1 printed in the u.S.A. 0406 part no. 197086-000 thank you for buying this energy efficient water heater. We appreciate your confidence in our products. You should thoroughly read this manual before installation and/ or operation of this water heater. Please pay particular attention to the important...

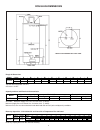

2 rough-in-dimensions rough-in-dimensions model units a b c d e f g h j k inches 70.62 68.20 51.90 20.90 9.15 12.00 22.00 8.00 15.81 26.92 btx-80 cm 179.37 173.23 131.83 53.09 23.24 30.48 55.88 20.32 40.16 68.38 top/side inlet and outlet: 3/4" npt gas inlet: 1/2" npt capacity and gas and electrical ...

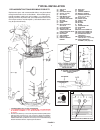

3 * caution harness has 120 vac. In operation. ** see "planning the vent system", "condensate" and "preparation of blower assembly" in the "installation" section for more information. *** the side recirculation loop connections may not be used as the primary water inlet and outlet connections. For y...

4 general safety information external damage do not operate the water heater until it has been fully checked out by a qualified technician, if the water heater: • has been exposed to fire or damage. • displays evidence of sooting. • produces steam or unusually hot water. If the water heater has been...

5 • do not cover the instruction manual. Keep it on the side of the water heater or nearby for future reference. • do obtain new warning and instruction labels for placement on the blanket directly over the existing labels. • do inspect the insulation blanket frequently to make certain it does not s...

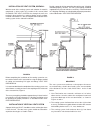

6 if the unconfined space is within a building of tight construction (building using the following construction: weather stripping, heavy insulation, caulking, vapor barrier, etc.), air for combustion and ventilation must be obtained from outdoors. The installation instructions for confined spaces m...

7 refer to fig. 1 for connection details. Before attaching the gas line be sure that all gas pipe is clean on the inside. To trap any dirt or foreign material in the gas supply line, a dirt leg (sometimes called drip leg) must be incorporated in the piping, figure 1. The dirt leg must be readily acc...

8 combustible materials must be provided in accordance with information in this manual under location of heater and installation of vent system, and with the national fuel gas code and local codes. Planning the vent system plan the route of the vent system from the discharge of the blower to the pla...

9 an incorporated reservoir may be used to pump the water to an appropriate drain. To avoid condensate spillage, select a pump with an overflow switch. Caution must be used to ensure that the drain is free and clear of debris and will not allow backflow through the condensate hose. Consideration mus...

10 warning condensate also drains from two locations on the blower assembly as shown in figure 5. A condensate hose must be secured to form a "trap" as shown in figure 5 for these condensate drain connections. These two hoses may be connected together. The hose(s) should be routed to a suitable drai...

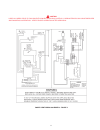

11 caution label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. Power vent wiring schematic - figure 7.

12 installation of vent system, sidewall with the route of the venting system and selection of materials completed, as discussed in the section of this manual titled planning the vent system, the through the wall vent terminal in place and the first section of piping, up to first elbow, installed at...

13 vent attenuation assembly installation instructions the vent attenuation assembly (vaa) is designed to provide a reduction in noise that may be transmitted through the vent pipe. This installation of this vaa is optional. Review directions thoroughly prior to installing the new vaa. Please contac...

14 8. Take the end of the tube at the bottom of the floor and route it to a suitable drain. This will provide an area where the condensate can drain without affecting the area around the appliance. 9. Once installed along with the rest of the vent configuration, make sure to operate the unit through...

15 vent pipe preparation 1. Initial preparation a. Make sure the solvent cement you are planning to use is designed for the specific application you are attempting. B. Know the physical and chemical characteristics and limitations of the pvc and cpvc piping materials that you are about to use. C. Kn...

16 depth-of-entry mark marking the depth of entry is a way to check if the pipe has reached the bottom of the fitting socket in step f. Measure the fitting depth and mark this distance on the pipe o.D. You may want to add several inches to the distance and make a second mark as the primer and cement...

17 for your safety read before lighting to turn off gas to appliance operating instructions 5. This appliance is equipped with a device which automatically lights the burner. Do not try to light the burner by hand. 6. Wait five (5) minutes to clear out any gas. If you then smell gas, stop! Follow "b...

18 1. "wake up" the temperature indicators by holding down both the "cooler" and "hotter" temperature adjustment buttons at the same time for one second (see figure 14). One or two of the temperature indicators will light up. These indicators will only remain on for 30 seconds if no further buttons ...

19 t & p valve at least once a year, the temperature and pressure relief valve must be checked to ensure that it is in operating condition. Lift the lever at the top of the valve several times until the valve seats properly and operates freely. Warning the water passing out of the valve during this ...

20 anode deterioration depends on water conductivity, not necessarily water condition. A corroded or pitted anode rod indicates high water conductivity and should be checked and/or replaced more often than an anode rod that appears to be intact. Replacement of a depleted anode rod can extend the lif...

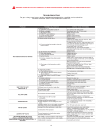

21 troubleshooting for your safety, water heater service should be performed only by a qualified service technician. Read the general safety information section first. Warning: do not by-pass any controls to make heater operate. Operate only as wired from factory..

22 w a ter hea ter control problem solution an open earth ground circuit to the 1. Check that the earth ground connection is ignition system. Properly connected. 2. Check that the ground conductor on the water heater is properly connected. Wiring error or a high resistance to 1. Check for proper con...

23 limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable water ther...

24.