- DL manuals

- Zanotti

- Refrigerator

- GM1

- Use And Maintenance Instructions

Zanotti GM1 Use And Maintenance Instructions

Summary of GM1

Page 1

Gm manuale uso e manutenzione use and maintenance instructions notice de mode d’emploi et d’entretien gebrauchs- und wartungshandbuch manual de uso y manutenciÓn i gb f d e.

Page 2

18 contents 1. Safety recommendations 2 . Table of warning and attention plates 3. Description of the unit 4. Operation 5. Handling 6. Installation 6.1 plates 6.2 dimensions 6.3 location 6.4 free room 6.5 installation 6.6 fitting the remote panel 6.7 safety devices 6.8 cleaning 7. Connecting the uni...

Page 3

19 thank you for choosing uniblock. Please read these instructions carefully. They provide details and advice on the correct method of installing, using and maintaining this unit, in order to obtain maximum reliability, efficiency and long life. 1 safety recommendations when installing and using the...

Page 4

20 2 table of warning and attention plates modello model matricola serial number tensione voltage assorbimento marcia run absorption refrigerante refrigerant massa mass v/ph/hz a kw kg kg via martin l. King, nr. 30 46020 pegognaga (mantova) - italy zanotti s.P.A. Modello model potenza nom.Compressor...

Page 5

21 3 description of the unit the gm series includes air-cooled or water-cooled (optional) condensing units built on the basis of the single-block principle. They consist of: 1. A condensing unit placed outside the cold room; 2. An insulating panel (optional) for wall-thru instead of straddle install...

Page 6

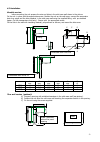

22 6 installation 6.1 plates the unit is supplied with warning and attention plates as listed in the relevant table. 6.2 dimensions a b c d e f g gm1 735 790 264 280 510 368 400 gm2 830 790 264 280 510 585 620 gm3 830 982 364 350 632 585 620 6.3 location to obtain optimal operation of the unit act a...

Page 7

23 a condensate drain line Ø 28 6.5 installation straddle version: before mounting the unit prepare the cuts and holes in the cold room wall shown in the picture. Fix the unit in place with the appropriate screws. Position the unit on the cold room, connect the evaporator drain tray spigot and the h...

Page 8

24 mod. A b c d e f g h gm1 735 264 280 110 400 335 375 100 gm2 830 264 280 110 400 335 590 100 gm3 830 364 350 110 522 440 590 100 6.6 fitting the remote panel (optional): fix the back plate to the wall using the pre-drilled holes; be careful the panel is kept in a vertical position. Fit the connec...

Page 9

25 6.7 safety devices the following mechanical safety devices are supplied: 1. Fixed upper and side protections for evaporator and condensing unit, secured by locking screws. 2. External fan protections placed on the evaporating and condensing units, secured with screws. The following electrical saf...

Page 10

26 connect the unit paying attention to the colours of the supply cable wires: a) 230v/1/50-60hz yellow/green = ground brown = phase b) 230v/3/50-60hz 4 wires blue = phase yellow/green = ground brown = phase black = phase c) 400/3/50 hz 5 wires blue = neutral yellow/green = ground brown = phase blac...

Page 11

27 8 electric controls 8.1 control panel 1. Control led (green) on : compressor is running, unit is refrigerating. Flashing : compressor is in start delay mode. Off : compressor is off, room temperature is down to set value. 2. Control led (green) on : evaporator fan is running. Flashing : evaporato...

Page 12

28 9. "on/off" key: when pressed for 3 seconds it turns the unit on or off. 10. "enter" key: it gives access to programming menu and submenus. Access to the programming mode requires the installator’s assistance and should be effected only if necessary. 9 checks, regulations and adjustments before t...

Page 13

29 10. Wiring a wiring diagram, specific for the units of the gm series, is enclosed with these use and maintenance instructions. 11. Maintenance and repairs suitable maintenance is crucial for obtaining longer life, perfect working conditions and high efficiency of the unit as well as for ensuring ...

Page 14

30 2 ice forms on the evaporator preventing air from flowing regularly. Possible causes are: - the door is opened too frequently; - faulty operation of evaporator fan; - faulty solenoid valve (in models with hot gas defrost); - faulty defrost heater (in models with electric defrost); - faulty defros...

Page 15

31 alarm display cause remedy high temperature (hi) red led and alarm relay are activated; hi is displayed in the alarm menu as indicated above. Excessive door openings excessive product load product too warm malfunction of the unit low temperature (li) red led, buzzer and alarm relay are activated;...

Page 16

32 voltage monitor (e8) the voltage monitor is an electronic device which checks the supply voltage of the unit. When voltage variations exceed +/- 12% the device activates the red led, the buzzer and the alarm led. Err and cold room temperature are displayed alternately. E8 is displayed in the alar...

Page 17

80 zanotti s.P.A. Via m.L. King, 30 - 46020 pegognaga (mn) italy tel. 0376.5551 - fax 0376.536554 info@zanotti.Com - www.Zanotti.Com 0man106/ e 04/ 2004.

Page 18

1 legenda schema elettrico - wiring diagram legende schema electrique - schaltplanlegenda leyenda esquema electrico - legenda esquema electrico ba sonda temperatura ambiente room sensor sonde chambre froide raumsonde sonda camara sonda temperatura ambiente bc sonda condensatore condenser alarm senso...

Page 19

2 f1 fusibile compressore compressor fuse fusible compresseur kompressorsicherung fusible compresor fusiveis compressor f1e centralina elettronica electronic control cab panneau de contrôle electronique elektronenkontroll- paneel panel de control electronico f20 fusibile ausiliario auxiliary fuse fu...

Page 20

3 moteur ventilateur condenseur kond.-ventilatormotor motor ventilador condensador motor ventilador condensador mve motore ventola evaporatore evaporator fan motor moteur ventilateur evaporateur verdmf.-ventilatormotor motor ventilador evaporador motor ventilador evaporador p1mx pressostato inserzio...

Page 21

4 zanotti s.P.A. Via m.L. King, 30 - 46020 pegognaga (mn) italy tel. 0376.5551 - fax 0376.536554 info@zanotti.Com - www.Zanotti.Com 0man 153 01/2003.