- DL manuals

- Yamaha

- Boat

- WaveRunner GP1200R

- Service Manual

Yamaha WaveRunner GP1200R Service Manual

Summary of WaveRunner GP1200R

Page 1

*lit186160215* service manual lit-18616-02-15 f0x-28197-za-11 waverunnergp1200r.

Page 2: Notice

E notice this manual has been prepared by the yamaha motor company ltd. Primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mecha...

Page 3: How to Use This Manual

E how to use this manual manual format all of the procedures in this manual are organized in a sequential, step-by-step format. The information has been compiled to provide the mechanic with an easy to read, handy refer- ence that contains comprehensive explanations of all disassembly, repair, assem...

Page 4

E important information in this service manual particularly important information is distinguished in the following ways. The safety alert symbol means attention! Become alert! Your safety is involved! Warning failure to follow warning instructions could result in severe injury or death to the machi...

Page 5

E how to use this manual 1 to help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section. 2 numbers are given in the order of the jobs in the exploded diagram. 3 symbols indicate parts to be lubricated or replaced (see “symbols”)...

Page 6: Gen

E a50001-1-4 symbols symbols 1 to 9 are designed as thumb- tabs to indicate the content of a chapter. 1 general information 2 specifications 3 periodic inspection and adjustment 4 fuel system 5 power unit 6 jet pump unit 7 electrical system 8 hull and hood 9 trouble analysis symbols 0 to e indicate ...

Page 7: Index

E index general information 1 specifications 2 spec periodic inspection and adjustment 3 fuel system 4 fuel power unit 5 powr jet pump unit 6 jet pump electrical system 7 elec hull and hood 8 hull hood trouble analysis 9 gen info insp adj – + trbl anls a30000-0

Page 8: Gen

E 1 gen info chapter 1 general information identification numbers ......................................................................... 1-1 primary l.D. Number........................................................................... 1-1 engine serial number .......................................

Page 9: Gen

1-1 e gen info identification numbers a60700-0* identification numbers primary l.D. Number the primary l.D. Number is stamped on a label attached to the inside of the engine compartment. Starting primary l.D. Number: f0x: 800101 ~ engine serial number the engine serial number is stamped on a label a...

Page 10: Gen

1-2 e gen info safety while working safety while working the procedures given in this manual are those recommended by yamaha to be fol- lowed by yamaha dealers and their mechanics. Fire prevention gasoline (petrol) is highly flammable. Petroleum vapor is explosive if ignited. Do not smoke while hand...

Page 11: Gen

1-3 e gen info safety while working under normal conditions of use there should be no hazards from the use of the lubricants mentioned in this manual, but safety is all-important, and by adopting good safety practises any risk is minimized. A summary of the most important precau- tions is as follows...

Page 12: Gen

1-4 e gen info safety while working 3. Non-reusable items always use new gaskets, packings, o- rings, oil seals, split-pins, circlips, etc., on reassembly. Disassembly and assembly 1. Clean parts with compressed air when disassembling. 2. Oil the contact surfaces of moving parts during assembly. 3. ...

Page 13: Gen

1-5 e gen info special tools special tools using the correct special tools recom- mended by yamaha, will aid the work and enable accurate assembly and tune-up. Improvisations and using improper tools can damage the equipment. Note: ● for u.S.A. And canada, use part numbers starting with “j-”, “yb-”,...

Page 14: Gen

1-6 e gen info special tools removal and installation 1. Coupler wrench p/n. Yw-06551 90890-06551 2. Flywheel holder p/n. Yw-06550 90890-06550 3. Flywheel puller p/n. Yb-06117 90890-06521 4. Drive shaft holder (impeller) p/n. Yb-06151 90890-06519 5. Slide hammer set (jet pump bearing) p/n. Yb-06096 ...

Page 15: Spec

E 2 spec chapter 2 specifications general specifications ......................................................................... 2-1 maintenance specifications ................................................................ 2-3 engine .................................................................

Page 16: Spec

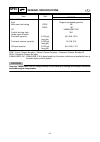

2-1 spec e general specifications general specifications item unit model gp1200r model code hull f0x engine 67x dimensions length mm (in) 2,930 (115.4) width mm (in) 1,150 (45.3) height mm (in) 1,020 (40.2) dry weight kg (lb) 306 (675) vehicle capacity 2 performance maximum output kw (ps) @ r/min 11...

Page 17: Spec

2-2 spec e pon*: pump octane number = (motor octane number + research octane number)/2 ron*: research octane number yamalube 2-w*: yamalube 2-w is developed for this water vehicles and available from a yamaha water vehicle dealer. Caution: use only yamalube 2-w oil. Using another oil can seriously d...

Page 18: Spec

2-3 spec e maintenance specifications maintenance specifications engine item unit model gp1200r cylinder head warpage limit mm (in) 0.1 (0.004) compression pressure *1 kpa (kg/cm 2 ) 500 (5.0) cylinders bore size mm (in) 80.000 ~ 80.018 (3.1496 ~ 3.1503) taper limit mm (in) 0.08 (0.003) out-of-round...

Page 19: Spec

2-4 spec e maintenance specifications jet pump unit hull and hood crankshaft assembly crank width a mm (in) 72.95 ~ 73.00 (2.872 ~ 2.874) deflection limit b mm (in) 0.05 (0.002) deflection limit c mm (in) 0.15 (0.006) big end side clearance d mm (in) 0.25 ~ 0.75 (0.010 ~ 0.030) maximum small end axi...

Page 20: Spec

2-5 spec e maintenance specifications electrical item unit model gp1200r battery type fluid capacity v-ah (kc) 12 - 19 (68.4) cdi unit (b/o – b for cylinder #1) (b/w – b for cylinder #2) (b/y – b for cylinder #3) output peak voltage lower limit @cranking 1 v 200 @cranking 2 v 180 @2,000 r/min v 190 ...

Page 21: Spec

2-6 spec e maintenance specifications rectifier/regulator (r – b) output peak voltage lower limit (unloaded) @cranking v 7 @2,000 r/min v 12.6 @3,500 r/min v 12.6 starter motor brush length mm (in) 12.5 (0.49) wear limit mm (in) 6.5 (0.26) commutator undercut mm (in) 0.7 (0.03) limit mm (in) 0.2 (0....

Page 22: Spec

2-7 spec e tightening torques tightening torques specified torques part to tightened part name thread size q’ty tightening torque remarks nm m•kgf ft•lb engine muffler cover – muffler bolt m6 3 12 1.2 8.7 242 lt muffler stay – cylinder body bolt m10 2 39 3.9 28 271 lt muffler – muffler stay 2 bolt m...

Page 23: Spec

2-8 spec e tightening torques cylinder – crankcase 1st bolt m10 12 22 2.2 16 572 lt 2nd 39 3.9 28 generator cover – crankcase 1st bolt m10 7 15 1.5 11 271 lt 2nd 50 5.0 36 generator cover/ground lead – crankcase 1st bolt m10 1 15 1.5 11 2nd 50 5.0 36 bracket – crankcase bolt m10 4 39 3.9 28 271 lt p...

Page 24: Spec

2-9 spec e tightening torques grip end – handlebar bolt m5 2 1 0.1 0.7 choke lever assembly – handlebar screw m5 2 3 0.3 2.2 qsts cable housing – cover screw m4 1 1 0.1 0.7 plate/steering column assembly – deck nut — 2 16 1.6 11 steering column – deck nut — 2 16 1.6 11 steering arm – steering column...

Page 25: Spec

2-10 spec e tightening torques engine mount – hull bolt m8 6 17 1.7 12 572 lt engine mount/plate – hull bolt m8 2 17 1.7 12 572 lt engine damper – hull bolt m6 4 5 0.5 3.6 part to tightened part name thread size q’ty tightening torque remarks nm m•kgf ft•lb general torque this chart specifies tighte...

Page 26: Spec

2-11 spec e cable and hose routing cable and hose routing i-i h-h j d-d e-e f-f g-g a c b 20˚ a b c e e g j g d d e e i i g g h h f f g g c 2 2 d e f c 6 i h a i b a 6 7 8 9 0 1 2 2 3 2 4 5 6 7 1 fuel filter 2 fuel breather hose 3 fuel hose 4 pilot water hose 5 bilge hose 6 speed sensor lead 7 elect...

Page 27: Spec

2-12 spec e cable and hose routing a h d g a g e-e f-f d b c i-i h i i i i f f c e e i i b i 1 5 7 9 0 a b c d e f 8 f d g h g d f f 9 2 5 4 g j h 6 1 2 2 3 4 5 8 k 1 choke cable 2 steering cable 3 cooling water hose 4 qsts cable 5 speed sensor lead 6 bilge hose 7 flushing hose 8 electrical box 9 to...

Page 28: Insp

E 3 insp adj chapter 3 periodic inspection and adjustment maintenance interval chart .............................................................. 3-1 periodic service ........................................................................................ 3-2 control system ..........................

Page 29: Insp

3-1 insp adj e maintenance interval chart maintenance interval chart the following chart should be considered strictly as a guide to general maintenance intervals. Depending on operating conditions, the intervals of maintenance should be changed. *1: after every ride *2: inspect fluid level before e...

Page 30: Insp

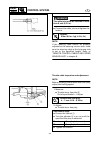

3-2 insp adj e control system periodic service control system steering column inspection 1. Inspect: ● steering column excessive play → replace the steer- ing column. Refer to “steering column” in chapter 8. Steering cable inspection and adjustment 1. Inspect: ● distance a , b out of specification →...

Page 31: Insp

3-3 insp adj e control system note: if the steering cable cannot be properly adjusted at the steering column side, make sure the steering cable at the jet pump side is set to the specified length. Refer to “remote control cables and speed sensor lead” in chapter 8. Throttle cable inspection and adju...

Page 32: Insp

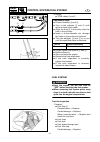

3-4 insp adj e control system warning after adjusting the free play, turn the han- dlebar to the right and left and make sure that the trolling speed does not increase. Choke cable inspection and adjustment 1. Check: ● choke lever operation incorrect operation → adjust. 2. Adjust: ● choke lever oper...

Page 33: Insp

3-5 insp adj e control system qsts cable inspection and adjustment 1. Measure: ● nozzle deflector set length a, b difference → adjust. Measurement steps: ● set the control grip in the neutral posi- tion. ● measure the nozzle deflector set length a and b. ● if a and b length are not even, adjust the ...

Page 34: Insp

3-6 insp adj e control system note: if correct adjustment by using the cable joint at the wheel end is not obtained, adjust the cable joint on the trim nozzle end. Refer to “remote control cables and speed sensor lead” in chapter 8. Ypvs cable adjustment 1. Check: ● ypvs valve position incorrect pos...

Page 35: Insp

3-7 insp adj e control system/fuel system 3. Adjust: ● ypvs cables 1 and 2 fuel system warning ● stop the engine, set the fuel cock to “off” before servicing the fuel system. ● when removing fuel system parts, wrap them in a cloth and take care that no fuel spills into the engine compartment. Fuel l...

Page 36: Insp

3-8 insp adj e fuel system 2. Inspect: ● water separator 1 water accumulation → drain. Note: if need the water draining, remove the drain plug 2. Trolling speed check and adjustment 1. Check: ● trolling speed out of specification → adjust. Trolling speed: 1,350 ± 50 r/min checking steps (with the ve...

Page 37: Insp

3-9 insp adj e oil injection system/power unit oil injection system oil line inspection refer to “oil tank” in chapter 4. Power unit spark plug inspection 1. Inspect: ● electrodes 1 damage/wear → replace. ● insulator color 2 distinctly different color → check the engine condition. 2. Clean: ● spark ...

Page 38: Insp

3-10 insp adj e power unit/electrical 4. Tighten: ● spark plug note: ● before installing the spark plug, clean the gasket surface and spark plug surface. Also, it is suggested to apply a thin film of anti-seize compound to the spark plug threads to prevent thread seizure. ● if a torque wrench is not...

Page 39: Insp

3-11 insp adj e electrical batteries generate explosive, hydrogen gas. Always follow these preventive mea- sures: ● charge batteries in a well-ventilated area. ● keep batteries away from fire, sparks or open flames (e.G., welding equipment, lighted cigarettes). ● do not smoke when charging or han- d...

Page 40: Insp

3-12 insp adj e electrical 2. Inspect: ● electrolyte level low → add distilled water. The electrolyte level should be between the upper a and lower b level marks. Caution: use only distilled water. Other types of water contain minerals which are harmful to batteries. Filling steps: ● remove each fil...

Page 41: Insp

3-13 insp adj e electrical/jet pump unit 5. Install: ● battery breather hose 1 ● battery ● battery positive lead 2 ● battery negative lead 3 ● band caution: ● connect the positive lead to the battery terminal first. ● make sure the battery leads are con- nected properly. Reversing the leads can seri...

Page 42: Insp

3-14 insp adj e jet pump unit/general water inlet strainer inspection 1. Inspect: ● water inlet strainer contaminants → clean. Cracks/damage → replace. Inspection steps: ● remove the water inlet cover 1. ● inspect the water inlet strainer mesh a. ● install the water inlet cover. 1 a bilge strainer i...

Page 43: Insp

3-15 insp adj e general lubrication points 1. Lubricate: ● throttle cable (handlebar side) note: before lubricating the throttle cable, squeeze the throttle lever and remove the rubber seal 1. Recommended lubricant: rust inhibitor 2. Lubricate: ● qsts control cables (handlebar side) note: before lub...

Page 44: Insp

3-16 insp adj e general 4. Lubricate: ● throttle cable (carburetor side) ● oil pump cable ● qsts cables (pulley side) ● ypvs cables recommended grease: yamaha marine grease, yamaha grease a (water resistant grease) 5. Lubricate: ● nozzle pivot shaft ● steering cable (nozzle side) ● qsts cable (nozzl...

Page 45: Insp

3-17 insp adj e general 6. Lubricate: ● steering cable ● steering cable joint note: disconnect the joints and apply a small amount of grease. Recommended grease: yamaha marine grease, yamaha grease a (water resistant grease) 7. Fill: ● intermediate housing note: fill the intermediate housing with th...

Page 46: Fuel

E fuel chapter 4 fuel system fuel cock and fuel filter ..................................................................... 4-1 exploded diagram ............................................................................. 4-1 removal and installation chart ............................................

Page 47: Fuel

E 4 fuel carburetor .............................................................................................. 4-18 exploded diagram ........................................................................... 4-18 removal and installation chart ............................................. 4-18 ...

Page 48: Fuel

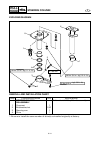

4-1 fuel e fuel cock and fuel filter fuel cock and fuel filter exploded diagram removal and installation chart step procedure/part name q’ty service points fuel cock and fuel filter removal follow the left “step” for removal. 1 screw 1 2 knob 1 3 nut 1 4 fuel cock assembly 1 5 fuel hose 3 6 holder 1...

Page 49: Fuel

4-2 fuel e fuel cock and fuel filter service points fuel filter inspection refer to “fuel system” in chapter 3. Fuel cock inspection 1. Check: ● fuel cock contaminants → clean. Rough movement → replace..

Page 50: Fuel

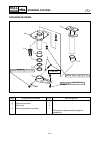

4-3 fuel e oil tank oil tank exploded diagram removal and installation chart step procedure/part name q’ty service points oil tank removal follow the left “step” for removal. Engine unit refer to “engine unit” in chapter 5. Steering console cover assembly refer to “steering console cover” in chapter...

Page 51: Fuel

4-4 fuel e oil tank exploded diagram step procedure/part name q’ty service points 6 breather hose 1 7 oil hose 1 8 bolt 2 9 tank belt 2 10 oil tank assembly 1 11 hose clamp 1 12 oil filler hose 1 13 oil level sensor 1 reverse the removal steps for installation..

Page 52: Fuel

4-5 fuel e oil tank service points oil line inspection 1. Inspect: ● oil filter contaminants → clean. Frays/tears → replace. ● rubber seal cracks/wear → replace. ● oil hose ● oil tank ● oil filler cap cracks/damage → replace. ● check valve malfunction → replace. Oil level switch inspection refer to ...

Page 53: Fuel

4-6 fuel e fuel tank fuel tank exploded diagram removal and installation chart step procedure/part name q’ty service points fuel tank removal follow the left “step” for removal. Oil tank refer to “oil tank”. 1 fuel level sensor coupler 1 2 hose clamp 1 3 nut 1 4 fuel filler neck 1 5 rubber seal 1 6 ...

Page 54: Fuel

4-7 fuel e fuel tank exploded diagram step procedure/part name q’ty service points 7 fuel hose 1 8 fuel return hose 1 red mark a 9 fuel breather hose 1 10 fuel tank assembly 1 11 hose clamp 1 12 fuel filler hose 1 13 hose clamp 1 14 fuel sensor assembly 1.

Page 55: Fuel

4-8 fuel e fuel tank exploded diagram step procedure/part name q’ty service points 15 one way valve 1 16 screw/washer 1/1 17 filter 1 18 screw/washer 1/1 19 sleeve 1 20 floatation 1 21 bolt 2 22 tank bolt 2 reverse the removal steps for installation..

Page 56: Fuel

4-9 fuel e fuel tank service points check valve inspection 1. Check: ● check valve faulty → replace. Fuel level switch inspection refer to “indication system” in chapter 7. Fuel tank inspection 1. Inspect: ● fuel tank cracks/damage → replace. Pipe joint inspection 1. Inspect: ● pipe contaminants → c...

Page 57: Fuel

4-10 fuel e intake duct and silencer intake duct and silencer exploded diagram removal and installation chart step procedure/part name q’ty service points intake duct and silencer removal follow the left “step” for removal. Exhaust chamber assembly refer to “exhaust chamber assembly” in chapter 5. 1...

Page 58: Fuel

4-11 fuel e intake duct and silencer exploded diagram step procedure/part name q’ty service points 6 bolt/collar/grommet 1/1/1 7 intake duct 1 8 silencer case 1 9 bolt 6 10 spark arrester 1 11 silencer plate 1 12 o-ring 3 reverse the removal steps for installation..

Page 59: Fuel

4-12 fuel e carburetor unit carburetor unit exploded diagram removal and installation chart step procedure/part name q’ty service points carburetor unit removal follow the left “step” for removal. Silencer plate refer to “intake duct and silencer”. 1 oil pump cable 1 note: before removing the oil pu...

Page 60: Fuel

4-13 fuel e carburetor unit exploded diagram step procedure/part name q’ty service points 5 fuel return hose 1 red mark a 6 oil delivery hose 3 7 clamp/fuel pump vacuum hose 3/3 8 remote throttle stop screw 1 9 bolt 6 10 bolt 4 11 carburetor assembly 1 12 gasket 1 reverse the removal steps for insta...

Page 61: Fuel

4-14 fuel e carburetor unit exploded diagram removal and installation chart step procedure/part name q’ty service points carburetor unit separation follow the left “step” for removal. 1 hose 2 fuel suction 2 hose 2 fuel return 3 accelerator pump hose 1 4 remote throttle stop screw assembly 1 5 throt...

Page 62: Fuel

4-15 fuel e carburetor unit exploded diagram step procedure/part name q’ty service points 7 bolt 3 8 cable holder 1 9 bolt 6 10 carburetor 3 11 gasket 3 12 plate 1 reverse the removal steps for installation. Not reusable.

Page 63: Fuel

4-16 fuel e carburetor unit service points throttle valve synchronization inspection and adjustment 1. Check: ● throttle valve synchronization not synchronized → adjust. Checking steps: ● loosen the remote throttle stop screw 1 until untouched the screw end from the throttle lever. ● check the each ...

Page 64: Fuel

4-17 fuel e carburetor unit choke cable and throttle cable installation 1. Install: ● choke cable 1 ● throttle cable 2 choke cable guide installation position a: 16 ~ 18 mm (0.63 ~ 0.71 in) throttle cable guide installation position b: 18 ~ 20 mm (0.71 ~ 0.79 in) 2. Adjust: ● throttle lever free pla...

Page 65: Fuel

4-18 fuel e carburetor carburetor exploded diagram removal and installation chart step procedure/part name q’ty service points carburetor disassembly follow the left “step” for disassembly. 1 accelerator pump delivery hose 2 for carburetor #3 2 accelerator pump fuel hose 1 3 screw 4 4 accelerator pu...

Page 66: Fuel

4-19 fuel e carburetor exploded diagram step procedure/part name q’ty service points 10 pilot jet 1 11 screw 1 12 arm 1 13 arm pin 1 14 spring 1 15 screw 1 16 needle valve seat holder 1 17 needle valve 1 18 needle valve seat 1 19 o-ring 1 reverse the disassembly steps for assembly..

Page 67: Fuel

4-20 fuel e carburetor exploded diagram removal and installation chart step procedure/part name q’ty service points accelerator pump disassembly follow the left “step” for disassembly. 1 screw 1 2 stay 1 3 spring 1 4 spring seat 1 5 screw 4 6 accelerator pump cover assembly 1 7 spring 1 8 diaphragm ...

Page 68: Fuel

4-21 fuel e carburetor service points caution: do not use steel wire for cleaning the jets. This may enlarge the jet diameters and seriously affect performance. Diaphragm inspection 1. Inspect: ● diaphragm damage → replace. Accelerator pump body inspection 1. Inspect: ● one way valve crack/damage → ...

Page 69: Fuel

4-22 fuel e regulator body inspection 1. Inspect: ● regulator body contaminants → clean. Damage → replace. ● valve (clear film) 1 damage → replace. Needle valve inspection 1. Inspect: ● needle valve ● needle valve seat contaminants a → clean. Wear b → replace. Note: always replace the needle valve a...

Page 70: Fuel

4-23 fuel e fuel pump fuel pump exploded diagram removal and installation chart step procedure/part name q’ty service points fuel pump disassembly follow the left “step” for disassembly. Carburetors refer to “carburetor”. 1 screw 4 2 fuel pump cover 1 3 gasket 1 4 diaphragm 1 5 o-ring 1 6 diaphragm ...

Page 71: Fuel

4-24 fuel e fuel pump exploded diagram step procedure/part name q’ty service points 7 rubber diaphragm 1 8 diaphragm 1 9 packing 1 10 fuel filter 1 reverse the disassembly steps for assembly..

Page 72: Fuel

4-25 fuel e fuel pump service points fuel pump inspection 1. Inspect: ● diaphragm ● rubber diaphragm ● diaphragm body damage → replace. Fuel filter inspection 1. Inspect: ● fuel filter clog/contaminants → clean. Damage → replace..

Page 73: Fuel

4-26 fuel e oil pump oil pump exploded diagram removal and installation chart step procedure/part name q’ty service points oil pump removal follow the left “step” for removal. Engine unit refer to “engine unit” in chapter 5. 1 bolt 1 2 bleed hose stay 1 3 bolt 2 4 oil pump assembly 1 5 gasket 1 6 oi...

Page 74: Fuel

4-27 fuel e oil pump exploded diagram removal and installation chart step procedure/part name q’ty service points oil pump hoses and cable removal follow the left “step” for removal. 1 bleed hose 1 2 air bleed screw 1 3 gasket 1 4 bleed hose stay 1 5 oil delivery hose 1 3 6 oil delivery hose 2 3 7 c...

Page 75: Fuel

4-28 fuel e oil pump service points oil pump inspection 1. Inspect: ● oil pump contaminants → clean. Damage/wear → replace. ● oil pump joint piece damage/wear → replace. Oil hose inspection 1. Inspect: ● oil hose cracks/damage → replace. Caution: ● if the oil delivery hoses are not full of oil, fill...

Page 76: Fuel

4-29 fuel e oil pump oil pump cable adjustment 1. Check: ● oil pump lever position incorrect → adjust. Checking steps: ● fully close the carburetor throttle valves. ● check that the mark a on the oil pump lever is aligned with the mark b on the oil pump body. 2. Adjust: ● oil pump cable note: if the...

Page 77: Fuel

4-30 fuel e oil pump oil injection pump air bleeding 1. Bleed: ● air air bleeding steps: ● place rags around the air bleed screw 1 to catch any oil that might spill. ● fill the oil tank with the recommended oil. Note: if the oil pump is replaced or the oil suc- tion hose is reinstalled, bleed air fr...

Page 78: Powr

E powr chapter 5 power unit muffler assembly ................................................................................... 5-1 exploded diagram ............................................................................. 5-1 removal and installation chart ........................................

Page 79: Powr

E 5 powr cylinders ................................................................................................... 5-25 exploded diagram ........................................................................... 5-25 removal and installation chart ............................................. 5...

Page 80: Powr

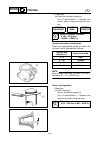

5-1 powr e muffler assembly exploded diagram removal and installation chart step procedure/part name q’ty service points water hoses and leads removal follow the left “step” for removal. Ypvs servomotor refer to “ypvs servomotor” in chapter 7. Battery box refer to “battery box” in chapter 8. 1 spark...

Page 81: Powr

5-2 powr e muffler assembly exploded diagram step procedure/part name q’ty service points 4 ac magneto coupler 1 5 cap/bolt 3/3 6 cover 1 7 water hose/clamp 2/2 Å for cooling water pilot outlet on port side 6 × 22 mm 12 nm (1.2 m • kgf, 8.7 ft • ib) 5 lt 242 7 6 7 1 2 3 4 Å.

Page 82: Powr

5-3 powr e muffler assembly exploded diagram step procedure/part name q’ty service points 8 hose clamp 2 slide the outer exhaust joint. 9 hose clamp 2 10 hose clamp 1 11 water lock band 1 slide the water lock. 12 bolt 4 13 intermediate housing grease hose 1 14 nut 2 15 eye 2 note: remove the spark p...

Page 83: Powr

5-4 powr e muffler assembly exploded diagram step procedure/part name q’ty service points 16 bolt 2 17 bolt 1 18 bolt 1 19 bolt 1 20 muffler stay 2 1 21 muffler assembly 1 note: remove the cylinder head if it is difficult to remove the muffler assembly. 22 outer exhaust joint 1 23 inner exhaust join...

Page 84: Powr

5-5 powr e muffler assembly exploded diagram removal and installation chart step procedure/part name q’ty service points muffler disassembly follow the left “step” for disassembly. 1 exhaust temperature sensor 1 2 water temperature sensor 1 3 bolt 2 4 muffler stay 1 5 bolt 6 6 cover 1 7 gasket 1 8 c...

Page 85: Powr

5-6 powr e muffler assembly exploded diagram step procedure/part name q’ty service points 9 gasket 1 10 catalyst 1 11 gasket 1 12 pin 2 13 bolt 6 14 mixing joint 1 15 gasket 1 16 muffler 1 reverse the disassembly steps for assembly. Not reusable not reusable not reusable.

Page 86: Powr

5-7 powr e muffler assembly service point catalyst inspection 1. Inspect: ● catalyst cracks/damage → replace..

Page 87: Powr

5-8 powr e exhaust chamber assembly exhaust chamber assembly exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust chamber assembly removal follow the left “step” for removal. Muffler assembly refer to “muffler assembly”. 1 clamp/hose 3/3 Å for cooling ...

Page 88: Powr

5-9 powr e exhaust chamber assembly exploded diagram step procedure/part name q’ty service points 8 exhaust chamber assembly 1 note: before installing the exhaust chamber assembly, install the clamp/hose (step no.7) and place the bolts (step no.2) in the bolts holes of the exhaust chamber assembly. ...

Page 89: Powr

5-10 powr e exhaust chamber assembly exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust chamber disassembly follow the left “step” for disassembly. 1 bolt 5 2 bolt 1 3 exhaust chamber joint 1 4 gasket 1 5 pin 2 6 exhaust chamber 1 reverse the disasse...

Page 90: Powr

5-11 powr e engine unit engine unit exploded diagram removal and installation chart step procedure/part name q’ty service points engine unit removal follow the left “step” for removal. Carburetor unit refer to “carburetor unit” in chapter 4. 1 clamp/water hose 1/1 should be white mark a up side 2 oi...

Page 91: Powr

5-12 powr e engine unit exploded diagram step procedure/part name q’ty service points 6 coupling cover 1 7 bolt/washer 4/4 8 engine assembly 1 9 shim * install the shims original position. Reverse the removal steps for installation. *: as required lt 572 lt 572 8 × 40 mm 17 nm (1.7 m • kgf, 12 ft • ...

Page 92: Powr

5-13 powr e engine unit service points shim removal 1. Remove: ● shims note: to ease reassembly and coupling align- ment, remove the shims and organize them in their respective groups (e.G., front right, rear left) prior to removing the mounting bolts. Engine mount inspection 1. Inspect: ● engine mo...

Page 93: Powr

5-14 powr e exhaust manifold exhaust manifold exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust manifold and leads removal follow the left “step” for removal. Engine unit refer to “engine unit”. 1 bolt 4 2 bolt 6 3 nut 2 4 exhaust manifold 1 5 gaske...

Page 94: Powr

5-15 powr e exhaust manifold exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust manifold disassembly follow the left “step” for disassembly. 1 clamp/hose 1/1 2 bolt 6 3 water pipe 1 4 o-ring 3 5 exhaust manifold 1 reverse the disassembly steps for as...

Page 95: Powr

5-16 powr e reed valves reed valves exploded diagram removal and installation chart step procedure/part name q’ty service points reed valve removal follow the left “step” for removal. Carburetor unit refer to “carburetor unit” in chapter 4. 1 bolt 18 note: tighten the bolts in the proper sequence as...

Page 96: Powr

5-17 powr e reed valves service points reed valve inspection 1. Inspect: ● reed valves cracks/damage → replace. 2. Measure: ● valve bending a out of specification → replace. 3. Measure: ● valve stopper height b out of specification → adjust or replace. Max. Valve bending: 0.2 mm (0.01 in) valve stop...

Page 97: Powr

5-18 powr e ypvs ypvs exploded diagram removal and installation chart step procedure/part name q’ty service points ypvs removal follow the left “step” for removal. Exhaust chamber assembly refer to “exhaust chamber assembly”. 1 bolt 12 2 ypvs valve cover 3 3 gasket 3 4 spacer 2 5 link joint/cover 2/...

Page 98: Powr

5-19 powr e ypvs exploded diagram step procedure/part name q’ty service points 7 washer 5 8 bolt 3 note: during installation, align the hole a in the ypvs shaft with the bolt. 9 shaft 3 1 10 shaft 2 1 11 shaft 1 1 12 ypvs valve arm 3.

Page 99: Powr

5-20 powr e ypvs exploded diagram step procedure/part name q’ty service points 13 bolt 3 14 ypvs valve assembly 3 15 oil seal 6 note: if the ypvs shaft is removed, the oil seal must be replaced. Reverse the removal steps for installation..

Page 100: Powr

5-21 powr e service points ypvs valve inspection 1. Eliminate: ● carbon deposits (with a rounded scraper 1) caution: do not use a sharp instrument to avoid damaging or scratching the surfaces. 2. Inspect: ● ypvs valve assembly crack/damage/wear → replace. Ypvs valve installation 1. Install: ● oil se...

Page 101: Powr

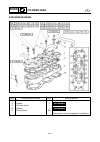

5-22 powr e cylinder head cylinder head exploded diagram removal and installation chart step procedure/part name q’ty service points cylinder head removal follow the left “step” for removal. Exhaust chamber assembly refer to “exhaust chamber assembly”. 1 spark plug 3 2 bolt 1 note: tighten the bolts...

Page 102: Powr

5-23 powr e cylinder head exploded diagram step procedure/part name q’ty service points 7 cylinder head cover 1 8 gasket 1 9 cylinder head 1 10 gasket 1 11 clamp/hose 2/2 a white mark reverse the removal steps for installation. Not reusable not reusable.

Page 103: Powr

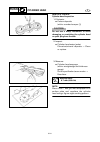

5-24 powr e cylinder head service points cylinder head inspection 1. Eliminate: ● carbon deposits (with a rounded scraper 1) caution: do not use a sharp instrument to avoid damaging or scratching the cylinder head or spark plug bore threads. 2. Inspect: ● cylinder head water jacket corrosion/mineral...

Page 104: Powr

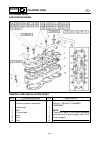

5-25 powr e cylinders cylinders exploded diagram removal and installation chart step procedure/part name q’ty service points cylinder removal follow the left “step” for removal. Ypvs refer to “ypvs”. Cylinder head refer to “cylinder head”. 1 bolt 12 note: tighten the bolts in a crisscross pattern an...

Page 105: Powr

5-26 powr e cylinders service points cylinder inspection 1. Eliminate: ● carbon deposits (with a rounded scraper 1) 2. Inspect: ● cylinder water jacket corrosion/mineral deposits → clean or replace. ● cylinder inner surface score marks → replace. 3. Measure: ● cylinder bore “d” (with a cylinder gaug...

Page 106: Powr

5-27 powr e pistons pistons exploded diagram removal and installation chart step procedure/part name q’ty service points piston removal follow the left “step” for removal. Cylinders refer to “cylinders”. 1 piston pin clip 2 caution: do not align the open end of the clip with the piston pin slot a. 2...

Page 107: Powr

5-28 powr e pistons exploded diagram step procedure/part name q’ty service points 5 bearing 1 6 piston ring 2 caution: align each end gap with its respective locating pin. Reverse the removal steps for installation..

Page 108: Powr

5-29 powr e pistons service points piston pin clip removal and installation 1. Remove and install: ● piston pin clip note: before removing or installing the piston pin clip, cover the crankcase opening with a clean rag to prevent the piston pin clip from falling into the crankcase. Piston inspection...

Page 109: Powr

5-30 powr e pistons 4. Calculate: ● piston-to-cylinder clearance out of specification → replace the piston, piston rings and cylinder as a set. Cylinder and piston combination select the appropriate piston to match the cylinder size by the table as follows. Note: new cylinder bore size = 80.000 + a/...

Page 110: Powr

5-31 powr e pistons 2. Measure: ● end gap (with a thickness gauge 1) out of specification → replace the piston rings as a set. Note: push the piston ring into the cylinder with the piston crown. End gap: 0.45 ~ 0.60 mm (0.018 ~ 0.024 in) piston pin and bearing inspection 1. Inspect: ● piston pins ● ...

Page 111: Powr

5-32 powr e pistons 4. Check: ● piston-pin-to-connecting-rod free play (with the piston pin in the small end of the connecting rod as shown) free play/small end wear → replace the piston pin, connecting rod or both..

Page 112: Powr

5-33 powr e generator and starter motor generator and starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points generator cover removal follow the left “step” for removal. Oil pump refer to “oil pump” in chapter 4. 1 bolt 1 2 bolt 7 3 ground lead 1 4 ...

Page 113: Powr

5-34 powr e generator and starter motor exploded diagram step procedure/part name q’ty service points 6 spring 1 7 packing 1 8 pin 2 9 bolt 2 10 bolt 2 11 bracket 1 reverse the removal steps for installation..

Page 114: Powr

5-35 powr e exploded diagram removal and installation chart step procedure/part name q’ty service points stator coil and pickup coil removal follow the left “step” for removal. 1 bolt 3 note: this washer holds the pickup coil lead. Make sure to not pinch the lead between the projection and the washe...

Page 115: Powr

5-36 powr e generator and starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points generator rotor and starter motor removal follow the left “step” for removal. 1 drive coupling 1 2 flywheel magneto bolt 1 3 flywheel magneto 1 4 woodruff key 1 5 star...

Page 116: Powr

5-37 powr e generator and starter motor exploded diagram step procedure/part name q’ty service points 8 nut/washer 1/1 9 starter motor lead 1 10 starter motor 1 reverse the removal steps for installation..

Page 117: Powr

5-38 powr e generator and starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points starter clutch disassembly follow the left “step” for disassembly. 1 clip 1 2 clip stopper 1 3 spring seat 1 4 spring 1 5 idle gear 1 6 circlip 1 7 plate 1 not reusabl...

Page 118: Powr

5-39 powr e generator and starter motor exploded diagram step procedure/part name q’ty service points 8 weight 3 9 spring ring 1 10 pinion gear 1 reverse the disassembly steps for assembly..

Page 119: Powr

5-40 powr e service points drive coupling removal and installation 1. Remove: ● drive coupling note: install the drive coupling with the same special tools that were used for removal. Coupler wrench: yw-06551/90890-06551 flywheel holder: yw-06550/90890-06550 flywheel magneto removal and installation...

Page 120: Powr

5-41 powr e generator and starter motor drive coupling inspection 1. Inspect: ● drive coupling damage/wear → replace. Flywheel magneto inspection 1. Inspect: ● ring gear damage/wear → replace. Starter clutch assembly inspection 1. Inspect: ● pinion gear 1 ● idle gear 2 damage/wear → replace. 2. Chec...

Page 121: Powr

5-42 powr e crankcase crankcase exploded diagram removal and installation chart step procedure/part name q’ty service points crankcase disassembly follow the left “step” for disassembly. Pistons refer to “pistons”. Generator cover and starter motor refer to “generator and starter motor”. 1 bolt 6 2 ...

Page 122: Powr

5-43 powr e crankcase exploded diagram step procedure/part name q’ty service points 7 bolt 1 note: tighten the bolts in sequence as shown. 8 bolt 16 9 lower crankcase 1 10 pin 2 11 crankshaft assembly 1 12 upper crankcase 1 reverse the disassembly steps for assembly..

Page 123: Powr

5-44 powr e crankcase service points crankcase inspection 1. Inspect: ● mating surfaces scratches → replace the crankcase. ● crankcase cracks/damage → replace. Crankcase installation 1. Apply: ● gasket maker ® (onto the crankcase mating surfaces) note: before applying gasket maker ® , clean the cran...

Page 124: Powr

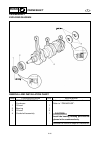

5-45 powr e crankshaft crankshaft exploded diagram removal and installation chart step procedure/part name q’ty service points crankshaft removal follow the left “step” for removal. Crankcase refer to “crankcase”. 1 oil seal 1 2 bearing 1 3 oil seal 2 4 crankshaft assembly 1 caution: install the bea...

Page 125: Powr

5-46 powr e crankshaft service points crankshaft inspection 1. Measure: ● crank width a out of specification → replace. Crank width: 72.95 ~ 73.00 mm (2.872 ~ 2.874 in) 2. Measure: ● deflection b (with a dial gauge) out of specification → replace. Max. Deflection: b 0.05 mm (0.002 in) c 0.15 mm (0.0...

Page 126: Powr

5-47 powr e crankshaft 5. Inspect: ● bearings damage/pitting → replace. Note: ● before inspection, thoroughly clean the bearings. ● immediately after inspection, lubricate the bearings to prevent rust. 6. Inspect: ● oil seals damage/wear → replace..

Page 127: Jet

E 6 jet pump chapter 6 jet pump unit jet pump unit ............................................................................................. 6-1 exploded diagram ............................................................................. 6-1 removal and installation chart ........................

Page 128: Jet

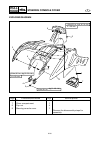

6-1 e jet pump jet pump unit jet pump unit exploded diagram removal and installation chart step procedure/part name q’ty service points jet pump unit removal follow the left “step” for removal. 1 bolt 2 2 bolt 2 3 intake grate 1 4 bolt 4 5 intake duct 1 6 screw 4 7 speed sensor 1 note: route the spe...

Page 129: Jet

6-2 e jet pump jet pump unit exploded diagram step procedure/part name q’ty service points 8 bolt 4 9 ride plate 1 10 qsts cable joint 1 11 bilge hose 1 12 nut/washer 1/2 13 steering cable joint 1 14 clamp/spout hose 1/1 15 bolt 1 16 bolt 4.

Page 130: Jet

6-3 e jet pump jet pump unit exploded diagram step procedure/part name q’ty service points 17 jet pump unit assembly 1 note: ● pull the jet pump unit straight back. ● when installing the jet pump unit, align the drive shaft spline (male) with the intermediate drive shaft spline (female). 18 dowel pi...

Page 131: Jet

6-4 e jet pump nozzle deflector and nozzle ring nozzle deflector and nozzle ring exploded diagram removal and installation chart step procedure/part name q’ty service points nozzle deflector and nozzle ring removal follow the left “step” for removal. Jet pump unit refer to “jet pump unit”. 1 bolt 2 ...

Page 132: Jet

6-5 e jet pump impeller duct, impeller housing, and intake duct impeller duct, impeller housing, and intake duct exploded diagram removal and installation chart step procedure/part name q’ty service points impeller duct and impeller housing removal follow the left “step” for removal. Nozzle ring ref...

Page 133: Jet

6-6 e jet pump impeller duct, impeller housing, and intake duct exploded diagram step procedure/part name q’ty service points 7 bolt 4 8 water inlet cover 1 9 packing 1 10 water inlet strainer 1 11 packing 1 reverse the removal steps for installation..

Page 134: Jet

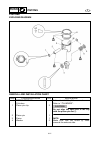

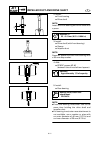

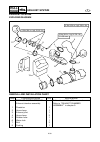

6-7 e jet pump impeller duct and drive shaft impeller duct and drive shaft exploded diagram removal and installation chart *1 : epnoc grease ap #0 step procedure/part name q’ty service points impeller duct and drive shaft disassembly follow the left “step” for disassembly. 1 impeller 1 left-hand thr...

Page 135: Jet

6-8 e jet pump impeller duct and drive shaft exploded diagram *1 : epnoc grease ap #0 step procedure/part name q’ty service points 8 drive shaft 1 9 rear bearing 1 10 spacer 1 11 front bearing 1 12 oil seal 1 13 oil seal 1 reverse the disassembly steps for assembly. Not reusable not reusable not reu...

Page 136: Jet

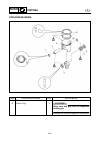

6-9 e jet pump impeller duct and drive shaft service points drive shaft removal 1. Remove: ● impeller note: the impeller has left-hand threads. Turn the impeller clockwise to loosen it. 2. Remove: ● nut 1 drive shaft holder: yb-06151/90890-06519 drive shaft holder: yb-06151/90890-06519 3. Remove: ● ...

Page 137: Jet

6-10 e jet pump impeller duct and drive shaft 5. Remove: ● front bearing note: remove the front bearing with a press. 6. Remove: ● oil seal note: remove the oil seal with press. Impeller inspection refer to “jet pump unit” in chapter 3. Drive shaft inspection 1. Inspect: ● drive shaft damage/wear → ...

Page 138: Jet

6-11 e jet pump impeller duct and drive shaft 2. Install: ● front bearing ● drive shaft note: install the front bearing and drive shaft with a press. 3. Install: ● drive shaft (with front bearing) ● spacer ● impeller duct note: press the spacer and the front bearing with a 36-mm deep socket. 4. Add:...

Page 139: Jet

6-12 e jet pump impeller duct and drive shaft 6. Add: ● epnoc grease ap #0 (into the cap) quantity: approximately 1/3 of capacity 7. Install: ● nut ● impeller drive shaft holder: yb-06151/90890-06519.

Page 140: Jet

6-13 e jet pump transom plate and hoses transom plate and hoses exploded diagram removal and installation chart step procedure/part name q’ty service points transom plate and hoses removal follow the left “step” for removal. Exhaust system refer to “exhaust system” in chapter 8. Jet pump unit refer ...

Page 141: Jet

6-14 e jet pump transom plate and hoses exploded diagram step procedure/part name q’ty service points 4 hose 1 cooling water inlet 5 nut/washer 4/4 6 transom plate 1 7 clamp/bilge hose 2 1/1 8 screw 1 9 bilge strainer holder 1 10 bilge strainer 1 reverse the removal steps for installation..

Page 142: Jet

6-15 e jet pump transom plate and hoses service points bilge strainer inspection refer to “jet pump unit” in chapter 3. Bilge hose inspection 1. Inspect: ● bilge hose cracks/damage/wear → replace..

Page 143: Jet

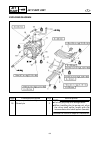

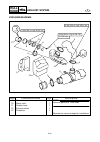

6-16 e jet pump bearing housing bearing housing exploded diagram removal and installation chart step procedure/part name q’ty service points bearing housing removal follow the left “step” for removal. Engine unit refer to “engine unit” in chapter 5. 1 rubber coupling 1 2 bolt 3 3 intermediate housin...

Page 144: Jet

6-17 e jet pump bearing housing exploded diagram removal and installation chart step procedure/part name q’ty service points bearing housing disassembly follow the left “step” for disassembly. 1 grease hose 1 2 grease nipple 1 3 grease nipple stay 1 4 nipple 2 5 driven coupling 1 6 washer 1 7 interm...

Page 145: Jet

6-18 e jet pump bearing housing exploded diagram step procedure/part name q’ty service points 8 o-ring 2 9 oil seal 1 10 oil seal 1 11 oil seal 1 12 circlip 1 13 bearing 1 14 circlip 1 reverse the disassembly steps for assembly. Not reusable not reusable not reusable not reusable.

Page 146: Jet

6-19 e jet pump bearing housing service points driven coupling removal and installation 1. Remove and install: ● driven coupling note: install the driven coupling with the same special tools that were used for removal. Intermediate drive shaft removal 1. Remove: ● intermediate drive shaft note: supp...

Page 147: Jet

6-20 e jet pump bearing housing bearing, driven coupling shaft, and grease hose inspection 1. Inspect: ● bearing rotate the inner race by hand. Damage/rough movement → replace. ● intermediate drive shaft damage/pitting → replace. ● grease hose cracks/wear → replace. Driven coupling inspection 1. Ins...

Page 148: Jet

6-21 e jet pump bearing housing 2. Install: ● intermediate drive shaft note: support the intermediate housing with steel blocks 1 and press the driven cou- pling shaft. 3. Install: ● oil seal 1 [8 mm (0.31 in)] ● oil seal 2 [10 mm (0.39 in)] distance a: 9.5 ~ 10.5 mm (0.37 ~ 0.41 in) distance a: 10....

Page 149: Elec

E – + elec chapter 7 electrical system electrical components ......................................................................... 7-1 electrical box ........................................................................................... 7-2 exploded diagram ....................................

Page 150: Elec

E 7 – + elec charging system .................................................................................... 7-25 wiring diagram................................................................................. 7-25 fuse ..............................................................................

Page 151: Elec

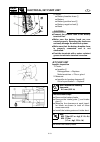

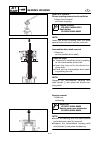

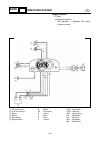

7-1 e – + elec electrical components electrical components 1 2 3 4 5 6 7 d c b a 9 > 8 1 buzzer 2 fuel level sensor 3 multi-function meter 4 ypvs servomotor 5 spark plugs 6 exhaust temperature sensor 7 electrical box 8 speed sensor 9 battery 0 water temperature sensor a starter motor b stator coil a...

Page 152: Elec

7-2 e – + elec electrical box electrical box exploded diagram removal and installation chart step procedure/part name q’ty service points electrical box removal follow the left “step” for removal. Engine unit refer to “engine unit” in chapter 5. Battery negative lead starter motor lead refer to “gen...

Page 153: Elec

7-3 e – + elec electrical box exploded diagram removal and installation chart step procedure/part name q’ty service points electrical box disassembly follow the left “step” for disassembly. 1 clamp 5 2 coupler 3 for water, exhaust temperature sensor and lighting coil 3 screw 2 4 rectifier/regulator ...

Page 154: Elec

7-4 e – + elec electrical box exploded diagram step procedure/part name q’ty service points 11 ignition coil 3 12 ignition coil lead 3 13 spark plug lead/cap 3/3 14 bolt 3 15 ground lead 6 16 lead 3 black/orange 17 nut 2 18 starter motor lead 1 19 battery positive lead 1 20 fuse lead 1 21 starter re...

Page 155: Elec

7-5 e – + elec electrical box exploded diagram step procedure/part name q’ty service points 23 lead holder 1 24 fuse lead 5 25 screw 2 26 fuse holder 1 27 lead/coupler 1/6 28 screw 2 29 coupler bracket 1 30 cdi unit 1 31 screw 8 32 lead holder plate 2 reverse the disassembly steps for assembly..

Page 156: Elec

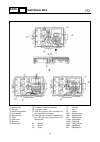

7-6 e – + elec electrical box 1 ignition coil 2 cdi unit 3 rectifier/regulator 4 fuse holder 5 starter relay 6 tape 7 clear tube 8 red tube 9 white tape Å to battery positive terminal ı to starter motor Ç affix the ignition coil connector to the electrical box holder. Î pass the 8 pin coupler leads ...

Page 157: Elec

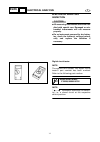

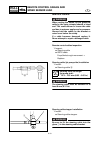

7-7 e – + elec electrical analysis electrical analysis inspection caution: ● all measuring instruments should be han- dled with special care. Damaged or mis- handled instruments will not measure properly. ● on an instrument powered by dry batter- ies, check the battery’s voltage periodi- cally and r...

Page 158: Elec

7-8 e – + elec electrical analysis low resistance measurement note: ● when measuring a resistance of 10 Ω or less with the digital tester, the correct measurement cannot be obtained because of the tester’s internal resistance. ● to obtain the correct value, subtract the internal resistance from the ...

Page 159: Elec

7-9 e – + elec electrical analysis ● when measuring the peak voltage, con- nect the peak voltage adaptor to the digi- tal tester and switch the selector to the dc voltage mode. Note: ● make sure that the adaptor leads are properly installed in the digital circuit tester. ● make sure that the positiv...

Page 160: Elec

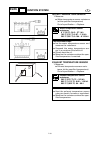

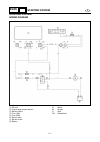

7-10 e – + elec ignition system ignition system wiring diagram 1 engine stop switch 2 engine stop lanyard switch 3 lighting coil 4 pickup coil 5 cdi unit 6 ignition coil 7 spark plug 8 fuse (20a) 9 battery 0 rectifier/regulator a exhaust temperature sensor b water temperature sensor b : black o : or...

Page 161: Elec

7-11 e – + elec ignition system ignition spark gap warning ● when checking the spark gap, do not touch any of the connections of the spark gap tester lead wires. ● when performing the spark gap test, take special care not to let sparks leak out of the removed spark plug cap. ● when performing the sp...

Page 162: Elec

7-12 e – + elec ignition system ignition system peak voltage warning when checking the electrical components, do not touch any of the connections of the digital tester lead wires. Note: ● if there is no spark, or the spark is weak, continue with the ignition system test. ● if a good spark is obtaine...

Page 163: Elec

7-13 e – + elec ignition system 2. Measure: ● pickup coil output peak voltage below specification → replace the pickup coil. Note: the starter motor will not operate when the test harness on the output side coupler is disconnected to measure the unloaded peak voltage for the pickup coil(s). There- f...

Page 164: Elec

7-14 e – + elec ignition system 4. Measure: ● rectifier/regulator output peak voltage below specification → replace the rectifier/regulator. Note: make sure the output lead (red lead) of the rectifier/regulator is disconnected when measuring the output peak voltage. Rectifier/regulator output peak v...

Page 165: Elec

7-15 e – + elec ignition coil 1. Measure: ● primary coil resistance out of specification → replace. Note: when measuring a resistance of 10 Ω or less with the digital tester, the correct mea- surement cannot be obtained because of the tester’s internal resistance. Refer to “low resistance measuremen...

Page 166: Elec

7-16 e – + elec water temperature sensor 1. Measure: ● water temperature sensor resistance (at the specified temperature) out of specification → replace. Water temperature sensor resistance: 0 ˚c (32 ˚f): 24.0 ~ 37.1 k Ω 100 ˚c (212 ˚f): 0.87 ~ 1.18 k Ω 200 ˚c (392 ˚f): 0.104 ~ 0.153 k Ω measurement...

Page 167: Elec

7-17 e – + elec starting system starting system wiring diagram 1 cdi unit 2 engine stop lanyard switch 3 starter switch 4 fuse (10a) 5 fuse (20a) 6 starter relay 7 starter motor 8 battery b : black br : brown r : red r/y : red/yellow.

Page 168: Elec

7-18 e – + elec starting system battery refer to “electrical” in chapter 3. Wiring connections 1. Check: ● wiring connections poor connections → properly connect. Fuse 1. Check: ● fuse holder continuity no continuity → check the fuse or replace the fuse holder. Fuse holder continuity: between 1 and ...

Page 169: Elec

7-19 e – + elec starting system starter switch 1. Check: ● continuity out of specification → replace. Starter continuity (natural color coupler) lock plate position leads red brown installed free push removed free push starter relay 1. Inspect: ● brown lead terminal ● black lead terminal loose → tig...

Page 170: Elec

7-20 e – + elec starter motor starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points starter motor disassembly follow the left “step” for disassembly. Starter motor refer to “generator and starter motor” in chapter 5. 1 o-ring 1 2 bolt 2 3 starter ...

Page 171: Elec

7-21 e – + elec starter motor exploded diagram step procedure/part name q’ty service points 8 starter motor rear cover 1 9 o-ring 1 10 shim * t = 0.2 mm, 0.8 mm 11 armature assembly 1 12 nut/spring washer/washer 1/1/4 13 o-ring 1 14 brush holder 1 15 brush spring 4 16 bolt 1 17 brush assembly 1 *: a...

Page 172: Elec

7-22 e – + elec starter motor exploded diagram step procedure/part name q’ty service points 18 spacer 1 19 holder 1 20 starter motor yoke 1 reverse the disassembly steps for assembly..

Page 173: Elec

7-23 e – + elec starter motor service points armature inspection 1. Inspect: ● armature shaft 1 damage/wear → replace. 1 2. Inspect: ● commutator dirt → clean with 600 grit sandpaper. 3. Measure: ● commutator diameter out of specification → replace. Min. Commutator diameter: 27.0 mm (1.06 in) 4. Che...

Page 174: Elec

7-24 e – + elec starter motor 6. Inspect: ● armature coil continuity out of specification → replace. Armature coil continuity: commutator segments 1 continuity segment - laminations 2 no continuity segment - armature shaft no continuity brush holder inspection 1. Measure: ● brush length a out of spe...

Page 175: Elec

7-25 e – + elec charging system charging system wiring diagram 1 lighting coil 2 battery 3 fuse (20a) 4 rectifier/regulator b : black g : green r : red g/w : green/white.

Page 176: Elec

7-26 e – + elec charging system fuse refer to “starting system”. Battery refer to “electrical” in chapter 3. Lighting coil refer to “ignition system”. Rectifier/regulator refer to “ignition system”..

Page 177: Elec

7-27 e – + elec ypvs ypvs wiring diagram 1 lighting coil 2 pickup coil 3 cdi unit 4 ypvs servomotor 5 fuse (10a) 6 fuse (20a) 7 battery 8 rectifier/regulator b : black gy : gray r : red b/o : black/orange r/l : red/blue r/w : red/white w/r : white/red.

Page 178: Elec

7-28 e – + elec ypvs fuse refer to “starting system”. Battery refer to “electrical” in chapter 3. Pickup coil refer to “ignition system”. Cdi unit refer to “ignition system”. Lighting coil refer to “ignition system”. Rectifier/regulator refer to “ignition system”..

Page 179: Elec

7-29 e – + elec ypvs servomotor ypvs servomotor exploded diagram removal and installation chart step procedure/part name q’ty service points ypvs servomotor removal follow the left “step” for removal. 1 bolt 2 2 cable holder 1 3 ypvs servomotor coupler 1 4 nut/washer 2/2 5 ypvs servomotor 1 6 ypvs c...

Page 180: Elec

7-30 e – + elec ypvs servomotor service points ypvs cable removal and installation 1. Remove: ● ypvs cables 1 and 2 note: ● there is a white paint mark a on ypvs cable 2. ● when installing the ypvs cable, make sure that the ypvs cable locknuts 3 are fully turned in. Removal steps: ● remove the ypvs ...

Page 181: Elec

7-31 e – + elec ypvs servomotor caution: do not disassemble the ypvs servomotor unit. It is a sealed unit and if it is faulty it must be replaced. Ypvs cable adjustment refer to “control system” in chapter 3. ● make sure the servomotor operates properly. Note: make sure the pulley operates three sec...

Page 182: Elec

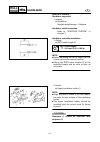

7-32 e – + elec indication system indication system wiring diagram 1 cdi unit 2 fuel level sensor 3 oil level sensor 4 buzzer 5 multi-function meter 6 speed sensor 7 engine stop lanyard switch 8 starter switch 9 battery 0 fuse (10a) a fuse (20a) b exhaust temperature sensor c water temperature senso...

Page 183: Elec

7-33 e – + elec indication system fuse refer to “starting system”. Battery refer to “electrical” in chapter 3. Lighting coil refer to “ignition system”. Rectifier/regulator refer to “ignition system”. Cdi unit refer to “ignition system”. Water temperature sensor refer to “ignition system”. Exhaust t...

Page 184: Elec

7-34 e – + elec indication system fuel level sensor 1. Measure: ● fuel level sensor resistance out of specification → replace. White/blue (w/l) – black (b) float position resistance ( Ω ) a 757 ~ 803 b 0 ~ 8 multi-function meter multi-function meter 1. Check: ● multi-function meter cracked meter hou...

Page 185: Elec

7-35 e – + elec indication system display function 1. Check: ● display function not operate → replace the multi- function meter. 1 oil level sensor 2 fuel level sensor 3 buzzer 4 battery 5 start switch 6 speed sensor b : black ch : chocolate g : green l : blue r : red y : yellow gy/b : gray/black gy...

Page 186: Elec

7-36 e – + elec indication system fuel level gauge 1. Check: ● fuel level gauge not operating → replace the multi- function meter. Checking steps: ● supply dc 12 voltage to the natural color six-pin connector (+: red, –: black) with a battery. ● disconnect the green two-pin connec- tor (white/blue a...

Page 187: Elec

7-37 e – + elec indication system oil level gauge 1. Check: ● oil level gauge not operating → replace the multi- function meter. Checking steps: ● supply dc 12 voltage to the natural color six-pin connector (+: red, –: black) with a battery. ● disconnect the white two-pin connec- tor (blue and black...

Page 188: Elec

7-38 e – + elec indication system overheat warning indicator 1. Check: ● overheat 1 warning indicator not operating → replace the multi- function meter. Checking steps: ● supply dc 12 voltage to the natural color six-pin connector (+: red, –: black) with a battery. ● connect the gray/black and black...

Page 189: Elec

7-39 e – + elec indication system ● make sure the water temperature sym- bol 3 display and “warning” lamp 4 on, and the buzzer sounds continu- ity. Warning yamaha 8 7 6 5 4 3 2 1 mph fuel hour x1000r/min multi d splay 4 3 3. Check: ● exhaust temperature warning indicator not operating → replace the ...

Page 190: Elec

7-40 e – + elec indication system speed meter 1. Check: ● speed meter output voltage within specification → check the speed sensor output voltage and pulses. Out of specification → replace. Speed sensor 1. Check: ● speed sensor output voltage and pulses out of specification → replace. Speed meter ou...

Page 191: Hull

E hull hood chapter 8 hull and hood handlebar ................................................................................................... 8-1 exploded diagram ............................................................................. 8-1 removal and installation chart .......................

Page 192: Hull

E 8 hull hood buzzer and hood lock ......................................................................... 8-27 exploded diagram ........................................................................... 8-27 removal and installation chart ............................................. 8-27 hoses ...

Page 193: Hull

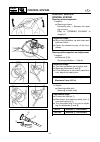

8-1 e hull hood handlebar handlebar exploded diagram removal and installation chart step procedure/part name q’ty service points handlebar cover removal follow the left “step” for removal. 1 screw 4 2 handlebar cover 1 3 screw 4 4 handlebar cover stay 1 5 spiral tube 1 6 band 1.

Page 194: Hull

8-2 e hull hood handlebar exploded diagram step procedure/part name q’ty service points 7 throttle cable 1 8 choke cable 1 9 bolt 4 10 upper handlebar holder 2 11 handlebar assembly 1 12 lower handlebar holder 2 reverse the removal steps for installation..

Page 195: Hull

8-3 e hull hood handlebar exploded diagram removal and installation chart step procedure/part name q’ty service points handlebar removal follow the left “step” for removal. Qsts cable (to jet nozzle) refer to “remote control cables and speed sensor lead”. 1 grommet 1 note: apply soapy water to the g...

Page 196: Hull

8-4 e hull hood handlebar exploded diagram step procedure/part name q’ty service points 4 qsts cable 1 1 note: route the qsts cables behind of the oil filler hose. 5 nut/washer 2/2 6 qsts converter 1 7 throttle cable 1 8 choke cable 1 reverse the removal steps for installation..

Page 197: Hull

8-5 e hull hood handlebar exploded diagram removal and installation chart step procedure/part name q’ty service points handlebar disassembly follow the left “step” for disassembly. 1 band 1 2 bolt 2 3 grip end 2 4 spacer 1 5 screw/washer/spring washer 1/1/1 6 qsts grip assembly 1 7 screw 2 8 handleb...

Page 198: Hull

8-6 e hull hood handlebar exploded diagram step procedure/part name q’ty service points 10 screw 2 11 throttle lever assembly 1 12 screw 2 13 choke lever assembly 1 14 handlebar grip 1 note: apply adhesive to the handlebar and the inner surface of the handlebar grip. 15 handlebar 1 reverse the disas...

Page 199: Hull

8-7 e hull hood handlebar service points handlebar inspection 1. Inspect: ● handlebar bends/cracks/damage → replace. Handlebar switch inspection refer to “starting system” in chapter 7. Handlebar assembly installation 1. Adjust: ● qsts cable length a note: ● before adjusting the qsts cables, set the...

Page 200: Hull

8-8 e hull hood handlebar 3. Install: ● throttle cable note: fit the seal into the glove in the bracket. 4. Install: ● band 1 note: after inserting the qsts cables into the grommet, tie the end of grommet with the band. 5. Install: ● spiral tube 1 note: be sure to install the spiral tube, containing...

Page 201: Hull

8-9 e hull hood handlebar 7. Adjust: ● choke lever operation refer to “control system” in chapter 3. 8. Adjust: ● throttle cable free play refer to “control system” in chapter 3. 9. Adjust: ● qsts cable free play refer to “control system” in chapter 3..

Page 202: Hull

8-10 e hull hood qsts grip qsts grip exploded diagram removal and installation chart step procedure/part name q’ty service points qsts grip disassembly follow the left “step” for disassembly. Qsts grip assembly refer to “handlebar”. 1 screw/washer 1/1 2 cover 1 3 ball 2 4 spring 2 5 qsts cable 1 1 6...

Page 203: Hull

8-11 e hull hood qsts grip exploded diagram step procedure/part name q’ty service points 7 screw/washer 2/2 8 collar 1 9 qsts shift lock lever 1 10 spring 1 11 spacer 1 12 qsts cable housing cover 1 13 qsts shift grip 1 reverse the disassembly steps for assembly..

Page 204: Hull

8-12 e hull hood qsts grip service points qsts cable inspection 1. Inspect: ● qsts cables frays/kinks/rough movement → replace. Qsts grip inspection 1. Inspect: ● qsts grip damage/wear → replace..

Page 205: Hull

8-13 e hull hood steering column steering column exploded diagram removal and installation chart step procedure/part name q’ty service points steering column removal follow the left “step” for removal. Steering console cover assembly refer to “steering console cover”. 1 nut/washer 4/4 2 plate 1 3 st...

Page 206: Hull

8-14 e hull hood steering column exploded diagram removal and installation chart *: be sure to install the same number of shim(s) as installed originally at factory. Step procedure/part name q’ty service points steering column disassembly follow the left “step” for disassembly. 1 grommet 1 2 bolt/wa...

Page 207: Hull

8-15 e hull hood steering column exploded diagram step procedure/part name q’ty service points 5 washer 1 6 steering column 1 7 bushing 2 8 steering column housing 1 reverse the disassembly steps for assembly. 8 × 60 mm 16 nm (1.6 m • kgf, 11 ft • ib) 5 nm (0.5 m • kgf, 3.6 ft • ib) 26 nm (2.6 m • k...

Page 208: Hull

8-16 e hull hood steering column service points steering column bushing inspection 1. Inspect: ● bushings damage/wear → replace. 2. Inspect: ● steering column inspection refer to “control system” in chapter 3..

Page 209: Hull

8-17 e hull hood remote control cables and speed sensor lead remote control cables and speed sensor lead exploded diagram removal and installation chart step procedure/part name q’ty service points remote control cables and speed sensor lead removal follow the left “step” for removal. 1 speed sensor...

Page 210: Hull

8-18 e hull hood remote control cables and speed sensor lead exploded diagram step procedure/part name q’ty service points 8 cap 1 9 nut 1 10 steering cable 1 11 nut 1 12 pin 1 13 qsts cable end 1 14 cap 1 15 nut 1 16 qsts cable 1 reverse the removal steps for installation..

Page 211: Hull

8-19 e hull hood remote control cables and speed sensor lead service points warning when routing the cables, do not grasp the cable by the outer crimped sheath or steel end. This could deform or loosen the cable end due to extreme angles and or pressure. Always hold the cables by the bracket or oute...

Page 212: Hull

8-20 e hull hood remote control cables and speed sensor lead qsts cable (jet pump side) installation 1. Install: ● qsts cable (jet pump side) a warning the qsts cable must be screwed in more than 8 mm (0.31 in). Qsts cable set length (jet pump side): 12.0 ~ 14.0 mm (0.47 ~ 0.55 in) qsts cable stoppe...

Page 213: Hull

8-21 e hull hood front hood front hood exploded diagram removal and installation chart step procedure/part name q’ty service points front hood removal follow the left “step” for removal. 1 bolt 2 2 screw 8 3 seal washer 8 4 wind shield 1 5 pop nut 8 6 bolt 2 10 9 1 11 2 3 5 8 4 16 nm (1.6 m • kgf, 1...

Page 214: Hull

8-22 e hull hood exploded diagram step procedure/part name q’ty service points 7 hood lock 1 8 front hood 1 9 nut 2 10 plate 1 11 hinge assembly 1 reverse the removal steps for installation. 10 9 1 11 2 3 5 8 4 16 nm (1.6 m • kgf, 11 ft • ib) 6 × 14 mm 5 nm (0.5 m • kgf, 3.6 ft • ib) 6 × 14 mm 6 nm ...

Page 215: Hull

8-23 e hull hood steering console cover steering console cover exploded diagram removal and installation chart step procedure/part name q’ty service points steering console cover removal follow the left “step” for removal. Handlebar assembly refer to “handlebar”. Knob (fuel cock) refer to “fuel cock...

Page 216: Hull

8-24 e hull hood steering console cover exploded diagram step procedure/part name q’ty service points 6 plate 1 7 nut/washer 2/2 8 bolt/square-ring 2/2 9 steering console cover assembly 1 note: remove the oil filler cap to remove the steering console cover assembly easier. Reverse the removal steps ...

Page 217: Hull

8-25 e hull hood steering console cover exploded diagram removal and installation chart step procedure/part name q’ty service points steering console cover disassembly follow the left “step” for disassembly. 1 screw 4 2 side cover 2 3 nut 2 4 holder 1 5 multifunction meter 1 6 8 7 2 nm (0.2 m • kgf,...

Page 218: Hull

8-26 e hull hood steering console cover exploded diagram step procedure/part name q’ty service points 6 screw 4 7 glove compartment 1 8 pop nut 4 9 steering console cover 1 reverse the disassembly steps for assembly. 6 8 7 2 nm (0.2 m • kgf, 1.4 ft • ib) 6 × 18 mm 3 nm (0.3 m • kgf, 2.2 ft • ib) 4 3...

Page 219: Hull

8-27 e hull hood buzzer and hood lock buzzer and hood lock exploded diagram removal and installation chart step procedure/part name q’ty service points buzzer and hood lock removal follow the left “step” for removal. Steering console cover assembly refer to “steering console cover”. Steering cable r...

Page 220: Hull

8-28 e hull hood buzzer and hood lock exploded diagram step procedure/part name q’ty service points 6 nut 2 7 bolt 2 8 hood lock assembly 1 9 grommet 1 reverse the removal steps for installation..

Page 221: Hull

8-29 e hull hood buzzer and hood lock exploded diagram removal and installation chart step procedure/part name q’ty service points hood lock disassembly follow the left “step” for disassembly. 1 screw 2 2 hood lock button assembly 1 3 circlip 1 4 washer 1 5 pin 1 6 hook lever 1 7 spring 1 8 hood loc...

Page 222: Hull

8-30 e hull hood hoses hoses exploded diagram removal and installation chart step procedure/part name q’ty service points hoses removal follow the left “step” for removal. Engine unit refer to “engine unit” in chapter 5. Steering console cover assembly refer to “steering console cover”. 1 band 2 2 v...

Page 223: Hull

8-31 e hull hood hoses exploded diagram step procedure/part name q’ty service points 4 band 1 5 check valve 1 6 oil tank breather hose 1 7 fuel tank breather hose 2 reverse the removal steps for installation..

Page 224: Hull

8-32 e hull hood hoses service points check valve inspection 1. Check: ● check valve faulty → replace. Checking steps: ● connect a hose to the end of check valve “a” and blow into it. Air should come out from end “b”. ● connect the hose to the end of check valve “b” and blow into it. Air should not ...

Page 225: Hull

8-33 e hull hood seats and hand grip seats and hand grip exploded diagram removal and installation chart step procedure/part name q’ty service points seats and hand grip removal follow the left “step” for removal. 1 seat assembly 1 2 bolt 2 3 seat lock assembly 1 4 nut 1 5 notch 1 6 washer 1.

Page 226: Hull

8-34 e hull hood seats and hand grip exploded diagram step procedure/part name q’ty service points 7 rubber ring 1 8 nut/washer 2/2 9 bolt 2 10 bolt 2 11 hand grip 1 12 bracket 1 reverse the removal steps for installation..

Page 227: Hull

8-35 e hull hood seats and hand grip service points seat lock inspection 1. Inspect: ● seat lock damage/wear → replace..

Page 228: Hull

8-36 e hull hood battery box battery box exploded diagram removal and installation chart step procedure/part name q’ty service points battery box removal follow the left “step” for removal. 1 band 1 2 fire extinguisher container 1 3 band 1 4 bolt 1 5 battery negative lead 1 6 bolt 1 7 battery positi...

Page 229: Hull

8-37 e hull hood battery box exploded diagram step procedure/part name q’ty service points 12 holder 1 13 cap nut/washer 2/2 14 nut/washer 4/4 15 electrical box 1 16 battery box 1 note: before installing the battery box, route the battery leads and battery breather hose through the holes of the batt...

Page 230: Hull

8-38 e hull hood exhaust system exhaust system exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust system removal follow the left “step” for removal. Exhaust chamber assembly refer to “exhaust chamber assembly” in chapter 5. 1 floatation 1 2 hose clam...

Page 231: Hull

8-39 e hull hood exhaust system exploded diagram step procedure/part name q’ty service points 9 hose clamp 2 note: remove parts 9 to 12 as a set. 10 water tank 1 11 rubber hose 1 12 exhaust outlet 1 13 floatation 1 reverse the removal steps for installation. 4 nm (0.4 m • kgf, 2.9 ft • ib) 6 × 30 mm...

Page 232: Hull

8-40 e hull hood exhaust system service points exhaust system inspection 1. Inspect: ● water lock band cracks/damage → replace. 2. Inspect: ● rubber hoses burns/cracks/damage → replace. 3. Inspect: ● water lock cracks/leaks → replace. 4. Inspect: ● water tank cracks/damage/leaks → replace. Exhaust c...

Page 233: Hull

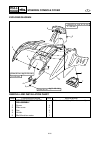

8-41 e hull hood deck and hull deck and hull exploded diagram removal and installation chart step procedure/part name q’ty service points deck and hull disassembly follow the left “step” for disassembly. 1 bolt 2 2 bow eye 1 3 nut 2 4 rope hole fitting 2 5 nut 1 6 spout 1 7 bolt 6.

Page 234: Hull

8-42 e hull hood deck and hull exploded diagram step procedure/part name q’ty service points 8 sponson 2 note: make sure install the starboard and port side sponsons to the same position. 9 bolt 8 10 flap 2 11 nut/washer 4/4 12 screw/washer 4/4 13 drain plug 2 14 packing 2 reverse the disassembly st...

Page 235: Hull

8-43 e hull hood engine mount engine mount exploded diagram removal and installation chart step procedure/part name q’ty service points engine mount removal follow the left “step” for removal. Engine assembly refer to “engine unit” in chapter 5. 1 bolt 4 2 damper 1 1 3 damper 2 1 4 bolt 8 5 engine m...

Page 236: Hull

8-44 e hull hood engine mount hull repair shallow scratches 1. Sand the scratches with 400 grit sand- paper (either wet or dry) until the scratches are smooth. Then, sand the scratches once again with 600 grit sand- paper (either wet or dry). Deep scratches 1. Remove any sharp or rough edges from th...

Page 237: Hull

8-45 e hull hood engine mount cracks and punctures note: before attempting to repair any cracks or punctures, refer to “water vehicle frp repair manual”. 1. Remove any damaged fiberglass. 2. Cut the damaged area and separate it approximately 0.25 inch. 3. On the outside of the hull, grind the separa...

Page 238: Hull

8-46 e hull hood engine mount insert nut note: use the insert nut when: ● a pop nut which was attached to the hull slipped off or, ● when a bolt which was fastened to an insert nut or pop nut broke. ● nut 1 ● thread direction 2 ● slot to be threaded 3 note: drilling size part no. Part name remarks e...

Page 239: Hull

8-47 e hull hood engine mount 4. First, apply tape 1 to the inner surface of the hull and then laminate fiberglass mats over the tape with resin. Note: when it is possible to work inside the hull, laminate the mats from the inside. 5. Sand the outer surface of the hull until it is smooth. 6. Install...

Page 240: Hull

8-48 e hull hood engine mount 2. To prevent water from entering the ure- thane foam, apply silicone sealant to the inside of the hole as shown. 3. Install the insert nut as explained in “example 1”. ● brass insert nut 1 ● hull 2 ● urethane foam 3 ● silicone sealant 4 graphic removal 1. Hold a hair d...

Page 241: Trbl

E 9 trbl anls chapter 9 trouble analysis trouble analysis ..................................................................................... 9-1 trouble analysis chart ................................................................. 9-1.

Page 242: Trbl

9-1 trbl anls e trouble analysis trouble analysis note: the following items should be checked before the “trouble analysis” chart is consulted. 1. The battery is charged and its specified gravity is within specification. 2. There are no incorrect wiring connections. 3. Wiring connections are properl...

Page 243: Trbl

9-2 trbl anls e trouble analysis rubber coupling 5 pilot water hose 5 water hose 5 water passage 5 jet pump unit duct 6 impeller 6 intake screen 6 bearings 6 intake duct 6 water inlet hose 6 bilge hose 6 bilge strainer 6 bilge hose joint 6 valve body 6 electrical cdi unit 7 lighting coil 7 pickup co...

Page 244

Printed on recycled paper printed in usa feb. 2000 – × 1 cr f0x-28197-za-11 (gp1200ay) yamaha motor co., ltd..

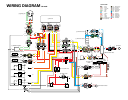

Page 245: Wiring Diagram

W b r br set pull + – n s m g w/r w/r b/o g b b/y b/o w/r gy/r gy/y g br gy w o gy/b b/w b/o b/y br r b b/y b/o b/y b/o b/o o gy/y w g gy gy/r gy/b b/y b/o b/o o r/w gy/y r gy/r g b gy/b b g b w b r/y br r/l r b gy b l b w/l b w/l l/r l/b b/y r/y b r/w y r br ch br g g b r b/o o w b b b wiring diagr...