- DL manuals

- Zebra

- Software

- 170PAX4

- User Manual

Zebra 170PAX4 User Manual

Summary of 170PAX4

Page 1

57516l-004 zebra ® 170pax4™ print engine user guide.

Page 2

© 2011 zih corp. The copyrights in this manual and the software and/or firmware in the print engine described therein are owned by zih corp. And zebra’s licensors. Unauthorized reproduction of this manual or the software and/or firmware in the print engine may result in imprisonment of up to one yea...

Page 3

3 declaration of incorporation 6/29/11 170pax4 user guide 57516l-004 rev. A declaration of incorporation zebra technologies corporation declares that the following information technology equipment zebra pax4 series complies with the following applicable directives and standards for the ite: heavy in...

Page 4: Compliance Information

Compliance information 4 57516l-004 rev. A 170pax4 user guide 6/29/11 compliance information fcc compliance statement this device complies with part 15 rules. Operation is subject to the following two conditions: 1. This device may not cause harmful interference, and 2. This device must accept any i...

Page 5

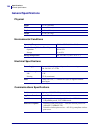

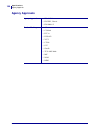

6/29/11 170pax4 user guide 57516l-004 rev. A contents about this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 who should use this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 how this doc...

Page 6

Contents 6 57516l-004 rev. A 170pax4 user guide 6/29/11 types of media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 ribbon overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

7 contents 6/29/11 170pax4 user guide 57516l-004 rev. A lcd error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105 print quality problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 8

Contents 8 57516l-004 rev. A 170pax4 user guide 6/29/11 glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153 index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 9

6/29/11 170pax4 user guide 57516l-004 rev. A about this document this section provides you with contact information, document structure and organization, and additional reference documents. Contents who should use this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 10: Who Should Use This Document

About this document who should use this document 10 57516l-004 rev. A 170pax4 user guide 6/29/11 who should use this document this user guide is intended for use by any person who needs to operate or troubleshoot problems with the print engine. How this document is organized the user guide is set up...

Page 11: Contacts

11 about this document contacts 6/29/11 170pax4 user guide 57516l-004 rev. A contacts technical support via the internet is available 24 hours per day, 365 days per year. Web site: www.Zebra.Com e-mail back technical library: e-mail address: emb@zebra.Com subject line: emaillist self service knowled...

Page 12: Document Conventions

About this document document conventions 12 57516l-004 rev. A 170pax4 user guide 6/29/11 document conventions the following conventions are used throughout this document to convey certain information. Alternate color (online only) cross-references contain hot links to other sections in this guide. I...

Page 13

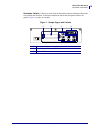

13 about this document document conventions 6/29/11 170pax4 user guide 57516l-004 rev. A illustration callouts callouts are used when an illustration contains information that needs to be labeled and described. A table that contains the labels and descriptions follows the graphic. Figure 1 provides ...

Page 14

About this document document conventions 14 57516l-004 rev. A 170pax4 user guide 6/29/11 notes • ___________________________________________________________________ __________________________________________________________________________ ____________________________________________________________...

Page 15

6/29/11 170pax4 user guide 57516l-004 rev. A 1 introduction this chapter shows the operational controls and location of major components used when loading media and ribbon. Contents print engine exterior view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 16: Print Engine Exterior View

Introduction print engine exterior view 16 57516l-004 rev. A 170pax4 user guide 6/29/11 print engine exterior view print engines are available in a right-hand configuration (media moves from left to right, figure 2 ) and a left-hand configuration (media moves from right to left, figure 3 ). Figure 2...

Page 17: Control Panel

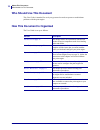

17 introduction control panel 6/29/11 170pax4 user guide 57516l-004 rev. A control panel all controls and indicators for the print engine are located on the control panel ( figure 4 ). The liquid crystal display (lcd) shows print engine operating status and feature parameters. The buttons are used t...

Page 18

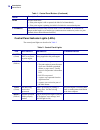

Introduction control panel 18 57516l-004 rev. A 170pax4 user guide 6/29/11 control panel indicator lights (leds) the control panel lights are described in table 2 . Feed feeds a blank label. • if the print engine is idle or paused, the label is fed immediately. • if the print engine is printing, the...

Page 19

19 introduction control panel 6/29/11 170pax4 user guide 57516l-004 rev. A ribbon (yellow) normal operation. Ribbon properly loaded. Ribbon in while print engine is in direct thermal mode, or no ribbon loaded while the print engine is in thermal transfer mode. The print engine is paused, lcd display...

Page 20: Power On/off Switch

Introduction power on/off switch 20 57516l-004 rev. A 170pax4 user guide 6/29/11 power on/off switch the print engine power switch is located to the side of the control panel, as shown in figure 5 . When this switch is placed in the on ( i ) position, the power light turns on, and the print engine a...

Page 21

6/29/11 170pax4 user guide 57516l-004 rev. A 2 print engine setup this section provides the tasks that you must complete and the issues that you must consider before you load and configure your print engine. Contents before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 22: Before You Begin

Print engine setup before you begin 22 57516l-004 rev. A 170pax4 user guide 6/29/11 before you begin review this checklist, and resolve any issues before you set up or use your print engine. unpack and inspect the print engine have you unpacked the print engine and inspected it for damage? If you ...

Page 23: Handling The Print Engine

23 print engine setup handling the print engine 6/29/11 170pax4 user guide 57516l-004 rev. A handling the print engine this section describes how to handle your print engine. Unpack and inspect the print engine when you receive the print engine, immediately unpack it and inspect for shipping damage....

Page 24: Print Engine Installation

Printer setup print engine installation 24 57516l-004 rev. A 170pax4 user guide 6/29/11 print engine installation this section provides basic information for mounting the print engine into an applicator. The illustrations in this section show the print engine from different angles and include dimens...

Page 25

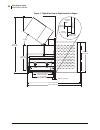

25 print engine setup print engine installation 6/29/11 170pax4 user guide 57516l-004 rev. A dimensions and clearance needs figure 6 • front view of right-hand print engine 10.433 in. (265 mm) 0.197 in. (5 mm) 0.197 in. (5 mm) 0.550 in. (13.97 mm) 0.320 in. (8.13 mm) 5 mounting screws - 0.218 in. (5...

Page 26

Print engine setup print engine installation 26 57516l-004 rev. A 170pax4 user guide 6/29/11 figure 7 • right side view of right-hand print engine 18.3 in. (465 mm) 0.394 in. (10.0 mm) 7.1 in. (180 mm) max backing width 7.000 in. (177.8 mm) max label width 8.500 in. (215.9 mm) 10.398 in. (264.1 mm) ...

Page 27

27 print engine setup print engine installation 6/29/11 170pax4 user guide 57516l-004 rev. A figure 8 • rear view of right-hand print engine install the print engine in an applicator this section provides the basic instructions for installing the print engine into an applicator. To install the print...

Page 28

Print engine setup print engine installation 28 57516l-004 rev. A 170pax4 user guide 6/29/11 figure 9 • front view of print engine in applicator 1 mounting screws (four total) 2 keyhole 3 center mounting bolt (shown inside hole on applicator) 4 applicator 4 2 1 1 3 1.

Page 29

29 print engine setup connect the print engine to a power source 6/29/11 170pax4 user guide 57516l-004 rev. A connect the print engine to a power source the power supply in the print engine automatically detects the applied line voltage and works in the 90 to 264 vac, 47 to 63 hz range. The ac power...

Page 30

Print engine setup connect the print engine to a power source 30 57516l-004 rev. A 170pax4 user guide 6/29/11 power cord specifications depending on how your print engine was ordered, a power cord may or may not be included. If one is not included or if the one included is not suitable for your requ...

Page 31

31 print engine setup select a data communication interface 6/29/11 170pax4 user guide 57516l-004 rev. A select a data communication interface table 4 provides basic information about data communication interfaces that you can use to connect your print engine to a computer. You may send label format...

Page 32

Print engine setup select a data communication interface 32 57516l-004 rev. A 170pax4 user guide 6/29/11 connector locations refer to figure 12 . The print engine comes standard with both an electronics industries association (eia) rs-232 serial interface (db-9 connector) and an ieee 1284 bidirectio...

Page 33

33 print engine setup select a data communication interface 6/29/11 170pax4 user guide 57516l-004 rev. A data cables and wireless cards you must supply all data cables or removeable radio cards for your application. (some wireless print servers come with an integrated radio card.) data cables ethern...

Page 34: Types of Media

Print engine setup types of media 34 57516l-004 rev. A 170pax4 user guide 6/29/11 types of media your print engine can use various types of media: • standard media—most standard media uses an adhesive backing that sticks individual labels or a continuous length of labels to a liner. • tag stock—tags...

Page 35

35 print engine setup types of media 6/29/11 170pax4 user guide 57516l-004 rev. A table 5 • roll and fanfold media media type how it looks description non-continuous roll media roll media is wound on a 3-in. (76-mm) core. Individual labels are separated by one or more of the following methods: • web...

Page 36: Ribbon Overview

Print engine setup ribbon overview 36 57516l-004 rev. A 170pax4 user guide 6/29/11 ribbon overview ribbon is a thin film that is coated on one side with wax, resin, or wax resin, which is transferred to the media during the thermal transfer process. The media determines whether you need to use ribbo...

Page 37

37 print engine setup ribbon overview 6/29/11 170pax4 user guide 57516l-004 rev. A adhesive test if you have labels available, perform the adhesive test to determine which side of a ribbon is coated. This method works well for ribbon that is already installed. To perform an adhesive test, complete t...

Page 38

Print engine setup ribbon overview 38 57516l-004 rev. A 170pax4 user guide 6/29/11 notes • ___________________________________________________________________ __________________________________________________________________________ __________________________________________________________________...

Page 39

6/29/11 170pax4 user guide 57516l-004 rev. A 3 operations if you have completed the tasks and resolved the issues in print engine setup on page 21 , follow the instructions in this chapter to load and calibrate your print engine. Contents load media . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 40: Load Media

Operations load media 40 57516l-004 rev. A 170pax4 user guide 6/29/11 load media figure 14 identifies the media-handling components. Figure 15 on page 41 shows the print engine with media loaded. Figure 14 • components for media loading important • if the print engine power is off ( o ), rollers in ...

Page 41

41 operations load media 6/29/11 170pax4 user guide 57516l-004 rev. A figure 15 • loaded media left-hand right-hand.

Page 42

Operations load media 42 57516l-004 rev. A 170pax4 user guide 6/29/11 to load media, complete these steps: 1. Load media on the media supply reel of the applicator (refer to the applicator’s user guide). 2. Open the media door. 3. Press down on the pinch roller release latch. The pinch roller assemb...

Page 43

43 operations load media 6/29/11 170pax4 user guide 57516l-004 rev. A 5. 6. See figure 16 . Thread the media through the upper media path as follows: a. Under the upper guide post ( 1 ) b. Between the top media sensor track assembly ( 2 ) and the label guide shelf assembly ( 3 ) c. Below the pinch r...

Page 44

Operations load media 44 57516l-004 rev. A 170pax4 user guide 6/29/11 8. Position the media ( 1 ) so that it is aligned with and just touching the inner media guide ( 2 —not visible from this angle). 9. Under the print engine, grasp the brass thumb nut of the outer media guide ( 1 ), and position th...

Page 45

45 operations load media 6/29/11 170pax4 user guide 57516l-004 rev. A 10. Press down on the pinch roller assembly ( 1 ) until it locks closed. 11. Close the printhead assembly by rotating the printhead latch ( 1 ) until it latches onto the locking pin ( 2 ). 12. Raise the peel roller latch ( 1 ) so ...

Page 46

Operations load media 46 57516l-004 rev. A 170pax4 user guide 6/29/11 13. 14. Rotate the peel roller assembly up until it locks into the closed position. 15. Thread the liner around the take-up spindle of the applicator (refer to the applicator’s user guide). 16. Close the media door. Thread the lin...

Page 47: Load Ribbon

47 operations load ribbon 6/29/11 170pax4 user guide 57516l-004 rev. A load ribbon use ribbon with thermal transfer media. The ribbon must be coated on the outside and wider than the media. If the ribbon is narrower than the media, areas of the printhead are unprotected and subject to premature wear...

Page 48

Operations load ribbon 48 57516l-004 rev. A 170pax4 user guide 6/29/11 figure 18 • loaded ribbon left-hand right-hand.

Page 49

49 operations load ribbon 6/29/11 170pax4 user guide 57516l-004 rev. A to load ribbon, complete these steps: 1. Place a full ribbon roll onto the ribbon supply spindle ( 1 ) so the ribbon rotates as shown, and then push the roll toward the print engine frame until it is fully seated. 2. Thread the r...

Page 50

Operations load ribbon 50 57516l-004 rev. A 170pax4 user guide 6/29/11 4. 5. Thread the ribbon under the printhead assembly ( 1 ) and then around the upper ribbon guide roller ( 2 ). Caution • the printhead may be hot and could cause severe burns. Allow the printhead to cool. Open the printhead asse...

Page 51

51 operations load ribbon 6/29/11 170pax4 user guide 57516l-004 rev. A 6. Place an empty ribbon core (1) onto the ribbon take-up spindle ( 2 ), and then push the core toward the print engine frame until it is fully seated. 7. Attach the end of the ribbon to the empty ribbon core with adhesive tape o...

Page 52: Remove Used Ribbon

Operations remove used ribbon 52 57516l-004 rev. A 170pax4 user guide 6/29/11 remove used ribbon to remove used ribbon, complete these steps: 1. Open the media door. 2. Examine the ribbon. Did the ribbon run out? If... Then... Yes a. Remove the empty core from the ribbon supply spindle. Save the cor...

Page 53: Calibrate The Print Engine

53 operations calibrate the print engine 6/29/11 170pax4 user guide 57516l-004 rev. A calibrate the print engine calibrate the print engine when it is first put into service. Calibration allows the print engine to establish the proper settings for the specific media and ribbon used in your applicati...

Page 54

Operations calibrate the print engine 54 57516l-004 rev. A 170pax4 user guide 6/29/11 sensor profile calibration the print engine auto-calibrates and prints a media sensor profile. See sensor profile on page 128 . Select the sensor profile option on the control panel. See print sensor profile on pag...

Page 55

55 operations adjust ribbon and media sensors 6/29/11 170pax4 user guide 57516l-004 rev. A adjust ribbon and media sensors this section describes how to adjust the sensors. Ribbon sensor the ribbon sensor is mounted in a fixed position, and no adjustment is required. Reflective media sensor some typ...

Page 56

Operations adjust ribbon and media sensors 56 57516l-004 rev. A 170pax4 user guide 6/29/11 figure 19 • media sensor adjustment (right-hand unit shown) 1 transmissive media sensor 2 adjustment knob 1 2.

Page 57

6/29/11 170pax4 user guide 57516l-004 rev. A 4 configuration this section describes the control panel parameters that are used to configure the print engine for operation. Contents setup mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 58: Setup Mode

Configuration setup mode 58 57516l-004 rev. A 170pax4 user guide 6/29/11 setup mode after you have installed the media and ribbon and the power-on self test (post) is complete, the control panel displays printer ready . You may now set print engine parameters for your application using the control p...

Page 59

59 configuration setup mode 6/29/11 170pax4 user guide 57516l-004 rev. A exit setup mode when you exit setup mode, you have several options for saving, changing, or not changing parameters. To leave setup mode, complete these steps: 1. While in setup mode, press setup/exit . The lcd displays save ch...

Page 60

Configuration change password-protected parameters 60 57516l-004 rev. A 170pax4 user guide 6/29/11 change password-protected parameters certain parameters, including the communication parameters, are password-protected by factory default. The first time that you attempt to change a password-protecte...

Page 61: Print A Configuration Label

61 configuration print a configuration label 6/29/11 170pax4 user guide 57516l-004 rev. A print a configuration label a configuration label lists the print engine settings that are stored in configuration memory. After you load the media and ribbon (if necessary), print a configuration label as a re...

Page 62

Configuration print a network configuration label 62 57516l-004 rev. A 170pax4 user guide 6/29/11 print a network configuration label if you are using a print server, you can print a network configuration label after the print engine is connected to the network. To print a network configuration labe...

Page 63: Control Panel Parameters

63 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A control panel parameters use the lcd on the control panel to view and adjust print engine settings. How to view or modify parameters while viewing parameters, press next to continue to the next parameter, or press...

Page 64

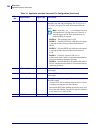

Configuration control panel parameters 64 57516l-004 rev. A 170pax4 user guide 6/29/11 standard print engine parameters table 7 shows parameters in the order in which they are displayed when you press next after entering setup mode. Table 7 • print engine parameters (page 1 of 26) parameter action/e...

Page 65

65 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A adjust backfeed speed if backfeed is on, adjusts the speed at which the label backs up before printing (given in inches per second). Default: 2 ips range: 1 to 12 ips to change the value shown: 1. Press the right ...

Page 66

Configuration control panel parameters 66 57516l-004 rev. A 170pax4 user guide 6/29/11 select print mode print mode settings tell the print engine the method of media delivery that you wish to use. Make sure that your print engine can support the selected option. Default: applicator selections: tear...

Page 67

67 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A select print method the print method parameter tells the print engine the method of printing that you wish to use: direct thermal (no ribbon) or thermal transfer (using thermal transfer media and ribbon). Default:...

Page 68

Configuration control panel parameters 68 57516l-004 rev. A 170pax4 user guide 6/29/11 set maximum label length this parameter is used during the media portion of the calibration process. Always set maximum label length to a value that is at least 1.0 in. (25.4 mm) greater than the actual label leng...

Page 69

69 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A set early warning for media when this parameter is enabled, the print engine provides warnings when labels are running low. Note • update the number of labels per roll when beginning use of the early warning syste...

Page 70

Configuration control panel parameters 70 57516l-004 rev. A 170pax4 user guide 6/29/11 reset media counter for early warning this parameter appears only when early warning for media is enabled. To reset the media counter: 1. Did you replace the media? A. If you replaced the media, press the right ov...

Page 71

71 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A set early warning for maintenance when this parameter is enabled, the print engine provides warnings when the printhead needs to be cleaned. Note • if necessary, update the number of labels per roll when beginning...

Page 72

Configuration control panel parameters 72 57516l-004 rev. A 170pax4 user guide 6/29/11 set printhead life for early warning this parameter appears only when early warning for maintenance is enabled. Set this value to the number of inches of media that the printhead is expected to print. Default: 1,0...

Page 73

73 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A list images this option prints a label that lists the available images stored in the print engine’s ram, flash memory, optional memory card, pcmcia cards, or compact flash cards. To print a list of the available i...

Page 74

Configuration control panel parameters 74 57516l-004 rev. A 170pax4 user guide 6/29/11 format memory card this option erases all previously stored information from the optional pcmcia card or compact flash card. Caution • this option completely erases the selected card. To format a memory card: 1. P...

Page 75

75 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A initialize flash memory this option erases all previously stored information from flash memory. Caution • this option completely erases the flash memory. To initialize flash memory: 1. Press the right oval to sele...

Page 76

Configuration control panel parameters 76 57516l-004 rev. A 170pax4 user guide 6/29/11 print sensor profile a sensor profile shows sensor settings compared to actual sensor readings. This label (which will extend across several actual labels or tags) can be used to troubleshoot printing problems. To...

Page 77

77 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A calibrate media and ribbon sensor sensitivity use this procedure to adjust sensitivity of media and ribbon sensors. Important • follow this procedure exactly as presented. All of the steps must be performed even i...

Page 78

Configuration control panel parameters 78 57516l-004 rev. A 170pax4 user guide 6/29/11 set parallel communications select the communications port that matches the one being used by the host computer. Default: bidirectional selections: bidirectional, unidirectional to change the value shown: 1. Press...

Page 79

79 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A set parity this setting applies only when the serial port is used. The parity of the print engine must match the parity of the host computer for accurate communications to take place. Select the parity that matche...

Page 80

Configuration control panel parameters 80 57516l-004 rev. A 170pax4 user guide 6/29/11 set communications mode the communication diagnostics mode is a troubleshooting tool for checking the interconnection between the print engine and the host computer. For more information, see communications diagno...

Page 81

81 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A set delimiter character the delimiter character is a two-digit hex value used as a parameter place marker in zpl/zpl ii format instructions. See the programming guide for zpl, zbi, set-get-do, mirror, and wml for ...

Page 82

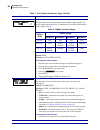

Configuration control panel parameters 82 57516l-004 rev. A 170pax4 user guide 6/29/11 set ribbon tension this parameter sets the tension applied to the ribbon supply spindle. The correct setting is determined by a combination of the ribbon width and the ribbon length ( table 8 ). Default: high sele...

Page 83

83 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A select head close option this parameter sets the action of the media when you close the printhead. Default: calibration selections: feed, calibration, length, short cal, and no motion • feed—feeds the labels to th...

Page 84

Configuration control panel parameters 84 57516l-004 rev. A 170pax4 user guide 6/29/11 adjust left position this parameter establishes how far from the left edge of a label the format begins to print by adjusting horizontal positioning on the label. Positive numbers adjust the printing away from the...

Page 85

85 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A set applicator port mode determines the action of the applicator port. Note • set this value as suggested by the applicator manufacturer. Default: off selections: off, mode 1, mode 2, mode 3, mode 4 • off: the app...

Page 86

Configuration control panel parameters 86 57516l-004 rev. A 170pax4 user guide 6/29/11 select start print signal this parameter determines how the print engine reacts to the start print signal input on pin 3 of the applicator interface connector at the rear of the print engine. Caution • start print...

Page 87

87 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A set ribbon low mode when the ribbon low feature is off, the output signal (pin 9) does not function, the low ribbon warning is not displayed, and the print engine continues to print until it runs out of ribbon. Wh...

Page 88

Configuration control panel parameters 88 57516l-004 rev. A 170pax4 user guide 6/29/11 these parameters are automatically set during the calibration procedure and should be changed only by a qualified service technician. Refer to the programming guide for zpl, zbi, set-get-do, mirror, and wml for in...

Page 89

89 configuration control panel parameters 6/29/11 170pax4 user guide 57516l-004 rev. A select idle display this parameter selects the lcd options for the real-time clock. Note • if the default value is not selected, pressing the left or right oval briefly displays the firmware version of the print e...

Page 90

Configuration control panel parameters 90 57516l-004 rev. A 170pax4 user guide 6/29/11 notes • ___________________________________________________________________ __________________________________________________________________________ ______________________________________________________________...

Page 91

6/29/11 170pax4 user guide 57516l-004 rev. A 5 routine maintenance this chapter provides routine cleaning and maintenance procedures. Contents replacing print engine components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 ordering replacement parts . . . . . . ....

Page 92

Routine maintenance replacing print engine components 92 57516l-004 a 170pax4 user guide 6/29/11 replacing print engine components some print engine components, such as the printhead and platen roller, may wear out over time and can be replaced easily. Regular cleaning may extend the life of some of...

Page 93: Lubrication

93 routine maintenance lubrication 6/29/11 170pax4 user guide 57516l-004 rev. A lubrication cleaning schedule cleaning your print engine regularly maintains print quality and may extend the life of the print engine. The recommended cleaning schedule is shown in table 9 . See the following pages for ...

Page 94: Clean The Media Compartment

Routine maintenance clean the media compartment 94 57516l-004 rev. A 170pax4 user guide 6/29/11 clean the media compartment remove any accumulated dirt and lint from the interior of the print engine using a soft bristle brush and/or vacuum cleaner. This area should be inspected every time a new ribb...

Page 95

95 routine maintenance clean the sensors 6/29/11 170pax4 user guide 57516l-004 rev. A figure 26 • door-open sensor location (right-hand unit shown) 1 door-open sensor 1.

Page 96

Routine maintenance clean the printhead and platen roller 96 57516l-004 rev. A 170pax4 user guide 6/29/11 clean the printhead and platen roller clean the printhead and platen roller according to the schedule in table 9 on page 93 . Clean the printhead more often if you see inconsistent print quality...

Page 97

97 routine maintenance clean the printhead and platen roller 6/29/11 170pax4 user guide 57516l-004 rev. A 4. Using preventative maintenance kit (part number 47362) or a solution of 90% isopropyl alcohol and 10% deionized water on a cotton swab, wipe the print elements from end to end. Allow the solv...

Page 98: Toggle Positioning

Routine maintenance toggle positioning 98 57516l-004 rev. A 170pax4 user guide 6/29/11 toggle positioning proper toggle positioning is important for proper print quality. The toggles should be positioned approximately 1/4 of the way in from each media edge. To adjust the toggles, complete these step...

Page 99

99 routine maintenance toggle positioning 6/29/11 170pax4 user guide 57516l-004 rev. A 5. Position the toggles approximately 1/4 of the way in from each edge of the media. 6. Tighten the locking nuts. 7. Print additional labels at 2.4 in. (61 mm) per second by again running the pause self test. (pre...

Page 100

Routine maintenance printhead pressure adjustment 100 57516l-004 rev. A 170pax4 user guide 6/29/11 printhead pressure adjustment before adjusting the printhead pressure, check that the toggles are positioned correctly. See toggle positioning on page 98 . Printhead life and drive system life (belts a...

Page 101

101 routine maintenance printhead pressure adjustment 6/29/11 170pax4 user guide 57516l-004 rev. A 4. Loosen the locking nuts on the toggle assemblies. 5. Move the adjusting nuts until the print quality is acceptable. Use the lowest pressure that provides the desired print quality. • to increase pri...

Page 102: Power Fuse Replacement

Routine maintenance power fuse replacement 102 57516l-004 rev. A 170pax4 user guide 6/29/11 power fuse replacement the print engine uses a metric-style fuse (5 × 20 mm iec) rated for 5 amps at 250 volts that bears the certification mark of a known international safety organization (see figure 11 on ...

Page 103

6/29/11 170pax4 user guide 57516l-004 rev. A 6 troubleshooting this section provides information about errors that you might need to troubleshoot. Assorted diagnostic tests are included. Contents troubleshooting checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

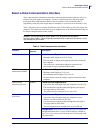

Page 104: Troubleshooting Checklists

Troubleshooting troubleshooting checklists 104 57516l-004 rev. A 170pax4 user guide 6/29/11 troubleshooting checklists if an error condition exists with the print engine, review this checklist: is there an error message on the lcd? If yes, see lcd error messages on page 105 . Are noncontinuous label...

Page 105: Lcd Error Messages

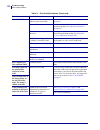

105 troubleshooting lcd error messages 6/29/11 170pax4 user guide 57516l-004 rev. A lcd error messages the lcd displays messages when there is an error. See table 10 for lcd errors, the possible causes, and the recommended solutions. Table 10 • lcd error messages lcd display/ print engine condition ...

Page 106

Troubleshooting lcd error messages 106 57516l-004 rev. A 170pax4 user guide 6/29/11 the ribbon light is on; the error light flashes. Ribbon is loaded, but the print engine is set for direct thermal mode. Ribbon is not required with direct thermal media. If you are using direct thermal media, remove ...

Page 107

107 troubleshooting lcd error messages 6/29/11 170pax4 user guide 57516l-004 rev. A the print engine prints while the error light flashes. Caution • an improperly connected printhead data or power cable can cause this error message. The printhead may be hot enough to cause severe burns. Allow the pr...

Page 108

Troubleshooting lcd error messages 108 57516l-004 rev. A 170pax4 user guide 6/29/11 the print engine stops. The print engine is defragmenting memory. Caution • do not turn off the print engine power during defragmenting. Doing so can damage the print engine. Allow the print engine to finish defragme...

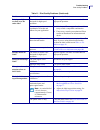

Page 109: Print Quality Problems

109 troubleshooting print quality problems 6/29/11 170pax4 user guide 57516l-004 rev. A print quality problems table 11 identifies problems with print quality, the possible causes, and the recommended solutions. Table 11 • print quality problems problem possible cause recommended solution general pr...

Page 110

Troubleshooting print quality problems 110 57516l-004 rev. A 170pax4 user guide 6/29/11 wrinkled ribbon ribbon was fed through the ribbon system incorrectly. Load the ribbon correctly. See load ribbon on page 47 . Incorrect burn temperature. Set the darkness to the lowest possible setting for good p...

Page 111

111 troubleshooting print quality problems 6/29/11 170pax4 user guide 57516l-004 rev. A printing too light or too dark over the entire label the media or ribbon is not designed for high-speed operation. Replace supplies with those recommended for high-speed operation. You are using an incorrect comb...

Page 112

Troubleshooting print quality problems 112 57516l-004 rev. A 170pax4 user guide 6/29/11 vertical image or label drift the print engine is using non-continuous labels but is configured in continuous mode. Configure the print engine for non-continuous and run calibration routine, if necessary. The med...

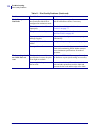

Page 113: Communications Problems

113 troubleshooting communications problems 6/29/11 170pax4 user guide 57516l-004 rev. A communications problems table 12 identifies problems with communications, the possible causes, and the recommended solutions. Table 12 • communications problems problem possible cause recommended solution a labe...

Page 114: Ribbon Problems

Troubleshooting ribbon problems 114 57516l-004 170pax4 user guide 6/29/11 ribbon problems table 13 identifies problems that may occur with ribbon, the possible causes, and the recommended solutions. Table 13 • ribbon problems problem possible cause recommended solution broken or melted ribbon darkne...

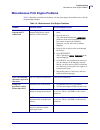

Page 115

115 troubleshooting miscellaneous print engine problems 6/29/11 170pax4 user guide 57516l-004 rev. A miscellaneous print engine problems table 14 identifies miscellaneous problems with the print engine, the possible causes, and the recommended solutions. Table 14 • miscellaneous print engine problem...

Page 116

Troubleshooting miscellaneous print engine problems 116 57516l-004 rev. A 170pax4 user guide 6/29/11 the print engine fails to calibrate or detect the top of the label. The print engine was not calibrated for the label being used. Perform the calibration procedure in calibrate media and ribbon senso...

Page 117: Print Engine Diagnostics

117 troubleshooting print engine diagnostics 6/29/11 170pax4 user guide 57516l-004 rev. A print engine diagnostics self tests and other diagnostics provide specific information about the condition of the print engine. The self tests produce sample printouts and provide specific information that help...

Page 118

Troubleshooting print engine diagnostics 118 57516l-004 rev. A 170pax4 user guide 6/29/11 cancel self test the cancel self test prints a configuration label ( figure 27 ). To perform the cancel self test, complete these steps: 1. Turn off ( o ) the print engine. 2. Press and hold cancel while turnin...

Page 119

119 troubleshooting print engine diagnostics 6/29/11 170pax4 user guide 57516l-004 rev. A pause self test this self test can be used to provide the test labels required when making adjustments to the print engine’s mechanical assemblies or to determine if any printhead elements are not working. Figu...

Page 120

Troubleshooting print engine diagnostics 120 57516l-004 rev. A 170pax4 user guide 6/29/11 feed self test different types of media may require different darkness settings. This section contains a simple but effective method for determining the ideal darkness for printing bar codes that are within spe...

Page 121

121 troubleshooting print engine diagnostics 6/29/11 170pax4 user guide 57516l-004 rev. A figure 29 • feed test label 4. See figure 30 and table 15 . Inspect the test labels and determine which one has the best print quality for your application. If you have a bar code verifier, use it to measure ba...

Page 122

Troubleshooting print engine diagnostics 122 57516l-004 rev. A 170pax4 user guide 6/29/11 figure 30 • bar code darkness comparison table 15 • judging bar code quality print quality description too dark labels that are too dark are fairly obvious. They may be readable but not “in-spec.” • the normal ...

Page 123

123 troubleshooting print engine diagnostics 6/29/11 170pax4 user guide 57516l-004 rev. A 5. Note the relative darkness value and the print speed printed on the best test label. 6. Add or subtract the relative darkness value from the darkness value specified on the configuration label. The resulting...

Page 124

Troubleshooting print engine diagnostics 124 57516l-004 rev. A 170pax4 user guide 6/29/11 feed and pause self test performing this self test temporarily resets the print engine configuration to the factory default values. These values are active only until power is turned off unless you save them pe...

Page 125

125 troubleshooting print engine diagnostics 6/29/11 170pax4 user guide 57516l-004 rev. A zpl mode configuration, zpl, and webview media power up configuration, zpl, and webview head close configuration, zpl, and webview backfeed configuration, zpl, and webview label top configuration, zpl, and webv...

Page 126

Troubleshooting print engine diagnostics 126 57516l-004 rev. A 170pax4 user guide 6/29/11 j8 interface fixed j7 interface fixed twinax/coax id zpl table 16 • control of parameters (continued) parameter controlled by.

Page 127

127 troubleshooting print engine diagnostics 6/29/11 170pax4 user guide 57516l-004 rev. A communications diagnostics test the communication diagnostics test is a troubleshooting tool for checking the interconnection between the print engine and the host computer. When the printer is in diagnostics m...

Page 128

Troubleshooting print engine diagnostics 128 57516l-004 rev. A 170pax4 user guide 6/29/11 sensor profile use the sensor profile label to troubleshoot the following types of problems: • if the media sensor experiences difficulty in determining gaps (web) between labels. • if the media sensor incorrec...

Page 129

6/29/11 170pax4 user guide 57516l-004 rev. A 7 data ports this section describes the standard communication ports available to connect the print engine to your computer or network. Contents parallel data port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 130: Parallel Data Port

Data ports parallel data port 130 57516l-004 rev. A 170pax4 user guide 6/29/11 parallel data port the parallel data interface supports ieee 1284 bidirectional parallel communications in nibble mode. The parallel interface provides a means of communication that typically is faster than the serial int...

Page 131

131 data ports parallel data port 6/29/11 170pax4 user guide 57516l-004 rev. A 19–30 ground 31 ninit 32 nfault/ndataavail 33, 34 not used 35 +5 v through a 1.8 k resistor 36 nselectin/1284 active table 17 • parallel cable pin configuration (continued) 36-pin connectors description.

Page 132: Serial Data Port

Data ports serial data port 132 57516l-004 rev. A 170pax4 user guide 6/29/11 serial data port to communicate using the serial data port of the print engine, you must choose the number of data bits, parity, and handshaking. Parity applies only to data transmitted by the print engine because the parit...

Page 133

133 data ports serial data port 6/29/11 170pax4 user guide 57516l-004 rev. A pin configuration connect the serial data cable to the female db-9 connector on the back of the print engine. For all rs-232 connections through a db-25 cable, use a db-9 to db-25 interface module (see db-9 to db-25 connect...

Page 134

Data ports serial data port 134 57516l-004 rev. A 170pax4 user guide 6/29/11 rs-232 interface connections the print engine is configured as data terminal equipment (dte). Figure 34 shows the internal connections of the print engine’s rs-232 connector. Figure 34 • rs-232 db9 mlb connections pin 9 is ...

Page 135

135 data ports serial data port 6/29/11 170pax4 user guide 57516l-004 rev. A db-9 to db-25 connections to connect the print engine’s rs-232 db-9 interface to a db-25 connector, an interface adapter is required. A generic db-25 adapter can be used, although the +5 vdc signal source would not be passe...

Page 136

Data ports applicator interface connector 136 57516l-004 rev. A 170pax4 user guide 6/29/11 applicator interface connector an external db-15 connector is present on the rear panel of the print engine for communication with a customer applicator. An optional db-15 to db-9 adapter cable (zebra part num...

Page 137

137 data ports applicator interface connector 6/29/11 170pax4 user guide 57516l-004 rev. A figure 39 • applicator signals (mode 3) figure 40 • applicator signals (mode 4) data ready (pin 14) start print (pin 3) end print (pin 11) label format sent label format processed waiting for start print signa...

Page 138

Data ports applicator interface connector 138 57516l-004 rev. A 170pax4 user guide 6/29/11 applicator interface connector pin configuration the applicator interface assembly is available in two versions: a +5 v i/o and a +24–28 v i/o. Table 19 lists the pin configurations and functions of the applic...

Page 139

139 data ports applicator interface connector 6/29/11 170pax4 user guide 57516l-004 rev. A 5 pause input to toggle the current pause state, this input must be asserted low for 200 milliseconds, or until the service required output (pin 10) changes state. 6 reprint input • if the reprint feature is e...

Page 140

Data ports applicator interface connector 140 57516l-004 rev. A 170pax4 user guide 6/29/11 11 end print output see applicator signals on page 136 for more information about the start and end print signals. See set applicator port mode on page 85 for more information about the modes. Note • a format ...

Page 141

141 data ports applicator interface connector 6/29/11 170pax4 user guide 57516l-004 rev. A jumper configurations and pinouts for +5 v i/o operation jumpers j4 and j5 are used together to produce isolated or non-isolated modes of operation for applicator input and output control signals. J4 configure...

Page 142

Data ports applicator interface connector 142 57516l-004 rev. A 170pax4 user guide 6/29/11 pinouts for +24-28 v i/o operation table 21 describes the pin configurations for +24–28 v i/o operation. There are no jumpers to configure for this mode. Table 21 • non-isolated and isolated modes for +24–28v ...

Page 143

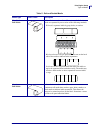

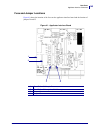

143 data ports applicator interface connector 6/29/11 170pax4 user guide 57516l-004 rev. A fuse and jumper locations figure 41 shows the location of the fuses on the applicator interface board and the location of jumpers j4 and j5. Figure 41 • applicator interface board 1 fuse f2 for +28 v at pin 7 ...

Page 144

Data ports applicator interface connector 144 57516l-004 rev. A 170pax4 user guide 6/29/11 notes • ___________________________________________________________________ __________________________________________________________________________ __________________________________________________________...

Page 145

6/29/11 170pax4 user guide 57516l-004 rev. A 8 specifications this chapter provides routine cleaning and maintenance procedures. Contents general specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146 physical . . . . . . . . . . . . . ...

Page 146: General Specifications

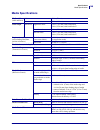

Specifications general specifications 146 57516l-004 rev. A 170pax4 user guide 6/29/11 general specifications physical environmental conditions electrical specifications communications specifications height 11.8 in. (300 mm) width 9.6 in. (245 mm) depth 18.3 in. (465 mm) weight 35.5 lb. (16.1 kg) op...

Page 147

147 specifications general specifications 6/29/11 170pax4 user guide 57516l-004 rev. A other standard features • real time clock • fast 32 bit 133 mhz risc processor • 10mb ram memory • flash memory including 2mb non-volatile memory storage for downloadable objects • type i & ii series c & d pc card...

Page 148: Agency Approvals

Specifications agency approvals 148 57516l-004 rev. A 170pax4 user guide 6/29/11 agency approvals agency approvals • iec 60950-1 • en55022, class a • en61000-6-2 product markings • culus • ce mark • fcc-a • ices-003 • vcci • c-tick • ccc • gost-r • tuv-ar/s mark • mic • nom • bsmi.

Page 149: Media Specifications

149 specifications media specifications 6/29/11 170pax4 user guide 57516l-004 rev. A media specifications media width (label and liner) minimum 3.0 in. (76 mm) maximum 7.1 in. (180 mm) label length minimum applicator mode 3.0 in. (76.2 mm) with backfeed on 1.0 in. (25.4 mm) with backfeed off rewind ...

Page 150: Ribbon Specifications

Specifications ribbon specifications 150 57516l-004 rev. A 170pax4 user guide 6/29/11 ribbon specifications thickness 4.5 microns width (wound coated side out) 3.0 in. To 7.1in. (76 mm to 180 mm) maximum length 2955 ft (900 m) roll size inner core diameter maximum roll size 1.0 in. (25.4 mm) 4.0 in....

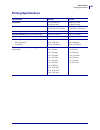

Page 151: Printing Specifications

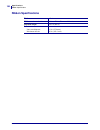

151 specifications printing specifications 6/29/11 170pax4 user guide 57516l-004 rev. A printing specifications specification 203 dpi 300 dpi resolution 203 dots per inch (8 dots per mm) 300 dots per inch (12 dots per mm) dot size 0.0049 in. X 0.0049 in. (0.125 mm x 0.125 mm) 0.0033 in. X 0.0039 in....

Page 152: Bar Codes

Specifications zebra programming language (zpl ii) 152 57516l-004 rev. A 170pax4 user guide 6/29/11 zebra programming language (zpl ii) bar codes • communicates in printable ascii characters • controlled via mainframe, mini, or pc • downloadable graphics, scalable and bitmap fonts, label templates a...

Page 153

6/29/11 170pax4 user guide 57516l-004 rev. A glossary alphanumeric indicating letters, numerals, and characters such as punctuation marks. Backfeed when the print engine pulls the media and ribbon (if used) backward into the print engine so that the beginning of the label to be printed is properly p...

Page 154

Glossary 154 57516l-004 rev. A 170pax4 user guide 6/29/11 direct thermal a printing method in which the printhead presses directly against the media. Heating the printhead elements causes a discoloration of the heat-sensitive coating on the media. By selectively heating the printhead elements as the...

Page 155

155 glossary 6/29/11 170pax4 user guide 57516l-004 rev. A non-continuous media media that contains an indication of where one label/printed format ends and the next one begins. Examples are die-cut labels, notched tag-stock, and stock with black mark registration marks. Non-volatile memory electroni...

Page 156

Glossary 156 57516l-004 rev. A 170pax4 user guide 6/29/11 notes • ___________________________________________________________________ __________________________________________________________________________ __________________________________________________________________________ ________________...

Page 157

6/29/11 170pax4 user guide 57516l-004 rev. A index a adhesive test for ribbon coating, 37 adjustments lcd, 88 left position, 84 media sensors, 55 print darkness, 64 printhead pressure, 100 tear-off position, 65 toggle positioning, 98 agency approvals, 148 applicator +24-28v isolated and non-isolated...

Page 158

Index 158 57516l-004 rev. A 170pax4 user guide 6/29/11 configuration changing parameters, 63 enter and use setup mode, 58 exit setup mode, 59 software or printer driver, 63 configuration label printing using cancel self test, 118 printing using list setup command, 73 connect printer to computer or n...

Page 159

159 index 6/29/11 170pax4 user guide 57516l-004 rev. A i idle display setting, 89 images list, 73 incorporation declaration, 3 initialize flash memory, 75 initialize memory card, 74 inspect for shipping damage, 23 installation procedure, 27 requirements, 24 international safety organization marks, 3...

Page 160

Index 160 57516l-004 rev. A 170pax4 user guide 6/29/11 p paper out message, 106 parallel port cabling requirements, 130 characteristics of parallel connection, 31 pin configuration, 130 setting parallel communications, 78 settings, 130 parity setting, 79 passwords default, 60 disable, 60 entering, 6...

Page 161

161 index 6/29/11 170pax4 user guide 57516l-004 rev. A printing specifications, 151 product markings, 148 protocol setting, 79 r recycling print engine parts, 92 recycling printer parts, 92 reflective media sensor, 55 remove used ribbon, 52 replacement parts, 92 report shipping damage, 23 reprint mo...

Page 162

Index 162 57516l-004 rev. A 170pax4 user guide 6/29/11 specifications agency approvals and markings, 148 bar codes, 152 communications options, 146 electrical, 146 environmental conditions, 146 fuses, 146 media, 149 physical, 146 power cord, 30 printing, 151 ribbon, 150 zebra programming language (z...

Page 164

Zebra technologies corporation zebra technologies corporation 475 half day road, suite 500 lincolnshire, il 60069 usa t: +1 847 634 6700 toll-free +1 866 230 9494 f: +1 847 913 8766 zebra technologies europe limited dukes meadow millboard road bourne end buckinghamshire, sl8 5xf, uk t: +44 (0)1628 5...