- DL manuals

- Yamaha

- Boat

- WaveRunner GP1200R

- Assembly Manual

Yamaha WaveRunner GP1200R Assembly Manual

Summary of WaveRunner GP1200R

Page 1

*lit186660029* waverunner gp800r assembly manual yamaha motor corporation, usa printed in usa oct. 2000 — ?.? × 1 cr f0w-28107-1a-11 (gp800a) f0w-28107-1a-11 lit-18666-00-29.

Page 2

E waverunner gp800r assembly manual ©2000 by yamaha motor corporation, usa 1st edition, october 2000 all rights reserved. Any reprinting or unauthorized use without the written permission of yamaha motor corporation, usa is expressly prohibited. Printed in usa p/n lit-18666-00-29.

Page 3

E preface this assembly manual contains the infor- mation needed to assemble the yamaha water vehicle correctly prior to delivery to the customer. Since some external parts of the water vehicle have not been assemblied at the yamaha factory for convenience of packing, assembly by the yamaha dealer i...

Page 4

E general torque specifications this chart specifies the torques for tighten- ing standard fasteners with standard clean dry iso threads at room temperature. Torque specifications for special compo- nents or assemblies are given in applicable sections of this manual. To avoid causing warpage, tighte...

Page 5

– 1 – e unpacking and checking carefully uncrate unit and inventory any missing or damaged parts. Note: for usa: if concealed damage is found during uncrating, refer to the yamaha warranty handbook, chapter 3. Documentation may be required for warranty reimbursement. Do not continue with uncrating o...

Page 6

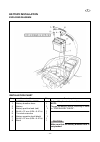

– 2 – e compartment diagram compartment part chart no. Part name q’ty part number 1 grommet 1 f0x-61469-00 2 lower handlebar holder 2 eu0-23814-01 3 handlebar assembly 1 f0w-u155a-00 4 upper handlebar holder 2 eu0-23814-30 5 bolt 8 × 55 mm (0.31 × 2.17 in) 4 90119-089um 6 band 2 90601-200u2 7 band 1...

Page 7

– 3 – e wire lead and cable routing exploded diagram installation chart step procedure/part name q’ty service points wire lead and cable routing follow “step” order for installation. Note: before starting work open the front hood and remove the storage compartment, and remove the seat. 1 choke cable...

Page 8

– 4 – e handlebar and throttle cable installation exploded diagram installation chart step procedure/part name q’ty service points handlebar and throttle cable installation follow “step” order for installation. 1 lower handlebar holder 2 2 handlebar assembly 1 3 upper handlebar holder 2 note: ● alig...

Page 9

– 5 – e exploded diagram step procedure/part name q’ty service points 5 band 1 fasten the qsts cables and handlebar switch lead with band at the handlebar. 6 band 1 7 throttle cable 1 installation steps: ● install the throttle cable end into the throttle lever. ● fit the seal into the groove in the ...

Page 10

– 6 – e choke cable installation exploded diagram installation chart step procedure/part name q’ty service points choke cable installation 1 choke cable 1 installation steps: ● install the choke cable end into the choke lever with the choke lever com- pletely closed. ● route the inner choke cable al...

Page 11

– 7 – e exploded diagram step procedure/part name q’ty service points note: if the inner cable is difficult to make taut using the adjuster 1 , adjust the choke lever so that the cable is taut. The cable must be taut when the choke lever end a is positioned within the line marks b . Reset the adjust...

Page 12

– 8 – e exploded diagram step procedure/part name q’ty service points 2 spiral tube 1 note: be sure to install the spiral tube, containing the throttle cable, choke cable and handle- bar switch lead, at least 50 mm (1.97 in) c into the steering column. ● make sure that the inner cable has some slack...

Page 13

– 9 – e handlebar cover installation exploded diagram installation chart step procedure/part name q’ty service points handlebar cover installation follow “step” order for installation. 1 handlebar cover stay 1 2 screw 6 × 15 mm (0.24 × 0.59 in) 4 3 handlebar cover 1 4 screw 6 × 19 mm (0.24 × 0.75 in...

Page 14

– 10 – e wiring connection installation exploded diagram installation chart step procedure/part name q’ty service points wiring connection installation follow “step” order for installation. 1 speed sensor coupler 1 white coupler (3 pins) 2 fuel level sensor coupler 1 green coupler (2 pins) 3 oil lev...

Page 15

– 11 – e qsts cable installation exploded diagram installation chart step procedure/part name q’ty service points qsts cable installation follow “step” order for installation. 1 qsts cable 1 1 note: ● set the inner cables length a to 77 ± 0.5 mm (3.03 ± 0.02 in), using the adjusting nuts 1 when the ...

Page 16

– 12 – e battery installation exploded diagram installation chart step procedure/part name q’ty service points battery installation follow “step” order for installation. 1 battery breather hose 1 note: charge the battery before installing it. Refer to “predelivery check”. 2 battery 1 3 battery posit...

Page 17

– 13 – e predelivery check checking chart check elements checking points reference page throttle lever free play 5 battery battery condition 13 oil pump air bleed 15 trolling speed trolling speed 16 steering system handlebar and steering nozzle positions 17 qsts trim nozzle position 18 battery warni...

Page 18

– 14 – e 1. Fill: ● battery electrolyte 2. Initial battery charging: ● battery warning turn the battery charger on after the bat- tery is connected to the charger. The sparking by connecting the charging cable to the battery terminal can cause an explosion to the explosive gases coming out from the ...

Page 19

– 15 – e 4. Install: ● filler caps caution: rinse off any electrolyte from the battery case and wipe the battery dry prior to installation. Oil pump air bleeding 1. Bleed: ● air caution: ● do not run the engine if oil does not flow out the air bleed screw. Inspect the oil lines for proper routing an...

Page 20

– 16 – e trolling speed 1. Measure: ● trolling speed out of specification → adjust. Trolling speed: 1,300 ± 50 r/min checking steps: (vehicle on water) ● start the engine and allow it to warm up for a few minutes. ● attach an engine tachometer to the spark plug lead. Engine tachometer: yu-8036-a/908...

Page 21

– 17 – e steering cable 1. Check: ● distance a , b (between the nozzle and nozzle deflector) out of specification → adjust. Difference of distances a and b : maximum 5 mm (0.2 in) checking steps: ● set the control grip in the neutral posi- tion. ● turn the handlebar lock to lock. ● measure the dista...

Page 22

– 18 – e qsts cable 1. Measure: ● nozzle deflector set length a , b difference → adjust. 2. Adjust: ● qsts cable note: if the qsts cable cannot be properly adjusted at the qsts converter side, make sure the qsts cable at the jet pump side is set to the specified length. Measurement steps: ● set the ...

Page 23

– 19 – e appendices service data *1 : pump octane number = (motor octane number + research octane number)/2 *2 : research octane number item unit gp800r trolling speed: r/min 1,300 ± 50 spark plug: type br8es gap mm (in) 0.7–0.8 (0.028–0.031) fuel and oil: fuel regular unleaded gasoline with a minim...

Page 24: Waverunner

*lit186660029* waverunner gp800r assembly manual yamaha motor corporation, usa printed in usa oct. 2000 — ?.? × 1 cr f0w-28107-1a-11 (gp800a) f0w-28107-1a-11 lit-18666-00-29.