- DL manuals

- Zebra

- Printer

- Z4Mplus DT

- Maintenance Manual

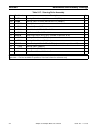

Zebra Z4Mplus DT Maintenance Manual - List Of Figures

13358L Rev. 1 11/17/03

Z4Mplus and Z6Mplus Maintenance Manual

xiii

List of Figures

List of Figures

Section 1 System Description

Figure 1-1. Default Fonts Examples .................................................................................................. 5

Figure 1-2. Interface Connections Z4Mplus and Z6Mplus ...................................................................9

Figure 1-3. RS-232 Connections ..................................................................................................... 11

Figure 1-4. DTE to DTE Interconnection .......................................................................................... 11

Figure 1-5. RS-232 Cable Connections ........................................................................................... 12

Figure 1-6. DB-9 to DB-25 Connections .......................................................................................... 13

Figure 1-7. RS-422/RS-485 Interconnecting Cable ......................................................................... 14

Figure 1-8. RS-232 Signaling ........................................................................................................... 15

Figure 1-9. RS-422/RS-485 Signaling ............................................................................................. 16

Section 2 Operations Overview

Figure 2-1. Location of Control Panel Keys ..................................................................................... 20

Figure 2-2. Ribbon Loading ............................................................................................................. 23

Figure 2-3. Media Loading Tear-Off Mode ....................................................................................... 24

Figure 2-4. Media Loading Cutter Mode .......................................................................................... 25

Figure 2-5. Media Loading Peel ....................................................................................................... 27

Figure 2-6. Locate Slot ..................................................................................................................... 28

Figure 2-7. Media Loading Peel with Liner Take-up ........................................................................ 29

Figure 2-8. Remove Liner ................................................................................................................ 29

Figure 2-9. Peel Rewind (Peel-Off Mode) ........................................................................................ 31

Figure 2-10. Peel Rewind (Rewind Mode) ....................................................................................... 33

Figure 2-11. Peel Rewind Media Adjustment ................................................................................... 34

Figure 2-12. Media Loading Fanfold ................................................................................................ 36

Figure 2-13. Adjusting the Optional Transmissive Sensor ............................................................... 38

Figure 2-14. Cancel Key Self Test Label (Configuration Label) ....................................................... 41

Figure 2-15. PAUSE Key Self Test Label ........................................................................................ 42

Figure 2-16. Feed Key Self Test Label ............................................................................................ 43

Figure 2-17. Pause and Cancel Key Self Test Label ....................................................................... 44

Figure 2-18. Communications Diagnostics Self Test ....................................................................... 45

Summary of Z4Mplus DT

Page 1

Z4mplus™ and z6mplus™ maintenance manual.

Page 2

Proprietary statement this manual contains proprietary information of zebra technologies corporation and its subsidiaries (“zebra technologies”). It is intended solely for the information and use of parties operating and maintaining the equipment described herein. Such proprietary information may no...

Page 3

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual iii warranty information warranty information all new zebra products are warranted by the manufacturer to be free from defect in material and workmanship. Please refer to the user guide for warranty information specific to each product. H...

Page 4

Iv z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 warranty information supplies products: supplies are warranted to be free from defect in material and workmanship for a period of six (6) months for media and twelve (12) months for ribbon from the date of shipment by zebra. This is pr...

Page 5: Table Of Contents

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual v table of contents table of contents section 1 system description scope ........................................................................................................................................... 1 related manuals ..........

Page 6

Vi z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 table of contents section 2 operations overview installation .................................................................................................................................. 19 unpack printer ............................

Page 7

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual vii table of contents section 3 troubleshooting general ...................................................................................................................................... 47 troubleshooting charts ........................

Page 8

Viii z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 table of contents replace power supply board .............................................................................................. 89 remove the power supply board ...............................................................

Page 9

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual ix table of contents options ..................................................................................................................................... 132 install pcmcia socket board ..............................................

Page 10

X z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 table of contents.

Page 11

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual xi list of tables list of tables section 1 system description table 1-1. Font matrix for 8 dot/mm (203 dpi) printheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 table 1-2. Font matrix for 12 dot/mm (300 dpi) printheads ....

Page 12

Xii z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 list of tables.

Page 13: List Of Figures

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual xiii list of figures list of figures section 1 system description figure 1-1. Default fonts examples .................................................................................................. 5 figure 1-2. Interface connections z4...

Page 14

Xiv z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 list of figures section 4 preventive and corrective maintenance figure 4-1. Printhead, platen roller and sensor cleaning .............................................................. 61 figure 4-2. Cleaning the peel-off module .........

Page 15

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual xv list of figures figure 4-37. Removal of the drive belt .......................................................................................... 100 figure 4-38. Locate electronics cover mounting screw ...................................

Page 16

Xvi z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 list of figures figure 4-74. Sample label ............................................................................................................ 137 figure 4-75. Psii parts ..........................................................

Page 17

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual xvii list of figures figure 4-111. E-ring removal and installation ............................................................................. 172 figure 4-112. Pc board assembly removal and installation ...................................

Page 18

Xviii z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 list of figures.

Page 19: Section 1

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 1 system description section 1 section 1 system description this manual contains information about the service and maintenance of zebra’s z4mplus and z6mplus printers. Thesethermal demand printers print high quality labels containing bar ...

Page 20

2 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 1 system description printer specifications a general description of the printer and the options available follows. Options zebra programming language ii (zpl ii) • cutter • peel • cutter tray • peel liner take-up (only availabl...

Page 21

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 3 system description section 1 bar codes standard printer fonts fonts a, b, c, d, e, f, g, h, and gs are expandable up to 10 times, height and width independently. However, fonts e and h (ocr-a and ocr-b) are not considered “in-spec” when...

Page 22

4 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 1 system description table 1-1. Font matrix for 8 dot/mm (203 dpi) printheads font matrix type* character size height width baseline dots inter- character gap cell width font matrix inches millimeters height width char/ inch hei...

Page 23

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 5 system description section 1 figure 1-1. Default fonts examples font v-- a b c d 1 2 3 4 5 w x y z a b c d a b c d a b c d a b c d a b c d a b c d 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 12345 abcd (scalable) wxyz w ...

Page 24

6 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 1 system description media specifications * media registration and minimum label length are affected by media type and width, ribbon type, print speed, and printer mode of operation. Performance improves as these factors are opt...

Page 25

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 7 system description section 1 ribbon specifications printer specifications ribbon specifications z4mplus z6mplus ribbon width to protect the printhead from wear, zebra recommends using ribbon at least as wide as the media you are using. ...

Page 26

8 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 1 system description general specifications electrical requirements • autoselect 90 to 264 vac; 48 to 62 hz • 5 amps for entire ac voltage range • 25 watts standby power consumption • 200/300/350/450 watts maximum power consumpt...

Page 27

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 9 system description section 1 communication specifications serial data communication interface overview a single data terminal equipment (dte) port supports rs-232, rs-422 and rs-485 serial data communications. Baud rate, parity, data le...

Page 28

10 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 1 system description communication buffer the printers have a communication buffer that stores the incoming data until that information can be acted upon (imaged). Communication handshaking (dtr/dsr control signals or xon/xoff ...

Page 29

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 11 system description section 1 rs-232 interface connections the printer is configured as data terminal equipment (dte). Figure 1-3 illustrates the internal connections of the printer’s rs-232 connector. Figure 1-3. Rs-232 connections fig...

Page 30

12 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 1 system description when the printer is connected via its rs-232 interface to data communication equipment (dce) such as a modem, use a standard rs-232 (straight-through) interface cable. Figure 1-5 illustrates the connections...

Page 31

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 13 system description section 1 rs-232 interconnections using a db-25 cable to connect the printer’s rs-232 db-9 interface to a db-25 connector, an interface adapter is required (zebra part number 33138). A generic db-25 adapter may also ...

Page 32

14 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 1 system description rs-422/rs-485 interconnections to connect the printer’s rs-232 db-9 interface to a host computer through an rs-422 or an rs-485 interface, an interface adapter is required (part number 33130). Figure 1-7 il...

Page 33

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 15 system description section 1 serial communication signal levels refer to figure 1-8. Rs-232 data signals are defined as either mark or space, while control signals are on (active-positive voltage) or off (inactive-negative voltage). Al...

Page 34

16 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 1 system description refer to figure 1-9. Rs-422 and rs-485 data signals are also either mark or space. The voltage levels are +5 vdc and 0 vdc when monitored from a specified reference point. The levels when referenced to sign...

Page 35

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 17 system description section 1 parallel port connector the table below shows pin configuration and function for a standard pc-to-printer centronics parallel cable. Table 1-6. Pin configuration and functions data status indicator on — ind...

Page 36

18 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 1 system description.

Page 37: Section 2

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 19 operations overview section 2 section 2 operations overview installation following is a detailed description of the installation procedures for the printer. Unpack printer save the carton and all packing materials in case shipping is r...

Page 38

20 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview operator controls this section discusses the functions of the various controls and indicators on the printer. The operator should become familiar with each of these functions. Front panel display the front...

Page 39

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 21 operations overview section 2 front panel keys key function forces the printer to feed one blank label each time it is pressed. • printer not printing: one blank label immediately feeds. • printing: blank label feeds after current batc...

Page 40

22 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview front panel lights light status indication off no power applied or printer turned off. On power applied and turned on. Off normal printer operation. On printer stopped all printing operations. Flashing pee...

Page 41

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 23 operations overview section 2 load media and ribbon load ribbon to place the spindle in the normal position, firmly pull out on the end segment (plastic part only) until it clicks in place as shown in figure 2-2. To place the spindle i...

Page 42

24 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview remove ribbon 1. Break the ribbon between the ribbon strip plate and the ribbon take-up spindle. 2. While turning the ribbon take-up spindle release knob counterclockwise, squeeze the ribbon against the ri...

Page 43

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 25 operations overview section 2 cutter mode (cutter option required.) refer to figure 2-4. 1. Press the printhead open lever. The printhead assembly springs up. 2. Flip down the media supply guide. 3. Slide the media guide out as far fro...

Page 44

26 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview peel-off mode (peel option required.) refer to figure 2-5. 1. Press the printhead open lever. The printhead assembly springs up. 2. Flip down the media supply guide. 3. Slide the media guide out as far fro...

Page 45

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 27 operations overview section 2 figure 2-5. Media loading peel peel bar media media guide dancer ribbon sensor label lever printhead open lever printhead assembly media supply guide media supply hanger transmissive sensor.

Page 46

28 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview peel-off mode with liner take-up refer to figure 2-7 1. Press the printhead open lever. The printhead assembly springs up. 2. Flip down the media supply guide. 3. Slide the media guide out as far from the ...

Page 47

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 29 operations overview section 2 figure 2-7. Media loading peel with liner take-up remove liner 1. Refer to figure 2-8. Using the liner slide tab, pull the liner slide towards you until it stops (about a third of the way down the liner ta...

Page 48

30 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview peel rewind (peel-off mode) refer to figure 2-9. 1. Press the printhead open lever. The printhead assembly springs up. 2. Flip down the media supply guide. 3. Slide the media guide out as far from the prin...

Page 49

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 31 operations overview section 2 figure 2-9. Peel rewind (peel-off mode) lever label media supply guide media guide ribbon sensor media supply hanger media alignment spindle printhead open lever take-up spindle rewind media guide thumbscr...

Page 50

32 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview peel rewind (rewind mode) refer to figure 2-10. 1. Press the printhead open lever. The printhead assembly springs up. 2. Flip down the media supply guide. 3. Slide the media guide out as far from the print...

Page 51

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 33 operations overview section 2 figure 2-10. Peel rewind (rewind mode) lever media supply guide media guide ribbon sensor media supply hanger media alignment spindle printhead open lever take-up spindle rewind media guide thumbscrew prin...

Page 52

34 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview peel rewind media alignment perform the following adjustment if the media does not track properly onto the take-up spindle. 1. Refer to figure 2-11. Turn the adjustment dial clockwise to align the media/li...

Page 53

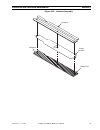

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 35 operations overview section 2 fanfold media loading fanfold media feeds through either the bottom or rear access slot. The lower rear cover guide surface can be used as a reference to align media in printer. Refer to figure 2-12 1. Pre...

Page 54

36 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview figure 2-12. Media loading fanfold printhead open lever printhead assembly media supply guide media guide media supply hanger printhead open lever printhead assembly media supply guide media guide media su...

Page 55

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 37 operations overview section 2 sensors align transmissive sensor there is no positioning of the fixed transmissive sensor. All media is to be loaded through the transmissive sensor as described in the media and ribbon loading chapters. ...

Page 56

38 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview figure 2-13. Adjusting the optional transmissive sensor select media sensor the z4mplus/z6mplus printers can be configured to select either of the sensors. By default the printer is set to auto select duri...

Page 57

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 39 operations overview section 2 media and media sensor considerations it is important that the appropriate media sensor is selected for the type media being used. If the transmissive sensor is set to auto select mode and an auto-calibrat...

Page 58

40 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview printer self tests the printer is designed to work with most zebra media and ribbon combinations. However, in some applications, changes to the printer’s configuration and mechanical settings may be requir...

Page 59

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 41 operations overview section 2 figure 2-14. Cancel key self test label (configuration label) z6mplus - 300dpi 4 4 z4mplus - 200dpi.

Page 60

42 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview pause key self test press and hold pause while turning on ( l ) the printer. Release the key anytime after the first front panel led turns off. The pause key self test prints a series of labels which can b...

Page 61

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 43 operations overview section 2 feed key self test press and hold feed while turning on ( l ) the printer. Release the key anytime after the first front panel led turns off. The quantity of labels printed during this print quality test d...

Page 62

44 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview pause and cancel key self test press and hold both pause and cancel while turning on ( l ) the printer. Release both keys anytime after the first front panel led turns off. The pause and cancel key self te...

Page 63

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 45 operations overview section 2 if errors are indicated, verify your communication parameters are correct. Figure 2-18. Communications diagnostics self test note • an fe indicates a framing error. An oe indicates an overrun error. An pe ...

Page 64

46 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 2 operations overview.

Page 65: Section 3

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 47 troubleshooting section 3 section 3 troubleshooting general consult the following troubleshooting tables if you encounter problems. If you encounter any problems that cannot be corrected with the aid of this manual, contact zebra’s tec...

Page 66

48 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 3 troubleshooting troubleshooting charts symptom diagnosis action no leds light. No ac power applied to the printer. Ensure the ac power cable is connected to a working voltage source. Faulty ac power fuse. Replace fuse no volt...

Page 67

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 49 troubleshooting section 3 wrinkled ribbon. Ribbon fed through printer incorrectly. Re-install ribbon. Incorrect darkness setting. Set darkness setting to the lowest value needed, from the control panel, for good print quality. Incorrec...

Page 68

50 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 3 troubleshooting.

Page 69: Section 4

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 51 table of contents section 4 section 4 table of contents preventive maintenance ................................................................................................... 55 tools required for preventive maintenance ..............

Page 70

52 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 table of contents replace power supply board .............................................................................................. 89 remove the power supply board .......................................................

Page 71

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 53 table of contents section 4 options ............................................................................................................................ 132 install pcmcia socket board .............................................

Page 72

54 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 table of contents.

Page 73: Section 4

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 55 preventive and corrective maintenance section 4 section 4 preventive and corrective maintenance preventive maintenance preventive maintenance consists of: • visual inspection • regular cleaning of the printhead and platen roller • gene...

Page 74

56 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance equipment safety tips after reviewing each procedure, place a check in the box. The ac power plug and iec 320 connectors on all zebra printers must bear the certification mark of at least...

Page 75

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 57 preventive and corrective maintenance section 4 equipment safety tips (continued) zebra recommends using a solution containing 90% isopropyl alcohol, 10% de-ionized water for cleaning of: • printheads • platen rollers • peel-off roller...

Page 76

58 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance personal safety tips do not wear any jewelry (rings, watches, etc.) or loose clothing when servicing the printers. Beware of “pinch points” on the printers. Be especially careful of: • op...

Page 77

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 59 preventive and corrective maintenance section 4 cleaning exterior the exterior surfaces of the printer may be cleaned with a lint-free cloth. Do not use harsh or abrasive cleaning agents or solvents. If necessary, a mild detergent or d...

Page 78

60 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance caution • observe proper electrostatic safety precautions when handling any static-sensitive components such as circuit boards and printheads. Caution • the printhead is hot and can cause...

Page 79

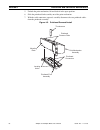

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 61 preventive and corrective maintenance section 4 figure 4-1. Printhead, platen roller and sensor cleaning sensors refer to figure 4-1. Brush or vacuum any accumulated paper lint and dust away from the printer sensors. The reflective sen...

Page 80

62 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 3. Use a swab soaked with the zebra-recommended solvent 1 to remove adhesive from the tear/peel bar. 4. Manually rotate the pinch and deflector rollers, and clean thoroughly with solvent ...

Page 81

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 63 preventive and corrective maintenance section 4 cutter module (cutter option required) caution • turn off (o) the printer and disconnect the printer from the power source before performing the following maintenance. Caution • the cutte...

Page 82

64 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance corrective maintenance corrective maintenance consists of the following: • troubleshooting printer faults to a modular level. • replacing or adjusting faulty or inoperable components. • r...

Page 83

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 65 preventive and corrective maintenance section 4 replace printhead use the following procedure to replace the printhead. Caution • turn off (o) the printer and disconnect the printer from the power source before performing the following...

Page 84

66 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 5. Unlatch the print mechanism, lift and latch it in the open position. 6. Slide the printhead fork assembly out of the print mechanism. 7. With the cable connectors exposed, carefully di...

Page 85

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 67 preventive and corrective maintenance section 4 install printhead see figures 4-4 and 4-5. 1. Connect the printhead cables to the printhead fork assembly and carefully slide the assembly into the print mechanism. 2. Ensure the two loca...

Page 86

68 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 7. Refer to figure 4-6. After completing a power-on self test (post), print a configuration label by performing a cancel key self test to verify print quality. 8. Press and hold cancel wh...

Page 87

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 69 preventive and corrective maintenance section 4 changeover printhead a field installable option for z4mplus permits changing the printhead density and drive system from 203 dpi to 300 dpi. Caution: caution • this installation must be p...

Page 88

70 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-9. Remove the electronics cover 6. Refer to figure 4-10. Remove the compound gear mounting screw. Turn the gear around. 7. Slide the gear back onto the printer, ensuring the gear...

Page 89

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 71 preventive and corrective maintenance section 4 figure 4-10. Change the compound gear and platen roller pulley 13. Loosen the stepper motor locking screw. While lifting up on the stepper motor, place the belt onto the stepper motor dri...

Page 90

72 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance replace latch kit caution • turn off (o) the printer and disconnect the printer from the power source before performing the following maintenance. Remove latch 1. Turn off ( o ) the print...

Page 91

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 73 preventive and corrective maintenance section 4 7. Using a small punch, very lightly tap the spring pin from the rear of the platen housing until it is free from the latch and can be removed. 8. Remove the latch and compression spring....

Page 92

74 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-13. Adjustment screw location 5. Refer to figure 4-14. Tighten the adjustment screw until the top of the strike plate is just below the top of the ribbon guide plate. 6. Refer to...

Page 93

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 75 preventive and corrective maintenance section 4 adjust print mechanism 1. Refer to figure 4-14. Insert the print mechanism gap pin gauges through the holes provided in the front of the ribbon guide plate. 2. Turn the adjustment screw u...

Page 94

76 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 6. Refer to figure 4-15. Slightly loosen the three mounting screws securing the print mechanism assembly to the main frame. 7. Place a small crescent wrench on the print mechanism adjustm...

Page 95

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 77 preventive and corrective maintenance section 4 replace platen roller if the platen roller is cut or cracked, it needs to be replaced. A damaged platen roller contributes dramatically to poor print quality. Caution: caution • this inst...

Page 96

78 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-17. Remove the electronics cover 6. Refer to figure 4-10 on page 71. Loosen the stepper motor locking screw and loosen the pivot screw. Pivot up the stepper motor and remove the ...

Page 97

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 79 preventive and corrective maintenance section 4 7. Refer to figure 4-18. Loosen the two set screws on the platen roller pulley. Remove the pulley and belt from the platen roller shaft. Figure 4-18. Platen roller assembly (z4mplus shown...

Page 98

80 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 9. Refer to figure 4-19. Using two standard screwdrivers or needle nose pliers, squeeze and push up on the barbed legs of outer spring clip to disengage it from the platen housing. 10. Lo...

Page 99

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 81 preventive and corrective maintenance section 4 install platen roller 1. If you removed the old inboard spring clip, insert a new spring clip part way into the inboard platen housing. 2. Refer to figure 4-20. Install the inboard bearin...

Page 100

82 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 9. While lifting up on the stepper motor, place the belt onto the stepper motor drive gear. 10. Adjust the position of the stepper motor to achieve the correct belt deflection and tighten...

Page 101

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 83 preventive and corrective maintenance section 4 replace main logic board caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified service tec...

Page 102

84 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 6. Refer to figure 4-22. Press in on the electronics cover with palm of hand, then lift up on the cover to remove it. Figure 4-22. Remove the electronics cover caution • observe proper el...

Page 103

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 85 preventive and corrective maintenance section 4 8. Refer to figure 4-23. Remove the psii board and cable assembly from the main logic board (mlb) by releasing it from the plastic standoffs in the upper right of the psii board and pulli...

Page 104

86 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-24. Remove and install pcmcia and psii boards 11. Press in on the locking tab of the two plastic standoffs and remove the pcmcia socket board by pulling straight out on the board...

Page 105

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 87 preventive and corrective maintenance section 4 14. Refer to figure 4-26. Disconnect all connectors from the main logic board. 15. Refer to figure 4-25. Remove and retain the two screws securing the main logic board to the mounting bra...

Page 106

88 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 4. Reinstall, but do not tighten, the screw and washer securing the serial port connector. 5. Reinstall, but do not tighten, the two screws and washers securing the parallel port connecto...

Page 107

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 89 preventive and corrective maintenance section 4 replace power supply board caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified service t...

Page 108

90 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 5. Refer to figure 4-28. Press in on the electronics cover with palm of hand, then lift up on the cover to remove it. Figure 4-28. Remove the electronics cover caution • observe proper el...

Page 109

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 91 preventive and corrective maintenance section 4 7. Place the printer on its side, media door side down. 8. Refer to figure 4-29. Disconnect all connectors from the power supply board. Figure 4-29. Power supply board assembly connection...

Page 110

92 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-30. Remove the power supply board heatsink clamp mounting screws power supply heatsink clamp power supply board insulator pad power supply board mounting screws locating pins nut...

Page 111

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 93 preventive and corrective maintenance section 4 install the power supply board 1. Refer to figure 4-31. Place the insulator pad over the locating pins on the printer. Verify that all holes align with holes in the main frame. Figure 4-3...

Page 112

94 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 4. Install, but do not tighten, the standoff and two screws securing the power supply to the main frame. 5. Place the nut bar over the main ac input and install, but do not tighten, the t...

Page 113

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 95 preventive and corrective maintenance section 4 figure 4-32. Heatsink assembly clamp pad clamp insulator heatsink adhesive.

Page 114

96 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 11. Refer to figure 4-33. Place the power supply heatsink clamp over the power supply board. Install, but do not tighten, the three screws securing the power supply heatsink clamp to the ...

Page 115

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 97 preventive and corrective maintenance section 4 19. Set your vom (voltage ohm meter) to the lowest ohm range and connect the meter between the main frame and the main ac input ground. The reading must be less than one ohm. Figure 4-34....

Page 116

98 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance replace drive belt caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified service technicia...

Page 117

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 99 preventive and corrective maintenance section 4 5. Refer to figure 4-36. Press in on the electronics cover with palm of hand, then lift up on the cover to remove it. Figure 4-36. Remove the electronics cover note • take note on which p...

Page 118

100 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 6. Refer to figure 4-37. Loosen the stepper motor locking screw and pivot screw. Remove the drive belt from the stepper motor. Figure 4-37. Removal of the drive belt install drive belt 1...

Page 119

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 101 preventive and corrective maintenance section 4 replace front panel caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified service technic...

Page 120

102 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-39. Remove the electronics cover caution • observe proper electrostatic safety precautions when handling any static-sensitive components such as circuit boards and printheads. 6...

Page 121

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 103 preventive and corrective maintenance section 4 figure 4-40. Front panel installation and connector location install front panel 1. Refer to figure 4-40. Route the front panel cable through the access hole and behind the white ferrite...

Page 122

104 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 6. Reinstall the screw through the washer and ground strap. Tighten the screw to snug in the new front panel. 7. Refer to figure 4-39. Reinstall the electronics cover by aligning the bot...

Page 123

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 105 preventive and corrective maintenance section 4 replace the dancer assembly caution • turn off (o) the printer and disconnect the printer from the power source before performing the following maintenance. Remove the dancer assembly 1....

Page 124

106 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-42. Remove the electronics cover caution • wear protective eyewear when removing e-rings, c-clips, snaprings, and springs. These are under tension and could fly off while removi...

Page 125

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 107 preventive and corrective maintenance section 4 6. Refer to figure 4-43. Relieve the spring tension from the dancer assembly by using a long nose pliers and moving the torsion spring leg off the printer post. Figure 4-43. Dancer assem...

Page 126

108 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance replace ribbon/head open sensor caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified ser...

Page 127

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 109 preventive and corrective maintenance section 4 5. Refer to figure 4-45. Press in on the electronics cover with palm of hand, then lift up on the cover to remove it. Figure 4-45. Remove the electronics cover 6. Refer to figure 4-46. R...

Page 128

110 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-46. Ribbon/head open sensor assemble and disassemble caution • observe proper electrostatic safety precautions when handling any static-sensitive components such as circuit boar...

Page 129

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 111 preventive and corrective maintenance section 4 9. Pull the wire through the access hole in the main frame. Figure 4-47. Ribbon/head open connection to main logic board install ribbon/head open sensor assembly 1. Refer to figure 4-46....

Page 130

112 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 5. Refer to figure 4-48. Using a 0.060 in. (1.5 mm) feeler gauge, check the distance between the ribbon/head open sensor assembly and the print mechanism assembly when closed. Once this ...

Page 131

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 113 preventive and corrective maintenance section 4 replace transmissive sensor caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified service...

Page 132

114 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 5. Refer to figure 4-50. Press in on the electronics cover with palm of hand, then lift up on the cover to remove it. Figure 4-50. Remove the electronics cover 6. Refer to figure 4-51. L...

Page 133

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 115 preventive and corrective maintenance section 4 figure 4-51. Transmissive sensor assembly connection 10. Refer to figure 4-52. Remove the transmissive sensor mounting screw and sensor. 11. Remove the transmissive sensor connection on ...

Page 134

116 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance install transmissive sensor 1. Feed the sensor wires through the access hole under the stepper motor as shown in figure 4-52. 2. Refer to figure 4-52. Install the sensor, ensure the guid...

Page 135

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 117 preventive and corrective maintenance section 4 replace reflective media sensor caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified ser...

Page 136

118 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-54. Remove the electronics cover caution • observe proper electrostatic safety precautions when handling any static-sensitive components such as circuit boards and printheads. 6...

Page 137

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 119 preventive and corrective maintenance section 4 figure 4-55. (reflective) media sensor connection to main logic board main logic board assembly reflective sensor connector main logic board connector (p7) detail.

Page 138

120 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 9. Refer to figure 4-56. Cut the cable tie securing the sensor wires inside the wireway of the platen roller assembly. Remove the platen assembly latch cover. 10. Slide the media sensor ...

Page 139

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 121 preventive and corrective maintenance section 4 6. Thread and wrap the sensor wires through and around the ferrite the same as the wires you removed. See detail in figure 4-55. 7. Connect the media sensor connector to the main logic b...

Page 140

122 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance replace ribbon take-up assembly caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified ser...

Page 141

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 123 preventive and corrective maintenance section 4 figure 4-58. Remove the electronics cover.

Page 142

124 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 6. Refer to figure 4-59. Loosen the two set screws on the ribbon take-up collar securing it to the shaft. Slide the collar, plastic thrust washer, gear clutch assembly, and washers off t...

Page 143

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 125 preventive and corrective maintenance section 4 replace ribbon supply assembly caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified serv...

Page 144

126 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 5. Refer to figure 4-61. Press in on the electronics cover with palm of hand, then lift up on the cover to remove it. Figure 4-61. Remove the electronics cover.

Page 145

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 127 preventive and corrective maintenance section 4 6. Refer to figure 4-62. Remove the stepper motor locking screw and nut. 7. Remove the stepper motor pivot screw. 8. Remove the stepper motor, belt, and idler gear. 9. Remove the ribbon ...

Page 146

128 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance install ribbon supply assembly refer to figure 4-64 1. Place a small amount of grease on the tolerance rings of the ribbon supply spindle shaft. Figure 4-64. Lubrication 2. Refer to figu...

Page 147

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 129 preventive and corrective maintenance section 4 5. Refer to figure 4-66. From the electronics side, install the screw into the spindle shaft until it bottoms out. 6. Slide the washer over the end of the screw until it is against the m...

Page 148

130 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 14. Refer to figure 4-61. Reinstall the electronics cover by aligning it and sliding down, ensuring the lower flange is inside the base and the upper flange is between the main frame and...

Page 149

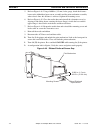

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 131 preventive and corrective maintenance section 4 replace media hanger remove media hanger 1. Turn off ( o ) the printer and remove the ac power cord and data cables. 2. Remove the media. 3. Refer to figure 4-67. Remove the three mounti...

Page 150

132 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance options install pcmcia socket board caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified...

Page 151

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 133 preventive and corrective maintenance section 4 figure 4-69. Remove the electronics cover 6. If there is no psii installed continue to the next step. If a psii is installed, refer to page 84 and remove the psii board from the mlb and ...

Page 152

134 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 10. Using the screw supplied, secure the top of the socket board to the long metal standoff. Figure 4-70. Standoff mounting location 11. • if no psii is installed, continue to next step ...

Page 153

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 135 preventive and corrective maintenance section 4 figure 4-71. Back cover installation 13. If you have a pcmcia card, insert it into the slot to ensure the card fits into the pcmcia socket board with no obstruction and install the memor...

Page 154

136 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance external psii this section provides you with an illustration of the external psii and the steps required for its installation. Figure 4-72. External printserver ii install the external p...

Page 155

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 137 preventive and corrective maintenance section 4 6. Press the test button located on the side of the external psii. This prints out a psii configuration label. A red status indicator blinks during the power on self test (post) and chan...

Page 156

138 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance internal psii caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified service technician. C...

Page 157

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 139 preventive and corrective maintenance section 4 3. Remove the media and ribbon. 4. Close the media door. Figure 4-76. Locate electronics cover mounting screw 5. Refer to figure 4-77. Press in on the electronics cover with palm of hand...

Page 158

140 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance installing the psii board 1. Refer to figure 4-77. Remove the two screws and back cover. 2. Refer to figure 4-78. Disconnect the cable from the i/o board at j4. Figure 4-78. Locate i/o b...

Page 159

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 141 preventive and corrective maintenance section 4 figure 4-79. Install psii board 4. With the psii board connected to the main logic board, route the connector up and through the mounting slot on the back of the printer. Refer to figure...

Page 160

142 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-80. Cable routing with psii installed 5. Refer to figure 4-81. Put the i/o board and back cover together. Figure 4-81. Install i/o board 6. Connect the psii cable to (j4) on the...

Page 161

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 143 preventive and corrective maintenance section 4 7. Install the back cover appropriate for your printer using the two screws previously removed in step 1 of the section installing the psii board on page 140. Figure 4-82. Back cover ins...

Page 162

144 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-83. Back cover options restore printer operations 1. Refer to figure 4-77. Reinstall the electronics cover by aligning it and sliding down, ensuring the lower flange is inside t...

Page 163

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 145 preventive and corrective maintenance section 4 6. Press the test button located just above the ethernet connector on the i/o board. This prints out a psii configuration label. A red status indicator blinks during the power on self te...

Page 164

146 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance solid red led (for more than 30 seconds) the psii has failed the power on self test (post). If the failure is not severe, the psii attempts to print a configuration label on the printer....

Page 165

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 147 preventive and corrective maintenance section 4 install cutter option caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified service techn...

Page 166

148 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 8. Refer to figure 4-85. Press in on the electronics cover with palm of hand, then lift up on the cover to remove it. Figure 4-85. Remove the electronics cover.

Page 167

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 149 preventive and corrective maintenance section 4 caution • the cutter blade is sharp. Do not touch or rub the blade with your fingers. 9. Refer to figure 4-86. Locate the cutter assembly in the kit. Verify that the mounting bracket is ...

Page 168

150 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-87. Install the cutter assembly (z4mplus shown) 10. Refer to figure 4-87. While holding the cutter assembly, route the cutter assembly wire harness through the opening under the...

Page 169

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 151 preventive and corrective maintenance section 4 13. Refer to figure 4-88. Place the cutter shield over the cutter assembly and secure in place using the thumb screw and lock washer provided. 14. Place catch tray in slot or slots in fr...

Page 170

152 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance caution • observe proper electrostatic safety precautions when handling any static-sensitive components such as circuit boards and printheads. 15. Refer to figure 4-89. Feed the cutter h...

Page 171

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 153 preventive and corrective maintenance section 4 install peel option caution • turn off (o) the printer and disconnect the printer from the power source before performing the following maintenance. 1. Turn off ( o ) the printer and rem...

Page 172

154 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-91. Tear bar removal 8. Using a hex key (allen wrench), install the two flanged mounting screws from the kit into the tear bar mounting screw holes. Tighten them to within 1/8 i...

Page 173

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 155 preventive and corrective maintenance section 4 figure 4-92. Rear of peel assembly peel assembly pems mounting slots.

Page 174

156 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 10. Refer to figure 4-93. Install the peel assembly with the pems to the rear and the opening in the mounting slot to the top. Insert the mounting slot opening over the two screws and li...

Page 175

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 157 preventive and corrective maintenance section 4 install liner take-up option caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified servic...

Page 176

158 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 4. Refer to figure 4-95. Press in on the electronics cover with palm of hand, then lift up on the cover to remove it. 5. Remove the two screws and back cover. Figure 4-95. Remove the ele...

Page 177

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 159 preventive and corrective maintenance section 4 figure 4-96. Install spindle 7. Refer to figure 4-97. Connect one end of the supplied cable assembly to p26 on the main logic board. Figure 4-97. Liner take-up motor harness installation...

Page 178

160 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 10. Refer to figure 4-98. Align the holes in the motor assembly mounting plate with the holes in the main frame. Secure the motor assembly with two screws. Figure 4-98. Liner take-up mot...

Page 179

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 161 preventive and corrective maintenance section 4 install rewind option caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed by a qualified service techn...

Page 180

162 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance remove base 1. Turn off ( o ) the printer and disconnect the ac power cord. 2. Refer to figure 4-100. Open the media door and remove the electronics cover mounting screw. Figure 4-100. L...

Page 181

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 163 preventive and corrective maintenance section 4 figure 4-101. Remove the electronics cover 6. Refer to figure 4-100. Remove the latch cover by prying out on the front edge with a small screwdriver. 7. Slide the front cover to the righ...

Page 182

164 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 9. Refer to figure 4-102. Loosen, but do not remove the three screws securing the rear cover to the main frame and base. Figure 4-102. Base removal 10. Remove the screw securing the plat...

Page 183

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 165 preventive and corrective maintenance section 4 install rewind pan 1. Refer to figure 4-103. Place the main frame onto the rewind pan assembly. Ensure the rear ledge of the main frame rests completely on the rear support in the pan. 2...

Page 184

166 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 5. Refer to figure 4-104. Place the rewind motor and spindle assembly inside the rewind pan assembly. Figure 4-104. Rewind motor location 6. Feed the rewind motor cable up through the ho...

Page 185

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 167 preventive and corrective maintenance section 4 caution • observe proper electrostatic safety precautions when handling any static-sensitive components such as circuit boards and printheads. 7. Refer to figure 4-105. Connect the rewin...

Page 186

168 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-106. Rewind motor assembly mounting 12. Refer to figure 4-101. Reinstall the electronics cover by aligning it and sliding down, ensuring the lower flange is inside the base and ...

Page 187

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 169 preventive and corrective maintenance section 4 maintenance kits install rewind pcb motor assembly caution: caution • this installation must be performed by a qualified service technician. Caution • this installation must be performed...

Page 188

170 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 4. Refer to figure 4-108. Press in on the electronics cover with palm of hand, then lift up on the cover to remove it. 5. Remove the two screws and back cover. Figure 4-108. Remove the e...

Page 189

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 171 preventive and corrective maintenance section 4 figure 4-109. Rewind motor cable location 9. Refer to figure 4-110. Rotate the spindle until one of the two access holes on the rewind back plate align with one of the mounting screws on...

Page 190

172 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance 11. Carefully slide the rewind motor and spindle assembly out of the rewind pan while guiding the media rewind cable through the hole in the bottom of the main frame. 12. Refer to figure...

Page 191

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 173 preventive and corrective maintenance section 4 figure 4-112. Pc board assembly removal and installation pcb dc motor assembly rewind back plate mounting screws media rewind cable.

Page 192

174 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance install pcb motor assembly 1. Refer to figure 4-113. Orient the new pcb motor assembly with the connector facing up. Using the two mounting screws previously removed, mount the pcb motor...

Page 193

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 175 preventive and corrective maintenance section 4 caution • observe proper electrostatic safety precautions when handling any static-sensitive components such as circuit boards and printheads. . 10. Refer to figure 4-109. Reconnect the ...

Page 194

176 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance steering roller remove steering roller 1. Turn off ( o ) the printer and disconnect the ac power cord and data cables. 2. Open the media door and remove all media and ribbon from the pri...

Page 195

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 177 preventive and corrective maintenance section 4 figure 4-115. Steering roller removal 8. Remove the steering assembly from the printer. 9. Refer to figure 4-116. Remove the steer knob by removing the snap ring. Inside mounting plate o...

Page 196

178 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance figure 4-116. Steer knob removal and installation 10. Remove and discard flat washer, wave washer and spacers. Install steer knob and steering roller 1. Refer to figure 4-116. Install th...

Page 197

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 179 preventive and corrective maintenance section 4 pinch roller kit caution • turn off (o) the printer and disconnect the printer from the power source before performing the following maintenance. Remove pinch roller 1. Turn off (o) the ...

Page 198

180 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance install pinch roller 1. Install the pinch roller in the mounting holes in the pinch roller holder assembly. 2. Install the bearings onto the shaft of the pinch roller, flange facing out ...

Page 199

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 181 preventive and corrective maintenance section 4 replace the fuse caution • turn off (o) the printer and disconnect the printer from the power source before performing the following maintenance. Figure 4-118. Removing the fuse from the...

Page 200

182 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 4 preventive and corrective maintenance.

Page 201: Section 5

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 183 maintenance and assembly drawings section 5 section 5 maintenance and assembly drawings general information use the mechanical assembly drawings when troubleshooting or replacing components and use the associated parts list when order...

Page 202

184 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings list of tables table 5-1. Main printer assemblies.................................................................................. 186 table 5-2. Electronics maintenance kits .................

Page 203

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 185 maintenance and assembly drawings section 5 list of figures figure 5-1. Main printer assemblies................................................................................. 187 figure 5-2. Electronics maintenance kits ...............

Page 204

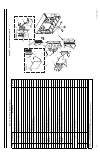

186 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-1. Main printer assemblies item part number description qty 1 79040m electronics cover 1 2 79032m front panel assembly maintenance kit 1 3 77302m static brush assembly kit (z4mplus) ...

Page 205

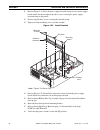

Main tenan ce and assembly drawings section 5 13358l r ev. 1 11/17/03 187 figure 5-1 . Ma in pri n ter assembl ies 1 2 3 5 6 7 8 9 12 13 14 15 16 4 10 11 17 18 19 20

Page 206

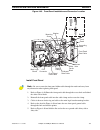

Section 5 maintenance and assembly drawings 188 11/17 /0313358l r ev. 1 f igure 5-2. Electronics main tenance ki ts table 5- 2. Electronic s ma intenanc e kit s ite m part numb er desc rip tion q ua ntity 1 7 7185 back cover , w/o pcmcia port 1 1 331 86 back cover , w/pcmcia port 1 1 790 13 back cov...

Page 207

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 189 maintenance and assembly drawings section 5 secti on 5 mai ntenance and assembly dr aw ings figure 5-3. (reflective) media sensor assembly maintenance kit table 5-3. (reflective) media sensor assembly maintenance kit item part number ...

Page 208

190 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-4. Platen assembly item part number description qty 1 77752m optical (transmissive) media sensor maintenance kit 1 1 77890m adjustable optical (transmissive) media sensor kit (option...

Page 209

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 191 maintenance and assembly drawings section 5 figure 5-4. Platen assembly 7 8 6 1 2 3 4 5 9 13 10 17 16 11 12 14 15 11 18.

Page 210

192 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-5. Platen roller shaft maintenance kit item part number description qty ref 77023m platen roller maintenance kit (z4mplus) 1 ref 77022m platen roller maintenance kit (z6mplus) 1 1 77...

Page 211

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 193 maintenance and assembly drawings section 5 figure 5-5. Platen roller shaft maintenance kit 1 2 3 4 4 5.

Page 212

194 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-6. Printhead housing maintenance kit item part number description qty 1 ref print mechanism 1 2 77804m cable printhead 4 inch maintenance kit 1 2 77831m cable printhead 6 inch mainte...

Page 213

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 195 maintenance and assembly drawings section 5 figure 5-6. Printhead housing maintenance kit printhead ground printhead data printhead power 3 1 2 4 5.

Page 214

196 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings figure 5-7. Static brush assembly maintenance kit table 5-7. Static brush assembly maintenance kit item part number description qty ref 77302m static brush assembly maintenance kit (z4mplus)...

Page 215

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 197 maintenance and assembly drawings section 5 * available only as a complete assembly for the z6mplus. Figure 5-8. Dancer assembly maintenance kit table 5-8. Dancer assembly maintenance kit item part number description qty 1 77331m * da...

Page 216

198 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-9. Ribbon supply assembly maintenance kit item part number description qty z4m z6m ref 77085m ribbon supply maintenance kit (z4mplus) 1 1 ref 77082m ribbon supply maintenance kit (z6...

Page 217

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 199 maintenance and assembly drawings section 5 figure 5-9. Ribbon supply assemblymaintenance kit z4mplus parts 1 2 3 4 5 6 7 7 8 9 10 8 11 12 13 14 9 10 8 12 13 14 9 10 11 z6mplus parts 15 16 17 18 19.

Page 218

200 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-10. Print mechanism latch kit item part number description qty 1 77112m print mechanism latch kit ref 2 77659 latch strike plate 1 3 77048 adjustment screw, m4 × 0.700 1 4 77276 stri...

Page 219

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 201 maintenance and assembly drawings section 5 figure 5-10. Print mechanism latch kit 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 6.

Page 220

202 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-11. Drive system – belts/pulleys item part number description qty 1 77814m clutch ribbon take-up maintenance kit 1 2 44165 clutch hub 1 3 77183 clutch gear 1 4 n/a clutch bearing 1 5...

Page 221

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 203 maintenance and assembly drawings section 5 figure 5-11. Drive system – belts/pulleys 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 note • gear 11 and pulley 13 are pictured for 203 dpi with the small part facing out. For 300 dpi...

Page 222

204 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-12. Cutter option kit item part number description qty 1 77971 cutter option kit (z4mplus) 1 1 77972 cutter option kit (z6mplus) 1 2 77041 catch tray (z4mplus) 1 2 77997 catch tray (...

Page 223

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 205 maintenance and assembly drawings section 5 figure 5-12. Cutter option kit motor connector 1 3 5 6 2 4 7 8 9 10

Page 224

206 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-13. Peel option assembly item part number description qty 1 78002m peel maintenance kit (z4mplus) 1 1 78012m peel maintenance kit (z6mplus) 1 2 77231 screw, m3 × 8 mm 2 3 78009 push-...

Page 225

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 207 maintenance and assembly drawings section 5 figure 5-13. Peel option assembly 1 2 3 4 5 5 6 6 7.

Page 226

208 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-14. Liner take-up assembly (z4mplus only) item part number description qty 1 79027m z4mplus liner take-up 1 2 77338 mounting bracket 1 3 77334 shaft 1 4 n/a spindle assembly 1 5 0631...

Page 227

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 209 maintenance and assembly drawings section 5 figure 5-14. Liner take-up assembly (z4mplus only) 1 2 3 4 5 6 7 8 9 10 11.

Page 228

210 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-15. Rewind option kit item part number descriptions qty 1 78205 peel/rewind combo option kit (z4mplus) 1 1 78205-6 peel/rewind combo option kit (z6mplus) 1 2 79026m spindle and motor...

Page 229

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 211 maintenance and assembly drawings section 5 figure 5-15. Rewind option kit 1 3 9 10 2 4 5 6 7 8 6 11.

Page 230

212 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-16. Communication and miscellaneous options item part number description qty 1 46692 zebranet ii external upgrade kit 1 2 78206 zebranet ii internal upgrade kit 1 3 34109 psii cable ...

Page 231

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 213 maintenance and assembly drawings section 5 figure 5-16. Communication and miscellaneous options 1 2 3 4 5 6 7.

Page 232

214 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings table 5-17. Steering roller assembly item part number description qty ref 77167m steering roller assembly maintenance kit (z4mplus) 1 ref 77168m steering roller assembly maintenance kit (z6m...

Page 233

13358l rev. 1 11/17/03 z4mplus and z6mplus maintenance manual 215 maintenance and assembly drawings section 5 figure 5-17. Steering roller assembly 1 2 3 4 5 6 7 8 9.

Page 234

216 z4mplus and z6mplus maintenance manual 13358l rev. 1 11/17/03 section 5 maintenance and assembly drawings.