- DL manuals

- A-Star

- Water Dispenser

- 2018 ED

- Installation Programming Troubleshooting

A-Star 2018 ED Installation Programming Troubleshooting

Summary of 2018 ED

Page 1

1 a-star premium water softening system installation programming troubleshooting version 05-2006.

Page 2

2 safety guides • follow the installation instructions carefully. Failure to install the softener properly voids the warranty. • before you begin installation, read this entire manual. Then, obtain all the materials and tools you will need to make the installation. • check local plumbing and electri...

Page 3

3 unpacking / inspection the softener is shipped in one master carton. The softeners are completely assembled at the factory, except as required at installation. Be sure to check the entire softener for any shipping damage or parts loss. Also note damage to the shipping cartons. Contact the transpor...

Page 4

4 specifications and dimensions 52 @ 0.8 86 @ 1.7 rated capacities @ salt dose (°fm³@kg) 122 @ 4.6 resin quantity (liters) 18 rated service flow (l/min) 26 pressure drop @ service flow (bar) 0.6 max flow rate to the drain (l/min) 11 max hardness (°f) 162 max clear water iron ( ppm) 5 tank size ( inc...

Page 5

5 before starting installation where to install the softener o place the softener as close as possible to the pressure tank (well system) or water meter (city water). O place the softener as close as possible to a floor drain, or other acceptable drain point (laundry tub, sump, standpipe, etc.). O c...

Page 6

6 plan how you will install the softener you must first decide how to run in and out pipes to the softener. Look at the house main water pipe at the point where you will connect the softener. Is the pipe soldered copper, glued plastic, or threaded galvanized? What is the pipe size? Now look at the t...

Page 7

7 installation steps note: for easier installation, remove the top cover cover forward and lift up. 1. Install bypass valve: o remove the plastic shipping plug and wire from valve outlet. O push the bypass valve (lubricate o--ring seals)into both ports of the valve...Figures 3a. O snap the two large...

Page 8

8 4. Install grounding clamps and wire (recommended): o to maintain electrical ground continuity in the house cold water piping, install the ground clamps (not included) as shown. Be sure the pipes are clean, under the clamps, to assure good contact. Note: a 3-valve bypass system maintains ground co...

Page 9

9 o if raising the drain hose overhead is required to get to the drain point, do not raise higher than 2.4 meters above the floor. Elevating the hose may cause a back-pressure that could reduce brine draw during regenerations. Connecting a rigid valve drain tube o to adapt a copper drain tube to the...

Page 10: 10.

10 g. Check your plumbing work for leaks and fix right away, if any are found. Be sure to observe previous caution notes. H. Turn on the gas or electric supply to the water heater. Light the pilot, if applicable. 9. Add water and salt to the brine tank: o slide open the salt storage area cover. Add ...

Page 11

11 program the timer: "electronic demand timer control settings required upon installation. Notes: o when the transformer is plugged in, the model code f 18 shows in the face plate display for a few seconds. The model code is then followed by a test number (example: j1.1). After the test number, 12:...

Page 12

12 hardness number in the display. Down ▼decreases the hardness value. Up ▲ increases the hardness value. Note : each press of a button changes the display by 1, between 1 and 25. Above 25, the display changes 5 at a time (25, 30, 35, etc.). Holding a button in changes the numbers at a rapid rate. 3...

Page 13

13 default setting is “auto”. 3. Press up ▲ or down ▼ buttons to change the setting. Press the select button to set. Set 97% feature by setting this feature to on, the unit will automatically recharge when 97% capacity has been used, at any time of day. 1. Press and hold the select button until the ...

Page 14

14 sanitizing procedures care is taken at the factory to keep your water softener clean and sanitary. Materials used to make the softener will not infect or contaminate your water supply, and will not cause bacteria to form or grow. However, during shipping, storage, installing and operating, bacter...

Page 15

15 water and water conditioning water man’s very existence depends on water. It is one of the basic commodities of life. Water is best as nature provides it, is a common misconception. Practically all natural water needs refinement or treatment to make it safe to drink or more satisfactory to use. T...

Page 16

16 o ferric (red water), and bacterial and organically bound irons are insoluble. This iron is visible immediately when drawn from a faucet because it has oxidized before reaching the home. It appears as small cloudy yellow, orange, or reddish suspended particles. After the water stands for a period...

Page 17

17 minerals from the resin beads. The hardness minerals, and brine are discharged to the drain. The nozzle and venturi create a suction to move the brine, maintaining a very slow rate to get the best resin cleaning with the least salt. O brine rinse: after a pre--measured amount of brine is used, th...

Page 18

18 general water softener maintenance and troubleshouting checking the salt storage level, and refilling brine (salt dissolved in water) is needed for each and every regeneration. The water for making brine is metered into the salt storage area by the softener valve and timer. However, you must keep...

Page 19

19 water begins to cloud or turn rust colored. A water softener will not remove any iron that makes the water cloudy or rusty as it comes from the faucet (called red water iron). To take red water iron out of water, or over the maximum of clear water iron, an iron filter or other equipment is needed...

Page 20

20 o timer not programmed: see.... Electronic demand timer -- page 11. Nozzle & venturi dirty, or salt in storage tank bridged: see page 19, and above to clean. Then, start a regeneration, or recharge. W water intermittently hard o possible increase in water hardness: see.... Electronic demand timer...

Page 21

21 automatic electronic diagnostics the timer computer has a self-diagnostic function for the electrical system (except input power and water meter). The computer monitors the electronic components and circuits for correct operation. If a malfunction occurs, an error code appears in the timer displa...

Page 22

22 pass a small magnet back and forth in front of the sensor. You should get a reading in the display. If you get a reading, unhook the in and out plumbing and check the turbine for binding. (b) the letter (p) and dash(es) indicate position switch operation. The letter appearing means the switch is ...

Page 23

23 2. After observing fill, press the touch – hold button to move the softener into brining. A slow flow of water to the drain will begin. Verify brine draw from the brine tank by shining a flashlight into the brine well and observing a noticeable drop in the liquid level. Note: be sure a salt bridg...

Page 24

24.

Page 25

25.

Page 26

26.

Page 27

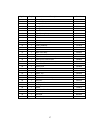

27 key no req’d description part n° 1 2 clamp section 7176292 2 2 retainer clamp 7088033 3 1 o-ring, 2-7/8 x 3-1/4 7170296 4 1 o-ring, 13/16 x 1-1/16 7170254 5 1 o-ring, 2-3/4 x 3 7170270 6 1 top distributor 7077870 7 1 rep’l bottom distributor 7105047 8 1 rep’l resin tank pkd 7197468 9 1 cu. Ft res...

Page 28

28.

Page 29

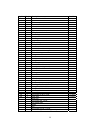

29 key no req’d description part n° 1 1 screw, #4-24 x 1-1/8” 7070412 2 1 spacer 7117816 3 1 switch 7030713 4 1 expansion pin 7077472 5 5 screw, #10-14 x 2” 7074123 6 1 valve cover 7085263 7 1 cap 7199729 8 1 o-ring seal, 1.1” x 1.4” 7170262 9 1 screen support 7167659 10 1 screen 7146043 11 1 flow p...