page 3-12. 1 oil cooler outlet hose 1 2 unio...

Page 276: Oil Cooler