- DL manuals

- Zebra

- Software

- 110PAX4

- User Manual

Zebra 110PAX4 User Manual - Print Engine Exterior View

Introduction

Print Engine Exterior View

8

57512L-002 Rev. A

110PAX4/R110PAX4 User Guide

12/14/05

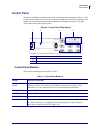

Print Engine Exterior View

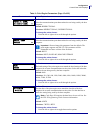

Print engines are available in a right-hand configuration (media moves from left to right,

) and a left-hand configuration (media moves from right to left,

Figure 2 • Right-Hand (RH) Print Engine

Figure 3 • Left-Hand (LH) Print Engine

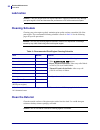

1

Power on/off switch

2

Control panel

3

Media door

4

Electronics cover

2

1

3

4

2

1

3

4

Summary of 110PAX4

Page 1

110 pax4™/r110pax4™ print engine user guide.

Page 2

© 2005 zih corp. The copyrights in this manual and the software and/or firmware in the label print engine described therein are owned by zih corp. Unauthorized reproduction of this manual or the software and/or firmware in the label print engine may result in imprisonment of up to one year and fines...

Page 3

Iii declaration of incorporation 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A declaration of incorporation zebra technologies corporation declares that the following information technology equipment zebra pax4 series complies with the following applicable directives and standards for the i...

Page 4: Compliance Information

Compliance information iv 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 compliance information fcc compliance statement this device complies with part 15 rules. Operation is subject to the following two conditions: 1. This device may not cause harmful interference, and 2. This device must a...

Page 5

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A contents about this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 who should use this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 h...

Page 6

Contents vi 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 print engine installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

Vii contents 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 5 • routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 8

Contents viii 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 8 • specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143 general specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 9

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A about this document this section provides you with contact information, document structure and organization, and additional reference documents. Contents who should use this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 10: Who Should Use This Document

About this document who should use this document 2 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 who should use this document this user guide is intended for use by any person who needs to operate or troubleshoot problems with the print engine. How this document is organized the user guide ...

Page 11: Contacts

3 about this document contacts 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A contacts you can contact zebra technologies at the following. Web site http://www.Zebra.Com technical support via the internet is available 24 hours per day, 365 days per year. Go to http://www.Zebra.Com/support . ...

Page 12: Document Conventions

About this document document conventions 4 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 document conventions the following conventions are used throughout this document to convey certain information. Alternate color (online only) cross-references contain hot links to other sections in this...

Page 13

5 about this document document conventions 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A illustration callouts callouts are used when an illustration contains information that needs to be labeled and described. A table that contains the labels and descriptions follows the graphic. Figure 1 ...

Page 14

About this document document conventions 6 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 notes • ___________________________________________________________________ __________________________________________________________________________ ___________________________________________________...

Page 15

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 1 introduction this chapter shows the operational controls and location of major components used when loading media and ribbon. Contents print engine exterior view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

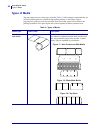

Page 16: Print Engine Exterior View

Introduction print engine exterior view 8 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 print engine exterior view print engines are available in a right-hand configuration (media moves from left to right, figure 2 ) and a left-hand configuration (media moves from right to left, figure 3 )....

Page 17: Control Panel

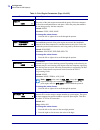

9 introduction control panel 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A control panel all controls and indicators for the print engine are located on the control panel ( figure 4 ). The liquid crystal display (lcd) shows print engine operating status and feature parameters. The buttons a...

Page 18

Introduction control panel 10 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 control panel indicator lights (leds) the control panel lights are described in table 2 . Cancel cancel functions only in pause mode. Pressing cancel has these effects: • cancels the label format that is currently p...

Page 19

11 introduction control panel 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A ribbon (yellow) normal operation. Ribbon properly loaded. Ribbon in while print engine is in direct thermal mode, or no ribbon loaded while the print engine is in thermal transfer mode. The print engine is paused, l...

Page 20: Power On/off Switch

Introduction power on/off switch 12 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 power on/off switch the print engine power switch is located to the side of the control panel, as shown in figure 5 . When this switch is placed in the on ( i ) position, the power light turns on, and the prin...

Page 21

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 2 print engine setup this section provides the tasks that you must complete and the issues that you must consider before you load and configure your print engine. Contents before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 22: Before You Begin

Print engine setup before you begin 14 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 before you begin review this checklist, and resolve any issues before you set up or use your print engine. Unpack and inspect the print engine have you unpacked the print engine and inspected it for damage?...

Page 23: Handling The Print Engine

15 print engine setup handling the print engine 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A handling the print engine this section describes how to handle your print engine. Unpack and inspect the print engine when you receive the print engine, immediately unpack it and inspect for shippi...

Page 24: Print Engine Installation

Print engine setup print engine installation 16 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 print engine installation this section provides basic information for mounting the print engine into an applicator. The illustrations in this section show the print engine from different angles and...

Page 25

17 print engine setup print engine installation 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A dimensions and clearance needs figure 6 • front view of right-hand print engine 5 mounting screws - 0.218 in. (5.5 mm) through - counterbore 0.350 in. X 0.197 in. (8.9 x 5 mm) deep - socket head ca...

Page 26

Print engine setup print engine installation 18 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 figure 7 • right side view of right-hand print engine.

Page 27

19 print engine setup print engine installation 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A figure 8 • rear view of right-hand print engine.

Page 28

Print engine setup print engine installation 20 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 figure 9 • top view of right-hand print engine install the print engine in an applicator this section provides the basic instructions for installing the print engine into an applicator. To install ...

Page 29

21 print engine setup print engine installation 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 3. Install the four corner mounting screws to secure the print engine to the applicator. Figure 10 • front view of print engine in applicator 1 mounting screws (four total) 2 keyhole 3 center mount...

Page 30

Print engine setup connect the print engine to a power source 22 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 connect the print engine to a power source the power supply in the print engine automatically detects the applied line voltage and works in the 90 to 264 vac, 47 to 63 hz range. Th...

Page 31

23 print engine setup connect the print engine to a power source 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A power cord specifications depending on how your print engine was ordered, a power cord may or may not be included. If one is not included or if the one included is not suitable for...

Page 32

Print engine setup select a communication interface 24 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 select a communication interface the way that you connect your print engine to a data source depends on the communication options installed in the print engine. You may use any available con...

Page 33

25 print engine setup select a communication interface 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A types of connections the method of connecting the print engine to a data source depends on the communication options installed in the print engine and the host. This section provides basic i...

Page 34

Print engine setup select a communication interface 26 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 ieee 1284 bidirectional parallel a common communication method available on most pcs and other hosts. • advantages: fastest of the communication interfaces; cables and connectors are readily...

Page 35

27 print engine setup select a communication interface 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A data cable requirements data cables must be fully shielded and fitted with metal or metallized connector shells. Shielded cables and connectors are required to prevent radiation and receptio...

Page 36: Types of Media

Print engine setup types of media 28 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 types of media the print engine can use various types of media ( table 3 ). Zebra strongly recommends the use of zebra-brand supplies for continuous high-quality printing. A wide range of paper, polypropylene...

Page 37

29 print engine setup types of media 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A non-continuous fanfold media fanfold media is folded in a zigzag pattern. Fanfold media can have the same label divisions as non- continuous roll media. The divisions would fall on or near the folds. Continuo...

Page 38: Ribbon Overview

Print engine setup ribbon overview 30 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 ribbon overview ribbon is a thin film that is coated on one side with wax, resin, or wax resin, which is transferred to the media during the thermal transfer process. The media determines whether you need to...

Page 39

31 print engine setup ribbon overview 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A adhesive test if you have labels available, perform the adhesive test to determine which side of a ribbon is coated. This method works well for ribbon that is already installed. To perform an adhesive test, ...

Page 40

Print engine setup ribbon overview 32 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 notes • ___________________________________________________________________ __________________________________________________________________________ ________________________________________________________...

Page 41

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 3 operations if you have completed the tasks and resolved the issues in print engine setup on page 13 , follow the instructions in this chapter to load and calibrate your print engine. Contents load media . . . . . . . . . . . . . . . . . . . . ...

Page 42: Load Media

Operations load media 34 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 load media figure 21 identifies the media-handling components. Figure 22 on page 35 shows the print engine with media loaded. Figure 21 • components for media loading important • if the print engine power is off ( o ), r...

Page 43

35 operations load media 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A figure 22 • loaded media to load media, complete these steps: 1. Load media on the media supply reel of the applicator (refer to the applicator’s user guide). 2. Open the media door. 3. Press the release button ( 1 ) on ...

Page 44

Operations load media 36 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 4. Slide the outer media guide ( 1 ) all the way out. 5. 1 caution • the printhead may be hot and could cause severe burns. Allow the printhead to cool. Open the printhead assembly by unlatching the printhead latch ( 1 )...

Page 45

37 operations load media 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 6. See figure 23 . Thread the media under the upper guide post ( 1 ), below the pinch roller assembly ( 2 ), and under the printhead assembly ( 3 ). 7. See figure 23 . Extend approximately 30 in. (75 cm) of media past th...

Page 46

Operations load media 38 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 10. Press down on the pinch roller assembly ( 1 ) until it locks closed. 11. Close the printhead assembly by rotating the printhead latch ( 1 ) until it latches onto the locking pin ( 2 ). 12. Raise the peel roller latch...

Page 47

39 operations load media 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 13. Thread the media liner around the peel bar ( 1 ), under the media liner roller ( 2 ), and through the peel roller assembly ( 3 ). 14. Rotate the peel roller assembly ( 1 ) up until it locks into the closed position. ...

Page 48: Load Ribbon

Operations load ribbon 40 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 load ribbon use ribbon with thermal transfer media. The ribbon must be coated on the outside and wider than the media. If the ribbon is narrower than the media, areas of the printhead are unprotected and subject to prem...

Page 49

41 operations load ribbon 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A figure 26 • loaded ribbon to load ribbon, complete these steps: 1. Place a full ribbon roll ( 1 ) onto the ribbon supply spindle ( 2 ) so that the ribbon rotates as shown, and then push the roll toward the print engine ...

Page 50

Operations load ribbon 42 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 2. See figure 27 . On the lower dancer assembly, squeeze the opening tabs ( 1 ) to pivot open the dancer arm ( 2 ). 3. See figure 27 . Carefully thread the ribbon ( 3 ) through the lower dancer assembly, and then slowly...

Page 51

43 operations load ribbon 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 6. 7. Thread the ribbon over the auxiliary roller ( 1 ), around the idler roller ( 2 ), and then up toward the upper dancer assembly. 8. See figure 27 on page 42 . On the upper dancer assembly, squeeze the opening tabs ...

Page 52

Operations load ribbon 44 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 10. Place an empty ribbon core ( 1 ) onto the ribbon take-up spindle ( 2 ). Push the core toward the print engine frame until it is fully seated. 11. Attach the end of the ribbon to the empty ribbon core with adhesive t...

Page 53: Remove Used Ribbon

45 operations remove used ribbon 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A remove used ribbon to remove used ribbon, complete these steps: 1. Open the media door. 2. Examine the ribbon. Did the ribbon run out? If... Then... Yes a. Remove the empty core from the ribbon supply spindle. Sa...

Page 54: Calibrate The Print Engine

Operations calibrate the print engine 46 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 calibrate the print engine calibrate the print engine when it is first put into service. Calibration allows the print engine to establish the proper settings for the specific media and ribbon used in your...

Page 55

47 operations calibrate the print engine 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A sensor profile calibration the print engine auto-calibrates and prints a media sensor profile. Select the sensor profile option on the control panel. See print sensor profile on page 69 for instructions. ...

Page 56

Operations adjust ribbon and media sensors 48 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 adjust ribbon and media sensors this section describes how to adjust the sensors. Ribbon sensor the ribbon sensor ( figure 28 ) is mounted in a fixed position, and no adjustment is required. Figure 2...

Page 57

49 operations adjust ribbon and media sensors 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 2. How does the current media indicate the start of labels? Figure 29 • media sensor adjustment (right-hand unit shown) if the media... Then... Has notches or holes between labels align the sensor wi...

Page 58

Operations adjust ribbon and media sensors 50 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 notes • ___________________________________________________________________ __________________________________________________________________________ ________________________________________________...

Page 59

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 4 configuration this section describes the control panel parameters that are used to configure the print engine for operation. Contents setup mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 60: Setup Mode

Configuration setup mode 52 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 setup mode after you have installed the media and ribbon and the power-on self test (post) is complete, the control panel displays printer ready . You may now set print engine parameters for your application using the...

Page 61

53 configuration setup mode 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A exit setup mode to leave setup mode, complete these steps: 1. Press setup/exit . The lcd displays save changes . 2. Press the left or right oval to display the save options ( table 5 ). 3. Press next to select the dis...

Page 62

Configuration change password-protected parameters 54 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 change password-protected parameters certain parameters, including the communication parameters, are password-protected by factory default. The first time that you attempt to change a passwor...

Page 63: Print A Configuration Label

55 configuration print a configuration label 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A print a configuration label a configuration label lists the print engine settings that are stored in configuration memory. After you load the media and ribbon (if necessary), print a configuration lab...

Page 64

Configuration print a network configuration label 56 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 print a network configuration label if you are using a print server, you can print a network configuration label after the print engine is connected to the network. To print a network configur...

Page 65: Control Panel Lcd Displays

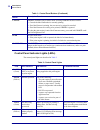

57 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A control panel lcd displays use the lcd display on the control panel to adjust print engine settings. Table 6 shows parameters in the order in which they are displayed when you press next after entering...

Page 66

Configuration control panel lcd displays 58 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 adjust slew speed adjusts the speed for feeding a blank label (given in inches per second). Default: 6 ips range: 1 to 12 ips to change the value shown: 1. Press the right oval to increase the value. 2...

Page 67

59 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A adjust the tear-off position this parameter establishes the position of the media over the tear-off/peel-off bar after printing. See figure 32 . Higher numbers move the media out (the tear line moves c...

Page 68

Configuration control panel lcd displays 60 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 set media type this parameter tells the print engine the type of media that you are using (see types of media on page 28 for more information). Selecting continuous media requires that you include a la...

Page 69

61 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A set maximum label length this parameter is used during the media portion of the calibration process. Always set maximum label length to a value that is at least 1.0 in. (25.4 mm) greater than the actua...

Page 70

Configuration control panel lcd displays 62 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 set early warning system when this parameter is enabled, the print engine provides warnings when labels are running low. Note • update the number of labels per roll when beginning use of the early warn...

Page 71

63 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A reset media counter for early warning this parameter appears only when early warning is enabled for media. To reset the media counter: 1. Did you replace the media? A. If you replaced the media, press ...

Page 72

Configuration control panel lcd displays 64 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 set early warning for maintenance when this parameter is enabled, the print engine provides warnings when the printhead needs to be cleaned. Note • update the number of labels per roll when beginning u...

Page 73

65 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A set printhead life for early warning this parameter appears only when early warning is enabled for maintenance. Set this value to the number of inches of media that the printhead is expected to print. ...

Page 74

Configuration control panel lcd displays 66 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 list images this option prints a label that lists the available images stored in the print engine’s ram, flash memory, optional memory card, pcmcia cards, or compact flash cards. To print a list of the...

Page 75

67 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A format memory card this option erases all previously stored information from the optional pcmcia card or compact flash card. Caution • this option completely erases the selected card. To format a memor...

Page 76

Configuration control panel lcd displays 68 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 initialize flash memory this option erases all previously stored information from flash memory. Caution • this option completely erases the flash memory. To initialize flash memory: 1. Press the right ...

Page 77

69 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A print sensor profile the sensor profile may be used to troubleshoot registration problems that may be caused when the media sensor detects preprinted areas on the media or if it experiences difficulty ...

Page 78

Configuration control panel lcd displays 70 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 calibrate media and ribbon sensor sensitivity use this procedure to adjust sensitivity of media and ribbon sensors. Important • follow this procedure exactly as presented. All of the steps must be perf...

Page 79

71 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A set parallel communications select the communications port that matches the one being used by the host computer. Default: bidirectional selections: bidirectional, unidirectional to change the value sho...

Page 80

Configuration control panel lcd displays 72 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 set parity the parity of the print engine must match the parity of the host computer for accurate communications to take place. Select the parity that matches the one being used by the host computer. D...

Page 81

73 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A set communications mode the communication diagnostics mode is a troubleshooting tool for checking the interconnection between the print engine and the host computer. When diagnostics is selected, all d...

Page 82

Configuration control panel lcd displays 74 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 set format prefix character the format prefix is a two-digit hex value used as a parameter place marker in zpl/zpl ii format instructions. The “h” that is displayed indicates hexadecimal and is not par...

Page 83

75 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A select media power-up option this parameter sets the action of the media when you turn on the print engine. Default: calibration selections: feed, calibration, length, short cal, and no motion • feed—f...

Page 84

Configuration control panel lcd displays 76 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 select backfeed sequence this parameter establishes when label backfeed occurs after a label is removed in applicator mode. It has no effect in rewind mode. This setting is superseded by ~js when recei...

Page 85

77 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A set the printhead resistor value caution • this parameter should be changed only by qualified service personnel. Do notset the value higher than that shown on the printhead. Setting a higher value may ...

Page 86

Configuration control panel lcd displays 78 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 set applicator error signal when print engine pauses when this option is enabled and the print engine is paused, the print engine sets the applicator error state. Default: enabled selections: enabled, ...

Page 87

79 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A set ribbon low mode when the ribbon low feature is off, the output signal (pin 9) does not function, the low ribbon warning is not displayed, and the print engine continues to print until it runs out o...

Page 88

Configuration control panel lcd displays 80 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 these parameters are automatically set during the calibration procedure and should be changed only by a qualified service technician. Refer to the zpl ii programming guide for information on these para...

Page 89

81 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A set rts supply dancer arm calibration value this parameter is used as a diagnostic tool to monitor the voltage supplied to the ribbon tensioning system supply dancer arm. Refer to the maintenance manua...

Page 90

Configuration control panel lcd displays 82 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 print server lcd displays the menu options shown in table 7 display only if you have a print server installed. Table 7 • print server parameters (page 1 of 4) parameter action/explanation load lan sour...

Page 91

83 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A specify ip address 2 this parameter allows you to select the ip address if permanent was chosen in ip protocol. (if a dynamic option was chosen, the user cannot select the address.) to change the value...

Page 92

Configuration control panel lcd displays 84 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 enable leap mode 3,4 leap is an encryption method that is available with some wireless cards. Set the leap user name and password through the print engine web pages. Default: off selections: on, off to...

Page 93

85 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A reset network 2,3 this option resets the wireless card and the print server when the wireless option is running. Selecting this option has no effect when the wireless option is not running, when there ...

Page 94

Configuration control panel lcd displays 86 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 rfid lcd displays this section shows the radio frequency identification (rfid) control panel parameters. The parameters shown in table 8 display only if you have an rfid reader installed. When you ente...

Page 95

87 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A calibrate rfid tag important • do not perform transponder calibration for rfid media that meets the transponder placement specifications for your print engine. Doing so will slow the print engine’s thr...

Page 96

Configuration control panel lcd displays 88 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 view or change rfid write power this parameter displays the current value for rfid write power. Default: hi selections: hi, med, low to change the value shown: 1. Press the left or right oval to scroll...

Page 97

89 configuration control panel lcd displays 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A read and display rfid tag data when this option is selected, the reader attempts to read a tag over the rfid antenna, even if the printhead is open. Results are displayed in hexadecimal format. The pri...

Page 98

Configuration control panel lcd displays 90 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 notes • ___________________________________________________________________ __________________________________________________________________________ __________________________________________________...

Page 99

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 5 routine maintenance this chapter provides routine cleaning and maintenance procedures. Contents lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 cleaning sch...

Page 100: Lubrication

Routine maintenance lubrication 92 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 lubrication cleaning schedule cleaning your print engine regularly maintains print quality and may extend the life of the print engine. The recommended cleaning schedule is shown in table 9 . See the following ...

Page 101: Clean The Media Compartment

93 routine maintenance clean the media compartment 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A clean the media compartment remove any accumulated dirt and lint from the interior of the print engine using a soft bristle brush and/or vacuum cleaner. This area should be inspected every time ...

Page 102

Routine maintenance clean the sensors 94 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 figure 37 • door-open sensor location (right-hand unit shown) figure 38 • ribbon sensor location (right-hand unit shown) 1 door-open sensor 1 ribbon sensor reflector 2 ribbon sensor 1 2 1.

Page 103

95 routine maintenance clean the printhead and platen roller 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A clean the printhead and platen roller clean the printhead and platen roller according to the schedule in table 9 on page 92 . Clean the printhead more often if you see inconsistent pri...

Page 104

Routine maintenance clean the printhead and platen roller 96 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 4. See figure 40 . Using a solution of 90% isopropyl alcohol and 10% deionized water on a cotton swab, wipe the print elements from end to end. Allow the solvent to evaporate. Figure 4...

Page 105: Toggle Positioning

97 routine maintenance toggle positioning 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A toggle positioning proper toggle positioning is important for proper print quality. The toggle should be positioned approximately midway across the width of the media. To adjust the toggles, complete the...

Page 106

Routine maintenance printhead pressure adjustment 98 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 printhead pressure adjustment before adjusting the printhead pressure, check that the toggles are positioned correctly. See toggle positioning on page 97 . You may need to adjust the printhead...

Page 107: Power Fuse Replacement

99 routine maintenance power fuse replacement 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A power fuse replacement the print engine uses a metric-style fuse (5 × 20 mm iec) rated for 5 amps at 250 volts that bears the certification mark of a known international safety organization (see figu...

Page 108

Routine maintenance power fuse replacement 100 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 notes • ___________________________________________________________________ __________________________________________________________________________ _______________________________________________...

Page 109

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 6 troubleshooting this section provides information about errors that you might need to troubleshoot. Assorted diagnostic tests are included. Contents troubleshooting checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 110: Troubleshooting Checklists

Troubleshooting troubleshooting checklists 102 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 troubleshooting checklists if an error condition exists with the print engine, review this checklist: is there an error message on the lcd? If yes, see lcd error messages on page 103 . are nonco...

Page 111: Lcd Error Messages

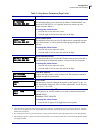

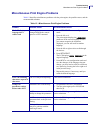

103 troubleshooting lcd error messages 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A lcd error messages the lcd displays messages when there is an error. See table 10 for lcd errors, the possible causes, and the recommended solutions. Table 10 • lcd error messages lcd display/ print engine ...

Page 112

Troubleshooting lcd error messages 104 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 ribbon light on, error light flashes. Ribbon is loaded, but the print engine is set for direct thermal mode. Ribbon is not required with direct thermal media. If you are using direct thermal media, remove r...

Page 113

105 troubleshooting lcd error messages 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A the print engine stops and the error light flashes. Caution • an improperly connected printhead data or power cable can cause this error message. The printhead may be hot enough to cause severe burns. Allow...

Page 114: Memory Errors

Troubleshooting memory errors 106 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 memory errors the memory errors in table 11 indicate that the print engine does not have enough memory to perform the function shown on the second line of the lcd. Table 11 • memory errors problem/lcd display po...

Page 115: Print Quality Problems

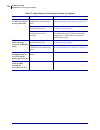

107 troubleshooting print quality problems 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A print quality problems table 12 identifies problems with print quality, the possible causes, and the recommended solutions. Table 12 • print quality problems problem possible cause recommended solution ...

Page 116

Troubleshooting print quality problems 108 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 wrinkled ribbon ribbon fed through the machine incorrectly. See load ribbon on page 40 . Incorrect burn temperature. Set the darkness to the lowest possible setting for good print quality. See adjust pr...

Page 117

109 troubleshooting print quality problems 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A printing too light or too dark over the entire label media or ribbon is not designed for high-speed operation. Replace supplies with those recommended for high-speed operation. You are using an incorrec...

Page 118

Troubleshooting print quality problems 110 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 vertical image or label drift the print engine is using noncontinuous labels but is configured in continuous mode. Configure the print engine for non-continuous and run calibration routine, if necessary...

Page 119: Communications Problems

111 troubleshooting communications problems 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A communications problems table 13 identifies problems with communications, the possible causes, and the recommended solutions. Table 13 • communications problems problem possible cause recommended solut...

Page 120: Rfid Problems

Troubleshooting rfid problems 112 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 rfid problems table 14 identifies problems that may occur with rfid print engines, the possible causes, and the recommended solutions. Table 14 • rfid problems problem possible cause recommended solution the rfi...

Page 121

113 troubleshooting rfid problems 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A poor yields. Too many rfid tags per roll are voided. The rfid labels are not within specifications for the print engine. The transponder is not in an area that can be programmed consistently. Make sure that the ...

Page 122

Troubleshooting rfid problems 114 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 the print engine stops at the rfid inlay. The print engine calibrated the label length only to the rfid inlay instead of to the interlabel gap. 1. Select feed for the media power up and head close parameters (se...

Page 123

115 troubleshooting miscellaneous print engine problems 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A miscellaneous print engine problems table 15 identifies miscellaneous problems with the print engine, the possible causes, and the recommended solutions. Table 15 • miscellaneous print engi...

Page 124

Troubleshooting miscellaneous print engine problems 116 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 the print engine fails to calibrate or detect the top of the label. The print engine was not calibrated for the label being used. Perform the calibration procedure in calibrate media and ri...

Page 125: Print Engine Diagnostics

117 troubleshooting print engine diagnostics 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A print engine diagnostics self tests and other diagnostics provide specific information about the condition of the print engine. The self tests produce sample printouts and provide specific information...

Page 126

Troubleshooting print engine diagnostics 118 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 cancel self test the cancel self test prints a configuration label ( figure 44 ). To perform the cancel self test, complete these steps: 1. Turn off (o) the print engine. 2. Press and hold cancel whil...

Page 127

119 troubleshooting print engine diagnostics 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A pause self test this self test can be used to provide the test labels required when making adjustments to the print engine’s mechanical assemblies or to determine if any printhead elements are not wor...

Page 128

Troubleshooting print engine diagnostics 120 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 feed self test different types of media may require different darkness settings. This section contains a simple but effective method for determining the ideal darkness for printing bar codes that are ...

Page 129

121 troubleshooting print engine diagnostics 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A figure 46 • feed test label 4. See figure 47 and table 16 . Inspect the test labels and determine which one has the best print quality for your application. If you have a bar code verifier, use it to ...

Page 130

Troubleshooting print engine diagnostics 122 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 figure 47 • bar code darkness comparison table 16 • judging bar code quality print quality description too dark labels that are too dark are fairly obvious. They may be readable but not “in-spec.” • t...

Page 131

123 troubleshooting print engine diagnostics 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 5. Note the relative darkness value and the print speed printed on the best test label. 6. Add or subtract the relative darkness value from the darkness value specified on the configuration label. The...

Page 132

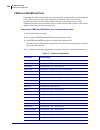

Troubleshooting print engine diagnostics 124 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 feed and pause self test performing this self test temporarily resets the print engine configuration to the factory default values. These values are active only until power is turned off unless you sa...

Page 133

125 troubleshooting print engine diagnostics 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A zpl mode configuration, zpl, and webview media power up configuration, zpl, and webview head close configuration, zpl, and webview backfeed configuration, zpl, and webview label top configuration, zpl...

Page 134

Troubleshooting print engine diagnostics 126 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 communications diagnostics test do not perform the following test until all configuration and calibration parameters have been set. For configuration information, see control panel lcd displays on pag...

Page 135

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 7 data ports this section describes the standard communication ports available to connect the print engine to your computer or network. Contents parallel data port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 136: Parallel Data Port

Data ports parallel data port 128 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 parallel data port the parallel data interface supports ieee 1284 bidirectional parallel communications in nibble mode. The parallel interface provides a means of communication that typically is faster than the ...

Page 137

129 data ports parallel data port 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 31 ninit 32 nfault/ndataavail 33, 34 not used 35 +5 v through a 1.8 k Ω resistor 36 nselectin/1284 active table 18 • parallel cable pin configuration (continued) 36-pin connectors description.

Page 138: Serial Data Port

Data ports serial data port 130 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 serial data port see rs-232 serial on page 25 for basic cabling information. To communicate using the serial data port of the print engine, you must choose the number of data bits, parity, and handshaking. Parity ...

Page 139

131 data ports serial data port 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A pin configuration connect the serial data cable to the female db-9 connector on the back of the print engine. For all rs-232 connections through a db-25 cable, use a db-9 to db-25 interface module (see db-9 to db-...

Page 140

Data ports serial data port 132 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 rs-232 interface connections the print engine is configured as data terminal equipment (dte). Figure 49 shows the internal connections of the print engine’s rs-232 connector. Figure 49 • rs-232 db9 mlb connections...

Page 141

133 data ports serial data port 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A db-9 to db-25 connections to connect the print engine’s rs-232 db-9 interface to a db-25 connector, an interface adapter is required. A generic db-25 adapter can be used, although the +5 vdc signal source would no...

Page 142

Data ports applicator interface connector 134 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 applicator interface connector an external db-15 connector is present on the rear panel of the print engine for communication with a customer applicator. An optional db-15 to db-9 adapter cable (zebr...

Page 143

135 data ports applicator interface connector 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A figure 54 • applicator signals (mode 3) figure 55 • applicator signals (mode 4) applicator interface connector pin configuration the applicator interface assembly is available in two versions: a +5 v...

Page 144

Data ports applicator interface connector 136 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 2 +5v i/o (fused at 1 a) caution • replace the fuse only with one of the same type and rating. Power see figure 56 on page 141 for fuse location. Using jumper j4, this pin can be configured as isolat...

Page 145

137 data ports applicator interface connector 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 8 power ground (+28 v dc return) ground the interface power ground. Note • if pin 7 is used to supply power to pin 2, use this pin to ground pin 1. 9 ribbon low output asserted if the ribbon low feat...

Page 146

Data ports applicator interface connector 138 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 11 end print output see applicator signals on page 134 for more information about the start and end print signals. See set applicator port mode on page 77 for more information about the modes. • mode...

Page 147

139 data ports applicator interface connector 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A jumper configurations and pinouts for +5 v i/o operation jumpers j4 and j5 are used together to produce isolated or non-isolated modes of operation for applicator input and output control signals. J4...

Page 148

Data ports applicator interface connector 140 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 pinouts for +24-28 v i/o operation table 22 describes the pin configurations for +24-28 v i/o operation. There are no jumpers to configure for this mode. Table 22 • non-isolated and isolated modes fo...

Page 149

141 data ports applicator interface connector 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A fuse and jumper locations figure 56 shows the location of the fuses on the applicator interface board and the location of jumpers j4 and j5. Figure 56 • applicator interface board 1 fuse f2 for +28 v...

Page 150

Data ports applicator interface connector 142 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 notes • ___________________________________________________________________ __________________________________________________________________________ ________________________________________________...

Page 151

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A 8 specifications this chapter provides routine cleaning and maintenance procedures. Contents general specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144 physical . . . . . . . . ...

Page 152: General Specifications

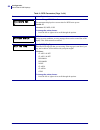

Specifications general specifications 144 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 general specifications physical environmental conditions electrical specifications height 11.8 in. (300 mm) width 9.6 in. (245 mm) depth 16.4 in. (417 mm) weight 36 lb (16.3 kg) operating temperature the...

Page 153

145 specifications general specifications 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A communications specifications parallel • bi-directional high-speed (36-pin connector) • ieee 1284-compliant software protocol (standard) serial • serial rs-232c with dtr hardware handshake via db-9 conne...

Page 154

Specifications general specifications 146 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 other standard features • real time clock • fast 32 bit 133 mhz risc processor • 10mb ram memory • flash memory including 2mb non-volatile memory storage for downloadable objects • type i & ii series c &...

Page 155: Agency Approvals

147 specifications agency approvals 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A agency approvals the agency approvals and product markings provided in this section apply only to the print engines specified. 110pax4 non-rfid or rfid-ready without rfid reader installed the following apply o...

Page 156

Specifications agency approvals 148 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 european union and efta (869.7–870 mhz) this device is intended for commercial and industrial use in all eu and efta member states. Agency approvals • en 55022 • en 61000-6-2 • en 300 220-3 • en 301 489-3 • en...

Page 157: Media Specifications

149 specifications media specifications 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A media specifications media width (label and liner) minimum non-rfid 0.63 in. (16 mm) rfid “smart” labels minimum label widths for rfid “smart” labels varies for each transponder type. Maximum 4.5 in. (114 ...

Page 158: Ribbon Specifications

Specifications ribbon specifications 150 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 ribbon specifications media unwind force steady state must be uniform and must not exceed 2 lb. (907 g) transient (start/stop) must not exceed 4 lb (1814 g) media rewind force applicator take-up pull tens...

Page 159: Printing Specifications

151 specifications printing specifications 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A printing specifications specification 203 dpi 300 dpi resolution 203 dots per inch (8 dots per mm) 300 dots per inch (12 dots per mm) dot size 0.0049 in. X 0.0049 in. (0.125 mm x 0.125 mm) 0.0033 in. X ...

Page 160: Bar Codes

Specifications zebra programming language (zpl ii) 152 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 zebra programming language (zpl ii) bar codes • communicates in printable ascii characters • controlled via mainframe, mini, or pc • downloadable graphics, scalable and bitmap fonts, label t...

Page 161

12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A index a adhesive test for ribbon coating, 31 adjustments lcd, 80 left position, 76 media sensors, 48 print darkness, 57 printhead pressure, 98 tear-off position, 59 toggle positioning, 97 agency approvals, 147 applicator +24-28v isolated and non...

Page 162

Index 154 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 configuration label printing using cancel self test, 118 printing using list setup command, 66 connect to power source, 22 contacts, 3 continuous media described, 29 setting media type, 60 control panel buttons, 9 enter setup mode, 52 ...

Page 163

155 index 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A installation procedure, 20 requirements, 16 interface db-15 applicator interface, 26 interfaces ieee 1284 bidirectional parallel, 26 print servers, 26 rs-232 serial, 25 international safety organization marks, 23 ip settings default ga...

Page 164

Index 156 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 o optional print servers, 26 ordering ribbon and media, 3 out of memory message, 105 p paper out message, 104 parallel port cabling requirements, 128 overview, 26 pin configuration, 128 setting parallel communications, 71 settings, 128...

Page 165

157 index 12/14/05 110pax4/r110pax4 user guide 57512l-002 rev. A printhead cleaning, 95 head close setting, 75 head resistor value setting, 77 pressure adjustment, 98 when to clean, 92 printing specifications, 151 product markings, 147 protocol setting, 72 r radiation exposure limits, iv read power ...

Page 166

Index 158 57512l-002 rev. A 110pax4/r110pax4 user guide 12/14/05 shipping report damage, 15 reshipping the print engine, 15 short calibration, 46 “smart” labels, 29 specifications agency approvals and markings, 147 bar codes, 152 communications options, 145 electrical, 144 environmental conditions, ...

Page 168

Zebra technologies corporation 333 corporate woods parkway vernon hills, illinois 60061.3109 u.S.A. Telephone: +1 847.793.2600 facsimile: +1 847.913.8766 zebra technologies europe limited zebra house the valley centre, gordon road high wycombe buckinghamshire hp13 6eq, uk telephone: +44 (0) 1494 472...