- DL manuals

- Yamaha

- Snowmobiles

- PZ50FXW

- Service Manual

Yamaha PZ50FXW Service Manual

Summary of PZ50FXW

Page 1

Service manual pz50w pz50gtw pz50fxw pz50mw pz50vtw pz50mpw lit-12618-02-58 8gc-28197-10 printed on recycled paper printed in u.S.A. 2006.07 cr (e) yamaha motor co., ltd. Cover_smb.Fm page 1 thursday, july 27, 2006 9:56 am.

Page 3: Notice

Notice this manual was written by the yamaha motor company primarily for use by yamaha dealers and their qualified mechanics. It is not possible to put an entire mechanic’s education into one manual, so it is assumed that persons using this book to perform maintenance and repairs on yamaha snowmobil...

Page 4: Gen

Illustrated symbols (refer to the illustration) illustrated symbols 1 to 9 are designed as thumb tabs to indicate the chapter’s number and content. 1 general information 2 periodic inspection and adjustment 3 chassis 4 power train 5 engine 6 cooling system 7 fuel injection system 8 electrical 9 spec...

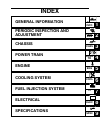

Page 5: Index

Index general information gen info 1 periodic inspection and adjustment insp adj 2 chassis chas 3 power train powr tr 4 engine eng 5 cooling system cool 6 fuel injection system fi 7 electrical elec 8 specifications spec 9 – +.

Page 6

Chapter 1. General information machine identification............................ 1-1 frame serial number ......................... 1-1 engine serial number........................ 1-1 important information .......................... 1-2 preparation for removal and disassembly..........................

Page 7

Pz50vt “europe”/pz50mp....................... 3-15 pz50m ...................................................... 3-16 inspection ............................................ 3-17 front suspension ................................... 3-18 pz50/pz50fx/pz50m............................... 3-18 pz50gt/pz5...

Page 8

Cylinder head........................................... 5-28 removal ................................................ 5-29 inspection ............................................ 5-29 installation ........................................ 5-30 valves and valve springs................... 5-32 removal...

Page 9

Lighting system ....................................... 8-22 circuit diagram.................................. 8-22 troubleshooting.............................. 8-24 bulb(s).................................................... 8-26 headlight beam switch ................... 8-26 headlight relay.........

Page 10: Gen

1-1 gen info general information machine identification frame serial number the frame serial number 1 is located on the right-hand side of the frame (just below the front of the seat). Engine serial number the engine serial number 1 is located on the left-hand side of the crank- case. Note: designs ...

Page 11: Gen

1-2 gen info important information important information preparation for removal and disassembly 1. Remove all dirt, mud, dust, and foreign material before removal and disassembly. While cleaning, take care to protect the electrical parts, such as relays, switches, motor, resistors, controllers, etc...

Page 12: Gen

1-3 gen info important information gaskets, oil seals, and o-rings 1. All gaskets, seals, and o-rings should be replaced when an engine is overhauled. All gasket surfaces, oil seal lips, and o-rings must be cleaned. 2. Properly oil all mating parts and bearings during reassembly. Apply grease to the...

Page 13: Gen

1-4 gen info special tools special tools some special tools are necessary for a completely accurate tune-up and assembly. Using the correct special tool will help prevent damage that can be caused by the use of improper tools or improvised techniques. Note: • be sure to use the correct part number w...

Page 14: Gen

1-5 gen info special tools • cooling system tester p/n: yu-24460-01 90890-01325 • adapter p/n: yu-33984 90890-01352 this tester and its adapter are used for checking the cooling system. • oil filter wrench p/n: ym-01469 90890-01469 this tool is needed to loosen or tighten the oil filter cartridge. •...

Page 15: Gen

1-6 gen info special tools • 40 and 50 mm bearing driver p/n: ym-04058 90890-04058 • mechanical seal installer p/n: ym-04145 90890-04145 these tools are used to install the water pump seal. • rotor holding tool p/n: yu-01235 90890-01235 this tool is used to hold the camshaft sprocket. • valve guide ...

Page 16: Gen

1-7 gen info special tools • dynamic spark tester p/n: ym-34487 • ignition checker p/n: 90890-06754 this tool is used to check the ignition system component. • engine mount spacer wrench p/n: ys-01516 90890-01516 used to turn the engine mounting bolts when removing/installing engine. • yamaha bond n...

Page 17: Gen

1-8 gen info special tools • clutch bushing press p/n: ys-42424 this tool is used for removing and installing the post bushings (primary sheave cap bush, sliding sheave bush and torque cam bush). • track clip installer p/n: ys-91045-c 90890-01721 this tool is used for installing the track clip. For ...

Page 18: Gen

1-9 gen info special tools • digital circuit tester p/n: yu-a1927 90890-03174 this instrument is necessary for checking the electrical componenets..

Page 19: Insp

2-1 insp adj periodic inspection and adjustment introduction this chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable machine operation and a longer ser- vice life. In addition,...

Page 20: Insp

2-2 insp adj general maintenance and lubrication chart general maintenance and lubrication chart item remarks pre-opera- tion check (daily) initial 1 month or 800 km (500 mi) (40 hr) every seasonally or 4,000 km (2,500 mi) (200 hr) engine oil check oil level. ∗ replace. ∗ engine oil filter cartridge...

Page 21: Insp

2-3 insp adj general maintenance and lubrication chart note: @ brake system: • after disassembling the master cylinder or caliper cylinder, always change the brake fluid. Regularly check the brake fluid level and add fluid if necessary. • replace the oil seals of the master cylinder and caliper cyli...

Page 22: Insp

2-4 insp adj spark plugs/fuel line inspection engine spark plugs 1. Remove: • fuel tank refer to “seat and fuel tank” in chap- ter 5. (pz50/pz50gt/pz50fx/pz50m) refer to “rider seat and fuel tank” in chapter 5. (pz50vt/pz50mp) 2. Remove: • spark plug caps • spark plugs 3. Inspect: • electrodes 1 dam...

Page 23: Insp

2-5 insp adj cooling system cooling system coolant replacement note: the coolant should be changed at least every sea- son. 1. Place the machine on a level surface. 2. Remove: • right side panel • right side cover refer to “cowlings” in chapter 3. 3. Remove: • coolant filler cap 1 warning do not rem...

Page 24: Insp

2-6 insp adj cooling system 7. Connect: • radiator outlet hose 1 8. Fill: • cooling system caution: • hard water or salt water is harmful to engine parts. If soft water is not available, use boiled or distilled water. • do not use water containing impurities or oil. 9. Bleed the air from the cooling...

Page 25: Insp

2-7 insp adj cooling system/valve clearance adjustment air bleeding steps: • remove the cap 1 on the radiator outlet pipe 1. • while slowly adding coolant to the coolant filler, drain the coolant until no more air bubbles appear. • install the cap 1. • add coolant to the full level a. • install the ...

Page 26: Insp

2-8 insp adj valve clearance adjustment 3. Remove: • cylinder head cover refer to “camshafts” in chapter 5. • timing mark accessing screw 1 • crankshaft end accessing screw 2 4. Measure: • valve clearance out of specification → adjust. Checking steps: • turn the crankshaft counterclockwise. • when p...

Page 27: Insp

2-9 insp adj valve clearance adjustment 5. Remove: • intake camshaft • exhaust camshaft note: • refer to “camshafts” in chapter 5. • when removing the timing chain and camshafts, fasten a wire to the timing chain to retrieve it if it falls into the crankcase. 6. Adjust: • valve clearance adjustment ...

Page 28: Insp

2-10 insp adj valve clearance adjustment example: original valve pad number = 148 (thickness = 1.48 mm (0.058 in)) rounded value = 150 • locate the rounded number of the original valve pad and the measured valve clearance in the valve pad selection table. The point where the column and row intersect...

Page 29: Insp

2-11 insp adj valve clearance adjustment valve pad selection table intake exhaust measured clearance ↓ installed pad number 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240 0.00 ~ 0.02 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 ...

Page 30: Insp

2-12 insp adj valve clearance adjustment • install the new valve pad 1 and the valve lifter 2. Note: • apply molybdenum disulfide oil to the valve pad and the valve lifter. • the valve lifter must turn smoothly when rotated by hand. • install the valve lifter and the valve pad in the cor- rect place...