- DL manuals

- Yamaha

- Engine

- MX-800

- Service Manual

Yamaha MX-800 Service Manual

Summary of MX-800

Page 1

Service manual mx775 mx800 mx825 7ud-f8197-e0 lit-19616-02-37 2016.12×1 ! 7ud-f8197-e0_cover.Indd 1 2016/12/13 11:23:58.

Page 2

7ud-f8197-e0_cover.Indd 2 2016/12/13 11:23:58.

Page 3

Mx775, mx800, mx825 service manual ©2016 by yamaha motor corporation, u.S.A. 1st edition, december 2016 all rights reserved. Any reprinting or unauthorized use without the written permission of yamaha motor corporation, u.S.A. Is expressly prohibited. Lit-19616-02-37.

Page 4

Important this manual was produced by the yamaha motor powered products co., ltd. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on...

Page 5

How to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. • the manual is divided int...

Page 6

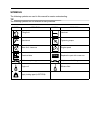

Symbols the following symbols are used in this manual for easier understanding. Tip the following symbols are not relevant to every machine. Symbol definition symbol definition filling fluid lubricant special tool tightening torque wear limit, clearance engine speed electrical data replace the part ...

Page 7

General information periodic checks and adjustments engine fuel electrical troubleshooting specifications 1 2 3 4 5 6 7 8 9 10 index.

Page 8

Memo.

Page 9

Table of contents general information machine identification ......................1-1 serial number .................................1-1 starting serial number...............1-1 dimensions .............................................1-2 top .......................................................1-...

Page 10

Cylinder head covers, cylinder heads......................................................3-20 cylinder head #1 ..........................3-20 cylinder head #2 ..........................3-22 checking the rocker arms and rocker arm shafts.............3-24 checking the push rods ...........3-24 removi...

Page 11

Fuel injectors and intake manifold .................................................4-9 removing the fuel injectors ........................................4-11 installing the fuel injectors ........................................4-12 removing the manifold absolute pressure sensor ....4-14 installi...

Page 12

General torque specifications ....................................7-10 lubrication points and type of lubricants...........................................7-11 wire routing diagram .....................7-12 upper side view.............................7-12 left side view ................................

Page 13

1 2 3 4 5 6 7 8 9 10 gener a l in forma t ion 1-1 general information machine identification serial number the serial number is printed on the label “1” affixed to the position of the multi-purpose engine as shown in the illus- tration. Tip • the first four digits identify the model, and the remaini...

Page 14

Dimensions 1-2 1 2 3 4 5 6 7 8 9 10 gen e ral i n for m a t ion dimensions top mounting base *1: unc: unified coarse thread (unit: in) *2: pcd: pitch circle diameter mm (in) mm (in) 157.1(6.19) 499.2(19.65 ) 35 ° 35 ° 45 ° 45 ° pcd 254 4 3/8-16unc.

Page 15

1-3 1 2 3 4 5 6 7 8 9 10 gener a l in forma t ion dimensions rear rear (for models equipped with a muffler) mm (in) mm (in) 463.8(18.26) 231.1(9.1) 463.8(18.26) 445.4(17.54) 231.1(9.1).

Page 16

Dimensions 1-4 1 2 3 4 5 6 7 8 9 10 gen e ral i n for m a t ion right side right side (for models equipped with a muffler) mm (in) mm (in) 416.2(16.39) 1 14.3(4.5) 639(25.16) 416.2(16.39) 639(25.16) 1 16.7(4.59).

Page 17

1-5 1 2 3 4 5 6 7 8 9 10 gener a l in forma t ion important information important information preparation for removal and disassembly caution on service fire prevention when servicing the engine, always keep the engine and yourself away from fire. Notes on service correct tools be sure to use the co...

Page 18

Important information 1-6 1 2 3 4 5 6 7 8 9 10 gen e ral i n for m a t ion tightening torque be sure to follow torque specifications. When tightening bolts, nuts or screws, start with the largest-diameter fas- tener and work from an inner position to an outer position in a crisscross pattern. Notes ...

Page 19

1-7 1 2 3 4 5 6 7 8 9 10 gener a l in forma t ion basic service information bearings and oil seals install the bearing(s) “1” and oil seal(s) “2” with their manu- facture’s marks or numbers facing outward. (in other words, the stamped letters must be on the side exposed to view.) when installing oil...

Page 20

Basic service information 1-8 1 2 3 4 5 6 7 8 9 10 gen e ral i n for m a t ion checking the connections check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: • lead • coupler • connector 2. Check: • lead • coupler • connector moisture dry with an air blower. Rust/...

Page 21

1-9 1 2 3 4 5 6 7 8 9 10 gener a l in forma t ion basic service information 3. Connect: • lead • coupler • connector tip • when connecting a coupler or connector, push both sec- tions of the coupler or connector together until they are connected securely. • make sure all connections are tight. 4. Ch...

Page 22

Basic service information 1-10 1 2 3 4 5 6 7 8 9 10 gen e ral i n for m a t ion 5. Check: • resistance tip the resistance values shown were obtained at the stan- dard measuring temperature of 20 c (68 f). If the mea- suring temperature is not 20 c (68 f), the specified measuring conditions will be s...

Page 23

1-11 1 2 3 4 5 6 7 8 9 10 gener a l in forma t ion special tools and testers special tools and testers the proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or improvised tech...

Page 24

Special tools and testers 1-12 1 2 3 4 5 6 7 8 9 10 gen e ral i n for m a t ion memo.

Page 25

1 2 3 4 5 6 7 8 9 10 period ic check s an d a d ju stmen t s 2-1 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable machine operati...

Page 26

2-2 1 2 3 4 5 6 7 8 9 10 pe riodic che cks and adjustments periodic maintenance periodic maintenance spark plugs 1. Remove: • spark plug caps “1” • spark plugs 2. Check: • spark plug type not correct replace. • electrode “1” wear/damage replace. • insulator color “2” not normal replace. 3. Measure: ...

Page 27

2-3 1 2 3 4 5 6 7 8 9 10 period ic check s an d a d ju stmen t s periodic maintenance 4. Install: • spark plugs tip to prevent threads from being damaged, temporally tighten “a” the spark plug before tightening it to the speci- fied torque “b”. Muffler (for models equipped with a muffler) 1. Remove:...

Page 28

2-4 1 2 3 4 5 6 7 8 9 10 pe riodic che cks and adjustments periodic maintenance 3. Remove: • muffler (refer to “muffler (for models equipped with a muffler)” on page 3-4) 4. Decarbonize: • muffler tap on the muffler in the area shown in the illustra- tion to loosen carbon buildup, and then shake it ...

Page 29

2-5 1 2 3 4 5 6 7 8 9 10 period ic check s an d a d ju stmen t s periodic maintenance 2. Check the areas outside of the engine for oil leakage. Oil leakage replace the gasket, oil seal, or o-ring. Engine oil level 1. Remove: • oil filler cap “1” 2. Check: • check that engine oil is at the specified ...

Page 30

2-6 1 2 3 4 5 6 7 8 9 10 pe riodic che cks and adjustments periodic maintenance oil warning light comes on add oil. Oil warning light does not comes on ok replacing the engine oil 1. Warm up the engine for several minutes, and then stop the engine. Place the oil pan under the engine. 2. Remove: • oi...

Page 31

2-7 1 2 3 4 5 6 7 8 9 10 period ic check s an d a d ju stmen t s periodic maintenance c. Tighten the new oil filter to specification with an oil filter wrench. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 5. Install: • oil drain bolt gasket “1” • oil drain bolt “2” 6. Fill: • engine oil make sure to fi...

Page 32

2-8 1 2 3 4 5 6 7 8 9 10 pe riodic che cks and adjustments periodic maintenance fuel leakage 1. Check: • leakage check at fuel pump, fuel hose, and throttle body. Fuel filter 1. Remove: • fuel filter 2. Check: • fuel filter damage replace. Dirt/clog clean. Tip clean the fuel filter with clean gasoli...

Page 33

2-9 1 2 3 4 5 6 7 8 9 10 period ic check s an d a d ju stmen t s periodic maintenance oil cooler 1. Check: • oil cooler damage replace. Dirt/clog clean. Air filter element 1. Remove: • dust cap “1” • air filter case cover “2” • air filter element “3” • inner element “4” 2. Check: • air filter elemen...

Page 34

2-10 1 2 3 4 5 6 7 8 9 10 pe riodic che cks and adjustments periodic maintenance 2. Remove: • cylinder head cover “3” • cylinder head cover gasket 3. Remove: • fan case cover “1” (refer to “case and fan” on page 3-11) • grass screen “2” (refer to “case and fan” on page 3-11) 4. Turn the crankshaft c...

Page 35

2-11 1 2 3 4 5 6 7 8 9 10 period ic check s an d a d ju stmen t s periodic maintenance 6. Adjust: • adjust to original set value tip • when adjust valve clearance, record the measured read- ing of current. • measure the valve clearance in the following sequence. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼...

Page 36

2-12 1 2 3 4 5 6 7 8 9 10 pe riodic che cks and adjustments periodic maintenance c. Check the thickness of the current adjusting pad. Tip the thickness of each adjusting pad is indicated in 1/100 mm units “a” and inscribed on the side. Example: if the adjusting pad is marked “180”, the pad thick- ne...

Page 37

2-13 1 2 3 4 5 6 7 8 9 10 period ic check s an d a d ju stmen t s periodic maintenance g. Install the rocker arm “5”. (refer to “cylinder head covers, cylinder heads” on page 3-20) tip • lubricate the rocker arm with engine oil. • turn the crankshaft clockwise several full turns to seat the parts. H...

Page 38

2-14 1 2 3 4 5 6 7 8 9 10 pe riodic che cks and adjustments periodic maintenance engine speed 1. Warm up the engine for several minutes. 2. Connect: • fi diagnostic tool “1” 3. Measure: • high engine speed (with no load) out of specification adjust. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Move ...

Page 39

2-15 1 2 3 4 5 6 7 8 9 10 period ic check s an d a d ju stmen t s periodic maintenance b. Check the low engine speed. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ adjusting the engine speed 1. Warm up the engine for several minutes. 2. Connect: • fi diagnostic tool “1” 3. Adjust: • high engine speed ▼▼...

Page 40

2-16 1 2 3 4 5 6 7 8 9 10 pe riodic che cks and adjustments periodic maintenance ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Move the throttle lever “1” to the low engine speed position “a”. B. Turn the screw “3” in direction “c” or “d” until obtain adequet low engine speed. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲...

Page 41

1 2 3 4 5 6 7 8 9 10 engine 3-1 engine engine inspection measuring the compression pressure the following procedure applies to all of the cylinders. Tip measure the compression pressure after checking and adjusting the valve clearance. 1. Warm up the engine for several minutes. 2. Remove: • spark pl...

Page 42

3-2 1 2 3 4 5 6 7 8 9 10 engine engine inspection ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. If the compression pressure is below the minimum specification, pour a teaspoonful of engine oil into the spark plug hole and measure again. Refer to the following table. B. If the compression pressure is ...

Page 43

3-3 1 2 3 4 5 6 7 8 9 10 engine air filter air filter order job/parts to remove q’ty remarks removing the air filter remove the parts in the order listed. 1 dust cap 1 2 air filter case cover 1 3 air filter element 1 4 inner element 1 5 air filter cover 1 1 6 air filter case stay 1 7 air filter case...

Page 44

3-4 1 2 3 4 5 6 7 8 9 10 engine muffler (for models equipped with a muffler) muffler (for models equipped with a muffler) order job/parts to remove q’ty remarks removing the muffler remove the parts in the order listed. 1 muffler 1 2 spark arrester 1 3 gasket 2 4 o 2 sensor 1 1 2 3 3.5 n ・ m (0.35 k...

Page 45

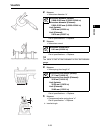

3-5 1 2 3 4 5 6 7 8 9 10 engine oil cooler oil cooler order job/parts to remove q’ty remarks removing the oil cooler remove the parts in the order listed. Engine oil drain. Refer to “replacing the engine oil” on page 2-6. 1 oil cooler 1 2 oil hose 1 1 3 oil hose 2 1 4 oil filter 1 5 adapter union bo...

Page 46

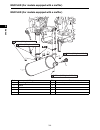

3-6 1 2 3 4 5 6 7 8 9 10 engine oil cooler removing the oil cooler 1. Remove: • hose clamp (clic-r) “1” tip • remove the hose clamp using the hose clamp pliers “2”. • when removing the hose clamp, make sure that the thick tip “a” of the hose clamp pliers is directed as shown in the illustration. 2. ...

Page 47

3-7 1 2 3 4 5 6 7 8 9 10 engine oil cooler tip • make sure the oil seal is positioned properly. • align the projection “a” on the adapter with the hole “b” in the crankcase cover 2. 3. Install: • oil filter • oil hose 2 • oil hose 1 • hose clamp (clic-r) “1” tip • install the hose clamp using the ho...

Page 48

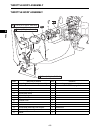

3-8 1 2 3 4 5 6 7 8 9 10 engine ecu, rectifier/regulator, and fuses ecu, rectifier/regulator, and fuses order job/parts to remove q’ty remarks removing the ecu, rectifier/regulator, and fuses remove the parts in the order listed. 1 ecu coupler 2 disconnect. 2 earth terminal 1 3 ecu 1 4 engine hunger...

Page 49

3-9 1 2 3 4 5 6 7 8 9 10 engine ecu, rectifier/regulator, and fuses installing the fuses 1. Install: • 30 a fuse “1” • 10 a fuses “2” 2 1 a for the 30 a fuse “1”, there is identification red tape “a” on the wire harness. Notice.

Page 50

3-10 1 2 3 4 5 6 7 8 9 10 engine ignition coils ignition coils order job/parts to remove q’ty remarks removing the ignition coils remove the parts in the order listed. Air filter case refer to “air filter” on page 3-3. Ecu and rectifier/regulator refer to “ecu, rectifier/regulator, and fuses” on pag...

Page 51

3-11 1 2 3 4 5 6 7 8 9 10 engine case and fan case and fan order job/parts to remove q’ty remarks removing the case and fan remove the parts in the order listed. Air filter case refer to “air filter” on page 3-3. Ecu and rectifier/regulator refer to “ecu, rectifier/regulator, and fuses” on page 3-8....

Page 52

3-12 1 2 3 4 5 6 7 8 9 10 engine case and fan removing the case and fan 1. Remove: • air filter case (refer to “air filter” on page 3-3) 2. Remove: • ecu and rectifier/regulator (refer to “ecu, rectifier/regulator, and fuses” on page 3-8) 3. Remove: • low-pressure fuel pump (refer to “fuel pumps” on...

Page 53

3-13 1 2 3 4 5 6 7 8 9 10 engine case and fan checking the case and fan 1. Check: • fan case cover “1” • grass screen “2” • fan case “3” • fan “4” damage replace. Dirt/clog clean. Installing the case and fan 1. Install: • fan “1” • fan bolts • fan case “2” • fan case bolts • grass screen “3” • grass...

Page 54

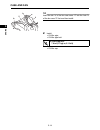

3-14 1 2 3 4 5 6 7 8 9 10 engine case and fan tip insert the tab “a” of the fan case cover “4” into the hole “b” of the fan case “2” first and then install. 2. Install: • oil filler pipe • oil filler pipe bolt • oil filler cap 2 4 a b a b oil filler pipe bolt: 7 n·m (0.7 kgf·m, 5.1 lb·ft) t r . ..

Page 55

3-15 1 2 3 4 5 6 7 8 9 10 engine flywheel and stator coil assembly flywheel and stator coil assembly order job/parts to remove q’ty remarks removing the flywheel and stator coil assembly remove the parts in the order listed. Air filter case refer to “air filter” on page 3-3. Ecu and rectifier/regula...

Page 56

3-16 1 2 3 4 5 6 7 8 9 10 engine flywheel and stator coil assembly removing the flywheel and stator coil assembly 1. Remove: • air filter case (refer to “air filter” on page 3-3) 2. Remove: • ecu and rectifier/regulator (refer to “ecu, rectifier/regulator, and fuses” on page 3-8) 3. Remove: • low-pr...

Page 57

3-17 1 2 3 4 5 6 7 8 9 10 engine flywheel and stator coil assembly 8. Remove: • flywheel “1” • woodruff key tip • remove the flywheel “1” using the heavy duty puller “2”. • fully tighten the tool holding bolts, making sure the tool body is parallel with the flywheel. If necessary, one bolt may be ba...

Page 58

3-18 1 2 3 4 5 6 7 8 9 10 engine flywheel and stator coil assembly 3. Install: • washer “1” • flywheel nut “2” tip tighten the flywheel nut “2” using the primary clutch holder “3” to hold the flywheel. 4. Install: • crankshaft position sensor • crankshaft position sensor bolts (refer to “installing ...

Page 59

3-19 1 2 3 4 5 6 7 8 9 10 engine flywheel and stator coil assembly installing the crankshaft position sensor 1. Install: • crankshaft position sensor • crankshaft position sensor bolts 2. Measure: • crankshaft position sensor air gap out of specification adjust. 3. Adjust: • crankshaft position sens...

Page 60

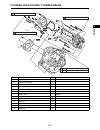

3-20 1 2 3 4 5 6 7 8 9 10 engine cylinder head covers, cylinder heads cylinder head covers, cylinder heads cylinder head #1 order job/parts to remove q’ty remarks removing the cylinder head covers, and cylinder heads remove the parts in the order listed. Air filter case refer to “air filter” on page...

Page 61

3-21 1 2 3 4 5 6 7 8 9 10 engine cylinder head covers, cylinder heads order job/parts to remove q’ty remarks 1 cylinder air shroud 1 2 cylinder head cover 1 3 cylinder head cover gasket 1 4 rocker arm shaft 1 intake 5 rocker arm shaft 1 exhaust 6 rocker arm 1 intake 7 rocker arm 1 exhaust 8 adjustin...

Page 62

3-22 1 2 3 4 5 6 7 8 9 10 engine cylinder head covers, cylinder heads cylinder head #2 order job/parts to remove q’ty remarks removing the cylinder head covers, and cylinder heads remove the parts in the order listed. Air filter case refer to “air filter” on page 3-3. Ecu, rectifier/regulator and fu...

Page 63

3-23 1 2 3 4 5 6 7 8 9 10 engine cylinder head covers, cylinder heads order job/parts to remove q’ty remarks 1 engine hunger 1 for maintenance. 2 cylinder air shroud 1 3 cylinder head cover 1 4 cylinder head cover gasket 1 5 rocker arm shaft 1 intake 6 rocker arm shaft 1 exhaust 7 rocker arm 1 intak...

Page 64

3-24 1 2 3 4 5 6 7 8 9 10 engine cylinder head covers, cylinder heads checking the rocker arms and rocker arm shafts the following procedure applies to all of the rocker arms and rocker arm shafts. 1. Check: • rocker arm “1” • rocker arm shaft “2” wear/damage/cracks replace. Checking the push rods t...

Page 65

3-25 1 2 3 4 5 6 7 8 9 10 engine cylinder head covers, cylinder heads 1. Check: • cylinder head combustion chamber check the combustion chamber for carbon depos- its. Any carbon deposits eliminate. Tip be sure not to damage the sealing surface of the cylinder head. 2. Check: • cylinder head cracks/d...

Page 66

3-26 1 2 3 4 5 6 7 8 9 10 engine cylinder head covers, cylinder heads cylinder head bolt: 1st: 12 n·m (1.2 kgf·m, 8.7 lb·ft) 2nd: 50 n·m (5.0 kgf·m, 36 lb·ft) t r . ..

Page 67

3-27 1 2 3 4 5 6 7 8 9 10 engine valves valves order job/parts to remove q’ty remarks removing the valves remove the parts in the order listed. The following procedure applies to both cylin- ders. Cylinder head assembly refer to “cylinder head covers, cyl- inder heads” on page 3-20. 1 valve cotter 3...

Page 68

3-28 1 2 3 4 5 6 7 8 9 10 engine valves removing the valves and valve springs the following procedure applies to all of the valves, valve springs and related components. 1. Remove: • valve cotter “1” • valve spring retainer “2” • valve spring “3” • valve stem seal “4” • valve spring seat “5” • valve...

Page 69

3-29 1 2 3 4 5 6 7 8 9 10 engine valves 2. Measure: • valve stem diameter “a” out of specifications replace. 3. Measure: • valve stem runout out of specifications replace. Tip the value is half of that indicated on the dial indicator gauge. 4. Measure: • valve spring free length “a” out of specifica...

Page 70

3-30 1 2 3 4 5 6 7 8 9 10 engine valves 6. Measure: • valve spring tilt “a” out of specifications replace. 7. Check: • valve spring contact surface “a” more than 2/3 of the contact surface does not con- tact replace. Checking the valve seats the following procedure applies to all of the valves and v...

Page 71

3-31 1 2 3 4 5 6 7 8 9 10 engine valves 4. Measure: • valve face contact width “a” make sure that the contact width along the entire valve face is within specifications. Out of specification/rough/eccentric wear replace. 5. Measure: • valve seat contact width “a” make sure that the contact width alo...

Page 72

3-32 1 2 3 4 5 6 7 8 9 10 engine valves 3. Once the contacting surface of the valve face is pol- ished and becomes shiny, apply mechanic’s blue lay- out fluid to make sure that there are traces of even contact in the center of the valve face. Tip after every lapping procedure, clean off the compound...

Page 73

3-33 1 2 3 4 5 6 7 8 9 10 engine oil pump oil pump order job/parts to remove q’ty remarks removing the oil pump remove the parts in the order listed. Cylinder head assembly refer to “cylinder head covers, cyl- inder heads” on page 3-20. 1 collar 1 2 crankcase cover 2 1 3 dowel pin 2 4 relief valve 1...

Page 74

3-34 1 2 3 4 5 6 7 8 9 10 engine oil pump disassembling the oil pump 1. Remove: • crankcase cover 2 2. Remove: • relief valve “1” 3. Remove: • oil pump cover “1” 4. Remove: • oil strainer cover “1” • oil strainer “2” • inner rotor “3” • outer rotor “4” checking the oil pump 1. Check: • inner rotor “...

Page 75

3-35 1 2 3 4 5 6 7 8 9 10 engine oil pump 3. Measure: • inner-rotor-to-outer-rotor-tip clearance “a” and “b” out of specification replace the defective part(s). 4. Check: • oil pump operation rough movement replace the defective part(s). Checking the relief valve 1. Check: • relief valve damage/wear...

Page 76

3-36 1 2 3 4 5 6 7 8 9 10 engine oil pump with the crankcase cover 2, apply loctite®, and tighten to the specified torque. Assembling the oil pump 1. Lubricate: • inner rotor • outer rotor 2. Install: • outer rotor “1” • inner rotor “2” • oil strainer “3” • oil strainer cover “4” tip face portion “a...

Page 77

3-37 1 2 3 4 5 6 7 8 9 10 engine oil pump installing the crankcase cover 2 1. Clean: • mating surfaces of the crankcase and the crank- case cover 2 (with a cloth dampened with lacquer thinner) 2. Apply: • sealant (onto the crankcase cover 2 mating surfaces) 3. Install: • crankcase cover 2 tip align ...

Page 78

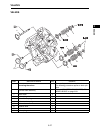

3-38 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft pistons, camshaft, crankcase, and crankshaft crankcase order job/parts to remove q’ty remarks removing the crankcase remove the parts in the order listed. Cylinder head assembly refer to “cylinder head covers, cyl- inder h...

Page 79

3-39 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft order job/parts to remove q’ty remarks 12 cover 1 1 13 dowel pin 2 14 reed valve 1 15 engine temperature sensor 1 16 oil seal 1 12 13 14 15 16 (8) (5) (5) 9 n ・ m (0.9 kgf ・ m, 6.5 lb ・ ft) 10 n ・ m (1.0 kgf ・ m, 7.2 lb ・ ...

Page 80

3-40 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft pistons, camshaft, and crankshaft order job/parts to remove q’ty remarks removing the pistons, camshaft, and crankshaft remove the parts in the order listed. 1 camshaft 1 2 valve lifter 4 3 connecting rod cap 2 4 crankshaf...

Page 81

3-41 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft removing the flyweight shaft assembly and governor fork 1. Remove: • crankcase cover 1 • governor assembly 2. Remove: • clips “1” • governor fork “2” • washers “3” 3. Remove: • flyweight shaft assembly “1” • washer “2” tip...

Page 82

3-42 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft 2. Check: • weight • flyweight shaft • collar • washer • weight shaft wear/damage replace. Assembling the flyweight shaft assembly 1. Install: • weight shaft “1” • circlip “2” • washer “3” • collar “4” • weights “5” • flyw...

Page 83

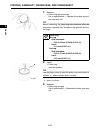

3-43 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft (refer to “installing the throttle body assembly” on page 4-7) removing the camshaft and valve lifters the following procedure applies to all of the camshaft and valve lifters. 1. Remove: • camshaft “1” tip remove the cams...

Page 84

3-44 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft 2. Check: • camshaft lobe dimensions “a” and “b” out of specification replace. 3. Check: • surface of camshaft gear teeth crack/damage/wear replace. 4. Check: • camshaft journal diameter “a” out of specification replace. C...

Page 85

3-45 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft 1. Check: • valve lifter damage replace. Checking the reed valve 1. Check: • reed valve damage replace. Installing the valve lifters and camshaft the following procedure applies to all of the camshaft and valve lifters. 1....

Page 86

3-46 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft 2. Apply: • sealant (onto the crankcase mating surfaces) 3. Install: • cover 1 • cover 1 bolts “1” to “5” tip tighten the bolts to the specified torque in order from “1” to “5”. Installing the cover 2 1. Install: • gasket ...

Page 87

3-47 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft installing the crankcase cover 1 1. Install: • crankcase cover 1 • crankcase cover 1 bolts “1” to “8” tip tighten the bolts to the specified torque in two steps and in order from “1” to “8”. Checking the cylinders and pist...

Page 88

3-48 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft tip measure cylinder bore “c” by taking side-to-side and front- to-back measurements of the cylinder. B. If out of specification, replace the crankcase assembly, and replace the piston and piston rings as a set. C. Measure...

Page 89

3-49 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft checking the crankcase 1. Check: • crankcase damage replace. • bearing noise/wear/rotational failure replace. Checking the piston pins the following procedure applies to all of the piston pins. 1. Check: • piston pin blue ...

Page 90

3-50 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft 1. Measure: • piston ring side clearance out of specification replace the piston and pis- ton rings as a set. Tip before measuring the piston ring side clearance, eliminate any carbon deposits from the piston ring grooves ...

Page 91

3-51 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft checking the crankshaft 1. Check: • crankshaft sprocket “1” damage/wear replace the crankshaft. 2. Measure: • crankshaft runout limit out of specification replace. Use a dial indicator gauge. 3. Measure: • crank pin outsid...

Page 92

3-52 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft checking the connecting rods oil clearance the following procedure applies to all of the connecting rods. Tip measure the oil clearance if replacing the crankshaft or connecting rod. 1. Place a piece of plastigauge® “1” on...

Page 93

3-53 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft rings and related components. 1. Install: • top ring “1” • 2nd ring “2” • oil ring “3” tip • be sure to install the top ring so that the “r” mark “a” faces toward the piston head. • be sure to install the 2nd ring so that ...

Page 94

3-54 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft installing the crankshaft 1. Make sure that the end gap of each piston ring is positioned correctly, as shown in the illustration. 2. Install: • piston with the connecting rod “1” 3. Attach: • piston ring compressor “1” ti...

Page 95

3-55 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft 5. Check: • piston #2 with the connecting rod #2 “1” position. Tip • make sure that the “ ” mark “a” on the piston #2 head faces toward the flywheel. • make sure that the “yamaha” mark “b” on the connect- ing rod #2 faces ...

Page 96

3-56 1 2 3 4 5 6 7 8 9 10 engine pistons, camshaft, crankcase, and crankshaft 8. Install: • connecting rod cap #2 “1” • connecting rod cap #2 bolts “2” tip • make sure that the “ ” mark “a” on the connecting rod #2 is aligned with the “ ” mark “b” on the connecting rod cap #2. • tighten the connecti...

Page 97

1 2 3 4 5 6 7 8 9 10 fuel 4-1 fuel fuel pumps order job/parts to remove q’ty remarks removing the fuel pumps remove the parts in the order listed. 1 fuel filter 1 2 fuel hose 1 3 low-pressure fuel pump 1 4 fuel pump bracket 1 5 fuel injector pipe 1 1 disconnect. 6 purge hose 2 1 disconnect. 7 high-p...

Page 98

4-2 1 2 3 4 5 6 7 8 9 10 fu el fuel pumps removing the high-pressure fuel pump 1. Disconnect: • fuel injector pipe 1 “1” tip • to remove the fuel injector pipe 1 from the high-pressure fuel pump joint, press the two buttons “2” on the sides of the connector, and then remove the pipe. • before removi...

Page 99

4-3 1 2 3 4 5 6 7 8 9 10 fuel fuel pumps checking the low-pressure fuel pump 1. Check: • fuel hose “1” • fuel delivery hose “2” • pulsar hose “3” • low-pressure fuel pump “4” cracks/damage replace. 2. Check: • low-pressure fuel pump operation ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Connect the ...

Page 100

4-4 1 2 3 4 5 6 7 8 9 10 fu el fuel pumps b. Connect the fuel pressure gauge “2” and fuel pres- sure adapter “3” to the fuel injector pipe 1. C. Start the engine. D. Measure the fuel pressure. Faulty replace the fuel pump. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ installing the high-pressure fuel p...

Page 101

4-5 1 2 3 4 5 6 7 8 9 10 fuel fuel pumps sure fuel pump joint until a distinct “click” is heard..

Page 102

4-6 1 2 3 4 5 6 7 8 9 10 fu el throttle body assembly throttle body assembly order job/parts to remove q’ty remarks removing the throttle body assembly remove the parts in the order listed. Air filter case refer to “air filter” on page 3-3. 1 governor spring 1 2 governor assembly 1 3 throttle lever ...

Page 103

4-7 1 2 3 4 5 6 7 8 9 10 fuel throttle body assembly removing the throttle body assembly 1. Remove: • governor spring • governor assembly • throttle lever comp • link rod/spring 2. Remove: • stay “1” • breather hose “2” • joint 1 “3” • throttle body assembly “4” • gaskets “5” checking the throttle b...

Page 104

4-8 1 2 3 4 5 6 7 8 9 10 fu el throttle body assembly 2. Install: • link rod/spring • throttle lever comp • governor assembly • governor spring “1” tip • install the bending portion (short) “a” of the governor spring “1” into the hole “c” of the throttle lever comp while installing the bending porti...

Page 105

4-9 1 2 3 4 5 6 7 8 9 10 fuel fuel injectors and intake manifold fuel injectors and intake manifold order job/parts to remove q’ty remarks removing the fuel injectors and intake manifold remove the parts in the order listed. Air filter case refer to “air filter” on page 3-3. Ecu and rectifier/regula...

Page 106

4-10 1 2 3 4 5 6 7 8 9 10 fu el fuel injectors and intake manifold order job/parts to remove q’ty remarks 4 manifold absolute pressure sensor lead coupler 1 disconnect. 5 fuel injector pipe 1 1 6 fuel injector pipe 2 1 7 inlet pipe 1 1 8 inlet pipe 2 1 9 fuel injector #1 1 10 fuel injector #2 1 11 i...

Page 107

4-11 1 2 3 4 5 6 7 8 9 10 fuel fuel injectors and intake manifold removing the fuel injectors the following procedure applies to all of the fuel injectors and related components. 1. Remove: • air filter case (refer to “air filter” on page 3-3) • ecu and rectifier/regulator (refer to “ecu, rectifier/...

Page 108

4-12 1 2 3 4 5 6 7 8 9 10 fu el fuel injectors and intake manifold 4. Remove: • fuel injector tip remove the fuel injector “1” with the inlet pipe “2” installed. 5. Remove: • inlet pipe tip after removing the retainer “1”, remove the inlet pipe “2” from the fuel injector. 6. Check: • fuel injectors ...

Page 109

4-13 1 2 3 4 5 6 7 8 9 10 fuel fuel injectors and intake manifold 2. Install: • retainer “1” tip engage the claw “a” of the retainer with the projection “b” on the fuel injector, and install to the fuel injector. 3. Install: • fuel injector tip engage the projection “a” on the fuel injector with the...

Page 110

4-14 1 2 3 4 5 6 7 8 9 10 fu el fuel injectors and intake manifold • ecu and rectifier/regulator (refer to “ecu, rectifier/regulator, and fuses” on page 3-8) • air filter case (refer to “air filter” on page 3-3) removing the manifold absolute pressure sensor 1. Disconnect: • manifold absolute pressu...

Page 111

4-15 1 2 3 4 5 6 7 8 9 10 fuel fuel injectors and intake manifold 2. Remove: • intake manifold “1” • intake manifold joints “2” • gaskets “3” checking the intake manifold 1. Check: • intake manifold • intake manifold joints cracks/damage replace. Installing the intake manifold 1. Install: • gaskets ...

Page 112

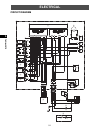

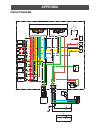

5-1 1 2 3 4 5 6 7 8 9 10 electrical electrical circuit diagram w/r y v br 250Ω led (b) (gy) r/l w g br/g l g y b g br b v r w/b b l y b/w b l/w p/l w/b w g/w l/w g br p/l b g/y o g/r gy r b gy r/l b g/r b o r b/w b g r gy b g/y br g/w r/w r/w b b r b r w w y l/o y/l l/o r r y/l r/y r/y r/y r/y r/y r...

Page 113

5-2 1 2 3 4 5 6 7 8 9 10 electrical circuit diagram color code 1. Ecu (engine control unit) 14.Rollover switch 2. Stator coil assembly 15.Fi diagnostic tool coupler 3. Rectifier/regulator 16.Engine temperature sensor 4. Fuse (30 a) 17.Manifold absolute pressure sensor 5. Fuse (10 a) 18.Throttle posi...

Page 114

5-3 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system fuel injection system fi diag tool instructions purpose this fi diagnostic tool is to diagnose electronic fuel injection system used on yamaha mx825v- efi, mx800v-efi and mx775v-efi engines. Functions there are 5 modes in this diag tool. • “c...

Page 115

5-4 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system buttons and leds the “up” button “1”/“down” button “2” 1. The “up”/“down” buttons are used to scroll each mode. 2. The “up”/“down” buttons are used to decide “yes” or “no” to delete history error code in “clear” mode. 3. Reboot fi diagnostic ...

Page 116

5-5 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system operation (buttons and leds) 1. Connect 10.Select 2. Connected 11.Current 3. Change mode 12.Select 4. (each) mode 13.Current 5. Determine mode 14.Diag 6. Failed 15.History 7. Reboot (up+down) (simultaneously more than 3 seconds) 16.Clear 8. W...

Page 117

5-6 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system details • “current” mode display when there is error display when there is no error • “diag” mode 1. Selected mode 3. Total number of error code 2. Error code 4. Current page number on display 1. Selected mode 2. Message diag code item what t...

Page 118

5-7 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system • “history” mode display when there is error code in the past display there is no error code in the past 1. Selected mode 3. Unit 2. Selected diag code 4. Sensor output 1. Selected mode 3. Total number of error code 2. Error code 4. Current p...

Page 119

5-8 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system • “clear” mode • “property” mode this mode is not needed for usual maintenance. 1. Question: delete? 4. Canceled 2. “down” button: no 5. Deleted 3. “up” button: yes no yes history clean? Deleted history canceled history 3 2 1 5 4.

Page 120

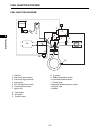

5-9 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system fuel injection diagram 1. Fuel filter 8. O 2 sensor 2. Fuel pump (low pressure) 9. Engine temperature sensor 3. Fuel pump (high pressure) 10.Crankshaft position sensor 4. Fuel injector 11.Throttle body 5. Ecu (engine control unit) 12.Manifold...

Page 121

5-10 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code list error code system or component detail p0107 manifold absolute pressure sensor (map) map circuit low voltage or open p0108 manifold absolute pressure sensor (map) map circuit high voltage p0112 intake air temperature sensor (i...

Page 122

5-11 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system diag code list diag tool mode diag code item what to dis- play unit how to diagnosis diag map manifold absolute pressure sen- sor manifold absolute pressure psi • compare the sensor output value with atmospheric absolute pressure (exam- ple:...

Page 123

5-12 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system fuel injection system troubleshooting error code no. P0107, p0108 error code p0107 system or component manifold absolute pressure sensor (map) detail of error map circuit low voltage or open engine symptoms • poor engine start • poor driveab...

Page 124

5-13 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0112, p0113 error code p0112 system or component intake air temperature sensor (iat) detail of error iat circuit low voltage engine symptoms • poor engine start • poor driveability • deteriorated exhaust • unstable engine idl...

Page 125

5-14 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0117, p0118 error code p0117 system or component engine temperature sensor (et) detail of error engine temperature sensor circuit low voltage engine symptoms • poor engine start • poor driveability • deteriorated exhaust • un...

Page 126

5-15 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0122, p0123 error code p0122 system or component throttle position sensor (tps) detail of error tps circuit low voltage or open engine symptoms • poor engine start (there is possibility it can’t start) • poor driveability • d...

Page 127

5-16 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0131, p0132 error code p0131 system or component oxygen sensor detail of error circuit low voltage engine symptoms deteriorated exhaust engine running availability able to run engine diag tool code mode “diag”, code “o 2 ” di...

Page 128

5-17 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0032, p0031 error code p0032 system or component oxygen sensor heater detail of error heater circuit high voltage engine symptoms deteriorated exhaust (until exhaust gas heated after engine starts) engine running availability...

Page 129

5-18 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0201, p0202 error code p0201 system or component fuel injector detail of error injector #1 circuit malfunction engine symptoms cylinder #1 stops engine running availability able to run with cylinder #2 alone diag tool code — ...

Page 130

5-19 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0230, p0232 error code p0230 system or component fuel pump relay (fpr) detail of error fpr coil circuit low voltage or open engine symptoms • engine stop • unable to start engine engine running availability unable to run engi...

Page 131

5-20 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0336, p0337 error code p0336 system or component crankshaft position sensor (cps) detail of error cps sensor noisy signal engine symptoms • poor engine start (there is possibility it can’t start) • poor driveability • deterio...

Page 132

5-21 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0351, p0352 error code p0351 system or component ignition coil detail of error cylinder #1 ignition coil malfunction engine symptoms cylinder #1 stops operating (injector also stops operating.) engine running availability abl...

Page 133

5-22 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0562, p0563 error code p0562 system or component system voltage detail of error system voltage low engine symptoms • engine stop • unable to start engine engine running availability depends on the case diag tool code — diagno...

Page 134

5-23 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code no. P0171, p0172, p0174 error code p0171 system or component blm maxadapt detail of error correction amount of injection fuel is beyond upper limit engine symptoms • poor engine start (there is possibility it can’t start) • poor d...

Page 135

5-24 1 2 3 4 5 6 7 8 9 10 electrical fuel injection system error code p0174 system or component pe system lean detail of error lean fuel ratio engine symptomes • poor drivability • deteriorated exhaust • unstable engine idling (different idling engine rpm) • overheat • engine knock sound engine runn...

Page 136

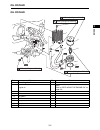

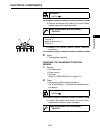

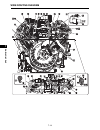

5-25 1 2 3 4 5 6 7 8 9 10 electrical electrical components electrical components 1 2 2 3 4 5 6 6 7 8 9 10 11 12 13 14.

Page 137

5-26 1 2 3 4 5 6 7 8 9 10 electrical electrical components 1. Manifold absolute pressure sensor 2. Fuel injector 3. Engine temperature sensor 4. High-pressure fuel pump 5. Oil pressure switch 6. Ignition coil/spark plug cap 7. Stator coil assembly 8. Rectifier/regulator 9. Crankshaft position sensor...

Page 138

5-27 1 2 3 4 5 6 7 8 9 10 electrical electrical components checking the switch continuity check each switch for continuity with the tester. If the con- tinuity reading is incorrect, check the wiring connections and if necessary, replace the switch. Tip • before checking for continuity, set the digit...

Page 139

5-28 1 2 3 4 5 6 7 8 9 10 electrical electrical components tip set the digital circuit tester selector to “ ”. B. If the digital circuit tester indicates “o.L”, replace the fuse. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Replace: • blown fuse ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Set the m...

Page 140

5-29 1 2 3 4 5 6 7 8 9 10 electrical electrical components 3. Connect: • digital circuit tester (between the engine ground and oil pressure switch terminal) 4. Check: • oil pressure switch continuity no continuity replace the oil pressure switch. Checking manifold absolute pressure sensor 1. Connect...

Page 141

5-30 1 2 3 4 5 6 7 8 9 10 electrical electrical components ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Connect the digital circuit tester ( ) to the throttle position sensor terminals as shown. B. Measure the throttle position sensor maximum resistance. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. ...

Page 142

5-31 1 2 3 4 5 6 7 8 9 10 electrical electrical components b. Measure the crankshaft position sensor resistance. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ checking the engine temperature sensor 1. Remove: • engine temperature sensor 2. Check: • engine temperature sensor resistance out of specificati...

Page 143

5-32 1 2 3 4 5 6 7 8 9 10 electrical electrical components e. Measure the engine temperature sensor resis- tance. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Install: • engine temperature sensor checking the ignition coils the following procedure applies to all of the ignition coils. 1. Check: • pr...

Page 144

5-33 1 2 3 4 5 6 7 8 9 10 electrical electrical components b. Measure the secondary coil resistance. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ checking the ignition spark gap the following procedure applies to all of the ignition coils. 1. Check: • ignition spark gap out of specification perform the...

Page 145

5-34 1 2 3 4 5 6 7 8 9 10 electrical electrical components ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Remove the spark plug cap from the high tension cord. B. Connect the digital circuit tester ( ) to the spark plug cap as shown. C. Measure the spark plug cap resistance. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲...

Page 146

5-35 1 2 3 4 5 6 7 8 9 10 electrical electrical components checking the rectifier/regulator 1. Check: • rectifier/regulator output voltage out of specification replace the rectifier/regula- tor. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Connect fi diagnostic tool. B. Connect the digital circuit t...

Page 147

5-36 1 2 3 4 5 6 7 8 9 10 electrical electrical components c. Measure the fuel injector resistance. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ checking the starter motor operation 1. Check: • starter motor operation does not operate perform the electric starting system troubleshooting, starting with ...

Page 148

5-37 1 2 3 4 5 6 7 8 9 10 electrical electric starting system electric starting system removing the starter motor order job/parts to remove q’ty remarks removing the starter motor remove the parts in the order listed. 1 starter relay terminals 1 disconnect. 2 earth terminal 1 disconnect. 3 starter m...

Page 149

5-38 1 2 3 4 5 6 7 8 9 10 electrical electric starting system disassembling the starter motor order job/parts to remove q’ty remarks disassembling the starter motor disassemble the parts in the order listed. 1 rear bracket 1 2 insulator 1 3 brush spring 4 4 brush 4 5 yoke 1 6 armature 1 7 starter re...

Page 150

5-39 1 2 3 4 5 6 7 8 9 10 electrical electric starting system checking the armature coil 1. Check: • commutator (outer surface) dirty clean it with #600 grit sandpaper. 2. Measure: • mica (insulation depth between the commutator segments) out of specification scrape the mica to the proper measuremen...

Page 151

5-40 1 2 3 4 5 6 7 8 9 10 electrical electric starting system checking the brush 1. Measure: • brush length (of each brush) “1” out of specification replace. 2. Check: • brush spring “2” fatigue/damage replace. Checking the starter relay 1. Measure: • magnetic switch coil resistance connect the digi...

Page 152

5-41 1 2 3 4 5 6 7 8 9 10 electrical electric starting system 2. Install: • armature and starter drive lever “1” 3. Install: • starter relay “1” 1 1 starter relay nut: 11 n·m (1.1 kgf·m, 8.0 lb·ft) t r . ..

Page 153

1 2 3 4 5 6 7 8 9 10 tr oubl eshoo t ing 6-1 troubleshooting engine does not start ignition system the ignition system fails to operate (no spark or intermittent spark). No. Checking steps possible remedy 1 check the fuses. (refer to “checking the fuses” on page 5-27) replace the fuse(s). 2 check th...

Page 154

6-2 1 2 3 4 5 6 7 8 9 10 tr oublesh oo tin g engine does not start electric starting system the starter motor fails to turn. Fuel injection system (refer to “fuel injection system” on page 5-3) fuel pump system if the high-pressure fuel pump fails to operate. No. Checking steps possible remedy 1 che...

Page 155

6-3 1 2 3 4 5 6 7 8 9 10 tr oubl eshoo t ing other troubles other troubles engine starts but stalls no. Checking steps possible remedy 1 check the fuel level. Add the fuel if it is insufficient. 2 check if the fuel filter is clogged. Clean or replace. 3 check if the fuel hoses is clogged. Clean. 4 c...

Page 156

6-4 1 2 3 4 5 6 7 8 9 10 tr oublesh oo tin g other troubles engine speed does not increase no. Checking steps possible remedy 1 check the spark plugs for dirt and check the spark plug gap. Clean, adjust, or replace the spark plugs. 2 check the air filter element for dirt. Replace the air filter elem...

Page 157

6-5 1 2 3 4 5 6 7 8 9 10 tr oubl eshoo t ing other troubles engine speed is uneven the battery is not charged no. Checking steps possible remedy 1 check the fuel level. Add the fuel if it is insufficient. 2 check if fuel has deteriorated. Replace the fuel. 3 check the spark plugs for dirt and check ...

Page 158

6-6 1 2 3 4 5 6 7 8 9 10 tr oublesh oo tin g oil pressure system governor operation oil pressure system if the oil pressure switch fails to operate. No. Checking steps possible remedy 1 check that the governor link operate smoothly. Adjust or replace. 2 check that the governor spring is stretched. R...

Page 159

1 2 3 4 5 6 7 8 9 10 s pecific a t io ns 7-1 specifications general specifications model: mx775 (7u2j) mx800 (7u1j) mx825 (7udj) dimensions: overall length 499 mm (19.65 in) overall width 463 mm (18.23 in) overall height 639 mm (25.16 in) dry weight 60 kg (132 lb) engine: engine type air cooled 4-st...

Page 160

7-2 1 2 3 4 5 6 7 8 9 10 specifica t ions general specifications ***** * yamaha engine has been designed to use regular unleaded gasoline with a pump octane number ((r+m)/2) of 86 or higher, or research octane number of 91 or higher. Gasohol containing ethanol can be used if the ethanol content does...

Page 161

7-3 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns maintenance specifications maintenance specifications engine piston: piston-to-cylinder clearance 0.033–0.047 mm (0.0013–0.0019 in) limit 0.15 mm (0.0059 in) piston diameter 79.959–79.980 mm (3.1480–3.1488 in) limit 79.900 mm (3.1457 in) measuring point (...

Page 162

7-4 1 2 3 4 5 6 7 8 9 10 specifica t ions maintenance specifications crankshaft: big end side clearance 0.20–0.65 mm (0.0079–0.0256 in) runout limit 0.03 mm (0.0012 in) crank pin outside diameter 40.950–41.050 mm (1.6122–1.6161 in) connecting rod: small end diameter 19.006–19.020 mm (0.7483–0.7488 i...

Page 163

7-5 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns maintenance specifications limit (intake) 1.6 mm (0.063 in) limit (exhaust) 1.6 mm (0.063 in) valve stem runout limit 0.01 mm (0.0004 in) valve guide guide inside diameter (intake) 6.000–6.012 mm (0.2362–0.2367 in) guide inside diameter (exhaust) 6.000–6....

Page 164

7-6 1 2 3 4 5 6 7 8 9 10 specifica t ions maintenance specifications fuel line pressure (at idle) 255–285 kpa (2.55–2.85 kgf/cm², 36.98–41.33 psi) fuel injector: resistance 11.4–12.6 oil pump: inner-rotor-to-outer-rotor-tip clearance 0.19–0.35 mm (0.008–0.013 in) relief valve operating pressure 342–...

Page 165

7-7 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns maintenance specifications electrical ignition coil: primary coil resistance 0.44–0.66 secondary coil resistance 5.6–8.4 k spark plug cap resistance 3.75–6.25 k crankshaft position sensor air gap 0.5–1.5 mm (0.02–0.06 in) minimum ignition spark gap 6.0 mm...

Page 166

7-8 1 2 3 4 5 6 7 8 9 10 specifica t ions tightening torques tightening torques item thread size tightening torque spark plug m14s 1.25 20 n·m (2.0 kgf·m, 14 lb·ft) spark arrester screw — 3.5 n·m (0.35 kgf·m, 2.5 lb·ft) oil filter — 14 n·m (1.4 kgf·m, 10 lb·ft) oil drain bolt m12 1.5 27 n·m (2.7 kgf...

Page 167

7-9 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns tightening torques engine temperature sensor m10 1.5 12 n·m (1.2 kgf·m, 8.7 lb·ft) reed valve m6 1.0 10 n·m (1.0 kgf·m, 7.2 lb·ft) scroll air shroud bolt m6 1.0 7 n·m (0.7 kgf·m, 5.1 lb·ft) low-pressure fuel pump bolt m6 1.0 7 n·m (0.7 kgf·m, 5.1 lb·ft) h...

Page 168

7-10 1 2 3 4 5 6 7 8 9 10 specifica t ions general torque specifications general torque specifications this chart specifies torque for standard fasteners with standard i.S.O. Pitch threads. Torque specifi- cations for special components or assemblies are included in the applicable sections of this b...

Page 169

7-11 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns lubrication points and type of lubricants lubrication points and type of lubricants part name type of lubricant oil seal lip oil hose 1, 2 governor fork oil seal lip bearing connecting rod big end crank pin crankshaft journal connecting rod cap bolt pist...

Page 170

7-12 1 2 3 4 5 6 7 8 9 10 specifica t ions wire routing diagram wire routing diagram upper side view.

Page 171

7-13 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns wire routing diagram 1. Hose clamp 8. Wire harness 2. Inlet pipe 2 9. Purge hose 2 3. Fuel injector #2 10.3 way joint 4. Fuel injector pipe 2 11.Purge hose 1 5. Fuel injector #1 12.Plastic locking tie 6. Inlet pipe 1 13.Fuel injector pipe 1 7. High-press...

Page 172

7-14 1 2 3 4 5 6 7 8 9 10 specifica t ions wire routing diagram.

Page 173

7-15 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns wire routing diagram 1. Crankshaft position sensor 12.Fuel injector #2 coupler 2. Ignition coil #2 13.Manifold absolute pressure sensor lead 3. Throttle position sensor lead 14.Ignition coil #2 coupler 4. Engine temperature sensor lead 15.Fuel injector #...

Page 174

7-16 1 2 3 4 5 6 7 8 9 10 specifica t ions wire routing diagram left side view.

Page 175

7-17 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns wire routing diagram 1. Rectifier/regulator 15.Fuse (10 a) coupler 2. Earth terminal 16.Fuse (30 a) coupler 3. Ecu 17.Starter motor 4. Ecu coupler (black) 18.Plastic locking tie 5. Ecu coupler (gray) 19.Throttle body 6. Fuel injector #1 lead 20.Throttle ...

Page 176

7-18 1 2 3 4 5 6 7 8 9 10 specifica t ions wire routing diagram right side view.

Page 177

7-19 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns wire routing diagram 1. Hose clamp 7. Fuel filter 2. Low-pressure fuel pump 8. Plastic locking tie 3. Fuel delivery hose 9. Lead 1 4. Fuel injector pipe 1 10.Purge hose 1 5. Fuel hose 11.Pulsar hose 6. High-pressure fuel pump a. • install the air filter ...

Page 178

7-20 1 2 3 4 5 6 7 8 9 10 specifica t ions wire routing diagram 1. Oil hose 1 4. Oil hose 2 2. Oil cooler 5. Oil filter 3. Hose clamp a. Insert the oil hose all the way into the oil cooler. B. Face the projection inward. C. Install the white painted portion in the direction shown in the illustration...

Page 179

7-21 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns wire routing diagram 1. Fuel injector #2 lead 5. High-pressure fuel pump coupler 2. Ignition coil #2 lead 6. Oil pressure switch 3. High-pressure fuel pump lead 7. Oil pressure switch lead 4. Purge hose 8. Spark plug cap a. The high-pressure fuel pump co...

Page 180

7-22 1 2 3 4 5 6 7 8 9 10 specifica t ions wire routing diagram rear side view.

Page 181

7-23 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns wire routing diagram 1. Air filter cover 1 4. Joint 2 2. Air filter case stay 5. Air filter case 3. Breather hose a. Install the air filter case stay into the groove in the air filter case. B. Install the screw in the direction shown in the illustration....

Page 182

7-24 1 2 3 4 5 6 7 8 9 10 specifica t ions wire routing diagram 1. Manifold absolute pressure sensor coupler 5. Plastic locking tie 2. Manifold absolute pressure sensor 6. Inlet manifold 3. Clamp 7. Ignition coil #1 lead 4. O 2 sensor coupler 8. Fuel injector #1 lead a. Fi diagnostic tool coupler b....

Page 183

7-25 1 2 3 4 5 6 7 8 9 10 s pecific a t io ns wire routing diagram memo.

Page 184

Appendix circuit diagram w/r y v br 250Ω led (b) (gy) r/l w g br/g l g y b g br b v r w/b b l y b/w b l/w p/l w/b w g/w l/w g br p/l b g/y o g/r gy r b gy r/l b g/r b o r b/w b g r gy b g/y br g/w r/w r/w b b r b r w w y l/o y/l l/o r r y/l r/y r/y r/y r/y r/y r/y r/y r/y r/y 30a 1 0a 10a off on st ...

Page 185

Color code 1. Ecu (engine control unit) 14.Rollover switch 2. Stator coil assembly 15.Fi diagnostic tool coupler 3. Rectifier/regulator 16.Engine temperature sensor 4. Fuse (30 a) 17.Manifold absolute pressure sensor 5. Fuse (10 a) 18.Throttle position sensor 6. Fuse (10 a) 19.O 2 sensor 7. Oil pres...

Page 186

Memo.

Page 187

7ud-f8197-e0_cover.Indd 2 2016/12/13 11:23:58.

Page 188: Mx775

Service manual mx775 mx800 mx825 7ud-f8197-e0 lit-19616-02-37 2016.12×1 ! 7ud-f8197-e0_cover.Indd 1 2016/12/13 11:23:58.