- DL manuals

- A.O. Smith

- Water Heater

- BTX-80

- Instruction Manual

A.O. Smith BTX-80 Instruction Manual

1

Instruction Manual

PRINTED 1207

197086-002

KEEP THIS MANUAL IN THE POCKET ON HEATER FOR FUTURE REFERENCE

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

POWER VENTED GAS MODELS W/HOT SURFACE IGNITION

ALL TECHNICAL AND WARRANTY QUESTIONS: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, PLEASE WRITE TO THE COMPANY LISTED ON THE RATING PLATE ON THE WATER HEATER.

COMMERCIAL GAS WATER HEATERS

•

For Your Safety

•

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

Ashland City, TN 37015

www.hotwater.com

Summary of BTX-80

Page 1

1 instruction manual printed 1207 197086-002 keep this manual in the pocket on heater for future reference whenever maintenance adjustment or service is required. Power vented gas models w/hot surface ignition all technical and warranty questions: should be directed to the local dealer from whom the...

Page 2

2 safe installation, use and service your safety and the safety of others is extremely important in the installation, use and servicing of this water heater. Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and others of a poten...

Page 3: General Safety

3 general safety.

Page 4: General Safety

4 general safety.

Page 5: Introduction

5 thank you for purchasing this water heater. Properly installed and maintained, it should give you years of trouble free service. Abbreviations found in this instruction manual: • csa - canadian standards association • ansi - american national standards institute • nfpa - national fire protection a...

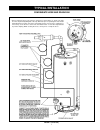

Page 6: Typical Installation

6 typical installation * caution harness has 120 vac. In operation. ** see "planning the vent system", "condensate" and "blower assembly installation" for more information. ***the side recirculation loop connections may not be used as the primary water inlet and outlet connections. For your convenie...

Page 7: Typical Installation

7 typical installation condensate hose and drain pan figure 1 (continued). * note: condensate trap loops must be oriented in a vertical plane as shown. The traps also must be primed by filling half of the loop with water prior to operating the water heater. Carefully plan the location of the loops a...

Page 8: Rough-In-Dimensions

8 rough-in-dimensions rough-in-dimensions top/side inlet and outlet: 3/4" npt gas inlet: 1/2" npt capacity and gas and electrical characteristics all models - maximum supply pressure: 14 inches w.C. (3.48kpa) minimum supply pressure natural gas: 5.0 inches w.C. (1.24kpa) minimum pressure must be mai...

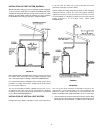

Page 9: Typical Installation

9 typical installation figure 2. Mixing valve usage this appliance has been design certified as complying with american national standard/csa standard for water heaters and is considered suitable for: water (potable) heating and space heating: all models are considered suitable for water (potable) h...

Page 10

10 facts to consider about the location carefully choose an indoor location for the new water heater, because the placement is a very important consideration for the safety of the occupants in the building and for the most economical use of the appliance. This water heater is not for use in manufact...

Page 11

11 in an alcove or closet, the entire floor must be covered by the panel. Failure to heed this warning may result in a fire hazard. Minimum clearances between the water heater and combustible construction are 0 inch at the sides and rear, 5.5" (14.0 cm) from the front and 12" (30.5 cm) from the top....

Page 12

12 a free area of one square inch per 1000 btu/hr (22 cm 2 /kw) of the total input of all appliances in the enclosure, but not less than 100 square inches (645 cm 2 ). If the confined space is within a building of tight construction, air for combustion and ventilation must be obtained from outdoors....

Page 13

13 water supply systems may, because of such events as high line pressure, frequent cut-offs, the effects of water hammer among others, have installed devices such as pressure reducing valves, check valves, back flow preventers, etc. To control these types of problems. When these devices are not equ...

Page 14

14 figure 10 shows the typical attachment of the water piping to the water heater. The water heater is equipped with 3/4 inch npt water connections. Note: if using copper tubing, solder tubing to an adapter before attaching the adapter to the water heater connections. Do not solder the water lines d...

Page 15

15 gas piping make sure the gas supplied is the same type listed on the model rating plate. The inlet gas pressure must not exceed 14 inch water column (3.5 kpa) for natural and propane gas (l.P.). The minimum inlet gas pressure shown on the rating plate is that which will permit firing at rated inp...

Page 16

16 sediment traps a sediment trap shall be installed as close to the inlet of the water heater as practical at the time of water heater installation. The sediment trap shall be either a tee fitting with a capped nipple in the bottom outlet or other device recognized as an effective sediment trap. If...

Page 17

17 vent pipe termination the first step is to determine where the vent pipe will terminate. See figures 15, 20 and 21. The vent may terminate through a sidewall as shown in figure 20 or through the roof as shown in figure 21. The vent system must terminate so that proper clearances are maintained as...

Page 18

18 planning the vent system plan the route of the vent system from the discharge of the blower to the planned location of the vent terminal. 1. Layout total vent system to use a minimum of vent pipe and elbows. 2. This water heater is capable of venting flue gases equivalent to 25' (7.6 m) of 2" pip...

Page 19

19 the condensate trap may be primed by filling the condensate u- assembly with tap water using the supplied hose while the water heater is not operating. The system is fully primed when the hose is lowered below the hose clamp on the side of the water heater and water begins to flow out of the hose...

Page 20

20 caution label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. Power vent wiring schematic - figure 19. 2. If the vent terminal is being installed on the outside of a finished wall, it may ...

Page 21

21 installation of vent system, sidewall with the route of the venting system and selection of materials completed, as discussed in the section of this manual titled planning the vent system, the through the wall vent terminal in place and the first section of piping, up to first elbow, installed at...

Page 22

22 vent attenuation assembly installation instructions the vent attenuation assembly (vaa) is designed to provide a reduction in fan noise created in the blower wheel. This installation of this vaa is optional. Review directions thoroughly prior to installing the new vaa. Please contact the manufact...

Page 23

23 8. Take the end of the tube at the bottom of the floor and route it to a suitable drain. This will provide an area where the condensate can drain without affecting the area around the appliance. 9. Once installed along with the rest of the vent configuration, make sure to operate the unit through...

Page 24

24 vent pipe preparation 1. Initial preparation a. Make sure the solvent cement you are planning to use is designed for the specific application you are attempting. B. Know the physical and chemical characteristics and limitations of the pvc and cpvc piping materials that you are about to use. C. Kn...

Page 25

25 b. Deburring use a knife, plastic pipe deburring tool, or file to remove burrs from the end of small diameter pipe. Be sure to remove all burrs from around the inside as well as the outside of the pipe. A slight chamfer (bevel) of about 10°-15° should be added to the end to permit easier insertio...

Page 26

26 for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the b...

Page 27: Temperature Regulation

27 it is recommended that lower water temperatures be used to avoid the risk of scalding. It is further recommended, in all cases, that the water temperature be set for the lowest temperature which satisfies your hot water needs. This will also provide the most energy efficient operation of the wate...

Page 28: For Your Information

28 for your information start up conditions smoke/odor it is not uncommon to experience a small amount of smoke and odor during the initial start-up. This is due to burning off of oil from metal parts, and will disappear in a short while. Thermal expansion water supply systems may, because of such e...

Page 29: Periodic Maintenance

29 venting system inspection at least once a year a visual inspection should be made of the venting system. You should look for: 1. Obstructions which could cause improper venting. The combustion and ventilation air flow must not be obstructed. 2. Damage or deterioration which could cause improper v...

Page 30

30 installed in suitable area: to insure sufficient ventilation and combustion air supply, proper clearances from the water heater must be maintained. See “locating the new water heater” section. Combustible materials such as clothing, cleaning materials, or flammable liquids, etc. Must not be place...

Page 31: Leakage Checkpoints

31 leakage checkpoints never use this water heater unless it is completely filled with water. To prevent damage to the tank, the tank must be filled with water. Water must flow from the hot water faucet before turning “on” gas to the water heater. A *condensation may be seen on pipes in humid weathe...

Page 32: Troubleshooting Guidelines

32 troubleshooting guidelines troubleshooting guidelines trouble shooting please check guidelines below. For your safety, water heater service should be performed only by a qualified service technician. Read the general safety information section first. Intelli-vent troubleshooting chart - residenti...

Page 33: Troubleshooting Guidelines

33 troubleshooting guidelines trouble shooting please check guidelines below. For your safety, water heater service should be performed only by a qualified service technician. Read the general safety information section first. Intelli-vent troubleshooting chart - residential control problem solution...

Page 34: Troubleshooting Guidelines

34 these guidelines should be utilized by a qualified service agent. Troubleshooting guidelines troubleshooting guidelines.

Page 35

35 limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable water ther...

Page 36

36.