- DL manuals

- Yamaha

- Snowmobiles

- PZ50FXW

- Service Manual

Yamaha PZ50FXW Service Manual

Yamaha Service Manual

Arranged by CycleHippie

The best Service Manuals have been CycleHippied!

Over 30 Years of Powersports Industy Experience goes

into the arrangement of the official

Yamaha Factory Service Data.

If you obtained this manual from a source other than

CycleHippie, It may not have been properly CycleHippied!

Summary of PZ50FXW

Page 1

Yamaha service manual arranged by cyclehippie www,cyclehippie.Com the best service manuals have been cyclehippied! Over 30 years of powersports industy experience goes into the arrangement of the official yamaha factory service data. If you obtained this manual from a source other than cyclehippie, ...

Page 2: Service Manual

Service manual pz50w pz50gtw pz50fxw pz50mw pz50vtw pz50mpw lit-12618-02-58 8gc-28197-10 printed on recycled paper printed in u.S.A. 2006.07 cr (e) yamaha motor co., ltd. Cover_smb.Fm page 1 thursday, july 27, 2006 9:56 am.

Page 3: Notice

Notice this manual was written by the yamaha motor company primarily for use by yamaha dealers and their qualified mechanics. It is not possible to put an entire mechanic’s education into one manual, so it is assumed that persons using this book to perform maintenance and repairs on yamaha snowmobil...

Page 4: Gen

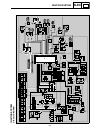

Illustrated symbols (refer to the illustration) illustrated symbols 1 to 9 are designed as thumb tabs to indicate the chapter’s number and content. 1 general information 2 periodic inspection and adjustment 3 chassis 4 power train 5 engine 6 cooling system 7 fuel injection system 8 electrical 9 spec...

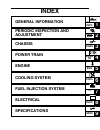

Page 5: Index

Index general information gen info 1 periodic inspection and adjustment insp adj 2 chassis chas 3 power train powr tr 4 engine eng 5 cooling system cool 6 fuel injection system fi 7 electrical elec 8 specifications spec 9 – +.

Page 6

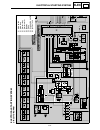

Chapter 1. General information machine identification............................ 1-1 frame serial number ......................... 1-1 engine serial number........................ 1-1 important information .......................... 1-2 preparation for removal and disassembly..........................

Page 7

Pz50vt “europe”/pz50mp....................... 3-15 pz50m ...................................................... 3-16 inspection ............................................ 3-17 front suspension ................................... 3-18 pz50/pz50fx/pz50m............................... 3-18 pz50gt/pz5...

Page 8

Cylinder head........................................... 5-28 removal ................................................ 5-29 inspection ............................................ 5-29 installation ........................................ 5-30 valves and valve springs................... 5-32 removal...

Page 9

Lighting system ....................................... 8-22 circuit diagram.................................. 8-22 troubleshooting.............................. 8-24 bulb(s).................................................... 8-26 headlight beam switch ................... 8-26 headlight relay.........

Page 10: Gen

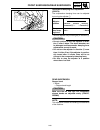

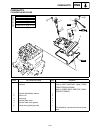

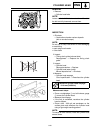

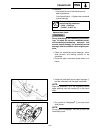

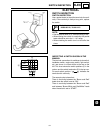

1-1 gen info general information machine identification frame serial number the frame serial number 1 is located on the right-hand side of the frame (just below the front of the seat). Engine serial number the engine serial number 1 is located on the left-hand side of the crank- case. Note: designs ...

Page 11: Gen

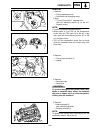

1-2 gen info important information important information preparation for removal and disassembly 1. Remove all dirt, mud, dust, and foreign material before removal and disassembly. While cleaning, take care to protect the electrical parts, such as relays, switches, motor, resistors, controllers, etc...

Page 12: Gen

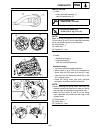

1-3 gen info important information gaskets, oil seals, and o-rings 1. All gaskets, seals, and o-rings should be replaced when an engine is overhauled. All gasket surfaces, oil seal lips, and o-rings must be cleaned. 2. Properly oil all mating parts and bearings during reassembly. Apply grease to the...

Page 13: Gen

1-4 gen info special tools special tools some special tools are necessary for a completely accurate tune-up and assembly. Using the correct special tool will help prevent damage that can be caused by the use of improper tools or improvised techniques. Note: • be sure to use the correct part number w...

Page 14: Gen

1-5 gen info special tools • cooling system tester p/n: yu-24460-01 90890-01325 • adapter p/n: yu-33984 90890-01352 this tester and its adapter are used for checking the cooling system. • oil filter wrench p/n: ym-01469 90890-01469 this tool is needed to loosen or tighten the oil filter cartridge. •...

Page 15: Gen

1-6 gen info special tools • 40 and 50 mm bearing driver p/n: ym-04058 90890-04058 • mechanical seal installer p/n: ym-04145 90890-04145 these tools are used to install the water pump seal. • rotor holding tool p/n: yu-01235 90890-01235 this tool is used to hold the camshaft sprocket. • valve guide ...

Page 16: Gen

1-7 gen info special tools • dynamic spark tester p/n: ym-34487 • ignition checker p/n: 90890-06754 this tool is used to check the ignition system component. • engine mount spacer wrench p/n: ys-01516 90890-01516 used to turn the engine mounting bolts when removing/installing engine. • yamaha bond n...

Page 17: Gen

1-8 gen info special tools • clutch bushing press p/n: ys-42424 this tool is used for removing and installing the post bushings (primary sheave cap bush, sliding sheave bush and torque cam bush). • track clip installer p/n: ys-91045-c 90890-01721 this tool is used for installing the track clip. For ...

Page 18: Gen

1-9 gen info special tools • digital circuit tester p/n: yu-a1927 90890-03174 this instrument is necessary for checking the electrical componenets..

Page 19: Insp

2-1 insp adj periodic inspection and adjustment introduction this chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable machine operation and a longer ser- vice life. In addition,...

Page 20: Insp

2-2 insp adj general maintenance and lubrication chart general maintenance and lubrication chart item remarks pre-opera- tion check (daily) initial 1 month or 800 km (500 mi) (40 hr) every seasonally or 4,000 km (2,500 mi) (200 hr) engine oil check oil level. ∗ replace. ∗ engine oil filter cartridge...

Page 21: Insp

2-3 insp adj general maintenance and lubrication chart note: @ brake system: • after disassembling the master cylinder or caliper cylinder, always change the brake fluid. Regularly check the brake fluid level and add fluid if necessary. • replace the oil seals of the master cylinder and caliper cyli...

Page 22: Insp

2-4 insp adj spark plugs/fuel line inspection engine spark plugs 1. Remove: • fuel tank refer to “seat and fuel tank” in chap- ter 5. (pz50/pz50gt/pz50fx/pz50m) refer to “rider seat and fuel tank” in chapter 5. (pz50vt/pz50mp) 2. Remove: • spark plug caps • spark plugs 3. Inspect: • electrodes 1 dam...

Page 23: Insp

2-5 insp adj cooling system cooling system coolant replacement note: the coolant should be changed at least every sea- son. 1. Place the machine on a level surface. 2. Remove: • right side panel • right side cover refer to “cowlings” in chapter 3. 3. Remove: • coolant filler cap 1 warning do not rem...

Page 24: Insp

2-6 insp adj cooling system 7. Connect: • radiator outlet hose 1 8. Fill: • cooling system caution: • hard water or salt water is harmful to engine parts. If soft water is not available, use boiled or distilled water. • do not use water containing impurities or oil. 9. Bleed the air from the cooling...

Page 25: Insp

2-7 insp adj cooling system/valve clearance adjustment air bleeding steps: • remove the cap 1 on the radiator outlet pipe 1. • while slowly adding coolant to the coolant filler, drain the coolant until no more air bubbles appear. • install the cap 1. • add coolant to the full level a. • install the ...

Page 26: Insp

2-8 insp adj valve clearance adjustment 3. Remove: • cylinder head cover refer to “camshafts” in chapter 5. • timing mark accessing screw 1 • crankshaft end accessing screw 2 4. Measure: • valve clearance out of specification → adjust. Checking steps: • turn the crankshaft counterclockwise. • when p...

Page 27: Insp

2-9 insp adj valve clearance adjustment 5. Remove: • intake camshaft • exhaust camshaft note: • refer to “camshafts” in chapter 5. • when removing the timing chain and camshafts, fasten a wire to the timing chain to retrieve it if it falls into the crankcase. 6. Adjust: • valve clearance adjustment ...

Page 28: Insp

2-10 insp adj valve clearance adjustment example: original valve pad number = 148 (thickness = 1.48 mm (0.058 in)) rounded value = 150 • locate the rounded number of the original valve pad and the measured valve clearance in the valve pad selection table. The point where the column and row intersect...

Page 29: Insp

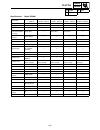

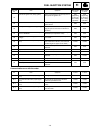

2-11 insp adj valve clearance adjustment valve pad selection table intake exhaust measured clearance ↓ installed pad number 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240 0.00 ~ 0.02 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 ...

Page 30: Insp

2-12 insp adj valve clearance adjustment • install the new valve pad 1 and the valve lifter 2. Note: • apply molybdenum disulfide oil to the valve pad and the valve lifter. • the valve lifter must turn smoothly when rotated by hand. • install the valve lifter and the valve pad in the cor- rect place...

Page 31: Insp

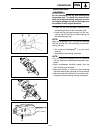

2-13 insp adj throttle body synchronization throttle body synchronization note: prior to synchronizing the throttle bodies, the valve clearance and the engine idle speed should be properly adjusted. 1. Remove: • headlight assembly (pz50/pz50gt/pz50fx/ pz50m) • air filter case assembly refer to “cowl...

Page 32: Insp

2-14 insp adj throttle body synchronization/ engine idle speed adjustment adjustment steps: • synchronize throttle body #1 and throttle body #2 by turning the synchronizing screws 1 in either direction until both gauges read the same. Note: after each step, rev the engine two or three times, each ti...

Page 33: Insp

2-15 insp adj engine idle speed adjustment/ throttle cable free play adjustment 3. Adjust: • engine idle speed adjustment steps: • remove the rubber cap 1. • turn the idle adjusting screw 2 in or out until the specified engine idle speed is obtained. Note: after adjusting the engine idle speed, the ...

Page 34: Insp

2-16 insp adj throttle cable free play adjustment/ throttle override system (t.O.R.S.) check • tighten the locknut. Note: if the specified throttle cable free play cannot be obtained on the throttle body side of the cable, use the adjusting nut on the handlebar side. (pz50/ pz50gt/pz50fx/pz50m) hand...

Page 35: Insp

2-17 insp adj throttle override system (t.O.R.S.) check/ compression pressure measurement warning if the engine does not run between 2,800 and 3,000 r/min, stop the engine by turning the main switch to the “off” position and check the electrical system. Compression pressure measurement note: insuffi...

Page 36: Insp

2-18 insp adj compression pressure measurement 6. Measure: • compression pressure above the maximum pressure → inspect the cylinder head, valve surfaces, and piston crown for carbon deposits. Below the minimum pressure → squirt a few drops of oil into the affected cylinder and measure again. Refer t...

Page 37: Insp

2-19 insp adj engine oil level inspection engine oil level inspection 1. Inspect: • engine oil level caution: do not run the engine with too much or not enough oil in the oil tank. Oil could flow into the air filter and the engine could be damaged. Inspection steps: • place the snowmobile on a level...

Page 38: Insp

2-20 insp adj engine oil level inspection/ engine oil replacement • start the engine, warm it up for several minutes, and then turn it off. • check the engine oil level again. Note: before checking the engine oil level, wait a few minutes until the oil has settled. Caution: • use only 4-stroke engin...

Page 39: Insp

2-21 insp adj engine oil replacement 8. Remove: • cylinder head cap 1 1 9. Remove: • oil pan engine oil drain bolt 1 1 10. Remove: • oil tank engine oil drain bolt 1 11. Drain: • engine oil (completely from the oil pan and oil tank) 12. If the oil filter cartridge is also to be replaced, perform the...

Page 40: Insp

2-22 insp adj engine oil replacement • apply a thin coat of engine oil onto the o-ring 4 of the new oil filter cartridge. Caution: make sure that the o-ring 4 is positioned cor- rectly in the groove of the oil filter cartridge. • tighten the new oil filter cartridge to specifica- tion with an oil fi...

Page 41: Insp

2-23 insp adj engine oil replacement/cylinder head breather hose inspection/throttle body joints inspection 17. Inspect: • engine oil pressure inspection steps: • remove the exhaust pipe joint upper cover. Refer to “exhaust pipe and muffler” in chapter 5. • slightly loosen the oil gallery bolt 1. • ...

Page 42: Insp

2-24 insp adj checking the air filter element 1. Remove: • air filter case cover refer to “cowlings” in chapter 3. 2. Lift up the air filter element frame and remove the air filter element. 3. Clean: • air filter element note: remove the snow. 4. Inspect: • air filter element damage/clogs → replace....

Page 43: Insp

2-25 insp adj exhaust system inspection exhaust system inspection 1. Remove: • fuel tank refer to “seat and fuel tank” in chap- ter 5. (pz50/pz50gt/pz50fx/pz50m) refer to “rider seat and fuel tank” in chapter 5. (pz50vt/pz50mp) 2. Inspect: • exhaust pipe joints 1 • exhaust pipe/muffler assembly 2 • ...

Page 44: Insp

2-26 insp adj sheave offset adjustment power train sheave offset adjustment 1. Remove: • left side panel • left side cover refer to “cowlings” in chapter 3. 2. Remove: • drive v-belt 3. Measure: • sheave offset a use a straightedge that is approximately 470 mm (18.5 in) long, 20 mm (0.79 in) wide, a...

Page 45: Insp

2-27 insp adj sheave offset adjustment • install the secondary sheave, secondary sheave bolt and washer. • recheck the sheave offset. If out of specifica- tion, repeat the above steps. Note: when adjusting the sheave offset, the secondary sheave free play (clearance) should be adjusted. T r . . Seco...

Page 46: Insp

2-28 insp adj drive v-belt drive v-belt warning when installing the new v-belt, make sure that it is positioned from 1.5 mm (0.06 in) above the edge of the secondary sheave to –0.5 mm (–0.02 in) below the edge a. If the v-belt is not positioned correctly, the clutch engagement speed will be changed....

Page 47: Insp

2-29 insp adj engagement speed check/ parking brake adjustment engagement speed check 1. Place the machine on a level surface of hard- packed snow. 2. Inspect: • clutch engagement speed inspection steps: • start the engine, and open the throttle lever gradually. • check the engine speed when the mac...

Page 48: Insp

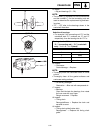

2-30 insp adj parking brake adjustment/ brake fluid level inspection 3. Adjust: • parking brake cable adjustment steps: • loosen the locknut 1. • turn the adjuster 2 in or out until the specified distance a is obtained. • tighten the locknut. Turning in → distance a is increased. Turning out → dista...

Page 49: Insp

2-31 insp adj brake fluid level inspection/ brake pad inspection note: for a correct reading of the brake fluid level, make sure that the top of the handlebar brake master cyl- inder reservoir is horizontal. Caution: brake fluid may corrode painted surfaces or plastic parts. Always clean up spilled ...

Page 50: Insp

2-32 insp adj brake hose inspection/ air bleeding (hydraulic brake system) brake hose inspection 1. Inspect: • brake hose cracks/damage/wear → replace. 2. Check: • fluid leakage apply the brake lever several times. Fluid leakage → replace the defective parts. Air bleeding (hydraulic brake system) wa...

Page 51: Insp

2-33 insp adj air bleeding (hydraulic brake system)/ drive chain j. Tighten the bleed screw. Note: if bleeding is difficult, it may be necessary to let the brake fluid settle for a few hours. Repeat the bleeding procedure when the tiny bub- bles in the system have disappeared. K. Add brake fluid to ...

Page 52: Insp

2-34 insp adj drive chain • remove the dipstick and check that the oil reaches the bottom of the dipstick. If the oil does not reach the bottom of the dipstick, add sufficient oil to raise it to the correct level. Caution: make sure that no foreign material enters the drive chain housing. Recommende...

Page 53: Insp

2-35 insp adj drive chain/track tension adjustment chain slack adjustment 1. Adjust: • drive chain slack adjustment steps: • loosen the locknut 1. • turn the adjusting bolt 2 clockwise until it is fin- ger tight, and then loosen it 1/4 turn. • hold the adjusting bolt 2 in place while tighten- ing th...

Page 54: Insp

2-36 insp adj track tension adjustment 3. Adjust: • track deflection adjustment steps: a. Place the machine onto a suitable stand to raise the track off of the ground. B. Loosen the rear axle nut 1. C. Start the engine and rotate the track once or twice. Stop the engine. D. Check the track alignment...

Page 55: Insp

2-37 insp adj slide runner inspection/ maximizing drive track life slide runner inspection 1. Inspect: • slide runner 1 cracks/damage/wear → replace. 2. Measure: • slide runner wear limit a out of specification → replace. Slide runner wear limit: 10.5 mm (0.41 in) maximizing drive track life recomme...

Page 56: Insp

2-38 insp adj maximizing drive track life off-trail riding avoid off-trail riding until there is sufficient snow coverage. It generally takes several feet of snow to provide a good overall base to properly cover debris, such as rocks, logs, etc. If snow coverage is not sufficient, stay on trails to ...

Page 57: Insp

2-39 insp adj chassis ski/ski runner 1. Inspect: • ski • ski runner damage/wear → replace. • ski runner thickness a • plastic ski thickness b out of specification → replace. Caution: to avoid scratching, wearing and damaging the plastic skis, be careful when loading and unloading the snowmobile and ...

Page 58: Insp

2-40 insp adj steering system toe-out adjustment 1. Place the machine on a level surface. 2. Measure: • ski toe-out ( a – c) • ski stance b point the skis forward. Out of specification → adjust. Ski toe-out: 0 ~ 15 mm (0 ~ 0.59 in) ski stance (center to center): pz50/pz50gt/pz50fx/pz50vt/ pz50mp: 1,...

Page 59: Insp

2-41 insp adj lubrication lubrication brake lever, throttle lever and throttle cable end 1. Lubricate the brake lever pivot, throttle lever and the ends of the throttle cables. Warning apply a dab of grease onto only the end of the cables. Do not grease the throttle cables. They could freeze and cau...

Page 60: Insp

2-42 insp adj headlight beam adjustment/battery inspection electrical headlight beam adjustment 1. Place the machine on a level surface. 2. Place the machine in front of a wall at the rec- ommended distance d. Refer to the table below. 3. Measure the distance h from the floor to the center of the he...

Page 61: Insp

2-43 insp adj battery inspection first aid in case of bodily contact: external • skin – wash with water. • eyes – flush with water for 15 minutes and get immediate medical attention. Internal • drink large quantities of water or milk fol- lowed with milk of magnesia, beaten egg or vegetable oil. Get...

Page 62: Insp

2-44 insp adj battery inspection 4. Inspect: • battery charge inspection steps: • connect a pocket tester to the battery terminals. Note: • the charge state of a mf battery can be checked by measuring its open-circuit voltage (i.E., the voltage when the positive terminal is discon- nected). • no cha...

Page 63: Insp

2-45 insp adj battery inspection 5. Charge: • battery (refer to the appropriate charging method illustration) warning do not quick charge a battery. Caution: • make sure that the battery vent is free of obstructions. • never remove the mf battery sealing caps. • do not use a high-rate battery charge...

Page 64: Insp

2-46 insp adj battery inspection charging method using a variable voltage charger measure the open-circuit voltage prior to charging. Connect a charged and amp meter to the battery and start charging. Make sure that the current is higher than the standard charging current written on the battery. By ...

Page 65: Insp

2-47 insp adj battery inspection charging method using a constant voltage charger measure the open-circuit voltage prior to charging. Note: set the charging time at 20 hours (maximum). Connect a charger and amp meter to the battery and start charging. Make sure that the current is higher than the st...

Page 66: Insp

2-48 insp adj battery inspection/fuse inspection 6. Install: • battery 7. Connect: • battery leads (to the battery terminals) caution: first, connect the positive battery lead 1, then the negative battery lead 2. 8. Check: • battery terminals dirt → clean with a wire brush. Loose connection → connec...

Page 67: Insp

2-49 insp adj fuse inspection 3. Replace: • blown fuse replacing steps: • set the main switch to “off”. • install a new fuse of the correct amperage. • set the main switch to “on” and verify if the electrical circuit is operational. • if the fuse immediately blows again, check the electrical circuit...

Page 68: Insp

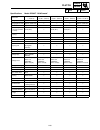

2-50 insp adj clutch tuning clutch high altitude specifications model: pz50/pz50fx l blue p pink r red È elevation ~ 800 m (~ 2,500 ft) 600 ~ 1,400 m (2,000 ~ 4,500 ft) 1,200 ~ 2,000 m (4,000 ~ 6,500 ft) 1,800 ~ 2,600 m (6,000 ~ 8,500 ft) 2,400 ~ 3,000 m (8,000 ~ 10,000 ft) É engine idle speed 1,800...

Page 69: Insp

2-51 insp adj clutch specifications model: pz50gt l blue p pink r red È elevation ~ 800 m (~ 2,500 ft) 600 ~ 1,400 m (2,000 ~ 4,500 ft) 1,200 ~ 2,000 m (4,000 ~ 6,500 ft) 1,800 ~ 2,600 m (6,000 ~ 8,500 ft) 2,400 ~ 3,000 m (8,000 ~ 10,000 ft) É engine idle speed 1,800 ± 100 r/min ← ← ← ← Ê engagement...

Page 70: Insp

2-52 insp adj clutch specifications model: pz50m g green r red y yellow È elevation ~ 800 m (~ 2,500 ft) 600 ~ 1,400 m (2,000 ~ 4,500 ft) 1,200 ~ 2,000 m (4,000 ~ 6,500 ft) 1,800 ~ 2,600 m (6,000 ~ 8,500 ft) 2,400 ~ 3,000 m (8,000 ~ 10,000 ft) É engine idle speed 1,800 ± 100 r/min ← ← ← ← Ê engageme...

Page 71: Insp

2-53 insp adj clutch specifications model: pz50vt “usa/canada” l blue y yellow È elevation ~ 800 m (~ 2,500 ft) 600 ~ 1,400 m (2,000 ~ 4,500 ft) 1,200 ~ 2,000 m (4,000 ~ 6,500 ft) 1,800 ~ 2,600 m (6,000 ~ 8,500 ft) 2,400 ~ 3,000 m (8,000 ~ 10,000 ft) É engine idle speed 1,800 ± 100 r/min ← ← ← ← Ê e...

Page 72: Insp

2-54 insp adj clutch specifications model: pz50vt “europe”/pz50mp go gold l blue È elevation ~ 800 m (~ 2,500 ft) 600 ~ 1,400 m (2,000 ~ 4,500 ft) 1,200 ~ 2,000 m (4,000 ~ 6,500 ft) 1,800 ~ 2,600 m (6,000 ~ 8,500 ft) 2,400 ~ 3,000 m (8,000 ~ 10,000 ft) É engine idle speed 1,800 ± 100 r/min ← ← ← ← Ê...

Page 73: Insp

2-55 insp adj clutch/gear selection the clutch may require tuning depending upon where the machine will be operated and the desired handling characteristics. The clutch can be tuned by changing the engagement and shifting speeds. Clutch engagement speed is defined as the engine speed at which the ma...

Page 74: Insp

2-56 insp adj gear selection 1 chain and sprocket part number 2 gear ratio 3 secondary sheave spring È parts name É teeth & links Ê parts no. Ë standard Ì drive sprocket 17 teeth 8gc-17682-70 pz50m “usa/canada” 18 teeth 8gc-17682-80 pz50/pz50fx/ pz50vt “europe”/pz50mp 19 teeth 8gc-17682-90 pz50m “eu...

Page 75: Insp

2-57 insp adj gear selection 4 secondary spring twist angle 90508-55007 (red) 90508-55012 (brown)/90508-58007 (blue)/90508-60015 (yellow) 5 torque cam (secondary spring seat) È seat 1 2 3 4 É sheave c 35° 65° 95° 5° a 45° 75° 105° 15° b 55° 85° 115° 25° È seat 1 2 3 4 É sheave c 40° 70° 100° 10° a 5...

Page 76: Insp

2-58 insp adj gear selection 6 primary spring Ë parts no. Ì spring rate n/mm (kg/mm) Í preload n/mm (kg) Î color Ï wire gauge mm (in) Ð outside diameter mm (in) Ñ no. Of coils Ò free length mm (in) Ó standard 90501-481j1 9.8 (1.0) 196 (20) silver-blue-silver 4.8 (0.189) 60 (2.362) 5.16 85.4 (3.362) ...

Page 77: Insp

2-59 insp adj gear selection 7 clutch weight È parts no. É weight g (oz) without bush and rivets Ê shape & id mark Ë standard 8bu-17605-20 45.41 (1.603) 8dn-17605-30 39.76 (1.404) pz50m 8es-17605-00 54.63 (1.928) 8fa-17605-10 63.81 (2.251) 8fn-17605-00 75.28 (2.657) 8fp-17605-00 67.81 (2.394) 8fs-17...

Page 78: Insp

2-60 insp adj gear selection 8 weight rivets 9 rollers È parts no. É material Ê length mm (in) Ë weight g (oz) Ì standard Í effects 90261-06033 steel 17.2 (0.677) 4.5 (0.159) in: pz50vt “europe”/pz50mp center, out: pz50vt/ pz50mp Î increased force Ï decreased force 90261-06034 steel 13.9 (0.547) 3.6...

Page 79: Insp

2-61 insp adj front suspension front suspension spring preload 1. Adjust: • spring preload adjustment steps: • loosen the locknut 1. • turn the spring seat 2 in or out. Pz50gt/pz50mp pz50vt “europe” pz50fx • turn the adjusting ring 3 to the proper position. Pz50/pz50m/pz50vt “usa/canada” È pz50gt/pz...

Page 80: Insp

2-62 insp adj front suspension caution: be sure that the left and right spring preload are the same. Warning these shock absorber contain highly pressur- ized nitrogen gas. Do not tamper with or attempt to open the shock absorber assemblies. Do not subject the shock absorber assemblies to flames or ...

Page 81: Insp

2-63 insp adj front suspension/rear suspension compression damping force adjustment (pz50fx) the compression damping force can be adjusted by turning the adjuster 1. * with the adjuster fully turned lightly in direction a caution: • do not continue to turn the adjuster in direc- tion a after it stop...

Page 82: Insp

2-64 insp adj rear suspension adjustment steps: • remove the stopper band bolts 1, nuts and washers. • adjust the length of the stopper bands 2 by inserting the bolts in different holes. • tighten the stopper band nuts. È pz50/pz50gt/pz50fx/pz50m É pz50vt/pz50mp standard setting: no. 1 hole (pz50/pz...

Page 83: Insp

2-65 insp adj rear suspension spring preload 1. Adjust: • spring preload adjustment step: front side • loosen the locknut 1. • turn the spring seat 2 in or out. Pz50gt “europe” pz50fx pz50vt “europe” pz50mp È pz50gt “europe”/pz50fx/pz50vt “europe”/ pz50mp spring seat distance standard shorter ← → lo...

Page 84: Insp

2-66 insp adj rear suspension • turn the adjusting ring 3 to the proper position. Pz50/pz50gt “usa/canada”/pz50m pz50vt “usa/canada” warning this shock absorber contains highly pressur- ized nitrogen gas. Do not tamper with or attempt to open the shock absorber assembly. Do not subject the shock abs...

Page 85: Insp

2-67 insp adj rear suspension rear suspension damping force adjustment the damping force can be adjusted by turning the adjuster 1. Pz50fx * with the adjuster fully turned lightly in direction a caution: • do not continue to turn the adjuster in direc- tion a after it stops. The shock absorber can b...

Page 86: Insp

2-68 insp adj rear suspension control rod (pz50vt/pz50mp) 1. Adjust: • control rod stroke a caution: make sure the adjusting bolt ends are set at the same position on each side. Adjustment steps: • loosen the locknut 1. • turn the adjusting nut 2 in or out to adjust the control rod stroke. Warning n...

Page 87: Insp

2-69 insp adj rear suspension 2-up adjusting block (pz50vt/pz50mp) 1. Position: • 2-up adjusting blocks note: be sure to change the position of the 2-up adjusting blocks when there is no load (rider or cargo) on the snowmobile. Positioning steps: • pull the lock lever 1 and turn the 2-up adjusting b...

Page 88: Chas

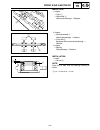

3-1 chas chassis cowlings pz50/pz50gt/pz50fx/pz50m order job name/part name q’ty remarks cowling removal remove the parts in the order listed below. 1 windshield 1 pz50gt 2 front panel 1 3 air filter case cover 1 4 headlight cover 1 5 left side panel 1 6 right side panel 1 7 left side cover 1 8 righ...

Page 89: Chas

3-2 chas cowlings order job name/part name q’ty remarks 14 cylinder-#1 intake air pressure sensor cou- pler 1 disconnect. 15 intake air temperature sensor coupler 1 disconnect. 16 cylinder head breather hose 1 disconnect. 17 oil tank breather hose 1 disconnect. 18 air filter case assembly 1 19 intak...

Page 90: Chas

3-3 chas cowlings pz50vt/pz50mp order job name/part name q’ty remarks cowling removal remove the parts in the order listed below. 1 air filter case cover 1 2 left side panel 1 3 right side panel 1 4 left side cover 1 5 right side cover 1 6 left lower cover 1 7 right lower cover 1 8 cylinder-#2 intak...

Page 91: Chas

3-4 chas steering steering pz50/pz50gt/pz50fx/pz50m order job name/part name q’ty remarks handlebar removal remove the parts in the order listed below. Windshield/left side panel/right side panel refer to “cowlings”. 1 windshield bracket 1 pz50gt/pz50fx/pz50m 2 multi-function meter coupler 1 3 multi...

Page 92: Chas

3-5 chas steering order job name/part name q’ty remarks 14 right handlebar switch cover 1 15 throttle cable holder 1 16 throttle cable 1 17 left handlebar switch 1 18 brake master cylinder holder 1 19 master cylinder assembly 1 note: after installing all parts, refer to “cable routing” in chapter 9,...

Page 93: Chas

3-6 chas steering pz50vt/pz50mp order job name/part name q’ty remarks handlebar removal remove the parts in the order listed below. Windshield/left side panel/right side panel refer to “cowlings”. 1 multi-function meter coupler 1 2 multi-function meter 1 3 multi-function meter bracket 1 4 steering p...

Page 94: Chas

3-7 chas steering order job name/part name q’ty remarks 14 throttle cable holder 1 15 throttle cable 1 16 left handlebar switch 1 17 brake master cylinder holder 1 18 master cylinder assembly 1 note: after installing all parts, refer to “cable routing” in chapter 9, to check the cable and lead routi...

Page 95: Chas

3-8 chas steering order job name/part name q’ty remarks steering column and tie rod removal remove the parts in the order listed below. Air filter case refer to “cowlings”. Fuel tank refer to “seat and fuel tank” in chap- ter 5. (pz50/pz50gt/pz50fx/pz50m) refer to “rider seat and fuel tank” in chapt...

Page 96: Chas

3-9 chas steering order job name/part name q’ty remarks 15 steering control arm 1 16 steering shaft 1 17 pivot arm cover 1 18 tie rod end bolt 2 19 pivot arm bracket 1 1 20 bushing 4 21 dust boots holder 2 22 dust boots 2 23 tie rod 2 24 idler arm 1 25 relay arm 1 26 pivot arm shaft 1 27 pivot arm b...

Page 97: Chas

3-10 chas steering removal 1. Straighten the lock washer tabs. Inspection 1. Inspect: • handlebar • steering column bends/cracks/damage → replace. Warning do not attempt to straighten a bent column. This may dangerously weaken the column. 2. Inspect: • bearings (steering column) • collars • bearings...

Page 98: Chas

3-11 chas steering installation 1. Install: • tie rod 1 • locknuts 2 • joints 3 2. Check: • tie rod angle c caution: after tightening the inside and outside ball joint locknut 2, make sure the tie rod 1 can be rotated freely through the ball joint travel. If not, loosen the locknut 2 and re-position...

Page 99: Chas

3-12 chas steering 4. Install: • steering arm 1 note: align the punch mark a on the steering arm 1 with the punch mark b on the pivot arm shaft 2. 1 2 a b 5. Install: • steering shaft 1 • locknuts 2 • joints 3 caution: always use new cotter pin. 6. Bend the lock washer tab along a flat side of the b...

Page 100: Chas

3-13 chas steering 7. Adjust: • skis adjustment steps: • temporarily install the handlebar. • hold the handlebar straight and check that the skis and relay arms are at right angles to the handlebar. • install the steering linkage alignment plate 1. • loosen the locknuts (steering shaft) 2. • hold th...

Page 101: Chas

3-14 chas ski ski pz50/pz50gt/pz50fx/pz50vt “usa/canada” order job name/part name q’ty remarks ski removal remove the parts in the order listed below. 1 cotter pin 1 2 nut 1 3 bolt 1 4 collar 1 5 collar 1 6 washer 2 7 collar 1 8 ski stopper 1 9 ski 1 for installation, reverse the removal proce- dure...

Page 102: Chas

3-15 chas ski pz50vt “europe”/pz50mp order job name/part name q’ty remarks ski removal remove the parts in the order listed below. 1 cotter pin 1 2 nut 1 3 bolt 1 4 collar 1 5 collar 1 6 washer 2 7 collar 1 8 ski stopper 1 9 ski stopper plate 1 10 ski 1 for installation, reverse the removal proce- d...

Page 103: Chas

3-16 chas ski pz50m order job name/part name q’ty remarks ski removal remove the parts in the order listed below. 1 cotter pin 1 2 nut 1 3 bolt 1 4 collar 2 5 collar 1 6 washer 2 7 collar 1 8 ski stopper 1 9 ski 1 for installation, reverse the removal proce- dure..

Page 104: Chas

3-17 chas ski inspection 1. Inspect: • ski • ski runner • ski stopper • ski stopper plate (pz50vt “europe”/ pz50mp) • ski handle wear/cracks/damage → replace. • mounting bolt • collar • collars wear/damage → replace..

Page 105: Chas

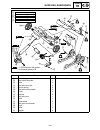

3-18 chas front suspension front suspension pz50/pz50fx/pz50m order job name/part name q’ty remarks front suspension removal remove the parts in the order listed below. Air filter case cover refer to “cowlings”. Pivot arm cover refer to “steering”. Ski refer to “ski”. 1 shock absorber 1 2 collar 2 p...

Page 106: Chas

3-19 chas front suspension order job name/part name q’ty remarks 11 stabilizer joint 1 12 stabilizer 1 13 lower arm 1 14 bushing 4 15 lower arm ball joint 1 for installation, reverse the removal proce- dure. New 3 3 2 2 8 9 10 7 8 14 14 14 13 12 11 15 5 4 6 1 60 nm (6.0 m • kg, 43 ft • lb) Ë: 45 nm ...

Page 107: Chas

3-20 chas front suspension pz50gt/pz50vt/pz50mp order job name/part name q’ty remarks front suspension removal remove the parts in the order listed below. Air filter case cover refer to “cowlings”. Pivot arm cover refer to “steering”. Ski refer to “ski”. 1 shock absorber 1 2 collar 2 3 bushing 4 4 t...

Page 108: Chas

3-21 chas front suspension order job name/part name q’ty remarks 11 stabilizer bracket 2 12 stabilizer 1 13 lower arm 1 14 bushing 4 15 lower arm ball joint 1 for installation, reverse the removal proce- dure. 3 3 2 2 8 8 14 14 14 13 12 11 11 15 5 4 6 1 34 nm (3.4 m • kg, 24 ft • lb) Ê: 45 nm (4.5 m...

Page 109: Chas

3-22 chas front suspension handling notes warning pz50gt/pz50fx/pz50vt “europe”/pz50mp this shock absorber contains highly com- pressed nitrogen gas. Before handling the shock absorber read and make sure that you understand the following information. The man- ufacturer cannot be held responsible for...

Page 110: Chas

3-23 chas front suspension installation 1. Install: • stabilizer 1 • bushing 2 • stabilizer holder 3 caution: always install the stabilizers, bushings, and stabilizer holders in the same positions on both sides of the snowmobile, otherwise poor han- dling and loss of stability may result. (pz50gt/ p...

Page 111: Chas

3-24 chas front suspension ski alignment note: be sure to verify the spring preload setting before adjusting the ski toe-out since this adjustments may affect the ski toe-out setting. Point the skis straight forward and measure the amount of ski toe-out. È ski toe-out: 0 ~ 15 mm (0 ~ 0.59 in) a – b ...

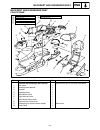

Page 112: Powr

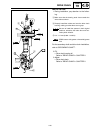

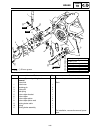

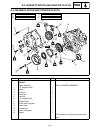

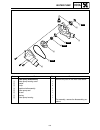

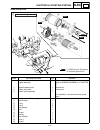

4-1 powr tr power train primary sheave and drive v-belt s order job name/part name q’ty remarks primary sheave removal remove the parts in the order listed below. Left side cover refer to “cowlings” in chapter 3. 1 v-belt 1 2 primary sheave assembly 1 for installation, reverse the removal proce- dur...

Page 113: Powr

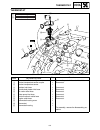

4-2 powr tr primary sheave and drive v-belt order job name/part name q’ty remarks primary sheave disassembly remove the parts in the order listed below. 1 primary sheave cap 1 2 primary sheave spring 1 3 collar 3 4 roller 3 5 washer 6 6 collar 3 7 weight 3 8 washer 6 9 fixed sheave 1 0 stopper 2 a s...

Page 114: Powr

4-3 powr tr primary sheave and drive v-belt removal 1. Remove: • primary sheave assembly 1 note: use the primary sheave holder 2 and primary sheave puller 3. Sheave holder: 90890-01701, ys-01880-a primary sheave puller: 90890-01898, ys-01881-a, ys-01881-1 disassembly 1. Remove: • fixed sheave 1 • st...

Page 115: Powr

4-4 powr tr primary sheave and drive v-belt • fit the primary sheave assembly onto the adapter and secure the supporting plates 8. Note: securely fit the projections on the adapter into the fixed sheave holes. • set the bar wrench 9 onto the spider and turn the special tool clockwise to loosen the s...

Page 116: Powr

4-5 powr tr primary sheave and drive v-belt 2. Inspect: • primary sheave spring 1 cracks/damage → replace. 3. Measure: • primary sheave spring (standard) free length a out of specification → replace the primary sheave spring. Note: when changing the primary sheave springs, refer to “gear selection” ...

Page 117: Powr

4-6 powr tr primary sheave and drive v-belt rivet replacement steps: • remove old rivet with the appropriate drill. • insert the rivet 1 from the id mark 2 side. • press or peen the rivet head so that the diame- ter a of the rivet head measures 8.2 mm (0.32 in) or larger. 6. Measure: • bushing insid...

Page 118: Powr

4-7 powr tr primary sheave and drive v-belt 2. Install: • fixed sheave (onto the spider) note: • clean the threads. • apply loctite ® #648 to the fixed sheave as shown. Caution: loctite ® should be applied only to the speci- fied area. Never apply it to the bushings and other areas. A 16 mm (0.63 in...

Page 119: Powr

4-8 powr tr primary sheave and drive v-belt • tighten the spider to specification using the bar wrench 3. Caution: the spider has a left-handed thread. Warning • do not operate the primary sheave until the loctite ® has dried completely. Wait 24 hours before operating the primary sheave. • since a h...

Page 120: Powr

4-9 powr tr installation 1. Install: • primary sheave assembly caution: be sure to remove any oil or grease from the tapered portion of the crankshaft and spider using a cloth dampened with thinner. 2. Apply: • engine oil (to threads of primary sheave bolt) 3. Tighten: • primary sheave bolt 1 tighte...

Page 121: Powr

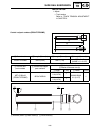

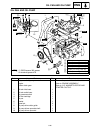

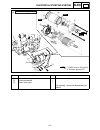

4-10 powr tr secondary sheave secondary sheave order job name/part name q’ty remarks secondary sheave removal remove the parts in the order listed below. Note: apply the brake to lock the secondary sheave. V-belt refer to “primary sheave and drive v- belt”. 1 washer 1 2 shim (left) — refer to “sheav...

Page 122: Powr

4-11 powr tr secondary sheave order job name/part name q’ty remarks secondary sheave disassembly remove the parts in the order listed below. 1 circlip 1 2 washer 1 3 spring seat 1 4 secondary sheave spring 1 5 sliding sheave 1 6 washer 2 7 fixed sheave 1 8 bushing 1 for assembly, reverse the disasse...

Page 123: Powr

4-12 powr tr secondary sheave disassembly warning • use extreme caution when disassembling the secondary sheave since serious injury can occur due to the sudden release of spring tension. Use the sheave compressor to con- tain the spring tension before removing the spring seat circlip. • do not atte...

Page 124: Powr

4-13 powr tr secondary sheave 5. Measure: • ramp shoe thickness a out of specification → replace the ramp shoe. Wear limit: 1.0 mm (0.04 in) assembly 1. Install: • secondary sheave spring 1 • spring seat 2 note: hook the end of the secondary sheave spring into the spring holes in the sliding sheave....

Page 125: Powr

4-14 powr tr secondary sheave installation 1. Lubricate: • splines (fixed sheave) 2. Tighten: • secondary sheave bolt 3. Adjust: • sheave offset • secondary sheave free play (clearance) refer to “sheave offset adjustment” in chapter 2. Recommended grease: esso beacon 325 grease or aeroshell grease #...

Page 126: Powr

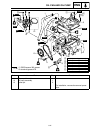

4-15 powr tr drive chain drive chain order job name/part name q’ty remarks drive chain housing removal remove the parts in the order listed below. Brake caliper/parking brake refer to “brake”. 1 shim — t = 0.5 2 shim — t = 1.0 3 brake disc 1 4 drain bolt 1 drain. 5 chain tension adjusting bolt 1 loo...

Page 127: Powr

4-16 powr tr drive chain removal 1. Remove: • driven sprocket 1 note: while holding the front axle assembly with spanner wrench 2, loosen the driven sprocket bolt. 2 1 inspection 1. Inspect: • drive chain cover cracks/damage → replace. • oil seals (drive chain cover) wear/damage → replace. • bearing...

Page 128: Powr

4-17 powr tr drive chain 3. Measure: • 14 link section a of the drive chain using a spring scale, pull on the drive chain with 36 kg (80 lb) of force b. Out of specification → replace the drive chain. Note: • measure the length between drive chain pin 1 and e as shown. • perform this measurement at ...

Page 129: Powr

4-18 powr tr drive chain installation 1. During installation, pay attention to the follow- ing. È make sure that the bearing seals face towards the drive chain as shown. É properly install the rubber seal onto the drive chain housing, making sure that there are no gaps. Be sure to install the spacer...

Page 130: Powr

4-19 powr tr secondary shaft secondary shaft pz50 order job name/part name q’ty remarks secondary shaft removal remove the parts in the order listed below. Secondary sheave assembly refer to “secondary sheave”. Drive chain refer to “drive chain”. 1 bearing holder 2 2 secondary shaft 1 3 circlip 1 4 ...

Page 131: Powr

4-20 powr tr secondary shaft removal 1. Remove: • drive chain parts refer to “drive chain”. • secondary sheave assembly refer to “secondary sheave”. 2. Remove: • bearing housing • secondary shaft 1 note: remove the secondary shaft 1 from the right side of the machine. 1 inspection 1. Inspect: • seco...

Page 132: Powr

4-21 powr tr secondary shaft 3. Tighten: • bearing holder bolts 1 4. Check: • secondary shaft stiffness caution: when the secondary shaft is operated in peri- odic motion, and if its movement is heavy, install it again correctly. T r . . Bearing holder bolt: 24 nm (2.4 m · kg, 17 ft · lb) 1.

Page 133: Powr

4-22 powr tr secondary shaft secondary shaft and drive chain installation 1. Install: • secondary shaft • drive chain parts installation steps: • install the secondary shaft. • install the drive chain parts. • install the drive chain, drive sprocket and driven sprocket. • tighten the bolt 1. • insta...

Page 134: Powr

4-23 powr tr secondary shaft and reverse gear case secondary shaft and reverse gear case pz50gt/pz50fx/pz50m/pz50vt/pz50mp order job name/part name q’ty remarks secondary shaft and reverse gear case removal remove the parts in the order listed below. Secondary sheave assembly refer to “secondary she...

Page 135: Powr

4-24 powr tr order job name/part name q’ty remarks 6 drive position switch connector 1 disconnect. 7 gear motor 1 8 shift arm 1 9 secondary shaft assembly 1 10 circlip 1 11 bearing 1 for installation, reverse the removal proce- dure. 3 (3) 11 10 7 6 4 9 1 1 5 8 2 Ê É É É È Ë new new new new lt lt (4...

Page 136: Powr

4-25 powr tr secondary shaft and reverse gear case order job name/part name q’ty remarks secondary shaft and reverse gear case disassembly remove the parts in the order listed below. 1 drive position switch 1 2 reverse position switch 1 3 right reverse gear case 1 4 gasket 1 5 dowel pin 2 6 middle s...

Page 137: Powr

4-26 powr tr secondary shaft and reverse gear case order job name/part name q’ty remarks f collar 1 g bearing 1 h left reverse gear case 1 i secondary shaft 1 j bearing 1 k bearing 1 l bearing 1 m bearing 1 for assembly, reverse the disassembly pro- cedure. I b 0 k d g f e d c a m 6 5 5 8 4 3 1 j 7 ...

Page 138: Powr

4-27 powr tr secondary shaft and reverse gear case removal 1. Check that the gear motor is in the drive posi- tion. Note: before removing the gear motor from the reverse gear case, make sure that the drive position indica- tor light on the speedometer unit is on. 2. Remove: • drive chain parts refer...

Page 139: Powr

4-28 powr tr secondary shaft and reverse gear case inspection 1. Inspect: • secondary shaft scratches (excessive)/damage → replace. • splines wear/damage → replace the secondary shaft. • bearing contact surface scratches/wear/damage → replace the sec- ondary shaft. Refer to “secondary shaft”. 2. Ins...

Page 140: Powr

4-29 powr tr secondary shaft and reverse gear case installation 1. Install: • secondary shaft assembly installation steps: • install the secondary shaft assembly. • install the secondary shaft assembly bolts 1. • install the bearing holder bolts 2. • tighten the secondary shaft assembly bolts 1. • t...

Page 141: Powr

4-30 powr tr secondary shaft and reverse gear case 3. Install: • drive chain parts refer to “drive chain”. 4. Check: • secondary shaft stiffness caution: when the secondary shaft is operated in peri- odic motion, and if its movement is heavy, install it again correctly. Secondary shaft and drive cha...

Page 142: Powr

4-31 powr tr brake brake order job name/part name q’ty remarks battery bracket removal remove the parts in the order listed below. Battery refer to “battery inspection” in chap- ter 2. 1 starter relay 1 2 main fuse 1 3 fuse box 1 4 ecu (engine control unit) 1 5 dc back buzzer 1 pz50gt/pz50fx/pz50m/p...

Page 143: Powr

4-32 powr tr brake order job name/part name q’ty remarks brake pad removal remove the parts in the order listed below. 1 retaining pin 2 2 brake pad 2 3 pad spring 1 4 brake caliper assembly 1 for installation, reverse the removal proce- dure. 4 1 1 2 3 È É Ê Ê 18 nm (1.8 m • kg, 13 ft • lb) 6 nm (0...

Page 144: Powr

4-33 powr tr brake caution: disc brake components rarely require disas- sembly. Do not: • do not disassemble components unless absolutely necessary. • do not use solvents on internal brake compo- nents. • do not use contaminated brake fluid for cleaning. • use only clean brake fluid. • do not allow ...

Page 145: Powr

4-34 powr tr brake 2. Install: • brake pads • pad spring installation steps: • connect a suitable hose 1 tightly to the caliper bleed screw 2. Put the other end of this hose into an open container. • loosen the caliper bleed screws and push the pistons into the caliper with your finger. • tighten th...

Page 146: Powr

4-35 powr tr brake order job name/part name q’ty remarks brake caliper and parking brake removal remove the parts in the order listed below. Brake fluid drain. 1 brake hose 1 2 retaining pin 2 3 brake pad 2 4 pad spring 1 5 brake caliper bracket 1 6 brake caliper 1 7 brake caliper piston 2 8 brake c...

Page 147: Powr

4-36 powr tr brake brake caliper disassembly note: before disassembling a caliper, drain brake fluid from brake hose, master cylinder, brake caliper and brake reservoir of their brake fluid. 1. Remove: • pistons • piston seals removal steps: • using a wood of piece, lock the piston. • blow compresse...

Page 148: Powr

4-37 powr tr brake 1. Inspect: • caliper piston scratches/rust/wear → replace the caliper assembly. • caliper cylinder wear/scratches → replace the caliper assembly. • caliper body cracks/damage → replace. • oil delivery passage (caliper body) blow out with compressed air. Warning replace the piston...

Page 149: Powr

4-38 powr tr brake order job name/part name q’ty remarks brake master cylinder removal remove the parts in the order listed below. Brake fluid drain. Left handlebar switch refer to “steering” in chapter 3. 1 brake light switch 1 2 brake lever 1 3 brake hose 1 4 holder 1 5 parking brake cable 1 disco...

Page 150: Powr

4-39 powr tr brake inspection 1. Inspect: • master cylinder 1 wear/scratches → replace the master cylin- der assembly. • master cylinder body 2 cracks/damage → replace. • oil delivery passage (master cylinder body) blow out with compressed air. 2. Inspect: • master cylinder kit scratches/wear/damage...

Page 151: Powr

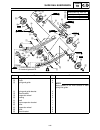

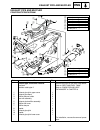

4-40 powr tr slide rail suspension slide rail suspension pz50/pz50gt/pz50fx/pz50m order job name/part name q’ty remarks slide rail suspension removal remove the parts in the order listed below. Rear axle nut loosen. Tension adjuster loosen. 1 slide rail suspension 1 for installation, reverse the rem...

Page 152: Powr

4-41 powr tr slide rail suspension order job name/part name q’ty remarks slide rail suspension disassembly remove the parts in the order listed below. 1 stopper band 1 2 front shock absorber 1 3 bushing 2 4 collar 1 5 bushing 2 6 collar 1 7 front pivot arm 1 8 bushing 2 9 shaft 1 0 collar 2 a shaft ...

Page 153: Powr

4-42 powr tr slide rail suspension order job name/part name q’ty remarks d suspension wheel 2 e circlip 2 f spring end guide 2 note: apply grease to the inner surface of each spring end guide. G spring end guide bracket 2 h wheel bracket 2 i suspension wheel 2 j bushing 2 k shaft 1 l front suspensio...

Page 154: Powr

4-43 powr tr slide rail suspension order job name/part name q’ty remarks q connecting arm 1 r rear shock absorber 1 s collar 2 t rear pivot arm joint 2 u torsion spring 2 v rear pivot arm protector 2 w circlip 2 x adjuster 2 y rear pivot arm 1 z shaft 1 [ guide wheel 2 \ rear pivot arm bracket 1 ] s...

Page 155: Powr

4-44 powr tr slide rail suspension order job name/part name q’ty remarks b rear axle 1 c guide wheel 2 d guide wheel 1 e collar 2 f tension adjuster 2 g collar 1 h collar 1 i suspension wheel 2 j wheel bracket 2 k shaft 1 l sliding frame 2 for assembly, reverse the disassembly pro- cedure. B c e f g...

Page 156: Powr

4-45 powr tr slide rail suspension pz50vt/pz50mp order job name/part name q’ty remarks slide rail suspension removal remove the parts in the order listed below. Rear axle nut loosen. Tension adjuster loosen. 1 slide rail suspension 1 for installation, reverse the removal proce- dure. 72 nm (7.2 m • ...

Page 157: Powr

4-46 powr tr slide rail suspension order job name/part name q’ty remarks slide rail suspension disassembly remove the parts in the order listed below. 1 stopper band 2 2 shaft 1 3 collar 2 4 collar 1 5 front pivot arm 1 6 bushing 2 7 shaft 1 8 collar 2 9 shaft 1 0 collar 1 a wheel bracket 2 b suspen...

Page 158: Powr

4-47 powr tr slide rail suspension order job name/part name q’ty remarks d bushing 2 e connecting arm 1 f collar 1 g front suspension bracket 1 h front shock absorber 1 i bushing 4 j collar 2 k suspension wheel 2 l circlip 2 m spring end guide 2 note: apply grease to the inner surface of each spring...

Page 159: Powr

4-48 powr tr slide rail suspension order job name/part name q’ty remarks o suspension wheel 2 p wheel bracket 2 q shaft 1 r bushing 2 s rear suspension bracket 1 t pull rod 2 u collar 4 v bushing 4 w rear shock absorber 1 x collar 2 y lock lever guide plate 2 z lock lever 2 [ collar 2 \ 2-up adjusti...

Page 160: Powr

4-49 powr tr slide rail suspension order job name/part name q’ty remarks c rear pivot arm protector 2 d bushing 2 e shaft 1 f rear pivot arm 1 g collar 2 h shaft 1 i bushing 4 j collar 1 k circlip 2 l adjuster 2 m control rod stopper 1 n circlip 2 o control rod 2 p locknut 2 q adjuster nut 2 new k n...

Page 161: Powr

4-50 powr tr slide rail suspension order job name/part name q’ty remarks r rear axle 1 s guide wheel 2 t collar 2 u collar 1 v guide wheel 1 w collar 1 x tension adjuster 2 y sliding frame 2 for assembly, reverse the disassembly pro- cedure. 75 nm (7.5 m • kg, 54 ft • lb) È: r s t x u w y v y t s È ...

Page 162: Powr

4-51 powr tr slide rail suspension removal 1. Unhook the torsion spring 1 (pz50/pz50gt/pz50fx/pz50m) note: for pz50/pz50gt/pz50fx/pz50m rotate the spring end guide 2 in the direction of the arrow shown to unhook the end of the torsion spring. 1 2 inspection 1. Inspect: • suspension wheel • guide whe...

Page 163: Powr

4-52 powr tr slide rail suspension 2. Install: • control rods 1 (pz50vt/pz50mp) note: install the control rods with the water drain holes a facing downward. A 1 3. Install: • rear pivot arm joint 1 (pz50/pz50gt/pz50fx/pz50m) note: align the punch mark a in the rear pivot arm joint with the punch mar...

Page 164: Powr

4-53 powr tr slide rail suspension 6. Install: • 2-up adjusting block 1 (pz50vt/pz50mp) note: install the lock lever guide plate 2 as shown in the illustration so that the projection on the plate con- tacts the projection a on the 2-up adjusting block. Make sure that the 2-up adjusting block is lock...

Page 165: Powr

4-54 powr tr slide rail suspension 7. Install: • stopper band 1 note: install the stopper band with a toward the front pivot arm and b toward the shaft. È pz50 É pz50gt/pz50m Ê pz50fx Ë pz50vt Ì pz50mp t r . . Stopper band nut: 4 nm (0.4 m · kg, 2.9 ft · lb) a b 1 È a b 1 É a b 1 Ê a 1 b Ë a 1 b Ì.

Page 166: Powr

4-55 powr tr slide rail suspension installation 1. Adjust: • track tension refer to “track tension adjustment” in chapter 2. Control rod part numbers (pz50vt/pz50mp) Ó standard position Ô metal washer(s) Õ plastic washer(s) È control rod 1 É length a mm (in) Ê length b mm (in) Ë length c mm (in) pz5...

Page 167: Powr

4-56 powr tr front axle and track front axle and track order job name/part name q’ty remarks front axle and track removal remove the parts in the order listed below. Drive chain refer to “drive chain”. Slide rail suspension refer to “slide rail suspension”. Secondary sheave refer to “secondary sheav...

Page 168: Powr

4-57 powr tr front axle and track inspection 1. Inspect: • track 1 • slide metal 2 wear/cracks/damage → replace. 1 2 2. Inspect: • sprocket wheels 1 wear/break/damage → replace. • front axle 2 bends/scratches (excessive)/damage → replace. 3. Inspect: • bearing pitting/damage → replace. 1 2 installat...

Page 169: Powr

4-58 powr tr front axle and track 2. Install: • sprocket wheels • guide wheels note: • when pressing the sprocket wheels onto the front axle, align the lugs on each sprocket wheel. • position each sprocket wheel on the axle as shown in the illustration. È pz50/pz50gt/pz50fx É pz50m Ê pz50vt/pz50mp 1...

Page 170: Eng

5-1 eng engine seat and fuel tank pz50/pz50gt/pz50fx/pz50m order job name/part name q’ty remarks seat and fuel tank removal remove the parts in the order listed below. 1 seat 1 2 rear cover 1 3 plastic band 4 4 tail/brake light coupler 1 disconnect. 5 tail/brake light assembly 1 6 main switch couple...

Page 171: Eng

5-2 eng seat and fuel tank order job name/part name q’ty remarks 11 plastic band 6 12 fuel tank assembly 1 13 fuel sender coupler 1 disconnect. 14 fuel hose 2 disconnect. 15 fuel pump 1 16 fuel tank lower plate 1 for installation, reverse the removal proce- dure. 1 (4) 14 3 3 4 15 8 2 11 9 16 6 5 13...

Page 172: Eng

5-3 eng backrest and passenger seat backrest and passenger seat pz50vt/pz50mp order job name/part name q’ty remarks backrest and passenger seat removal remove the parts in the order listed below. 1 rear cover 1 2 passenger seat bracket 1 3 backrest 1 4 passenger seat 1 5 left side rear cover 1 6 rig...

Page 173: Eng

5-4 eng backrest and passenger seat order job name/part name q’ty remarks 11 tail/brake light assembly 1 12 tail/brake light switch coupler 1 disconnect. 13 passenger grip warmer coupler 2 disconnect. 14 rear carrier 1 15 passenger grip warmer 2 for installation, reverse the removal proce- dure. 13 ...

Page 174: Eng

5-5 eng rider seat and fuel tank rider seat and fuel tank pz50vt/pz50mp order job name/part name q’ty remarks rider seat and fuel tank removal remove the parts in the order listed below. Passenger seat refer to “backrest and passenger seat”. 1 sub-wire harness 3 coupler 1 disconnect. 2 rider seat 1 ...

Page 175: Eng

5-6 eng rider seat and fuel tank order job name/part name q’ty remarks 11 fuel tank assembly 1 12 fuel sender coupler 1 disconnect. 13 fuel return hose 2 disconnect. 14 fuel pump 1 for installation, reverse the removal proce- dure. 11 14 10 10 10 12 1 13 4 3 3 6 8 (6) 5 2 7 9 8 nm (0.8 m • kg, 5.8 f...

Page 176: Eng

5-7 eng rider seat and fuel tank removal 1. Extract the fuel in the fuel tank through the fuel tank cap with a pump. 2. Remove: • fuel hose connector holder • fuel hose caution: • be sure to disconnect the fuel hose by hand. Do not forcefully disconnect the hose with tools. • although the fuel has b...

Page 177: Eng

5-8 eng rider seat and fuel tank installation 1. Install: • fuel pump gasket • fuel pump • fuel pump bracket note: • do not damage the installation surface of the fuel tank when installing the fuel pump. • always use a new fuel pump gasket. • install the fuel pump bracket by aligning the pro- jectio...

Page 178: Eng

5-9 eng exhaust pipe and muffler exhaust pipe and muffler pz50/pz50gt/pz50fx/pz50m order job name/part name q’ty remarks exhaust pipe and muffler removal remove the parts in the order listed below. Fuel tank refer to “seat and fuel tank”. Radiator outlet pipe 2 refer to “radiator and heat exchanger”...

Page 179: Eng

5-10 eng pz50vt/pz50mp order job name/part name q’ty remarks exhaust pipe and muffler removal remove the parts in the order listed below. Fuel tank refer to “rider seat and fuel tank”. Radiator outlet pipe 2 refer to “radiator and heat exchanger” in chapter 6. Slide rail suspension refer to “slide r...

Page 180: Eng

5-11 eng exhaust pipe and muffler installation 1. Install: • muffler damper holder (temporarily) 2. Install: • exhaust pipe/muffler assembly note: position the exhaust pipe bolt 1 at the rear of the hole a in the seat rail assembly, and then finger tighten it. È forward a 1 È 3. Install: • exhaust p...

Page 181: Eng

5-12 eng oil tank oil tank order job name/part name q’ty remarks oil tank removal remove the parts in the order listed below. Right side panel refer to “cowlings” in chapter 3. Engine oil drain. Refer to “engine oil replacement” in chapter 2. 1 oil level switch coupler 1 disconnect. 2 oil tank breat...

Page 182: Eng

5-13 eng engine assembly hose and leads order job name/part name q’ty remarks hose and leads removal remove the parts in the order listed below. Coolant drain. Refer to “cooling system” in chapter 2. Engine oil drain. Refer to “engine oil replacement” in chapter 2. Throttle body refer to “throttle b...

Page 183: Eng

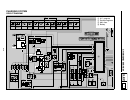

5-14 eng engine assembly order job name/part name q’ty remarks exhaust pipe/muffler assembly refer to “exhaust pipe and muffler”. Water pump refer to “water pump” in chapter 6. Battery refer to “battery inspection” in chap- ter 2. 1 a.C. Magneto lead coupler 2 disconnect. 2 rectifier/regulator lead ...

Page 184: Eng

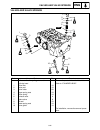

5-15 eng engine assembly engine assembly order job name/part name q’ty remarks engine assembly removal remove the parts in the order listed below. 1 frame rear cross member 1 2 nut 3 3 washer 1 4 washer 1 5 front engine right mounting bolt/washer 1/1 6 engine mounting bracket 1 7 front engine left m...

Page 185: Eng

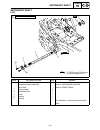

5-16 eng engine assembly removal 1. Remove: • rear engine mounting nut • front engine mounting nuts • washers note: do not remove the engine mounting bolts. 2. Remove: • engine assembly removal steps: • screw in the engine mounting bolt spacers (front and rear) using the engine mount spacer wrench 1...

Page 186: Eng

5-17 eng engine assembly installation steps: • install the engine mounting bolt spacer (front left side). • install the engine assembly, and then install the rear engine mounting bolt spacer. • install the rear engine mounting bolt and front engine left mounting bolt. • install the engine mounting b...

Page 187: Eng

5-18 eng camshafts camshafts cylinder head cover order job name/part name q’ty remarks cylinder head cover removal remove the parts in the order listed below. Fuel tank refer to “seat and fuel tank”. (pz50/ pz50gt/pz50fx/pz50m) refer to “rider seat and fuel tank”. (pz50vt/pz50mp) 1 cylinder identifi...

Page 188: Eng

5-19 eng camshafts camshafts order job name/part name q’ty remarks camshaft removal remove the parts in the order listed below. Engine refer to “engine assembly”. 1 timing accessing screw 1 2 crankshaft end accessing screw 1 3 timing chain tensioner 1 4 timing chain tensioner gasket 1 5 intake camsh...

Page 189: Eng

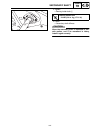

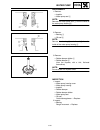

5-20 eng camshafts removal 1. Remove: • timing accessing screw • crankshaft end accessing screw 2. Align: • “i” mark a on the a.C. Magneto rotor (with the stationary pointer b on the a.C. Magneto cover) note: • turn the crankshaft counterclockwise. • when piston #1 is at tdc on the compression strok...

Page 190: Eng

5-21 eng camshafts 6. Remove: • intake camshaft sprocket 1 (use the special tool 2) rotor holding tool: 90890-01235, yu-01235 inspection 1. Inspect: • camshaft lobes blue discoloration/pitting/scratches → replace the camshaft. 2. Measure: • camshaft lobe dimensions a and b out of specification → rep...

Page 191: Eng

5-22 eng camshafts 4. Measure: • camshaft-journal-to-camshaft-cap clearance out of specification → measure the camshaft journal diameter. Measurement steps: • install the camshaft into the cylinder head (with- out the dowel pins and camshaft caps). • position a strip of plastigauge ® 1 onto the cams...

Page 192: Eng

5-23 eng camshafts 7. Inspect: • decompression system inspection steps: • check that the decompressor lever pins 1 projects from the camshaft. • check that the decompressor cams 2 moves smoothly. 8. Inspect: • timing chain guide (top side) damage/wear → replace the timing chain guide. 2 1 1 9. Remov...

Page 193: Eng

5-24 eng camshafts assembly steps: • install the timing chain tensioner spring, timing chain tensioner spring seat, and timing chain tensioner rod 1. • squeeze the timing chain tensioner clip 2, and then push the timing chain tensioner rod 3 into the timing chain tensioner housing. Note: do not rele...

Page 194: Eng

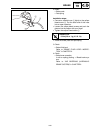

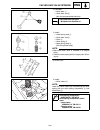

5-25 eng camshafts installation 1. Install: • intake camshaft sprocket 1 (with the special tool 2) • camshaft sprocket bolts note: make sure that the position to the cylinder #1 cam a and marks b and c on the camshaft sprockets are in the position shown in the illustration. B: exhaust side “—” c: in...

Page 195: Eng

5-26 eng camshafts 3. Install: • dowel pins • intake camshaft cap • exhaust camshaft cap note: install the camshaft caps with the arrow mark a pointing towards the right side of the engine. 4. Install: • camshaft cap bolts note: tighten the camshaft cap bolts in stages and in a crisscross pattern, w...

Page 196: Eng

5-27 eng camshafts 7. Inspect: • timing chain • check that the timing chain is taut. If the chain is slack, reinstall the timing chain tensioner. Note: if the engine is not disassembled, start the engine and check for any abnormal noise. If any abnormal noise is heard, reinstall the timing chain ten...

Page 197: Eng

5-28 eng cylinder head cylinder head order job name/part name q’ty remarks cylinder head removal remove the parts in the order listed below. Engine refer to “engine assembly”. Camshafts refer to “camshafts”. 1 timing chain guide (exhaust side) 1 2 cylinder head 1 3 cylinder head gasket 1 4 dowel pin...

Page 198: Eng

5-29 eng cylinder head removal 1. Remove: • cylinder head bolts note: loosen each bolt 1/2 of a turn at a time. After all of the bolt are fully loosened, remove them. 5 6 2 3 1 4 inspection 1. Eliminate: • combustion chamber carbon deposits (with a rounded scraper) note: do not use a sharp instrumen...

Page 199: Eng

5-30 eng cylinder head installation 1. Install: • dowel pins 1 • gasket 2 1 1 2 new new 2. Install: • cylinder head note: pass the timing chain through the timing chain cav- ity. 3. Tighten: • cylinder head bolts (m10) note: the tightening procedure of the cylinder head bolts is angle controlled, th...

Page 200: Eng

5-31 eng cylinder head • tighten the cylinder head bolts further to reach the specified angle 180° in the proper tightening sequence as shown. Warning when the bolts are tightened more than the specified angle, do not loosen the bolt and then retighten it. Replace the bolt with a new one and perform...

Page 201: Eng

5-32 eng valves and valve springs valves and valve springs order job name/part name q’ty remarks valves and valve springs removal remove the parts in the order listed below. Cylinder head refer to “cylinder head”. 1 valve lifter 10 2 valve pad 10 3 valve cotter 20 4 upper spring seat 10 5 valve spri...

Page 202: Eng

5-33 eng valves and valve springs removal the following procedure applies to all of the valves and related components. Note: before removing the internal parts of the cylinder head (e.G., valves, valve springs, valve seats), make sure the valves properly seal. 1. Remove: • valve lifter 1 • valve pad...

Page 203: Eng

5-34 eng valves and valve springs 4. Remove: • upper spring seat 1 • valve spring 2 • valve 3 • valve stem seal 4 • lower spring seat 5 note: identify the position of each part very carefully so that it can be reinstalled in its original place. Inspection 1. Measure: • valve-stem-to-valve-guide clea...

Page 204: Eng

5-35 eng valves and valve springs • after installing the valve guide, bore the valve guide with the valve guide reamer 3 to obtain the proper valve-stem-to-valve-guide clearance. Note: after replacing the valve guide, reface the valve seat. 3. Eliminate: • carbon deposits (from the valve face and va...

Page 205: Eng

5-36 eng valves and valve springs 9. Measure: • valve seat width a out of specification → replace the cylinder head. Measurement steps: • apply mechanic’s blueing dye (dykem) 1 onto the valve face. • install the valve into the cylinder head. • press the valve through the valve guide and onto the val...

Page 206: Eng

5-37 eng valves and valve springs • install the valve into the cylinder head. • turn the valve until the valve face and valve seat are evenly polished, then clean off all of the lapping compound. Note: for the best lapping results, lightly tap the valve seat while rotating the valve back and forth b...

Page 207: Eng

5-38 eng valves and valve springs 12. Measure: • compressed valve spring force a out of specification → replace the valve spring. B installed length compressed valve spring force (installed): intake: 120.7 ~ 138.9 n at 30.13 mm (12.3 ~ 14.2 kg at 30.13 mm, 27.1 ~ 31.2 lb at 1.19 in) exhaust: 150.6 ~...

Page 208: Eng

5-39 eng valves and valve springs 2. Lubricate: • valve stem 1 • valve stem seal 2 (with the recommended lubricant) recommended lubricant: molybdenum disulfide oil 3. Install: • lower spring seat 1 • valve stem seal 2 • valve 3 • valve spring 4 • upper spring seat 5 (into the cylinder head) note: • ...

Page 209: Eng

5-40 eng valves and valve springs 5. To secure the valve cotters onto the valve stem, lightly tap the valve tip with a soft-face hammer. Caution: hitting the valve tip with excessive force could damage the valve. 6. Lubricate: • valve pad • valve lifter (with the recommended lubricant) 7. Install: •...

Page 210: Eng

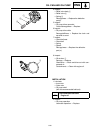

5-41 eng a.C. Magneto rotor and starter clutch a.C. Magneto rotor and starter clutch i order job name/part name q’ty remarks a.C. Magneto rotor and starter clutch removal remove the parts in the order listed below. Engine assembly refer to “engine assembly”. 1 a.C. Magneto cover 1 2 gasket 1 3 dowel...

Page 211: Eng

5-42 eng a.C. Magneto rotor and starter clutch removal 1. Remove: • a.C. Magneto rotor bolt • washer note: • while holding the a.C. Magneto rotor 1 with the sheave holder 2, loosen the magneto rotor bolt. • do not allow the sheave holder to touch the pro- jection on the a.C. Magneto rotor. Sheave ho...

Page 212: Eng

5-43 eng a.C. Magneto rotor and starter clutch 3. Remove: • starter clutch note: • while holding the magneto rotor with the sheave holder, remove the starter clutch bolts 1. • do not allow the sheave holder to touch the pro- jection on the magneto rotor. Sheave holder: 90890-01701, ys-01880-a inspec...

Page 213: Eng

5-44 eng a.C. Magneto rotor and starter clutch 4. Inspect: • starter clutch operation installation steps: • install the starter clutch gear onto the starter clutch and hold the starter clutch. • when turning the starter clutch gear clockwise È, the starter clutch and the starter clutch gear should e...

Page 214: Eng

5-45 eng a.C. Magneto rotor and starter clutch 4. Tighten: • a.C. Magneto rotor bolt 1 note: • lubricate the a.C. Magneto rotor bolt and washer with engine oil. • while holding the a.C. Magneto rotor 2 with the sheave holder 3, tighten the magneto rotor bolt. • do not allow the sheave holder to touc...

Page 215: Eng

5-46 eng oil pan and oil pump oil pan and oil pump order job name/part name q’ty remarks oil pan and oil pump removal remove the parts in the order listed below. Engine refer to “engine assembly”. Starter clutch gear refer to “a.C. Magneto rotor and starter clutch”. 1 oil tank inlet hose 1 2 oil tan...

Page 216: Eng

5-47 eng oil pan and oil pump order job name/part name q’ty remarks 11 oil pump drive chain 1 12 oil pump assembly 1 13 dowel pin 2 for installation, reverse the removal proce- dure. : 1 esso beacon 325 grease or aeroshell grease #7a e e lt lt lt 1 5 6 7 8 9 10 11 13 12 7 2 3 4 30 nm (3.0 m • kg, 22...

Page 217: Eng

5-48 eng oil pan and oil pump order job name/part name q’ty remarks oil pump disassembly remove the parts in the order listed below. 1 oil pump housing cover 1 1 2 spring 1 3 relief valve 1 4 oil pump inner rotor 1 1 5 pin 2 6 oil pump outer rotor 1 1 7 oil pump housing cover 2 1 8 oil pump inner ro...

Page 218: Eng

5-49 eng oil pan and oil pump removal 1. Remove: • oil pan note: loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. Inspection 1. Inspect: • oil pump housing • oil pump cover cracks/damage/wear → replace the defec-...

Page 219: Eng

5-50 eng oil pan and oil pump 4. Inspect: • relief valve body 1 • relief valve 2 • spring 3 damage/wear → replace the defective part(s). 5. Inspect: • oil pump driven sprocket cracks/damage/wear → replace. 6. Inspect: • oil pump drive chain damage/stiffness → replace the chain and sprocket as a set....

Page 220: Eng

5-51 eng oil pan and oil pump 3. Install: • oil pump driven sprocket shaft 1 note: align the slit a on the oil pump driven sprocket shaft with the projection b on the oil pump shaft. 4. Install: • dowel pins • gasket • oil pan • oil pan bolts note: tighten the oil pan bolts in stages and in a criss-...

Page 221: Eng

5-52 eng balancer balancer order job name/part name q’ty remarks balancer shaft removal remove the parts in the order listed below. Engine refer to “engine assembly”. Cylinder head refer to “cylinder head”. A.C. Magneto rotor/starter clutch gear refer to “a.C. Magneto rotor and starter clutch”. 1 pr...

Page 222: Eng

5-53 eng balancer order job name/part name q’ty remarks 11 circlip 1 12 bearing 1 13 circlip 1 14 bearing 1 15 bearing retainer 1 16 bearing 1 17 bearing 1 18 circlip 1 19 bearing 1 for installation, reverse the removal proce- dure. 4 5 8 16 7 6 15 4 13 14 2 1 (2) (4) (10) 3 17 18 19 10 9 11 12 É É ...

Page 223: Eng

5-54 eng balancer removal 1. Straighten the lock washer tab. 2. Loosen: • right balancer weight nut 1 caution: the right balancer weight nut has left-handed threads. To loosen the nut, turn it clockwise. Note: place an aluminum plate 2 between the teeth of the balancer shaft drive gear 3 and balance...

Page 224: Eng

5-55 eng balancer inspection 1. Inspect: • bearings clean and lubricate the bearings, then rotate the inner race with your finger. Rough movement → replace. 2. Inspect: • balancer shaft drive gear • balancer shaft driven gear damage/wear → replace. 3. Inspect: • balancer weight cracks/damage/wear → ...

Page 225: Eng

5-56 eng balancer 3. Install: • balancer shaft driven gear 1 • lock washers • balancer shaft driven gear nut • right balancer weight nut • balancer shaft drive gear bolt note: • align the punch mark a on the balancer shaft driven gear with the shorter spline b on the bal- ancer shaft end. • align th...

Page 226: Eng

5-57 eng balancer 5. Tighten: • primary sheave drive shaft cover bolt note: apply loctite ® to the bolts (black) indicated by the “ ” marks on the primary sheave drive shaft cover. T r . . Primary sheave drive shaft cover bolt: 12 nm (1.2 m · kg, 8.7 ft · lb) loctite ®.

Page 227: Eng

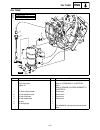

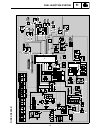

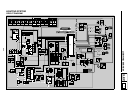

5-58 eng crankcase crankcase crankcase order job name/part name q’ty remarks crankcase removal remove the parts in the order listed below. Engine refer to “engine assembly”. Cylinder head refer to “cylinder head”. A.C. Magneto rotor/starter clutch gear refer to “a.C. Magneto rotor and starter clutch...

Page 228: Eng

5-59 eng crankcase connecting rods and pistons order job name/part name q’ty remarks connecting rods and pistons removal remove the parts in the order listed below. 1 connecting rod cap 2 2 big end bearing 4 3 piston pin clip 4 4 piston pin 2 5 piston 2 6 connecting rod 2 7 top ring 2 8 2nd ring 2 9...

Page 229: Eng

5-60 eng crankcase crankshaft order job name/part name q’ty remarks crankshaft removal remove the parts in the order listed below. 1 crankshaft 1 2 crankshaft journal bearing 6 3 upper crankcase 1 for installation, reverse the removal proce- dure. 1 2 2 2 3 2 e e e e.

Page 230: Eng

5-61 eng crankcase removal 1. Remove: • crankcase bolts note: • loosen the bolts in decreasing numerical order of the embossed numbers on the crankcase. • loosen each bolt 1/4 of a turn at a time. After all of the bolts are fully loosened, remove them. È cylinder head side É oil pan side 17 18 19 È ...

Page 231: Eng

5-62 eng crankcase 5. Remove: • piston pin clips 1 • piston pin 2 • piston 3 • connecting rod 4 caution: do not use a hammer to drive the piston pin out. Note: • for reference during installation, put identification marks on the piston crown. • before removing the piston pin, deburr the piston pin c...

Page 232: Eng

5-63 eng crankcase inspection 1. Inspect: • piston wall • cylinder wall vertical scratches → rebore or replace the cylinder, and replace the piston and piston rings as a set. 2. Measure: • piston-to-cylinder clearance measurement steps: 1st step: • measure cylinder bore “c” with the cylinder bore ga...

Page 233: Eng

5-64 eng crankcase 3rd step: • calculate the piston-to-cylinder clearance with the following formula. Piston-to-cylinder clearance = cylinder bore “c” – piston skirt diameter “p” • if out of specification, replace the cylinder, and the piston and piston rings as a set. Piston-to-cylinder clearance: ...

Page 234: Eng

5-65 eng crankcase 5. Measure: • piston ring end gap out of specification → replace the piston rings as a set. Note: the oil ring expander spacer’s end gap cannot be measured. If the oil ring rail’s gap is excessive, replace all three piston rings. 6. Inspect: • piston pin blue discoloration/grooves...

Page 235: Eng

5-66 eng crankcase 9. Calculate: • piston pin to piston pin bore clearance out of specification → replace the piston pin and piston as a set. Piston pin to piston pin bore clearance = piston pin bore size – piston pin outside diameter piston pin to piston pin bore clear- ance: 0.002 ~ 0.022 mm (0.00...

Page 236: Eng

5-67 eng crankcase 12. Measure: • crankshaft-journal-to-crankshaft-journal- bearing clearance out of specification → replace the crankshaft journal bearings. Measurement steps: caution: do not interchange the crankshaft journal bear- ings. To obtain the correct crankshaft-journal- to-crankshaft-jour...

Page 237: Eng

5-68 eng crankcase • install the crankshaft journal lower bearings 1 into the lower crankcase and assemble the crankcase halves. Note: • align the projections a of the crankshaft journal lower bearings with the notches b in the crank- case. • do not move the crankshaft until the clearance measuremen...

Page 238: Eng

5-69 eng crankcase 13. Select: • crankshaft journal bearings (j1 ~ j3) note: • the numbers È stamped into the crankshaft web and the numbers É stamped into the lower crankcase are used to determine the replace- ment crankshaft journal bearing sizes. • “j1 ~ j3” refer to the bearings shown in the cra...

Page 239: Eng

5-70 eng crankcase measurement steps: caution: do not interchange the big end bearings and connecting rods. To obtain the correct crank- shaft-pin-to-big-end-bearing clearance and pre- vent engine damage, the big end bearings must be installed in their original positions. • clean the big end bearing...

Page 240: Eng

5-71 eng crankcase • tighten the connecting rod bolts. • replace the connecting rod bolts with new ones. Caution: tighten the connecting rod bolts using the plastic-region tightening angle method. Always install new bolts. Tightening steps: • clean the connecting rod bolts. • tighten the connecting ...

Page 241: Eng

5-72 eng crankcase 15. Select: • big end bearings (p1 ~ p2) note: • the numbers È stamped into the crankshaft web and the numbers 1 on the connecting rods are used to determine the replacement big end bear- ing sizes. • “p1” ~ “p2” refer to the bearings shown in the crankshaft illustration. Selectio...

Page 242: Eng

5-73 eng crankcase installation 1. Install: • crankshaft journal upper bearing (into the upper crankcase) • crankshaft journal lower bearing (into the lower crankcase) note: • align the projections a on the crankshaft journal bearings with the notches b in the crankcase. • be sure to install each cr...

Page 243: Eng