- DL manuals

- Yamaha

- Motorcycle

- K480

- Owner's Service Manual

Yamaha K480 Owner's Service Manual

OWNER’S SERVICE MANUAL

MANUEL D’ATELIER DU

PROPRIETAIRE

FAHRER- UND

WARTUNGSHANDBUCH

YZ450F(Z)

33D-28199-80

PRINTED IN JAPAN

2009.07—2.1

×

1

!

(E, F, G)

YAMAHA MOTOR CO., LTD.

2500 SHINGAI IWATA SHIZUOKA JAPAN

PRINTED ON RECYCLED PAPER

2010

YZ450F

(Z

)

2010

q

Read this manual carefully before operating this vehicle.

q

Il convient de lire attentivement ce manuel avant la première utilisation du véhicule.

q

Bitte lesen Sie diese Bedienungsanleitung sorgfältig durch, bevor Sie das Fahrzeug in Betrieb nehmen.

33D-9-80̲cover 09.7.16 13:46 ページ 1

Summary of K480

Page 1

Owner’s service manual manuel d’atelier du proprietaire fahrer- und wartungshandbuch yz450f(z) 33d-28199-80 printed in japan 2009.07—2.1 × 1 ! (e, f, g) yamaha motor co., ltd. 2500 shingai iwata shizuoka japan printed on recycled paper 2010 yz450f (z ) 2010 q read this manual carefully before operat...

Page 2

Q read this manual carefully before operating this vehicle. This manual should stay with this vehicle if it is sold. Q il convient de lire attentivement ce manuel avant la première utilisation du véhicule. Le manuel doit être remis avec le véhicule en cas de vente de ce dernier. Q bitte lesen sie di...

Page 3: Yz450F(Z)

Yz450f(z) yz450f(z) 2010 2010 33d-28199-80-e0 33d-28199-80-e0 owner’s service manual owner’s service manual read this manual carefully before operating this vehicle. Read this manual carefully before operating this vehicle..

Page 5

Yz450f(z) owner's service manual ©2009 by yamaha motor co., ltd. 1st edition, august 2009 all rights reserved. Any reprinting or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited. Printed in japan.

Page 6

Foreword introduction congratulations on your purchase of a yamaha yz series. This model is the culmination of yamaha's vast ex- perience in the production of paceset- ting racing machines. It represents the highest grade of craftsmanship and reliability that have made yama- ha a leader. This manual...

Page 7

F.I.M. Machine weights weights of machines without fuel the minimum weights for motocross machines are: for the class 125 cc: minimum 88 kg (194 lb) for the class 250 cc: minimum 98 kg (216 lb) for the class 500 cc: minimum 102 kg (225 lb) in modifying your machine (e.G., for weight reduction), take...

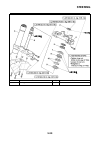

Page 8

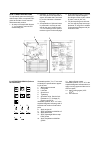

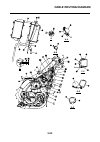

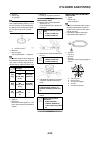

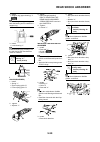

How to read descriptions to help identify parts and clarify pro- cedure steps, there are exploded dia- grams at the start of each removal and disassembly section. 1. An easy-to-see exploded diagram "1" is provided for removal and disassembly jobs. 2. Numbers "2" are given in the or- der of the jobs ...

Page 9: Table of Contents

Table of contents general information 1 specifications 2 regular inspection and adjustments 3 engine 4 chassis 5 fuel system 6 electrical 7 tuning 8.

Page 10

Contents chapter 1 general information location of important labels ..... 1-1 description ................. 1-5 consumer information................. 1-6 features....................... 1-7 included parts .......... 1-9 important information................. 1-9 handling the electronic parts ... 1-1...

Page 11

1-1 location of important labels general information location of important labels please read the following important labels carefully before operating this vehicle. Canada 1.

Page 12

1-2 location of important labels europe.

Page 13

1-3 location of important labels aus, nz, za.

Page 14

1-4 location of important labels familiarize yourself with the following pictograms and read the explanatory text. Read owner's service manual. This unit contains high-pressure nitrogen gas. Mishandling can cause explosion. Do not incinerate, puncture or open. Turn off the main switch after riding t...

Page 15

1-5 description description • the machine you have purchased may differ slightly from those shown in the following. • designs and specifications are subject to change without notice. 1. Clutch lever 2. Front brake lever 3. Throttle grip 4. Radiator cap 5. Fuel tank cap 6. Engine stop switch 7. Kicks...

Page 16

1-6 consumer information consumer information there are two significant reasons for knowing the serial number of your machine: 1. When ordering parts, you can give the number to your yamaha dealer for positive identification of the model you own. 2. If your machine is stolen, the au- thorities will ...

Page 17

1-7 features features outline of the fi system the main function of a fuel supply system is to provide fuel to the combustion chamber at the optimum air-fuel ratio in ac- cordance with the engine operating conditions and the atmospheric temperature. In the conventional carburetor system, the air-fue...

Page 18

1-8 features fi system the fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains thefuel pressure that is applied to the fuel injector at only 324 kpa (3.24 kgf/cm ² , 47.0 psi). Accordingly,when the energizing signal from the ecu energizes the fuel injec...

Page 19

1-9 included parts included parts detachable sidestand this sidestand "1" is used to support only the machine when standing or transporting it. • never apply additional force to the sidestand. • remove this sidestand before starting out. Valve joint this valve joint "1" prevents fuel from flowing ou...

Page 20

1-10 handling the electronic parts 4. During the machine disassembly, clean all parts and place them in trays in the order of disassembly. This will speed up assembly time and help assure that all parts are correctly reinstalled. 5. Keep away from fire. All replacement parts 1. We recommend to use y...

Page 21

1-11 checking of connection if the contact seems not good, pull the terminal by hand and check its condition. 4. Connect: • lead • coupler • connector make sure all connections are tight. 5. Check: • continuity (with the pocket tester) • if there is no continuity, clean the terminals. • when checkin...

Page 22

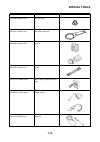

1-12 special tools special tools the proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or improvised techniques. The shape and part number used for the special tool differ by ...

Page 23

1-13 special tools cap bolt wrench ym-01500, 90890-01500 this tool is used to loosen or tighten the base valve. Cap bolt ring wrench ym-01501, 90890-01501 this tool is used to loosen or tighten the damper assembly. Fork seal driver ym-a0948, 90890-01502 this tool is used when install the fork oil se...

Page 24

1-14 special tools fi diagnostic tool yu-03182, 90890-03182 this tool is used to check the fault codes and diagnose any problems. Fuel pressure adapter ym-03186, 90890-03186 this tool is used to attach the pres- sure gauge. Test harness s-pressure sensor (3p) yu-03207, 90890-03207 this tool is conne...

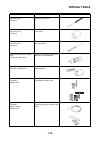

Page 25

1-15 special tools valve guide remover 5.5 mm (0.22 in) ym-01122 this tool is needed to remove and install the valve guide. Valve guide installer 5.5 mm (0.22 in) ym-04015 this tool is needed to install the valve guide. Valve guide reamer 5.5 mm (0.22 in) ym-01196 this tool is needed to rebore the n...

Page 26

1-16 special tools digital tachometer yu-39951-b, 90890-06760 this tool is needed for observing en- gine rpm. Yamaha bond no. 1215 (three- bond ® no. 1215) 90890-85505 this sealant (bond) is used for crankcase mating surface, etc. Tool name/part number how to use illustration.

Page 27

1-17 control functions control functions engine stop switch the engine stop switch "1" is located on the left handlebar. Continue push- ing the engine stop switch till the en- gine comes to a stop. Clutch lever the clutch lever "1" is located on the left handlebar; it disengages or en- gages the clu...

Page 28

1-18 starting and break-in • unlike a two-stroke engine, this engine cannot be kick started when the throttle is open be- cause the kickstarter may kick back. Also, if the throttle is open the air/fuel mixture may be too lean for the engine to start. • before starting the machine, per- form the chec...

Page 29

1-19 torque-check points torque-check points concerning the tightening torque, refer to "tightening torques" section in the chapter 2. Frame construction frame to rear frame combined seat and fuel tank fuel tank to frame exhaust system silencer to rear frame engine mounting frame to engine engine br...

Page 30

1-20 cleaning and storage cleaning and storage cleaning frequent cleaning of your machine will enhance its appearance, maintain good overall performance, and ex- tend the life of many components. 1. Before washing the machine, block off the end of the exhaust pipe to prevent water from enter- ing. A...

Page 31

2-1 general specifications specifications general specifications model name: yz450fz (usa, cdn, aus, nz) yz450f (europe, za) model code number: 33d1 (usa,cdn) 33d2 (europe) 33d4 (aus, nz, za) dimensions: usa, cdn europe aus, nz, za overall length 2,193 mm (86.34 in) 2,191 mm (86.26 in) 2,194 mm (86....

Page 32

2-2 general specifications fuel: type premium unleaded gasoline only tank capacity 6.0 l (1.30 imp gal, 1.59 us gal) throttle body: type 30ra manufacturer keihin spark plug: type/manufacturer cr8e/ngk (resistance type) gap 0.7–0.8 mm (0.028–0.031 in) clutch type: wet, multiple-disc transmission: pri...

Page 33

2-3 maintenance specifications maintenance specifications engine wheel travel: front wheel travel 310 mm (12.2 in) rear wheel travel 315 mm (12.4 in) (for usa, cdn) 312 mm (12.3 in) (for europe, aus, nz, za) electrical: ignition system tci item standard limit cylinder head: warp limit ---- 0.05 mm (...

Page 34

2-4 maintenance specifications timing chain: timing chain type/no. Of links 98xrh2010-122m/122 ---- timing chain adjustment method automatic ---- valve, valve seat, valve guide: valve clearance (cold) in 0.10–0.15 mm (0.0039–0.0059 in) ---- ex 0.20–0.25 mm (0.0079–0.0098 in) ---- valve dimensions: "...

Page 35

2-5 maintenance specifications stem-to-guide clearance (in) 0.010–0.037 mm (0.0004–0.0015 in) 0.08 mm (0.003 in) stem-to-guide clearance (ex) 0.020–0.047 mm (0.0008–0.0019 in) 0.10 mm (0.004 in) stem runout limit ---- 0.01 mm (0.0004 in) valve seat width (in) 0.9–1.1 mm (0.0354–0.0433 in) 1.6 mm (0....

Page 36

2-6 maintenance specifications piston: piston to cylinder clearance 0.020–0.045 mm (0.0008–0.0018 in) 0.1 mm (0.004 in) piston size "d" 96.965–96.980 mm (3.8175–3.8181 in) ---- measuring point "h" 9.0 mm (0.354 in) ---- piston off-set zero mm (zero in) ---- piston pin bore inside diameter 18.004–18....

Page 37

2-7 maintenance specifications crankshaft: crank width "a" 61.95–62.00 mm (2.439–2.441 in) ---- runout limit "c" 0.03 mm (0.0012 in) 0.05 mm (0.002 in) big end side clearance "d" 0.15–0.45 mm (0.0059–0.0177 in) 0.50 mm (0.02 in) small end free play "f" 0.4–1.0 mm (0.02–0.04 in) 2.0 mm (0.08 in) bala...

Page 38

2-8 maintenance specifications throttle position sensor: ---- throttle position sensor maximum resistance 5 k Ω ---- throttle position sensor variable resistance 0–2 k Ω (full closed) ---- throttle position sensor input voltage 4–6 v ---- fuel injection sensor: ---- crankshaft position sensor resist...

Page 39

2-9 maintenance specifications chassis item standard limit steering system: steering bearing type taper roller bearing ---- front suspension: usa, cdn europe, aus, nz, za front fork travel 310 mm (12.2 in) ← ---- fork spring free length 470 mm (18.5 in) ← 465 mm (18.3 in) spring rate, std k = 4.6 n/...

Page 40

2-10 maintenance specifications electrical front disc brake: disc outside dia.×thickness 250 × 3.0 mm (9.84 × 0.12 in) 250 × 2.5 mm (9.84 × 0.10 in) pad thickness 4.4 mm (0.17 in) 1.0 mm (0.04 in) master cylinder inside dia. 9.52 mm (0.375 in) ---- caliper cylinder inside dia. 22.65 mm (0.892 in) × ...

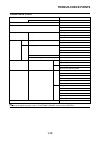

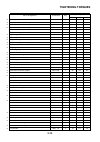

Page 41

2-11 tightening torques tightening torques engine △ - marked portion shall be checked for torque tightening after break-in or before each race. Part to be tightened thread size q'ty tightening torque nm m•kg ft•lb spark plug m10s × 1.0 1 13 1.3 9.4 camshaft cap m6 × 1.0 8 10 1.0 7.2 cylinder head bl...

Page 42

2-12 tightening torques *1: tighten the cylinder head bolts to 30 nm (3.0 m•kg, 22 ft•lb) in the proper tightening sequence, remove and retighten the cylinder head bolts to 20 nm (2.0 m•kg, 14 ft•lb) in the proper tightening sequence, and then tighten the cylinder head bolts further to reach the spe...

Page 43

2-13 tightening torques chassis △ - marked portion shall be checked for torque tightening after break-in or before each race. Part to be tightened thread size q'ty tightening torque nm m•kg ft•lb △ upper bracket and outer tube m8 × 1.25 4 21 2.1 15 △ lower bracket and outer tube m8 × 1.25 4 21 2.1 1...

Page 44

2-14 tightening torques △ driven sprocket and wheel hub m8 × 1.25 6 42 4.2 30 △ nipple (spoke) — 72 3 0.3 2.2 △ disc cover and rear brake caliper m6 × 1.0 2 10 1.0 7.2 △ protector and rear brake caliper m6 × 1.0 2 7 0.7 5.1 drive chain puller adjust bolt and locknut m8 × 1.25 2 21 2.1 15 engine moun...

Page 45

2-15 tightening torques 1. First, tighten the steering ring nut approximately 38 nm (3.8 m•kg, 27 ft•lb) by using the steering nut wrench, then loosen the steering ring nut one turn. 2. Retighten the steering ring nut 7 nm (0.7 m•kg, 5.1 ft•lb). Electrical △ rear fender (front) m6 × 1.0 3 7 0.7 5.1 ...

Page 46

2-16 tightening torques general torque specifications this chart specifies torque for stan- dard fasteners with standard i.S.O. Pitch threads. Torque specifications for special components or assem- blies are included in the applicable sections of this book. To avoid war- page, tighten multi-fastener...

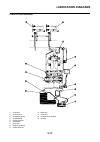

Page 47

2-17 lubrication diagrams lubrication diagrams 1. Oil strainer 2. Oil check bolt 3. Scavenging pump 4. Oil feed pump 5. Oil filter element 6. Crankshaft 7. Oil nozzle 8. Exhaust camshaft 9. Intake camshaft 10. Main axle 11. Drive axle 12. Oil level check window 13. Oil tank.

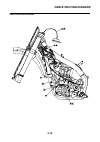

Page 48

2-18 cable routing diagram cable routing diagram.

Page 49

2-19 cable routing diagram 1. Fuel tank breather hose 2. Coupler for connecting optional part 3. Cylinder head breather hose 4. Hose holder 5. Radiator hose 3 a. Insert the end of the fuel tank breather hose into the hole in the steering stem. B. Fit the accessory coupler into the connector to faste...

Page 50

2-20 cable routing diagram f-f a b d-d c-c e f f c c d d b a e 100mm.

Page 51

2-21 cable routing diagram 1. Clutch cable 2. Throttle cable (return) 3. Throttle cable (pull) 4. Cable holder 5. Clamp 6. Rectifier/regulator 7. Ignition coil 8. Ignition coil coupler 9. Ac magneto coupler 10. Radiator hose 2 11. Ground lead terminal 12. Plug cap 13. Ignition coil bracket 14. Clamp...

Page 52

2-22 cable routing diagram b b f g a-a c-c d-d e-e b-b g f c c d d e e a a.

Page 53

2-23 cable routing diagram 1. Tension pipe 2. Coolant temperature sensor coupler 3. Front engine bracket 4. Fuel pump coupler 5. Fuel pump 6. Intake air temperature sensor coupler 7. Radiator hose 2 8. Radiator breather hose 9. Radiator hose 1 10. Radiator hose 4 11. Radiator pipe 2 12. Radiator hos...

Page 54

2-24 cable routing diagram 1. Ignition coil coupler 2. Coolant temperature sensor lead 3. Atmospheric pressure sensor coupler 4. Intake air temperature sensor lead 5. Clamp 6. Intake air pressure sensor cou- pler 7. Cover 8 fuel hose 9. Fuel pump lead 10. Fuel injector coupler 11. Throttle body 12. ...

Page 55

2-25 cable routing diagram 1. Brake master cylinder 2. Brake hose holder 3. Brake hose a. Install the brake hose so that its pipe portion directs as shown and lightly touches the projec- tion on the brake caliper. B. Pass the brake hose into the brake hose holders. C. If the brake hose contacts the ...

Page 56

2-26 cable routing diagram 1. Throttle cable 2. Clutch cable 3. Clamp 4. Engine stop switch lead 5. Hose guide 6. Main harness a. Route the clutch cable to the rear of the number plate band. B. Fasten the engine stop switch lead to the handlebar. C. Route the brake hose to the front of the number pl...

Page 57

3-1 maintenance intervals regular inspection and adjustments maintenance intervals • the following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as weather, terrain, geographical location, and individual usage will alter the required maintenan...

Page 58

3-2 maintenance intervals cylinder head inspect carbon deposits and eliminate them. Inspect and clean ● change gasket. Cylinder inspect and clean ● inspect score marks. Replace ● inspect wear. Clutch inspect and adjust ● ● inspect housing, friction plate, clutch plate and spring. Replace ● transmiss...

Page 59

3-3 maintenance intervals air filter clean and lubricate ● ● use foam air-filter oil or equivalent oil. Replace ● oil filter replace ● ● engine guard replace ● breakage frame clean and inspect ● ● fuel tank, fuel pump inspect ● ● fuel hose inspect ● replace ● every four years brakes adjust lever pos...

Page 60

3-4 maintenance intervals swingarm inspect, lube and retighten ● ● molybdenum disulfide grease relay arm, connecting rod inspect, lube and retighten ● ● molybdenum disulfide grease steering head inspect free play and retighten ● ● clean and lube ● lithium base grease replace bearing ● tire, wheels i...

Page 61

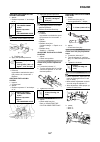

3-5 pre-operation inspection and maintenance pre-operation inspection and maintenance before riding for break-in operation, practice or a race, make sure the machine is in good operating condition. Before using this machine, check the following points. General inspection and maintenance item routine...

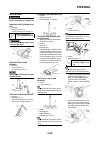

Page 62

3-6 engine engine checking the coolant level do not remove the radiator cap "1", drain bolt and hoses when the engine and radiator are hot. Scald- ing hot fluid and steam may be blown out under pressure, which could cause serious injury. When the engine has cooled, place a thick towel over the radia...

Page 63

3-7 engine checking the radiator cap opening pressure 1. Attach: • radiator cap tester "1" and adapt- er "2" apply water on the radiator cap seal. 3. Radiator cap 2. Apply the specified pressure. 3. Inspect: • pressure impossible to maintain the speci- fied pressure for 10 seconds → replace. Checkin...

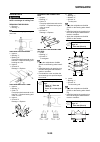

Page 64

3-8 engine adjusting the throttle cable free play 1. Check: • throttle grip free play "a" out of specification → adjust. 2. Adjust: • throttle grip free play throttle grip free play adjustment steps: a. Slide the adjuster cover. B. Loosen the locknut "1". C. Turn the adjuster "2" until the specified...

Page 65

3-9 engine 8. Apply: • foam-air-filter oil or equivalent oil to the element squeeze out the excess oil. Element should be wet but not dripping. 9. Install: • air filter element "1" • air filter guide "2" • binder 10. Install: • mounting bolt for air filter case cover 11. Install: • fuel tank bolt (f...

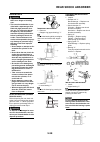

Page 66

3-10 engine changing the engine oil 1. Start the engine and let it warm up for several minutes. 2. Stop the engine and place an oil pan under the drain bolt. 3. Remove: • oil filler cap "1" • drain bolt (with gasket) "2" • drain bolt (with gasket) "3" drain the engine oil. 4. If the oil filter is to...

Page 67

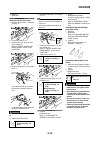

3-11 engine adjusting the valve clearance • this section is intended for those who have basic knowledge and skill concerning the servicing of yama- ha motorcycles (e.G., yamaha deal- ers, service engineers, etc.) those who have little knowledge and skill concerning servicing are requested not to und...

Page 68

3-12 engine d. Round off the last digit of the in- stalled pad number to the nearest increment. Example: installed pad number = 148 rounded off value = 150 pads can only be selected in 0.05 mm increments. E. Locate the rounded-off value and the measured valve clearance in the chart "pad selection ta...

Page 69

3-13 engine intake exhaust.

Page 70

3-14 chassis chassis bleeding the hydraulic brake system bleed the brake system if: • the system has been disassem- bled. • a brake hose has been loosened or removed. • the brake fluid is very low. • the brake operation is faulty. A dangerous loss of braking per- formance may occur if the brake syst...

Page 71

3-15 chassis c. Tighten the locknut. Be sure to tighten the locknut, as it will cause poor brake perfor- mance. Checking and replacing the front brake pads 1. Inspect: • brake pad thickness "a" out of specification → replace as a set. 2. Replace: • brake pad brake pad replacement steps: a. Remove th...

Page 72

3-16 chassis 2. Replace: • brake pad brake pad replacement steps: a. Remove the protector "1" and pad pin plug "2". B. Loosen the pad pin "3". C. Remove the rear wheel "4" and brake caliper "5". Refer to "front wheel and rear wheel" section in the chapter 5. D. Remove the pad pin "6" and brake pads ...

Page 73

3-17 chassis a. Lower level a. Front b. Rear checking the sprocket 1. Inspect: • sprocket teeth "a" excessive wear → replace. Replace the drive sprocket, rear wheel sprocket and drive chain as a set. Checking the drive chain 1. Measure: • drive chain length (15 links) "a" out of specification → repl...

Page 74

3-18 chassis c. Turn each adjuster exactly the same amount to maintain correct axle alignment. (there are marks "a" on each side of the drive chain puller alignment.) notice: im- proper drive chain slack will overload the engine aswell as other vital parts of the motorcy- cle and can lead to chain s...

Page 75

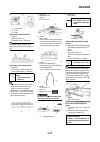

3-19 chassis do not force the adjuster past the minimum or maximum extent of adjustment. The adjuster may be damaged. Always adjust each front fork to the same setting. Uneven adjust- ment can cause poor handling and loss of stability. Adjusting the front fork compression damping force 1. Adjust: • ...

Page 76

3-20 chassis adjusting the rear shock absorber rebound damping force 1. Adjust: • rebound damping force by turning the adjuster "1". • standard position: this is the position which is back by the specific number of clicks from the fully turned-in position. (which align the punch mark "a" on the adju...

Page 77

3-21 chassis checking the tire pressure 1. Measure: • tire pressure out of specification → adjust. • check the tire while it is cold. • loose bead stoppers allow the tire to slip off its position on the rim when the tire pressure is low. • a tilted tire valve stem indicates that the tire slips off i...

Page 78

3-22 chassis e. Loosen the steering ring nut one turn. F. Retighten the steering ring nut us- ing the steering nut wrench. Avoid over-tightening. G. Check the steering stem by turn- ing it lock to lock. If there is any binding, remove the steering stem assembly and inspect the steer- ing bearings. H...

Page 79

3-23 chassis lubrication to ensure smooth operation of all components, lubricate your machine during setup, after break-in, and after every race. 1. All control cable 2. Clutch lever pivot 3. Shift pedal pivot 4. Footrest pivot 5. Throttle-to-handlebar contact 6. Drive chain 7. Tube guide cable wind...

Page 80

3-24 electrical electrical checking the spark plug 1. Remove: • spark plug 2. Inspect: • electrode "1" wear/damage → replace. • insulator color "2" normal condition is a medium to light tan color. Distinctly different color → check the engine condition. An extended run at low speeds causes the insul...

Page 81

3-25 electrical troubleshooting the following guide for troubleshooting does not cover all the possible causes of problems. If the following problems occur, perform the specified checks or maintenance jobs. If a problem occurs that is not listed in this manual or if the problem cannot be corrected b...

Page 82

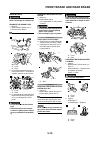

4-1 seat and side covers engine this section is intended for those who have basic knowledge and skill concerning the servicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.) those who have little knowledge and skill concerning servicing are request- ed not to undertake inspect...

Page 83

4-2 seat and side covers checking and replacing the insulator 1. Inspect: • insulator 1 "1" • insulator 2 "2" • insulator 3 "3" • insulator 4 "4" • insulator 5 "5" damage → replace. • affix insulators 1–5 to the side cov- ers as shown. • if the insulators overlap, affix insula- tors 2 and 4 on top o...

Page 84

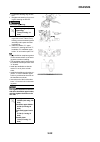

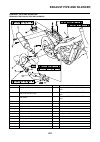

4-3 exhaust pipe and silencer exhaust pipe and silencer removing the exhaust pipe and silencer order part name q'ty remarks seat refer to "seat and side covers" sec- tion. Side cover (left and right) refer to "seat and side covers" sec- tion. Rear fender refer to "seat and side covers" sec- tion. 1 ...

Page 85

4-4 exhaust pipe and silencer 12 heat protector 1 order part name q'ty remarks.

Page 86

4-5 exhaust pipe and silencer checking the silencer and exhaust pipe 1. Inspect: • gasket "1" damage → replace. Changing the silencer fiber for usa and cdn 2. Remove: • bolt "1" • inner pipe "2" do not hit the silencer stay "a" as it may do damage to the silencer. Remove the inner pipe while holding...

Page 87

4-6 exhaust pipe and silencer installing the silencer and exhaust pipe 1. Install: • gasket • exhaust pipe "1" • nut (exhaust pipe) "2" first temporarily tighten both nuts to 7 nm (0.7 m•kg, 5.1 ft•lb). Then retight- en the same nut to 10 nm (1.0 m•kg, 7.2 ft•lb). 2. Install: • silencer clamp (front...

Page 88

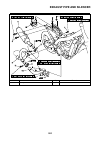

4-7 radiator radiator removing the radiator order part name q'ty remarks drain the coolant. Refer to "changing the coolant" sec- tion in the chapter 3. Seat refer to "seat and side covers" sec- tion. Fuel tank refer to "fuel tank" section in the chap- ter 6. Air filter case refer to "throttle body" ...

Page 89

4-8 radiator 11 pipe 1/o-ring 1/1 order part name q'ty remarks.

Page 90

4-9 radiator handling note do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be blown out under pressure, which could cause serious injury. When the engine has cooled, open the radiator cap by the following procedure: place a thick rag, like a towe...

Page 91

4-10 camshafts camshafts removing the cylinder head cover order part name q'ty remarks seat refer to "seat and side covers" sec- tion. Fuel tank refer to "fuel tank" section in the chap- ter 6. Cover refer to "throttle body" section in the chapter 6. 1 spark plug 1 2 cylinder head breather hose 1 3 ...

Page 92

4-11 camshafts removing the camshafts order part name q'ty remarks 1 timing mark accessing screw 1 refer to removal section. 2 crankshaft end accessing screw 1 refer to removal section. 3 timing chain tensioner cap bolt 1 refer to removal section. 4 timing chain tensioner 1 refer to removal section....

Page 93

4-12 camshafts removing the camshaft 1. Remove: • timing mark accessing screw "1" • crankshaft end accessing screw "2" 2. Align: • alignment mark checking steps: a. Turn the crankshaft counterclock- wise with a wrench. B. Align the alignment mark "a" on the rotor with the alignment mark "b" on the c...

Page 94

4-13 camshafts 4. Measure: • camshaft-to-cap clearance out of specification → measure camshaft outside diameter. Measurement steps: a. Install the camshaft onto the cylin- der head. B. Position a strip of plastigauge ® "1" onto the camshaft. C. Install the clip, dowel pins and camshaft caps. • tight...

Page 95

4-14 camshafts do not turn the crankshaft during the camshaft installation. Damage or improper valve timing will re- sult. D. Install the clips, camshaft caps "4" and bolts (camshaft cap) "5". • before installing the clips, cover the cylinder head with a clean rag to prevent the clips from into the ...

Page 96

4-15 cylinder head cylinder head removing the cylinder head order part name q'ty remarks seat refer to "seat and side covers" sec- tion. Fuel tank refer to "fuel tank" section in the chap- ter 6. Exhaust pipe and silencer refer to "exhaust pipe and silencer" section. Radiator refer to "radiator" sec...

Page 97

4-16 cylinder head tighten the cylinder head bolts to 30 nm (3.0 m•kg, 22 ft•b) in the proper tightening sequence, remove and retighten the cylinder head bolts to 20 nm (2.0 m•kg, 14 ft•lb) in the proper tightening sequence, and then tighten the cylinder head bolts further to reach the specified ang...

Page 98

4-17 cylinder head checking the cylinder head 1. Eliminate: • carbon deposits (from the com- bustion chambers) use a rounded scraper. Do not use a sharp instrument to avoid damaging or scratching: • spark plug threads • valve seats 2. Inspect: • cylinder head scratches/damage → replace. Replace the ...

Page 99

4-18 cylinder head tighten the bolts two times at speci- fied angles of 90°and 60° to reach the specified angle of 150° in the proper tightening sequence as shown. 3. Install: • bolt (cylinder head) "1" bolts (cylinder head): final: specified angle 150° bolt (cylinder head): 10 nm (1.0 m•kg, 7.2 ft•...

Page 100

4-19 valves and valve springs valves and valve springs removing the valves and valve springs order part name q'ty remarks cylinder head refer to "cylinder head" section. 1 valve lifter 4 refer to removal section. 2 adjusting pad 4 refer to removal section. 3 valve cotter 8 refer to removal section. ...

Page 101

4-20 valves and valve springs removing the valve lifter and valve cotter 1. Remove: • valve lifter "1" • pad "2" identify each lifter "1" and pad "2" po- sition very carefully so that they can be reinstalled in their original place. 2. Check: • valve sealing leakage at the valve seat → in- spect the...

Page 102

4-21 valves and valve springs 4. Measure: • margin thickness "a" out of specification → replace. 5. Measure: • runout (valve stem) out of specification → replace. • when installing a new valve always replace the guide. • if the valve is removed or replaced always replace the oil seal. 6. Eliminate: ...

Page 103

4-22 valves and valve springs checking the valve springs 1. Measure: • valve spring free length "a" out of specification → replace. 2. Measure: • compressed spring force "a" out of specification → replace. B. Installed length 3. Measure: • spring tilt "a" out of specification → replace. Checking the...

Page 104

4-23 cylinder and piston cylinder and piston removing the cylinder and piston order part name q'ty remarks cylinder head refer to "cylinder head" section. 1 bolt (cylinder) 1 2 cylinder 1 3 gasket 1 4 dowel pin 2 5 piston pin clip 2 refer to removal section. 6 piston pin 1 refer to removal section. ...

Page 105

4-24 cylinder and piston removing the piston and piston ring 1. Remove: • piston pin clip "1" • piston pin "2" • piston "3" • put identification marks on each piston head for reference during re- installation. • before removing each piston pin, deburr the clip groove and pin hole area. If the piston...

Page 106

4-25 cylinder and piston 2. Position: • piston ring (in cylinder) insert a ring into the cylinder and push it approximately 40mm (1.57 in) into the cylinder. Push the ring with the piston crown so that the ring will be at a right angle to the cylinder bore. A. 40 mm (1.57 in) 3. Measure: • ring end ...

Page 107

4-26 cylinder and piston 3. Install: • piston "1" • piston pin "2" • piston pin clip "3" • apply engine oil onto the piston. • apply molybdenum disulfide oil onto the piston pin. • install the piston with the f mark "a" on it pointing to its intake (front) side. • before installing the piston pin cl...

Page 108

4-27 clutch clutch removing the clutch order part name q'ty remarks drain the engine oil. Refer to "changing the engine oil" section in the chapter 3. Brake pedal refer to "engine removal" section. Clutch cable disconnect at engine side. 1 clutch cover 1 2 gasket 1 3 clutch spring 6 4 pressure plate...

Page 109

4-28 clutch 14 conical washer 1 refer to removal section. 15 clutch boss 1 refer to removal section. 16 thrust washer 1 17 primary driven gear 1 18 push lever shaft 1 order part name q'ty remarks.

Page 110

4-29 clutch removing the clutch boss 1. Remove: • nut "1" • conical washer "2" • clutch boss "3" use the clutch holding tool "4" to hold the clutch boss. A. For usa and cdn b. Except for usa and cdn checking the clutch housing and boss 1. Inspect: • clutch housing "1" cracks/wear/damage → replace. •...

Page 111

4-30 clutch installing the clutch 1. Install: • primary driven gear "1" • thrust washer "2" • clutch boss "3" apply the engine oil on the primary driven gear inner circumference. 2. Install: • conical washer "1" • nut (clutch boss) "2" make sure to tighten to specifica- tion; otherwise, it may damag...

Page 112

4-31 oil filter element and water pump oil filter element and water pump removing the oil filter element and water pump order part name q'ty remarks right engine guard refer to "engine removal" section. Drain the engine oil. Refer to "changing the engine oil" section in the chapter 3. Drain the cool...

Page 113

4-32 oil filter element and water pump 9 dowel pin/o-ring 3/1 10 impeller 1 refer to removal section. 11 washer 1 refer to removal section. 12 impeller shaft 1 refer to removal section. 13 oil seal 1 1 refer to removal section. 14 oil seal 2 1 refer to removal section. 15 bearing 1 refer to removal ...

Page 114

4-33 oil filter element and water pump removing the impeller shaft 1. Remove: • impeller "1" • washer "2" • impeller shaft "3" hold the impeller shaft on its width across the flats "a" with spanners, etc. And remove the impeller. Removing the oil seal it is not necessary to disassemble the water pum...

Page 115

4-34 oil filter element and water pump installing the right crankcase cover 1. Install: • dowel pin "1" • o-ring "2" • collar "3" • gasket "4" apply the lithium soap base grease on the o-ring. 2. Install: • right crankcase cover "1" • bolt "2" • apply the engine oil on the impeller shaft end. • when...

Page 116

4-35 balancer balancer removing the balancer order part name q'ty remarks primary driven gear refer to "clutch" section. Right crankcase cover refer to "oil filter element and wa- ter pump" section. Stator refer to "ac magneto" section. 1 nut (balancer) 1 refer to removal section. 2 nut (primary dri...

Page 117

4-36 balancer removing the balancer 1. Straighten the lock washer tab. 2. Loosen: • nut (balancer) "1" • nut (primary drive gear) "2" • nut (balancer shaft driven gear) "3" place an aluminum plate "a" between the teeth of the balancer shaft drive gear "4" and driven gear "5". Checking the primary dr...

Page 118

4-37 oil pump oil pump removing the oil pump order part name q'ty remarks primary driven gear refer to "clutch" section. Right crankcase cover refer to "oil filter element and wa- ter pump" section. 1 circlip 1 2 washer 1 3 oil pump drive gear 1 4 oil pump assembly 1 5 dowel pin 2 6 outer rotor 2 1 ...

Page 119

4-38 oil pump 15 oil pump drive shaft 1 16 rotor housing 1 order part name q'ty remarks.

Page 120

4-39 oil pump checking the oil pump 1. Inspect: • oil pump drive gear • oil pump drive shaft • rotor housing • oil pump cover cracks/wear/damage → re- place. 2. Measure: • tip clearance "a" (between the inner rotor "1" and outer rotor "2") • side clearance "b" (between the outer rotor "2" and rotor ...

Page 121

4-40 kick shaft and shift shaft kick shaft and shift shaft removing the kick shaft and shift shaft order part name q'ty remarks oil pump refer to "oil pump" section. 1 kick idle gear 1 2 kick shaft assembly 1 refer to removal section. 3 spring guide 1 4 torsion spring 1 5 ratchet wheel 1 6 kick gear...

Page 122

4-41 kick shaft and shift shaft 17 pawl 2 18 pawl pin 2 19 spring 2 20 bolt (stopper lever) 1 21 stopper lever 1 22 torsion spring 1 23 segment 1 refer to removal section. Order part name q'ty remarks.

Page 123

4-42 kick shaft and shift shaft removing the kick shaft assembly 1. Remove: • kick shaft assembly "1" unhook the torsion spring "2" from the hole "a" in the crankcase. Removing the shift guide and shift lever assembly 1. Remove: • bolt (shift guide) • shift guide "1" • shift lever assembly "2" the s...

Page 124

4-43 kick shaft and shift shaft installing the stopper lever 1. Install: • torsion spring "1" • washer "2" • stopper lever "3" • bolt (stopper lever) "4" align the stopper lever roller with the slot on segment. Installing the shift guide and shift lever assembly 1. Install: • spring "1" • pawl pin "...

Page 125

4-44 kick shaft and shift shaft 3. Install: • spring guide "1" slide the spring guide into the kick shaft, make sure the groove "a" in the spring guide fits on the stopper of the torsion spring. 4. Install: • kick shaft assembly "1" • washer "2" • apply the molybdenum disulfide grease on the contact...

Page 126

4-45 ac magneto ac magneto removing the ac magneto order part name q'ty remarks seat refer to "seat and side covers" sec- tion. Fuel tank refer to "fuel tank" section in the chaper 6. Disconnect the ac magneto lead 1 left crankcase cover 1 2 gasket 1 3 dowel pin 2 4 nut (rotor) 1 refer to removal se...

Page 127

4-46 ac magneto removing the rotor 1. Remove: • nut (rotor) "1" • washer 2. Remove: • rotor "1" use the rotor puller 2. Checking the ac magneto 1. Inspect: • rotor inner surface "a" • stator outer surface "b" damage → inspect the crank- shaft runout and crankshaft bear- ing. Checking the woodruff ke...

Page 128

4-47 engine removal engine removal removing the electronic parts order part name q'ty remarks hold the machine by placing the suitable stand under the frame. Refer to "handling note". Seat refer to "seat and side covers" sec- tion. Fuel tank refer to "fuel tank" section in the chaper 6. Air filter c...

Page 129

4-48 engine removal removing the engine order part name q'ty remarks hold the machine by placing the suitable stand under the frame. Refer to "handling note". Throttle body refer to "throttle body" section in the chapre 6. Rear fender refer to "seat and side covers" sec- tion. Exhaust pipe and silen...

Page 130

4-49 engine removal 5 clip 1 6 bolt (brake pedal) 1 7 brake pedal 1 8 upper engine bracket 2 9 lower engine bracket 2 10 engine mounting bolt 4 11 pivot shaft 1 refer to removal section. 12 engine 1 refer to removal section. Order part name q'ty remarks.

Page 131

4-50 engine removal handling note support the machine securely so there is no danger of it falling over. Removing the drive sprocket 1. Remove: • nut (drive sprocket) "1" • lock washer "2" • straighten the lock washer tab. • loosen the nut while applying the rear brake. 2. Remove: • drive sprocket "...

Page 132

4-51 engine removal 2. Install: • lock washer "1" • nut (drive sprocket) "2" tighten the nut while applying the rear brake. Make sure to tighten to specifica- tion; otherwise, it may damage the other part that is fastened togeth- er. 3. Bend the lock washer tab to lock the nut. 4. Install: • drive c...

Page 133

4-52 crankcase and crankshaft crankcase and crankshaft removing the crankshaft order part name q'ty remarks engine refer to "engine removal" section. Piston refer to "cylinder and piston" section. Balancer refer to "balancer" section. Kick shaft assembly refer to "kick shaft and shift shaft" section...

Page 134

4-53 crankcase and crankshaft 10 balancer shaft 1 refer to removal section. 11 crankshaft 1 refer to removal section. Order part name q'ty remarks.

Page 135

4-54 crankcase and crankshaft removing the crankcase bearing order part name q'ty remarks transmission refer to "transmission, shift cam and shift fork" section. Shift cam and shift fork refer to "transmission, shift cam and shift fork" section. 1 circlip 1 2 oil seal 3 3 bearing 10 refer to removal...

Page 136

4-55 crankcase and crankshaft disassembling the crankcase 1. Separate: • right crankcase • left crankcase separation steps: a. Remove the crankcase bolts, hose guide and clutch cable hold- er. Loosen each bolt 1/4 of a turn at a time and after all the bolts are loos- ened, remove them. B. Remove the...

Page 137

4-56 crankcase and crankshaft 3. Inspect: • oil seal damage → replace. Checking the crankshaft 1. Measure: • runout limit "a" • small end free play limit "b" • connecting rod big end side clearance "c" • crank width "d" out of specification → replace. Use the dial gauge and a thick- ness gauge. Chec...

Page 138

4-57 crankcase and crankshaft 3. Install: • oil strainer "1" • bolt (oil strainer) "2" 4. Apply: • sealant on the right crankcase. Clean the contacting surface of left and right crankcase before applying the sealant. 5. Install: • dowel pin "1" • right crankcase to left crankcase. • fit the right cr...

Page 139

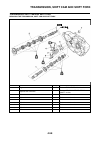

4-58 transmission, shift cam and shift fork transmission, shift cam and shift fork removing the transmission, shift cam and shift fork order part name q'ty remarks engine refer to "engine removal" section. Separate the crankcase. Refer to "crankcase and crank- shaft" section. 1 main axle 1 refer to ...

Page 140

4-59 transmission, shift cam and shift fork removing the transmission 1. Remove: • main axle "1" • drive axle "2" • shift cam • shift fork 3 • shift fork 2 • shift fork 1 • remove assembly with the collar "3" installed to the crankcase. • remove assembly carefully. Note the position of each part. Pa...

Page 141

4-60 transmission, shift cam and shift fork 3. Install: • washer "1" • circlip "2" • be sure the circlip sharp-edged cor- ner "a" is positioned opposite side to the washer and gear "b". • install the circlip with its ends "c" settled evenly on the spline crests. 4. Install: • collar "1" • apply the ...

Page 142

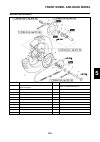

5-1 front wheel and rear wheel chassis this section is intended for those who have basic knowledge and skill concerning the servicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.) those who have little knowledge and skill concerning servicing are request- ed not to undertake ...

Page 143

5-2 front wheel and rear wheel removing the rear wheel order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". 1 nut (rear wheel axle) 1 2 rear wheel axle 1 3 drive chain puller 2 4 rear wheel 1 refer to removal section. 5 collar 2 6 re...

Page 144

5-3 front wheel and rear wheel handling note support the machine securely so there is no danger of it falling over. Removing the rear wheel 1. Remove: • wheel "1" push the wheel forward and remove the drive chain "2". Removing the wheel bearing 1. Remove: • bearing "1" remove the bearing using a gen...

Page 145

5-4 front wheel and rear wheel 2. Install: • brake disc "1" • bolt (brake disc) "2" tighten the bolts in stage, using a crisscross pattern. 3. Install: • collar "1" • apply the lithium soap base grease on the oil seal lip. • install the collars with their projec- tions "a" facing the wheel. 4. Insta...

Page 146

5-5 front wheel and rear wheel 2. Install: • brake disc "1" • bolt (brake disc) "2" tighten the bolts in stage, using a crisscross pattern. 3. Install: • rear wheel sprocket "1" • bolt (rear wheel sprocket) "2" • washer (rear wheel sprocket) "3" • nut (rear wheel sprocket) "4" tighten the nuts in st...

Page 147

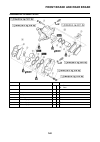

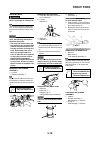

5-6 front brake and rear brake front brake and rear brake removing the front brake order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Drain the brake fluid. Refer to removal section. 1 brake hose holder (protector) 2 2 union bolt 2...

Page 148

5-7 front brake and rear brake removing the rear brake order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Rear wheel refer to "front wheel and rear wheel" section. Drain the brake fluid. Refer to removal section. 1 brake pedal 1 2 ...

Page 149

5-8 front brake and rear brake disassembling the brake caliper order part name q'ty remarks a. Front b. Rear a b 1 pad pin 1 1 2 brake pad 2 2 3 pad support 1 1 4 brake caliper piston 2 1 refer to removal section. 5 brake caliper piston dust seal 2 1 refer to removal section. 6 brake caliper piston ...

Page 150

5-9 front brake and rear brake disassembling the brake master cylinder order part name q'ty remarks a. Front b. Rear 1 brake master cylinder cap 1 2 diaphragm 1 3 reservoir float 1 4 push rod (front) 1 5 brake master cylinder boot 1 6 circlip 1 use a long nose circlip pliers. 7 washer 1 8 push rod (...

Page 151

5-10 front brake and rear brake handling note support the machine securely so there is no danger of it falling over. Draining the brake fluid 1. Remove: • brake master cylinder cap "1" • protector (rear brake) do not remove the diaphragm. A. Front b. Rear 2. Connect the transparent hose "2" to the b...

Page 152

5-11 front brake and rear brake 3. Inspect: (front brake only) • reservoir float "1" damage → replace. 4. Inspect: • brake master cylinder piston "1" • brake master cylinder cup "2" wear/damage/score marks → re- place brake master cylinder kit. Checking the brake caliper 1. Inspect: • brake caliper ...

Page 153

5-12 front brake and rear brake 2. Install: • brake caliper "1" • bolt (brake caliper) "2" 3. Tighten: • pad pin "3" 4. Install: • pad pin plug "4" installing the rear brake caliper 1. Install: • pad support "1" • brake pad "2" • pad pin "3" • install the brake pads with their pro- jections "a" into...

Page 154

5-13 front brake and rear brake installing the front brake master cylinder 1. Install: • brake master cylinder "1" • brake master cylinder bracket "2" • bolt (brake master cylinder brack- et) "3" • install the bracket so that the arrow mark "a" face upward. • first tighten the bolts on the upper sid...

Page 155

5-14 front brake and rear brake install the brake hose so that its pipe portion "a" directs as shown and lightly touches the projection "b" on the brake caliper. 2. Install: • brake hose holder "1" • bolt (brake hose holder) "2" align the top "a" of the brake hose holder with the paint "b" of the br...

Page 156

5-15 front brake and rear brake brake fluid may erode painted sur- faces or plastic parts. Always clean up spilled fluid immediately. A. Front b. Rear 2. Air bleed: • brake system refer to "bleeding the hy- draulic brake system" sec- tion in the chapter 3. 3. Inspect: • brake fluid level fluid at lo...

Page 157

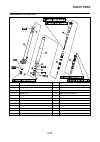

5-16 front fork front fork removing the front fork order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Front wheel refer to "front wheel and rear wheel" section. Front brake caliper refer to "front brake and rear brake" section. Num...

Page 158

5-17 front fork disassembling the front fork order part name q'ty remarks 1 adjuster 1 drain the fork oil. Refer to removal section. 2 fork spring 1 3 dust seal 1 refer to removal section. 4 stopper ring 1 refer to removal section. 5 inner tube 1 refer to removal section. 6 outer tube 1 7 piston met...

Page 159

5-18 front fork handling note support the machine securely so there is no danger of it falling over. The front fork requires careful atten- tion. So it is recommended that the front fork be maintained at the deal- ers. To prevent an accidental explosion of air, the following instructions should be o...

Page 160

5-19 front fork the front fork with a built-in piston rod has a very sophisticated inter- nal construction and is particularly sensitive to foreign material. Use enough care not to allow any foreign material to come in when the oil is replaced or when the front fork is disassembled and re- assembled...

Page 161

5-20 front fork 5. Measure: • oil level (left and right) "a" out of specification → adjust. 6. Tighten: • locknut "1" fully finger tighten the locknut onto the damper assembly. 7. Loosen: • compression damping adjuster "1" • loosen the compression damping adjuster finger tight. • record the set posi...

Page 162

5-21 front fork 16. Install: • piston metal "1" install the piston metal onto the slot on inner tube. 17. Install: • outer tube "1" to inner tube "2". 18. Install: • slide metal "1" • oil seal washer "2" to outer tube slot. Press the slide metal into the outer tube with fork seal driver "3". 19. Ins...

Page 163

5-22 front fork 25. Install: • damper assembly "1" to inner tube "2". To install the damper assembly into the inner tube, hold the inner tube aslant. If the inner tube is held vertically, the damper assembly may fall into it, damaging the valve inside. 26. Loosen: • rebound damping adjuster "1" • lo...

Page 164

5-23 front fork 33. Install: • protector guide "1" installing the front fork 1. Install: • front fork "1" • temporarily tighten the pinch bolts (lower bracket). • do not tighten the pinch bolts (up- per bracket) yet. 2. Tighten: • damper assembly "1" use the cap bolt ring wrench "2" to tighten the d...

Page 165

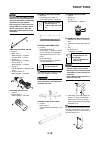

5-24 handlebar handlebar removing the handlebar order part name q'ty remarks number plate remove the band only. 1 clutch cable 1 disconnect at the lever side. 2 clutch lever holder 1 3 engine stop switch 1 4 brake master cylinder 1 refer to removal section. 5 throttle cable cap 1 6 throttle cable #1...

Page 166

5-25 handlebar removing the brake master cylinder 1. Remove: • brake master cylinder bracket "1" • brake master cylinder "2" • do not let the brake master cylin- der hang on the brake hose. • keep the brake master cylinder cap side horizontal to prevent air from coming in. Removing the grip 1. Remov...

Page 167

5-26 handlebar 3. Tighten: • nut (handlebar lower holder) "1" • cap "2" install the cap "2" onto the handlebar lower holder nut (left). 4. Install: • left grip "1" apply the adhesive to the handle- bar "2". • before applying the adhesive, wipe off grease or oil on the handlebar surface "a" with a la...

Page 168

5-27 handlebar 11. Install: • engine stop switch "1" • clutch lever holder "2" • bolt (clutch lever holder) "3" •clamp "4" • the engine stop switch, clutch lever holder and clamp should be in- stalled according to the dimensions shown. • pass the engine stop switch lead in the middle of the clutch l...

Page 169

5-28 steering steering removing the steering order part name q'ty remarks tightening steps: • tighten ring nut. 38 nm (3.8 m•kg, 27 ft•lb) • loosen it one turn. • retighten it. 7 nm (0.7 m•kg, 5.1 ft•lb) hold the machine by placing the suitable stand under the engine. Refer to "handling note". Numbe...

Page 170

5-29 steering 10 bearing race 2 refer to removal section. Order part name q'ty remarks.

Page 171

5-30 steering handling note support the machine securely so there is no danger of it falling over. Removing the steering ring nut 1. Remove: • steering ring nut "1" use the steering nut wrench "2". Support the steering stem so that it may not fall down. Removing the lower bearing 1. Remove: • lower ...

Page 172

5-31 steering 6. Install: • washer "1" 7. Install: • front fork "1" • upper bracket "2" • temporarily tighten the pinch bolts (lower bracket). • do not tighten the pinch bolts (up- per bracket) yet. 8. Install: • steering stem nut "1" apply the lithium soap base grease on the contact surface of the ...

Page 173

5-32 swingarm swingarm removing the swingarm order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Brake hose holder refer to "front brake and rear brake" section. Rear brake caliper refer to "front brake and rear brake" section. Bolt...

Page 174

5-33 swingarm disassembling the swingarm order part name q'ty remarks 1 relay arm 1 2 connecting rod 1 3 collar 2 4 oil seal 2 5 thrust bearing 2 6 bushing 2 7 oil seal 8 8 bearing 10 refer to removal section..

Page 175

5-34 swingarm handling note support the machine securely so there is no danger of it falling over. Removing the bearing 1. Remove: • bearing "1" remove the bearing by pressing its outer race. Checking the swingarm 1. Inspect: • bearing "1" • bushing "2" free play exists/unsmooth revolu- tion/rust → ...

Page 176

5-35 swingarm installing the swingarm 1. Install: • bushing "1" • thrust bearing "2" • oil seal "3" • collar "4" to swingarm "5". Apply the molybdenum disulfide grease on the bushings, thrust bear- ings, oil seal lips and contact surfaces of the collar and thrust bearing. 2. Install: • collar "1" • ...

Page 177

5-36 swingarm 10. Tighten: • nut (connecting rod) "1" 11. Tighten: • nut (relay arm) "1" 12. Install: • bolt (lower chain tensioner) "1" • washer "2" • collar "3" • lower chain tensioner "4" • nut (lower chain tensioner) "5" 13. Install: • drive chain support "1" • drive chain support cover "2" • bo...

Page 178

5-37 rear shock absorber rear shock absorber removing the rear shock absorber order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Seat refer to "seat and side covers" section in the chapter 4. Silencer refer to "exhaust pipe and sil...

Page 179

5-38 rear shock absorber handling note • support the machine securely so there is no danger of it falling over. • this rear shock absorber is pro- vided with a separate type tank filled with high-pressure nitro- gen gas. To prevent the danger of explosion, read and under- stand the following informa...

Page 180

5-39 rear shock absorber 2. Install: • stopper ring (upper bearing) "1" after installing the stopper ring, push back the bearing until it contacts the stopper ring. 3. Install: • lower bearing "1" install the bearing by pressing it on the side having the manufacture's marks or numbers. Installing th...

Page 181

6-1 fuel tank fuel system this section is intended for those who have basic knowledge and skill concerning the servicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.) those who have little knowledge and skill concerning servicing are request- ed not to undertake inspection, a...

Page 182

6-2 fuel tank removing the fuel tank 1. Extract the fuel in the fuel tank through the fuel tank cap with a pump. Be careful not to damage the fuel pump. 2. Remove: • fuel pump coupler although the fuel has been re- moved from the fuel tank be care- ful when removing the fuel hoses, since there may b...

Page 183

6-3 fuel tank 2. Install: • fuel pump coupler • air scoop (left/right) • seat refer to "seat and side cov- ers" in the chapter 4. Checking the fuel pressure 1. Check: • pressure regulator operation 2. Remove the fuel tank. Refer to "removeing the fuel tank" section. 3. Connect the pressure gauge "1"...

Page 184

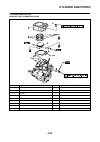

6-4 throttle body throttle body removing the throttle body order part name q'ty remarks seat refer to "seat and side covers" section in the chapter 4. Air scoop (left/right) refer to "seat and side covers" section in the chapter 4. Fuel tank refer to "fuel tank" section. 1 cover 1 2 air filter case ...

Page 185

6-5 throttle body disassembling the throttle body order part name q'ty remarks 1 injector 1 2 gasket 2.

Page 186

6-6 throttle body checking the injector replace the fuel injector with a new one if you have dropped or im- pacted it. 1. Check: • injectors damage → replace. Checking the throttle body • before removing the throttle body, clean the area around the throttle body to prevent dirt and other foreign mat...

Page 187

7-1 electrical components and wiring diagram electrical this section is intended for those who have basic knowledge and skill concerning the servicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.) those who have little knowledge and skill concerning servicing are request- ed ...

Page 188

7-2 electrical components and wiring diagram wiring diagram 1. Crankshaft position sensor 2. Ac magneto 3. Rectifier/regulator 4. Condenser 5. Fuel pump 6. Engine stop switch 7. Ecu 8. Ignition coil 9. Spark plug 10. Fuel injector 11. Intake air temperature sensor 12. Intake air pressure sensor 13. ...

Page 189

7-3 ignition system ignition system inspection steps use the following steps for checking the possibility of the malfunctioning engine being attributable to ignition system failure and for checking the spark plug which will not spark. *marked: only when the ignition checker is used. • remove the fol...

Page 190

7-4 ignition system spark gap test 1. Disconnect the spark plug cap from spark plug. 2. Connect the dynamic spark tester "1" (ignition checker "2") as shown. • spark plug cap "3" • spark plug "4" a. For usa and cdn b. Except for usa and cdn 3. Kick the kickstarter crank. 4. Check the ignition spark ...

Page 191

7-5 ignition system 2. Inspect: • stator coil resistance out of specification → replace. Checking the ecu 1. Check: • all electrical components. 2. Check: • ecu installation status make sure that the ecu is in- stalled correctly. • the lean angle sensor is built into the ecu. • the lean angle sensor...

Page 192

7-6 throttle position sensor system throttle position sensor system inspection steps if the throttle position sensor will not operate, use the following inspection steps. *marked: refer to "ignition system" section. Use the following special tools in this inspection. Check entire ignition system for...

Page 193

7-7 throttle position sensor system handling note do not loosen the screw (throttle position sensor) "1" except when changing the throttle position sen- sor due to failure because it will cause a drop in engine perfor- mance. Checking the couplers and leads connection 1. Check: • couplers and leads ...

Page 194

7-8 throttle position sensor system checking the throttle position sensor input voltage 1. Disconnect the throttle position sensor coupler. 2. Connect the test harness-speed sensor (3p) "1" as shown. 3. Start the engine. 4. Inspect: • throttle position sensor input volt- age out of specification → r...

Page 195

7-9 fuel injection system fuel injection system troubleshooting method engine starting problems, engine idling speed problems, and medium and high-speed performance prob- lems 1. Check: • refer to "troubleshooting" section in the chapter 3. 2. Connect the fi diagnostic tool. (refer to "connecting th...

Page 196

7-10 fuel injection system setting the diagnostic mode when the fi diagnostic tool is set to the diagnostic mode, the sensor out- put data can be displayed and the op- eration of the actuators can be checked. 1. While pressing the "mode" but- ton, set the switch on the fi diag- nostic tool sub-wire ...

Page 197

7-11 fuel injection system sensor operation table diagnos- tic code no. Item actuation or display checking method actuation or lcd standard display values d01 throttle angle display displays the throttle angle. 0–125° check with throttle fully closed. When throttle is fully closed:15–19° check with ...

Page 198

7-12 fuel injection system d36 injectors actuation check that power is supplied to the fuel injector. • check the fuel injector operation by listening for the operating sound or by confirming the oper- ation visually. Actuates the injector for five times every second. The "warning" led on the fi di-...

Page 199

7-13 fuel injection system troubleshooting details this section describes the countermeasures per fault code number displayed on the fi diagnostic tool. Check and service the items or components that are the probable cause of the malfunction following the order given. After the check and ser- vice o...

Page 200

7-14 fuel injection system if fault code nos. 13 and 14 are both displayed, perform the checks and maintenance jobs for fault code no. 13 first. 5 defective crankshaft position sensor. Sensor malfunction → replace. Refer to "checking the ac magneto" section. Crank the engine and check the fault code...

Page 201

7-15 fuel injection system 3 continuity of harness open or short circuit → replace. Between the intake air pressure sensor coupler and ecu coupler. (black/blue–black/blue) (pink/white–pink/white) (blue–blue) set the switch on the fi di- agnostic tool sub-wire har- ness to "on", and then check the fa...

Page 202

7-16 fuel injection system if fault code nos. 13 and 14 are both displayed, perform the checks and maintenance jobs for fault code no. 13 first. Fault code no. 14 symptom intake air pressure sensor system malfunction detected. (clogged hole or disconnected sensor) fail-safe system able to start able...

Page 203

7-17 fuel injection system fault code no. 15 symptom throttle position sensor signal is not received properly. Fail-safe system able to start able to drive diagnostic code no. D01 fi diagnostic tool display • 15–19° (fully closed position) • 95–101° (fully opened position) checking method • check wi...

Page 204

7-18 fuel injection system 5 applied voltage of throttle position sensor lead measure the output voltage. Refer to "checking the throttle position sen- sor". Set the switch on the fi di- agnostic tool sub-wire har- ness to "on", and then check the fault code dis- play. Fault code number is not displ...

Page 205

7-19 fuel injection system fault code no. 16 symptom signal from throttle position sensor does not change. Fail-safe system able to start able to drive diagnostic code no. D01 fi diagnostic tool display • 15–19° (fully closed position) • 95–101° (fully opened position) checking method • check with t...

Page 206

7-20 fuel injection system make sure that the engine is completely cool before checking the coolant temperature sensor. Fault code no. 21 symptom coolant temperature sensor signal is not received properly. Fail-safe system able to start able to drive diagnostic code no. D06 fi diagnostic tool displa...

Page 207

7-21 fuel injection system make sure that the engine is completely cool before checking the intake air temperature sensor. 5 defective coolant temperature sensor. Execute the diagnostic mode (di- agnostic code no. D06). Cold engine: displayed temper- ature is close to the ambient temperature. Displa...

Page 208

7-22 fuel injection system 2 check the connection and locking condition of the wire harness ecu coupler. Disconnect the coupler and check the pins. (bent or broken terminals and locking condition of the pins) poor connection → properly con- nect, repair, or replace. Set the switch on the fi di- agno...

Page 209

7-23 fuel injection system fault code no. 23 symptom atmospheric pressure sensor signal is not received properly. Fail-safe system able to start able to drive diagnostic code no. D02 fi diagnostic tool display atmosphere checking method measure the atmospheric pressure. Item item/components and prob...

Page 210

7-24 fuel injection system 5 defective atmospheric pressure sensor. Execute the diagnostic mode (di- agnostic code no. D02). When the engine is stopped, displays the atmospheric pres- sure according to the elevation and weather. 0 m above sea level: approx. 101 kpa 1000 m above sea level: ap- prox. ...

Page 211

7-25 fuel injection system fault code no. 30 symptom turnover of vehicle fail-safe system able to start unable to drive diagnostic code no. D08 fi diagnostic tool display lean angle sensor • 1.0 v (upright) • 4.0 v (overturned) checking method remove the ecu and incline it 45° or more. Item item/com...

Page 212

7-26 fuel injection system fault code no. 33 symptom ignition system circuit signal is not received properly. Fail-safe system unable to start unable to drive diagnostic code no. D30 fi diagnostic tool display actuates the ignition coil for five times every second. The "warning" led on the fi diagno...

Page 213

7-27 fuel injection system 4 installed condition of ignition coil check that the sensor is installed securely and that there are no pinched leads.Check that the ecu is installed securely and that there are no pinched leads. Incorrect installation → reinstall or repair. Start the engine and let it id...

Page 214

7-28 fuel injection system fault code no. 39 symptom injection system circuit signal is not received properly. Fail-safe system unable to start unable to drive diagnostic code no. D36 fi diagnostic tool display actuates the injector for five times every second. The "warning" led on the fi diagnostic...

Page 215

7-29 fuel injection system 4 continuity of harness open or short circuit → replace. Between injector coupler and ecu coupler. (red–red) (red/black–red/black) start the engine and let it idle for approximately 5 seconds. After completing the above operation, check whether a fault code number is dis- ...

Page 216

7-30 fuel injection system fault code no. 44 symptom error is detected while reading or writing on eeprom. Fail-safe system able to start engine (depending on circumstances) able to drive vehicle (depending on circumstances) diagnostic code no. D60 fi diagnostic tool display 00: no fault 01: co adju...

Page 217

7-31 fuel injection system fault code no. 46 symptom power supply to the ecu is not normal. Fail-safe system able to start (depending on circumstances) able to drive vehicle (depending on circumstances) diagnostic code no. — fi diagnostic tool display — checking method — item item/components and pro...

Page 218

7-32 fuel injection system 4 defective ac magneto. Defective → replace. Refer to "checking the ac magneto" section. Start the engine, set the switch on the fi diagnostic tool sub-wire harness to "off" while the engine is idling, and let the engine continue to idle for 5 sec- onds or more. After comp...

Page 219

7-33 fuel injection system fault code no. Waiting for connection symptom communication signal is not received. Fail-safe system able to start (unable when ecu is malfunctioning) able to drive vehicle (unable when ecu is malfunctioning) diagnostic code no. — fi diagnostic tool display — checking meth...

Page 220

7-34 fuel injection system fault code no. Er-4 symptom registered data cannot be received from the fi diagnostic tool. Fail-safe system able to start able to drive diagnostic code no. — fi diagnostic tool display — checking method — item item/components and probable cause check or maintenance job ch...

Page 221

7-35 fuel pump system fuel pump system inspection steps if the fuel pump is not operating normally, perform the following procedures in the order given. • remove the following parts before inspection. 1. Seat 2. Side cover (right/left) 3. Fuel tank • use the following special tools in this inspectio...

Page 222

7-36 electrical components electrical components checking the coolant temperature sensor 1. Remove: •coolant temperature sensor refer to "removing the cyl- inder head" section in the chapter 4. • handle the coolant temperature sensor with special care. • never subject the coolant tem- perature senso...

Page 223

7-37 electrical components 3. Connect the fi diagnostic tool sub-wire harness to a battery, and then set the switch on the harness to "on". When checking the atmospheric pressure sensor, do not start the engine. 4. Measure the atmospheric pres- sure sensor output voltage. Out of specification → repl...

Page 224

8-1 chassis tuning chassis selection of the secondary reduction ratio (sprocket) ondary gear reduction ratio> • it is generally said that the second- ary gear ratio should be reduced for a longer straight portion of a speed course and should be increased for a course with many corners. Actual- ly, h...

Page 225

8-2 chassis a. Air spring characteristics in relation to oil amount change b. Load c. Stroke 1. Max. Oil amount 2. Standard oil amount 3. Min. Oil amount setting of spring after replacement as the front fork setting can be easily affected by rear suspension, take care so that the machine front and r...

Page 226

8-3 chassis setting of spring after replacement after replacement, be sure to adjust the spring to the set length [sunken length 90–100 mm (3.5–3.9 in)] and set it. 1. Use of soft spring • set the soft spring for less re- bound damping to compensate for its less spring load. Run with the rebound dam...

Page 227

8-4 chassis suspension setting (front fork) • if any of the following symptoms is experienced with the standard position as the base, make resetting by reference to the adjustment procedure given in the same chart. • before any change, set the rear shock absorber sunken length to the standard figure...

Page 228

8-5 chassis suspension setting (rear shock absorber) • if any of the following symptoms is experienced with the standard position as the base, make resetting by reference to the adjustment procedure given in the same chart. • adjust the rebound damping in 2-click increments or decrements. • adjust t...

Page 229

Q read this manual carefully before operating this vehicle. This manual should stay with this vehicle if it is sold. Q il convient de lire attentivement ce manuel avant la première utilisation du véhicule. Le manuel doit être remis avec le véhicule en cas de vente de ce dernier. Q bitte lesen sie di...

Page 230

Printed in japan (e) printed on recycled paper yamaha motor co., ltd. 2500 shingai iwata shizuoka japan.