- DL manuals

- Z Corporation

- 3D Printers

- Z 406

- User Manual

Z Corporation Z 406 User Manual

Summary of Z 406

Page 1

Z406 system user manual november 2002 copyright © 2002 z corporation part number 09504 z ® 406 3d color printer user manual z corporation revision d.

Page 2

Z corporation z406 system user manual 2 z corporation service (781)852-5050/(887)88-zcorp table of contents: 1 your z406 system .................................................................................................. 6 1.1 introduction .........................................................

Page 3

Z406 system user manual z corporation www.Zcorp-users.Com 3 4.4.1 using z corp. Recommended resin ...............................................................31 5 advanced user features ................................................................................32 5.1 orientation for speed .....

Page 4

Z corporation z406 system user manual 4 z corporation service (781)852-5050/(887)88-zcorp table of figures figure 1. The printing process ................................................................................................. 7 figure 2: the z406 system shelling and infrastructure features...

Page 5

Z406 system user manual z corporation www.Zcorp-users.Com 5 use of equipment the equipment was manufactured under patents licensed to z corp. To be used for the fabrication of appearance models and prototypes. Other uses may be restricted; contact z corporation for further information. The equipment...

Page 6

Z corporation z406 system user manual 6 z corporation service (781)852-5050/(887)88-zcorp 1 your z406 system 1.1 introduction 1.1.1 overview this z406 3d color printer manual will speed you along the path towards quickly and inexpensively building parts. The manual contains the following sections: 1...

Page 7

Z406 system user manual z corporation www.Zcorp-users.Com 7 1.1.2 how it works the z406 system is based on the massachusetts institute of technology’s patented 3dp (3d printing) technology. The software first converts a three-dimensional design built using 3d cad (and saved in vrml or stl format) ...

Page 8

Z corporation z406 system user manual 8 z corporation service (781)852-5050/(887)88-zcorp the z406 system employs several techniques to quickly build parts. First, binder solution is applied in a higher concentration around the edges of the part, creating a strong “shell” around the exterior of the ...

Page 9

Z406 system user manual z corporation www.Zcorp-users.Com 9 figure 3: illustration of z406 system print orientations accuracy. The accuracy of the system depends on the materials you choose. You can employ the anisotropic scaling feature in the software to adjust for expected shrinkage and bring you...

Page 10

Z corporation z406 system user manual 10 z corporation service (781)852-5050/(887)88-zcorp 1.2 the parts of the z406 3d printer figure 4: the z406 3d printer overflow bin washer fluid wastebottle clear binder bottle primary color binder feed box print heads build box control panel overflow chute ser...

Page 11

Z406 system user manual z corporation www.Zcorp-users.Com 11 1.3 the parts on the printer assembly and gantry figure 5: gantry and printer assembly carriage cover head clamp cover head clamp latch print heads head release lever spreader roller gantry.

Page 12

Z corporation z406 system user manual 12 z corporation service (781)852-5050/(887)88-zcorp 1.4 z406 system components zd4i depowdering station z406 3d printer zw4 automated waxer figure 6: z406 system components.

Page 13

Z406 system user manual z corporation www.Zcorp-users.Com 13 printing a part overview printing a part using the z406 3d printer is fast, easy, clean and fully compatible with an office environment. This manual will show tips on how to print the most challenging parts, but for most purposes, printing...

Page 14

Z corporation z406 system user manual 14 z corporation service (781)852-5050/(887)88-zcorp 2 preparing the z406 system to print 2.1 hardware controls the front control panel on the z406 3d printer has the following features: online button. Enables and disables printer communication. Spread button. T...

Page 15

Z406 system user manual z corporation www.Zcorp-users.Com 15 2.2 preparing the 3d printer if the machine is off, switch it on by pressing and releasing the power on/off switch. The red power light and yellow error light will turn on. Then the gantry will move slowly as it orients itself. We recommen...

Page 16

Z corporation z406 system user manual 16 z corporation service (781)852-5050/(887)88-zcorp 2.2.1 filling the feed box with powder 3. Grip the powder scoop and using a stabbing motion, insert it repeatedly a few inches into the loose powder to compact it. Continue for about 10-15 seconds until the po...

Page 17

Z406 system user manual z corporation www.Zcorp-users.Com 17 6. Vacuum up any powder spilled on the top deck. 7. Spread the gantry so that it is above the feed piston. Press and hold the feed up button until the surface of the powder is even with the top deck. 8. Raise the build piston until it is a...

Page 18

Z corporation z406 system user manual 18 z corporation service (781)852-5050/(887)88-zcorp 2.2.2 cleaning the service station figure 9: service station detail the service station cleans the array of the print heads during printing. The service station should be cleaned after every build. This should...

Page 19

Z406 system user manual z corporation www.Zcorp-users.Com 19 to clean the service station: 1. Move the gantry to the left of the top deck by pressing the ‘spread’ button. 2. Lift the top cover. 3. Manually lift up the metal plate covering the service station. 4. Squirt distilled water onto the squee...

Page 20

Z corporation z406 system user manual 20 z corporation service (781)852-5050/(887)88-zcorp 7. Squirt distilled water on the nozzles. Use the brush to clean off any debris. 8. When finished, replace the service station cover. 9. Close the top cover. 10. Return the gantry by pressing the ‘spread’ butt...

Page 21

Z406 system user manual z corporation www.Zcorp-users.Com 21 4. Unscrew and remove the primary color binder bottle. 5. Fill the bottle up with binder. Replace binder bottle in the proper order – cyan, magenta, yellow (from front to back). 2.2.4 checking powder overflow bin 1. Check the overflow bin ...

Page 22

Z corporation z406 system user manual 22 z corporation service (781)852-5050/(887)88-zcorp 2. Use the vacuum to clean off the filter found above the overflow bin. 3. Slide the bin back into place. Make sure it is pushed all the way in. 2.2.5 putting the machine online press the ‘online’ button. The ...

Page 23

Z406 system user manual z corporation www.Zcorp-users.Com 23 3 setting up the build this chapter will briefly explain how to set up the build, check the 3d print settings, and print. For more information about the features in the zprint software, please refer to the zprint user manual. Please note: ...

Page 24

Z corporation z406 system user manual 24 z corporation service (781)852-5050/(887)88-zcorp 3.2 orienting the part 3.2.1 part containing an opening or hollow area • if the part has an opening or is hollow, place the opening or hollow side up. This will allow for the removal of powder during the gross...

Page 25

Z406 system user manual z corporation www.Zcorp-users.Com 25 3.3 checking build settings always check build settings before printing: 1. Choose the ‘3d print setup’ option from the file menu (or toolbar). 2. Check that the selected printer, powder type, and powder settings for the build are correct....

Page 26

Z corporation z406 system user manual 26 z corporation service (781)852-5050/(887)88-zcorp 3.3.1 powder settings 3.3.1.1 anisotropic scaling values anisotropic scaling values scale the model to accommodate any shrinkage or expansion of the part either due to characteristics of the material system or...

Page 27

Z406 system user manual z corporation www.Zcorp-users.Com 27 3.3.1.2 saturation values the saturation values determine how much binder is placed on the powder to print the part. The part is made up of two areas, the shell and the core, as described in section 1.1.2, how it works. Thus, there are two...

Page 28

Z corporation z406 system user manual 28 z corporation service (781)852-5050/(887)88-zcorp 4 post processing the part 4.1 removing the finished part after the build is complete, remove the finished parts from the build box as follows: 1. With starch-based parts, wait approximately ten to fifteen min...

Page 29

Z406 system user manual z corporation www.Zcorp-users.Com 29 4.2 depowdering the part 1. Place parts inside depowdering unit. 2. Using the compressed air system included in the depowdering station, remove any excess powder that remains in any concave surfaces. Technical tip - the air pressure on you...

Page 30

Z corporation z406 system user manual 30 z corporation service (781)852-5050/(887)88-zcorp 4.3 drying the part 4.3.1 starch and plaster parts to infiltrate starch or plaster parts with wax, the parts must be hot and dry. Preheat part at 165 degrees fahrenheit in the automated waxer or in a drying ov...

Page 31

Z406 system user manual z corporation www.Zcorp-users.Com 31 4.4 infiltrating the part the parts can be infiltrated with a variety of materials to produce a range of material properties. As an early stage design tool, it may not be necessary to infiltrate the parts at all. If you wish to use the par...

Page 32

Z corporation z406 system user manual 32 z corporation service (781)852-5050/(887)88-zcorp 5 advanced user features 5.1 orientation for speed parts oriented with their largest dimension along the y or “fast” axis (print heads direction of travel), next longest along the x or “slow” axis (gantry dire...

Page 33

Z406 system user manual z corporation www.Zcorp-users.Com 33 6 maintenance 6.1 changing the print heads warning: do not touch or contaminate the gold contacts on either the print heads or the carriage with your fingers. Avoid spilling binder on the contacts. If you do get binder or anything else on ...

Page 34

Z corporation z406 system user manual 34 z corporation service (781)852-5050/(887)88-zcorp heads’. 3. Press the ‘start’ dialog box button to begin the process. The front panel lights will flash rapidly and the gantry and print heads will move into position. 4. Wait for the printer to finish moving a...

Page 35

Z406 system user manual z corporation www.Zcorp-users.Com 35 8. To remove the print head, lift the blue handle and pull up gently. Repeat for all four print heads. Please note: all print heads should be changed at the same time to ensure proper print head logging. 9. Before inserting new print head,...

Page 36

Z corporation z406 system user manual 36 z corporation service (781)852-5050/(887)88-zcorp 6.2 aligning the print heads 1. Select the ‘service print head’ option under the service menu. This will get the print heads started and verify that they are operating correctly. 2. Bring the build piston all ...

Page 37

Z406 system user manual z corporation www.Zcorp-users.Com 37 4. Close the top cover and put the printer online. 5. Select the ‘alignment’ option under the 406service menu. 6. Click on ‘print test pattern’ in the alignment dialog box. It will take a minute to initialize the printer, send the pattern,...

Page 38

Z corporation z406 system user manual 38 z corporation service (781)852-5050/(887)88-zcorp bull's eye targets, one for each head. When it looks well centered, the head is in alignment. This area warms up the heads to get them printing evenly. It does not factor into the alignment. These reticules ar...

Page 39

Z406 system user manual z corporation www.Zcorp-users.Com 39 see the examples below for properly and improperly aligned reticules. Normal reticule patterns: fast axis to the left good fast axis reticule the three short lines are interleaved with the long lines. Fast axis to the right examples of pro...

Page 40

Z corporation z406 system user manual 40 z corporation service (781)852-5050/(887)88-zcorp 9. Look up the numbers that are next to the best-aligned pattern as described above. 10. Choose ‘edit alignment’ in the alignment dialog box. 11. Enter numbers for each row into the corresponding (fast and slo...

Page 41

Z406 system user manual z corporation www.Zcorp-users.Com 41 all bull's eyes are centered. All targets are evenly spaced. 15. Purge print heads after alignment process with clear binder. This will clear print heads of black ink and fill them will clear binder. The process should take about 10 minute...

Page 42

Z corporation z406 system user manual 42 z corporation service (781)852-5050/(887)88-zcorp 6.3 color alignment 1. Make sure you have run through the standard alignment, purged the print heads, and changed the binder supply to color mode. 2. Spread powder onto the build piston. 3. Choose ‘color align...

Page 43

Z406 system user manual z corporation www.Zcorp-users.Com 43 6. Look at the left and right edges of the squares. Look for the least color fringing on the sides. For each color choose the corresponding square in the dialog box. In this case, the ‘0’ square would be chosen among the blue squares. Clic...

Page 44

Z corporation z406 system user manual 44 z corporation service (781)852-5050/(887)88-zcorp 6.4 flushing the binder 1. If the machine is not in daily use, binder should be flushed bi-weekly for one minute. This may be done by choosing the ‘flush binder’ option under the ‘service’ menu in the zprint s...

Page 45

Z406 system user manual z corporation www.Zcorp-users.Com 45 6.6 oiling the snowplows (for non-zcast powder users) two snowplows are located between the roller on the gantry. Snowplows needs to be oiled before every build. To oil snowplows, squeeze a few drops of oil into the wicks on the snowplow. ...

Page 46

Z corporation z406 system user manual 46 z corporation service (781)852-5050/(887)88-zcorp 6. Press ‘ok’ on the software dialog box to repark. 6.8 oil slow axis front rail (for zcast powder users) oil the slow axis rail before every build to prevent slow axis errors. 1. Squeeze a few drops of oil on...

Page 47

Z406 system user manual z corporation www.Zcorp-users.Com 47 6.9 replacing the scraper blade (for zcast powder users) the plastic scraper blade will eventually become worn and will need replacement. Five replacement blades are included in the kit. To replace the blade, peel off the old blade. Take a...

Page 48

Z corporation z406 system user manual 48 z corporation service (781)852-5050/(887)88-zcorp 6.10 changing the binder supply changing the binder supply allows you to change between monochrome and color mode. To change binder supplies, choose the ‘change binder supply’ option under the 406service menu....

Page 49

Z406 system user manual z corporation www.Zcorp-users.Com 49 front bearing snowplows scraper blade assembly 6.11 changing material system if using zcast powder before using zcast powder, a hardware upgrade (z406 zcast kit, part number 06105) is needed to prevent damage to your printer. The three har...

Page 50

Z corporation z406 system user manual 50 z corporation service (781)852-5050/(887)88-zcorp 3. Remove the powder from the overflow bin and empty into a sealed container. 4. To prevent any material contamination, vacuum any remaining powder in the overflow bin. 5. Before replacing the overflow bin, va...

Page 51

Z406 system user manual z corporation www.Zcorp-users.Com 51 zb52 binder 6. Change binder solution (color and clear binder) if necessary. 7. Change printer mode from color to monochrome or monochrome to color if needed. 8. If you changed binder solution, flush binder for two minutes by choosing the ...

Page 52

Z corporation z406 system user manual 52 z corporation service (781)852-5050/(887)88-zcorp 10. Set up the printer as described in section 2.2.2, filling the feed box with powder. Change powder type 11. Open or import your file into the zprint software using version 6.0 or higher. 12. Open up the 3d ...

Page 53

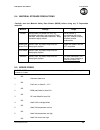

Z406 system user manual z corporation www.Zcorp-users.Com 53 recommended saturation values 14. Override or approve shell and core saturation values and anisotropic scaling factors. Review bleed compensation values. 15. Then proceed to printing your part..

Page 54

Z corporation z406 system user manual 54 z corporation service (781)852-5050/(887)88-zcorp 7 troubleshooting 7.1 the binder solution is being applied in erratic stripes if the binder appears to be applied in fragmented stripes, check the following: 1. Rinse the squeegee clear of any debris. 2. Make ...

Page 55

Z406 system user manual z corporation www.Zcorp-users.Com 55 7.5 my starch-based parts are unusually “cakey” • is the saturation too high? If your parts (especially bulky parts) are unusually difficult to depowder, too much moisture has moved from the part into the immediately surrounding powder. Th...

Page 56

Z corporation z406 system user manual 56 z corporation service (781)852-5050/(887)88-zcorp 8 z406 system details 8.1 description of rear i/o panel power input diagnostic video connector diagnostic keyboard connector main power fuse serial input connection serial port connection: this is an rs-232 se...

Page 57

Z406 system user manual z corporation www.Zcorp-users.Com 57 8.2 symbols used the following symbols are used on the z406 3d printer: this is the international symbol for ‘standby power’. It is used on the z406 3d printer power switch. The z406 3d printer is partially powered as soon as you plug it i...

Page 58

Z corporation z406 system user manual 58 z corporation service (781)852-5050/(887)88-zcorp 8.3 system specifications z406 3d printer dimensions: 40” x 31” x 44” high (102cm x 79cm x 112cm high) z406 3d printer weight: 470 lbs. (210 kg) power requirements and operating conditions at site of installat...

Page 59

Z406 system user manual z corporation www.Zcorp-users.Com 59 8.4 material storage precautions carefully read the material safety data sheets (msds) before using any z corporation materials. Material storage usage powder store powder on pallets in a cool, dry, ventilated area away from sources of hea...

Page 60

Z corporation z406 system user manual 60 z corporation service (781)852-5050/(887)88-zcorp 7 100 8 head cover is open 100 9 head %d fire voltage stuck 101 0 invalid head temperature 110 0 system: out of memory in thread %d 120 0 thread %d: can't create events 120 1 thread %d: can't initialize window...

Page 61

Z406 system user manual z corporation www.Zcorp-users.Com 61 140 3 keyboard: error reading pipe 150 0 keymap: duplicate key %d 150 1 keymap: bad key index %d 160 0 com%d is not a valid port 160 1 com%d: queue is too small 160 2 com%d: ets monitor is using port 160 3 com%d: port already in use 160 4 ...

Page 62

Z corporation z406 system user manual 62 z corporation service (781)852-5050/(887)88-zcorp 1 170 2 status: unknown system message %d 170 3 status: invalid state %d 170 4 status: unknown dispatch type %d 170 5 status: message queue overrun 170 6 status: can't save state 170 7 status: can't restore st...

Page 63

Z406 system user manual z corporation www.Zcorp-users.Com 63 200 4 stripes: bad print mode %d 200 5 stripes: bad line offset 210 0 unrle: bad layer number 210 1 unrle: bad print mode %d 220 0 bmoco: lm629 does not respond 220 1 bmoco: can't reset motor %d 230 0 mover: bad axis 230 1 mover: axis %d d...

Page 64

Z corporation z406 system user manual 64 z corporation service (781)852-5050/(887)88-zcorp 0 250 1 shaker: bad layer number 260 0 head: bad rom format 270 0 drawspan: bad bit number 270 1 drawspan: bad print mode 280 0 tigercom: serial write timeout 280 1 tigercom: serial read timeout 290 0 tiger: b...

Page 65

Z406 system user manual z corporation www.Zcorp-users.Com 65 301 1 sequencer: error in dpc, flags = %x 301 2 sequencer: spurious interrupt, flags = %x 301 3 sequencer: timed out finishing swath, flags = %x 310 0 printer: spurious read event 310 1 printer: bad dispatch type %d 310 2 printer: unknown ...

Page 66

Z corporation z406 system user manual 66 z corporation service (781)852-5050/(887)88-zcorp 2 360 3 blink: undefined sequence 370 0 lcd: object already exists 370 1 lcd: object not initialized 370 2 lcd: object has too many users 380 0 lowlevel: can't find pci card 380 1 lowlevel: error opening fpga ...

Page 67

Z406 system user manual z corporation www.Zcorp-users.Com 67 400 8 tcp: error %d selecting socket 400 9 tcp: error %d getting received byte count 401 0 tcp: error %d receiving from socket 401 1 tcp: error %d looking up host by name 401 2 tcp: error %d connecting to host 401 3 tcp: error %d sending t...

Page 68

Z corporation z406 system user manual 68 z corporation service (781)852-5050/(887)88-zcorp 0 440 1 bitbus: object not initialized 440 2 bitbus: readback error 450 0 fluids: object already exists 450 1 fluids: object not initialized 450 2 fluids: unsupported pump rate 460 0 carwash: object already ex...

Page 69

Z406 system user manual z corporation www.Zcorp-users.Com 69 9 index 3 3d print, 27 a aligning the print heads. See alignment alignment, 36 edit alignment, 40 anisotropic scaling values, 26 plaster, 26 starch, 26 zcast powder, 26 b build, 23 collision detection, 25 open file, 23 part orientation, 24...

Page 70

Z corporation z406 system user manual 70 z corporation service (781)852-5050/(887)88-zcorp s saturation values, 27 plaster, 27 starch, 27 zcast powder, 27 scraper blade replacement, 47 shelling, 8 speed, 32 strength, 32 striping of binder solution, 54 system specifications, 58 t troubleshooting, 54 ...